Fire-proof door structure

A fire-resistant door and fire-resistant glass technology, which is applied to fire-resistant doors, windows/doors, building components, etc., can solve the problems of inability to transfer equipment, equipment burnout, and difficulty in extinguishing the fire, so as to avoid the spread of fire and increase the fire prevention effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

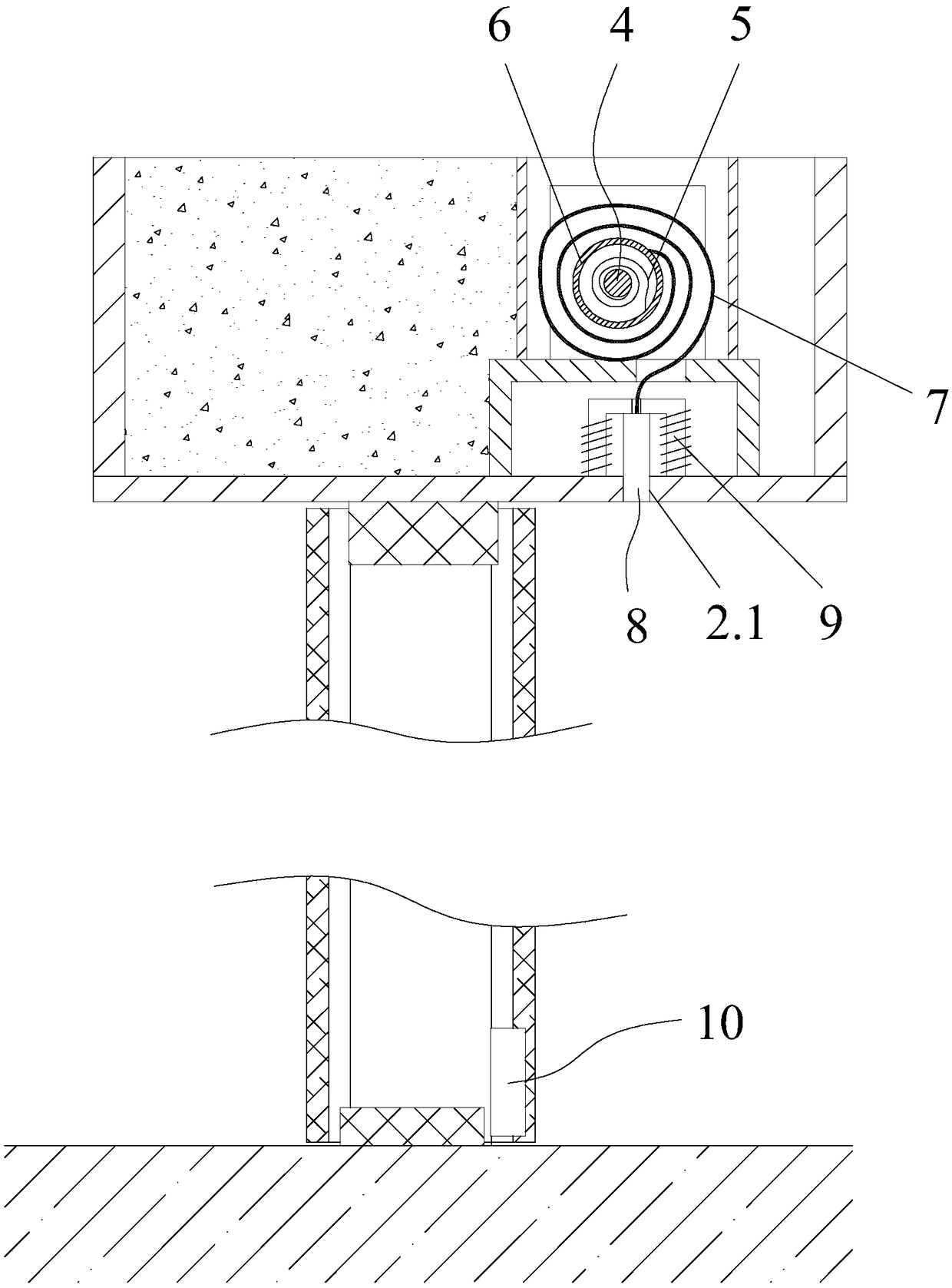

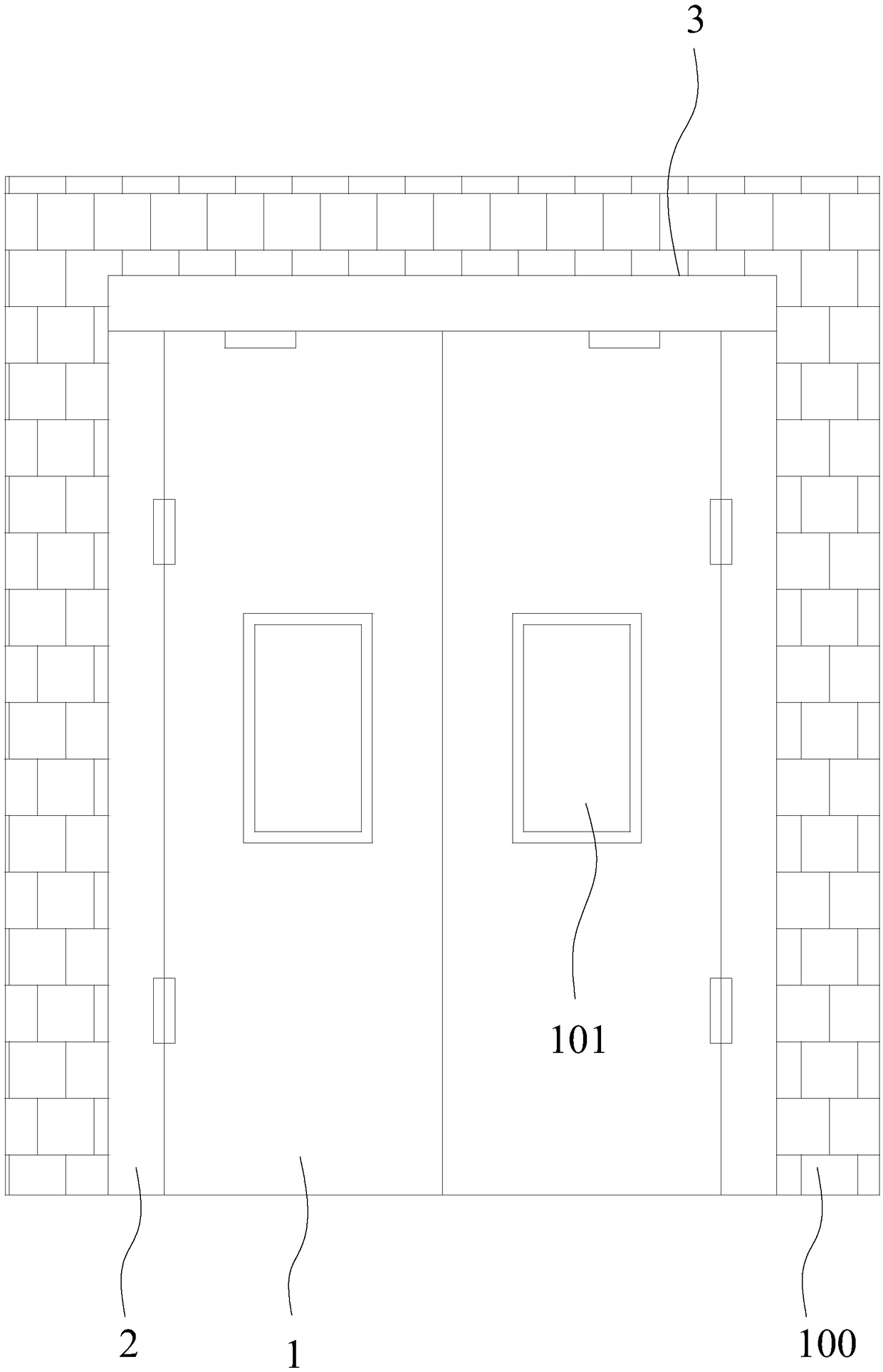

[0028] On the basis of the basic structure, in the top cavity of the door frame 2 close to the door panel 1, a rotating shaft 4 is provided along the width direction of the door frame. One end of the spring 5 is connected to the rotating shaft 4, and the other end of the return spring 5 is connected to the mounting cylinder 6; the external roll of the mounting cylinder 6 is provided with a fireproof curtain 7. And, when back-moving spring 5 is crimped in the state outside rotating shaft 4, fireproof screen 7 is also wound on the outside of mounting tube 6; Under the action of gravity, the fire curtain 7 can be opened slowly. The top of the door frame 2 is provided with a channel 2.1 for the passage of the iron block 8, and an electromagnetic coil 9 is also provided in the cavity at the top of the door frame 2. The electromagnetic coil 9 is electrically connected to an external power supply. In order to ensure the stability of the power supply, the An uninterruptible power sup...

