Marine floating garbage treatment equipment

A kind of garbage disposal equipment and marine technology, applied in the field of marine environment, can solve the problems of low overall efficiency, time-consuming and labor-intensive process, complicated and laborious process, etc., and achieve the effect of improving efficiency, simple and convenient process, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

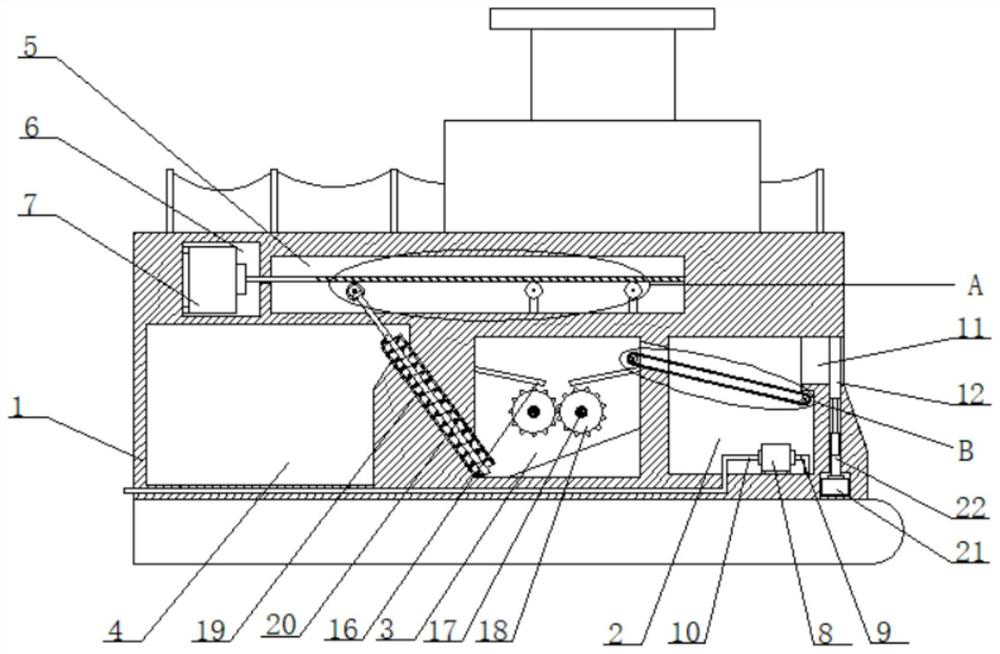

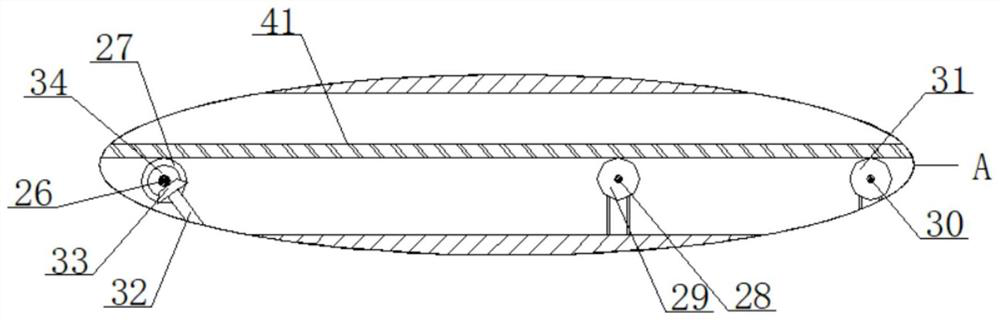

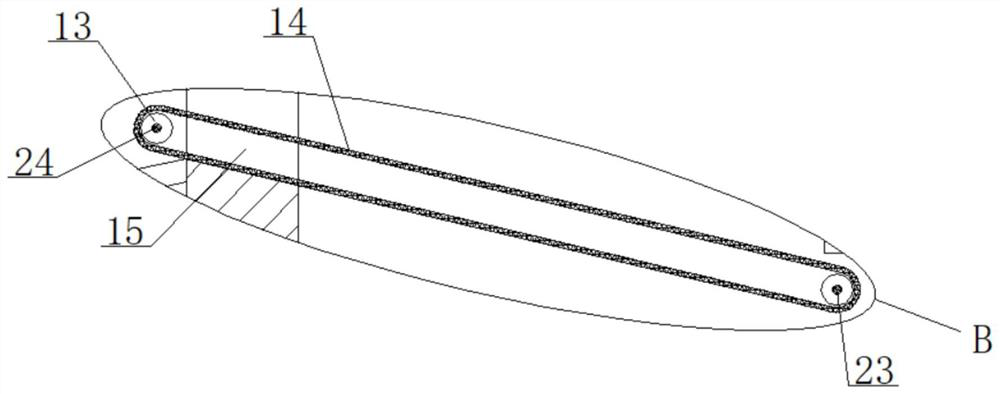

[0032] refer to Figure 1-7 , a marine floating garbage processing equipment, including a hull 1, a collection chamber 2, a crushing chamber 3, a storage chamber 4, a transmission chamber 5 and a motor chamber 6 are provided in the hull 1, and a motor is fixedly installed on the inner wall of one side of the motor chamber 6 7. A worm 41 is rotated in the transmission chamber 5. One end of the worm 41 extends into the motor chamber 6 and is welded to the output shaft of the motor 7. A water pump 8 is fixedly installed on the inner wall of the bottom of the collection chamber 2. On the input port of the water pump 8 A suction pipe 9 is connected, and a drain pipe 10 is connected to the outlet of the water pump 8. One end of the drain pipe 10 extends to the outside of the tail of the hull 1, and a collection port 11 connected to the collection chamber 2 is provided on one side of the head of the hull 1. , the inner wall of the bottom of the collection port 11 is provided with a s...

Embodiment 2

[0043] refer to Figure 1-7 , a kind of marine floating garbage processing equipment, including a hull 1, a collection chamber 2, a crushing chamber 3, a storage chamber 4, a transmission chamber 5 and a motor chamber 6 are provided in the hull 1, and the inner wall of one side of the motor chamber 6 is fixed and installed by bolts There is a motor 7, and a worm 41 is installed for rotation in the transmission chamber 5. One end of the worm 41 extends into the motor chamber 6 and is welded with the output shaft of the motor 7. The bottom inner wall of the collection chamber 2 is fixed with a water pump 8 by bolts. The input port of 8 is connected with a suction pipe 9, and the output port of the water pump 8 is connected with a drain pipe 10. One end of the drain pipe 10 extends to the outside of the tail of the hull 1, and one side of the head of the hull 1 is connected with the collection chamber 2. The collection port 11, the bottom inner wall of the collection port 11 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com