Laser welding method of side electrode precious metal of spark plug

A laser welding and side electrode technology, applied in spark plug manufacturing and other directions, can solve the problems of uneven fusion at the welding place, affecting product quality, gaps and cracks, etc., to achieve uniform fusion, convenient welding, no gaps and cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

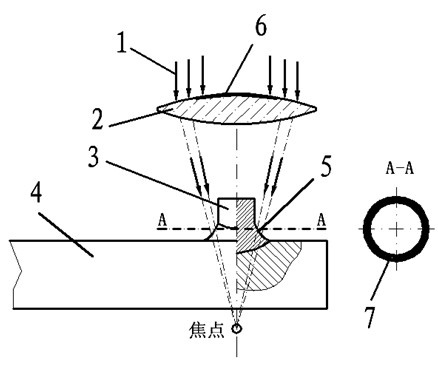

[0036] attached figure 1 As one embodiment of the present invention, it can be seen from the accompanying drawings that the present invention relates to a side electrode laser welding method, especially a laser welding method for a side electrode noble metal head through an annular laser spot emitted from above the noble metal head; The ring-shaped laser spot mentioned above can be condensed by a convex lens, and the direct laser light source that has not been fully focused is refracted by the convex lens so that the direction is gathered into a ring. The method of generating the ring beam is: emit a parallel downward laser beam 1 from the top of the side electrode noble metal head, the laser beam 2 passes through a convex lens 2 and then irradiates the root area 5 of the junction between the side electrode noble metal head 3 and the side electrode plate 4, and at the same time A circular light-shielding surface 6 is provided at the center of the convex lens 2, and the light-s...

Embodiment 2

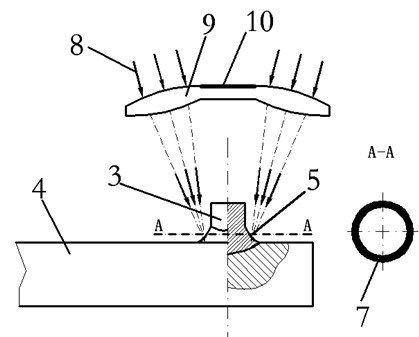

[0038] attached figure 2 As another embodiment of the present invention, it can be seen from the accompanying drawings that the present invention relates to a side electrode laser welding method, especially a laser welding method for the side electrode noble metal head through the annular laser spot emitted from above the noble metal head; The annular laser spot can also be condensed by a special-shaped lens, and the incident laser light source that has not been fully focused is refracted through the lens to make the direction converge into a ring. The method of generating the ring-shaped beam is: emit the laser beam 8 from above the side electrode noble metal head, the laser beam 8 passes through a special-shaped lens 9 and then irradiates to the root area 5 of the junction of the side electrode noble metal head 3 and the side electrode plate 4, and at the same time, the special-shaped lens 9 is provided with a circular lens shading surface 10, the lens shading surface 10 ca...

Embodiment 3

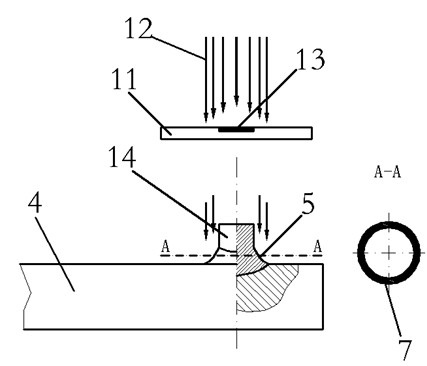

[0040] attached image 3 As another embodiment of the present invention, it can be seen from the accompanying drawings that the present invention relates to a side electrode laser welding method, especially a laser welding method for the side electrode noble metal head through the annular laser spot emitted from above the noble metal head; The ring-shaped laser spot can be formed by using a flat lens to block the converged laser beam to create a hollow in the middle of the beam. The method of generating the ring-shaped beam is: emit a parallel downward laser beam 11 from above the side electrode noble metal head, and the laser beam 11 passes through a flat lens 12 and then irradiates to the root region 5 of the junction between the side electrode noble metal head 3 and the side electrode plate 4, At the same time, a circular light-shielding surface 13 is provided at the center of the flat lens, and the light-shielding surface 13 can block part of the laser beam 11 emitted para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com