Monocrystalline silicon wafer texturing agent and texturing method

A single-crystal silicon wafer, texturing agent technology, applied in chemical instruments and methods, crystal growth, final product manufacturing, etc., to reduce costs, reduce cleaning steps, and ensure the effect of texturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

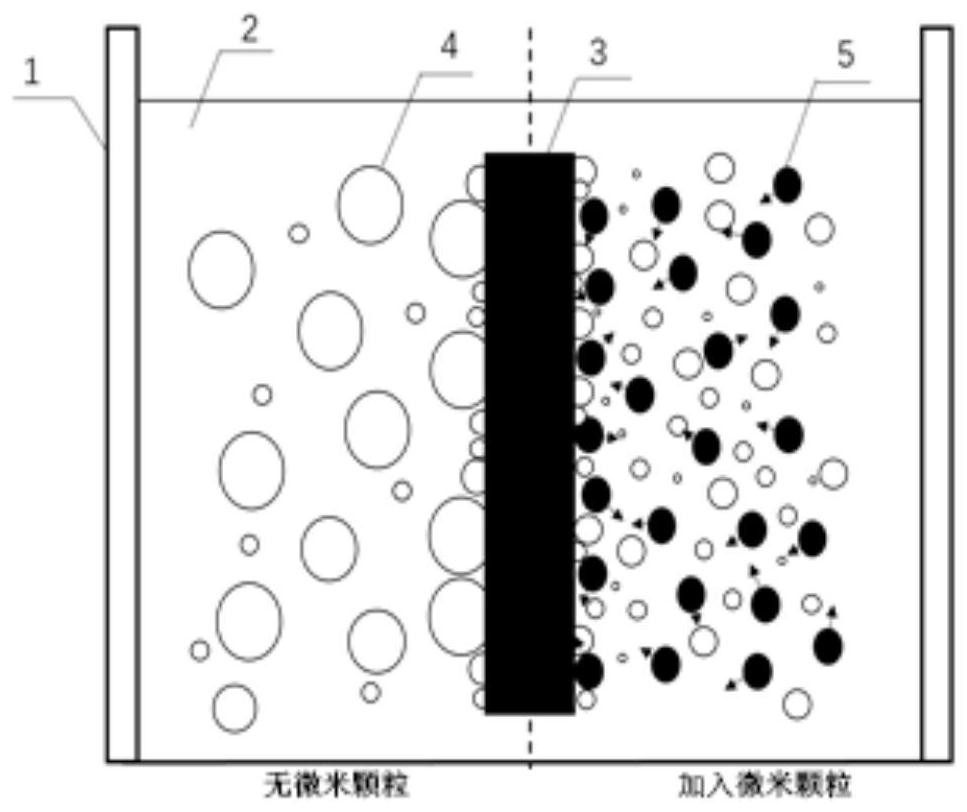

[0038] This embodiment provides a monocrystalline silicon wafer texturing agent. In this embodiment, the monocrystalline silicon wafer texturing agent includes lye, and micron particles with kinetic energy are distributed in the lye, and the micron particles are high in fluorine At least one of molecules, alkali-resistant organic polymers, inorganic non-metals, and metal materials.

[0039] When the micron particles use fluorine-containing polymer materials, the fluorine-containing polymer is polytetrafluoroethylene, ethylene-tetrafluoroethylene copolymer, tetrafluoroethylene-hexafluoropropylene copolymer, tetrafluoroethylene-perfluoroether copolymer one or more. Fluorine-containing polymers are non-toxic, non-volatile, excellent in acid and alkali corrosion resistance, hardly cause loss in lye, safe and environmentally friendly, and can be used repeatedly for a long time, which can greatly reduce the cost of texturing of monocrystalline silicon wafers. cost of the drug. At ...

Embodiment 2

[0049] During the preparation of the textured surface, the size and density of hydrogen bubbles and the adhesion time on the surface of the single crystal silicon wafer will directly affect the morphology, size and uniformity of the textured surface on the surface of the single crystal silicon wafer, which in turn will affect the quality of the monocrystalline silicon wafer. The anti-reflection effect of the surface and the matching status with other coating layers. Based on the above factors, the present invention also provides a method for making texture of a single crystal silicon wafer, which uses the above-mentioned single crystal silicon wafer texturing agent to texture the surface of the single crystal silicon wafer.

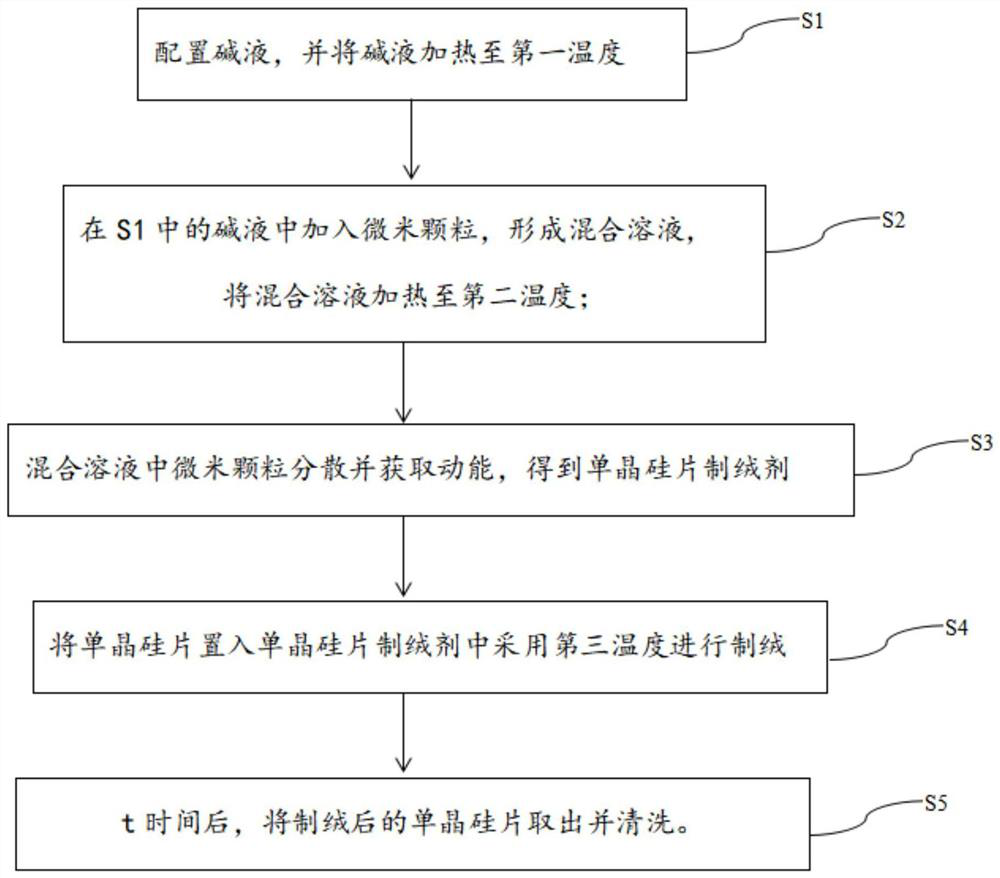

[0050] Such as figure 1 as shown, figure 1 It is a flow chart of the monocrystalline silicon wafer texturing method of this embodiment, and the monocrystalline silicon wafer texturing method comprises the following steps:

[0051] S1. Arrange the lye 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com