Low wall quick change wear-resistant prefabricated part

A technology of prefabricated parts and low walls, which is applied in the field of refractory materials, can solve the problems of frequent replacement of refractory linings, difficult control of pouring quality, and random addition of water, so as to improve thermal shock resistance, corrosion resistance, low thermal conductivity, and good The effect of acid and alkali corrosion resistance and strong adaptability to the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 22 parts of corundum aggregate;

[0051] 25 parts of calcium titanate zirconate aggregate;

[0052] 10 parts of calcium zirconium titanate powder;

[0053] 10 parts of calcium aluminum titanate powder;

[0054] 5 parts of silica powder;

[0055] 9 parts of alumina micropowder;

[0056] 9 parts of aluminate cement;

[0057] 10 parts vitrified perlite;

[0058] Extras, including:

[0059] Sodium tripolyphosphate 0.08~0.1 part;

[0060] Explosion-proof fiber 0.06~0.1 part.

Embodiment 2

[0062] 20 parts corundum aggregate;

[0063] 27 parts of calcium titanate zirconate aggregate;

[0064] 10 parts of calcium zirconium titanate powder;

[0065] 10 parts of calcium aluminum titanate powder;

[0066] 5 parts of silica powder;

[0067] 9 parts of alumina micropowder;

[0068] 9 parts of aluminate cement;

[0069] 10 parts vitrified perlite;

[0070] Extras, including:

[0071] Sodium tripolyphosphate 0.08~0.1 part;

[0072] Explosion-proof fiber 0.06~0.1 part.

Embodiment 3

[0074] 25 parts corundum aggregate;

[0075] Calcium titanate zirconate aggregate 22 parts;

[0076] 10 parts of calcium zirconium titanate powder;

[0077] 10 parts of calcium aluminum titanate powder;

[0078] 5 parts of silica powder;

[0079] 9 parts of alumina micropowder;

[0080] 9 parts of aluminate cement;

[0081] 10 parts vitrified perlite;

[0082] Extras, including:

[0083] Sodium tripolyphosphate 0.08~0.1 part;

[0084] Explosion-proof fiber 0.06~0.1 part.

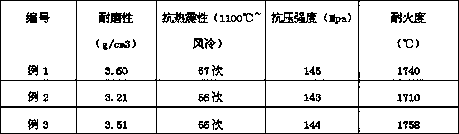

[0085] Table is the prepared brick performance parameter of embodiment 1~embodiment 3

[0086] The above results show that: the prefabricated part of the present invention has the characteristics of high thermal shock resistance, high compressive strength and low thermal conductivity, and can ensure the service life and thermal insulation performance of the outer wall of the cement kiln;

[0087] It can be seen from the table that the wear resistance of the prefabricated part of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com