Embodiment 2

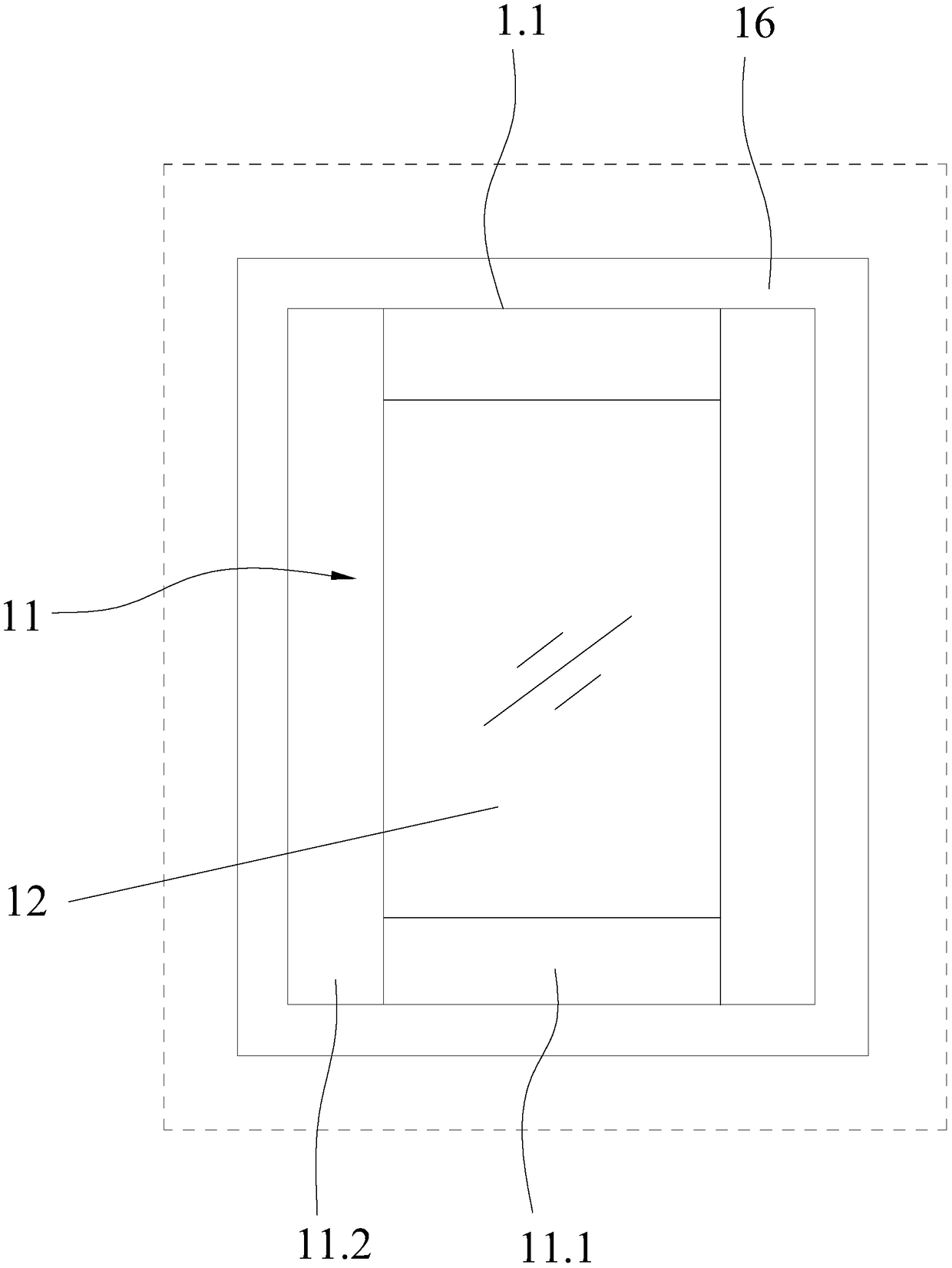

[0036] A glass window 101 is also provided on the door panel 1 , and the glass window 101 includes a glass frame 11 and fireproof glass 12 . The glass frame 11 is made of fireproof material.

[0037] Specifically, an installation opening 1.1 is provided on the door panel 1, and a glass frame 11 is provided in the installation opening 1.1, and a fireproof glass 12 is provided in the glass frame 11. Specifically, the glass frame 11 is spliced by two horizontal bars 11.1 and two vertical bars 11.2, and each horizontal bar 11.1 and vertical bar 11.2 is provided with a mounting groove 11.3, and the fireproof glass 12 is embedded around the In the corresponding installation groove 11.3 on the glass frame 11, the outside of the glass frame 11 is embedded in the installation opening 1.1.

[0038] As an improvement, after the fireproof glass 12 is embedded on the glass frame 11, squeeze and fill the fireproof glue in each installation groove 11.3 in the glass frame 11 to further imp...

Embodiment 3

[0041] On the basis of Embodiment 2, a number of dovetail grooves 13 are provided on the circumferential side wall of the installation opening 1.1 on the door panel 1 along the thickness direction of the door panel 1, and a number of dovetail grooves 13 are provided on the circumferential outer wall of the glass frame 11. A plurality of limit protrusions 14 fitted with the dovetail groove 13, when the glass frame 11 is embedded in the installation opening 1.1, each limit protrusion 14 on the glass frame 11 is fitted in the corresponding dovetail groove one by one within 13.

[0042] As preferably, an annular fireproof sealant strip 15 is set on the circumferential outer wall of the glass frame 11, and several dovetail grooves 13 on the sidewall of the installation port 1.1 are provided on the outer wall of the fireproof sealant strip 15. Fitting stop lug 15.1. Further, the fireproof sealing strip 15 is a fireproof sealing strip with a thermal expansion effect. When a fire occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com