Carbon dioxide heat pump sludge drying system

A carbon dioxide and sludge drying technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Low temperature and other problems can prevent volatile odor and harmful gas from overflowing, avoid adhesion and blockage, and improve drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to highlight the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the examples, and the examples are expressed by way of explanation of the present invention rather than limiting the present invention. The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

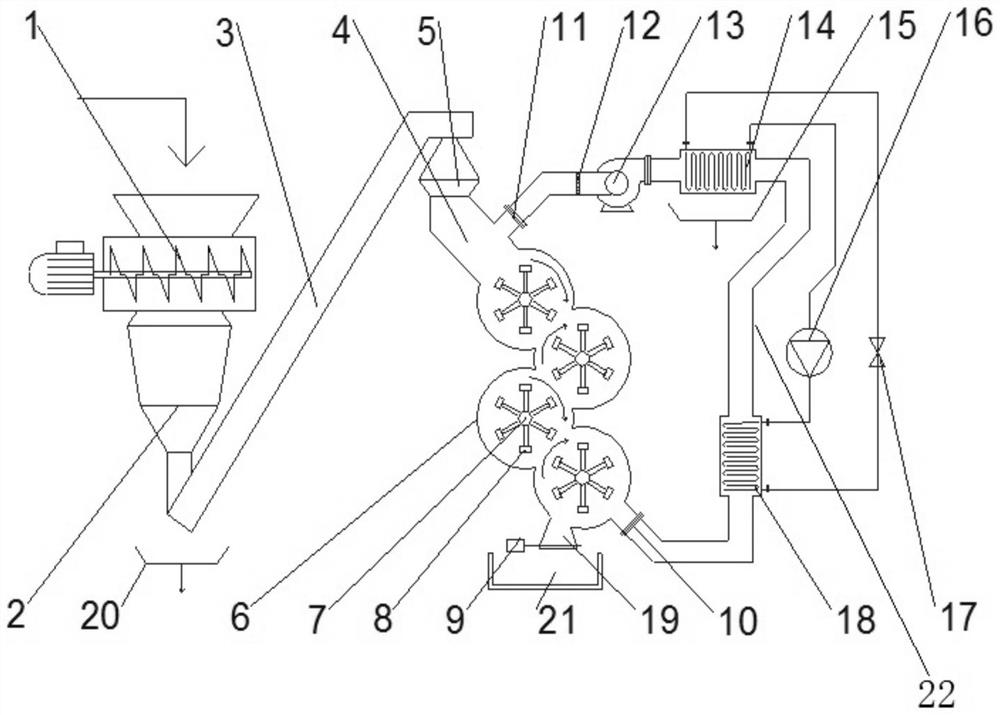

[0034] see figure 1, the present invention provides a carbon dioxide heat pump sludge drying system, the carbon dioxide heat pump sludge drying system includes a mud cake pulverizer 1, a screw conveyor 3, a sludge drying unit and a carbon dioxide heat pump unit (preferably a supercritical carbon dioxide heat pump unit ); the mud cake crusher 1 is used to coarsely crush the mud cake; the screw conveyor 3 is used to send the coarsely crushed mud cake to the sludge drying unit; the sludge drying unit is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com