Determination method of material's uniaxial constitutive relation through biconical indentation prediction

A technology of constitutive relationship and measurement method, applied in the direction of testing the hardness of materials, etc., can solve the problems of popularization and application limitations, the difficulty of obtaining universal laws for numerical relations, and the lack of theoretical basis, etc., and achieve ideal effects and universal applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] In the technical solution of the present invention, based on the principle of energy equivalence and a small number of finite element parameter calibrations, a new technical theory system for predicting the uniaxial constitutive relationship of materials is proposed using biconical (conical or regular pyramidal) indentation.

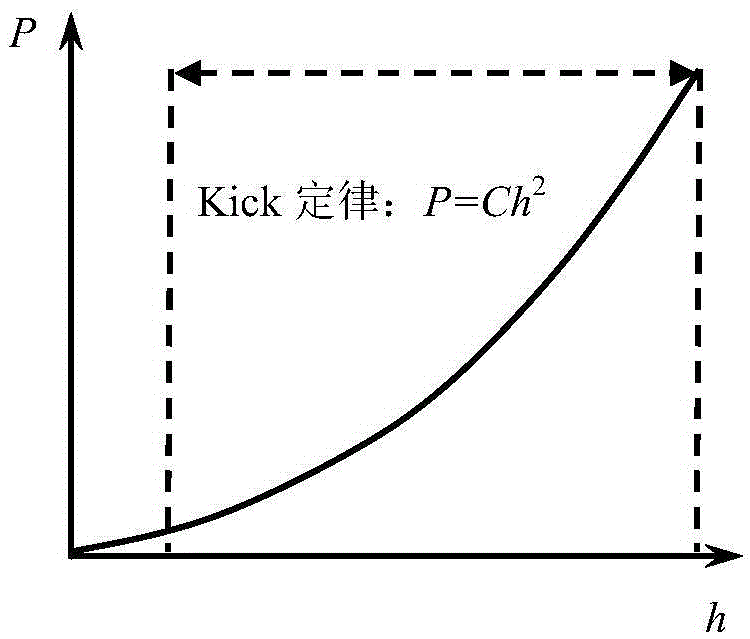

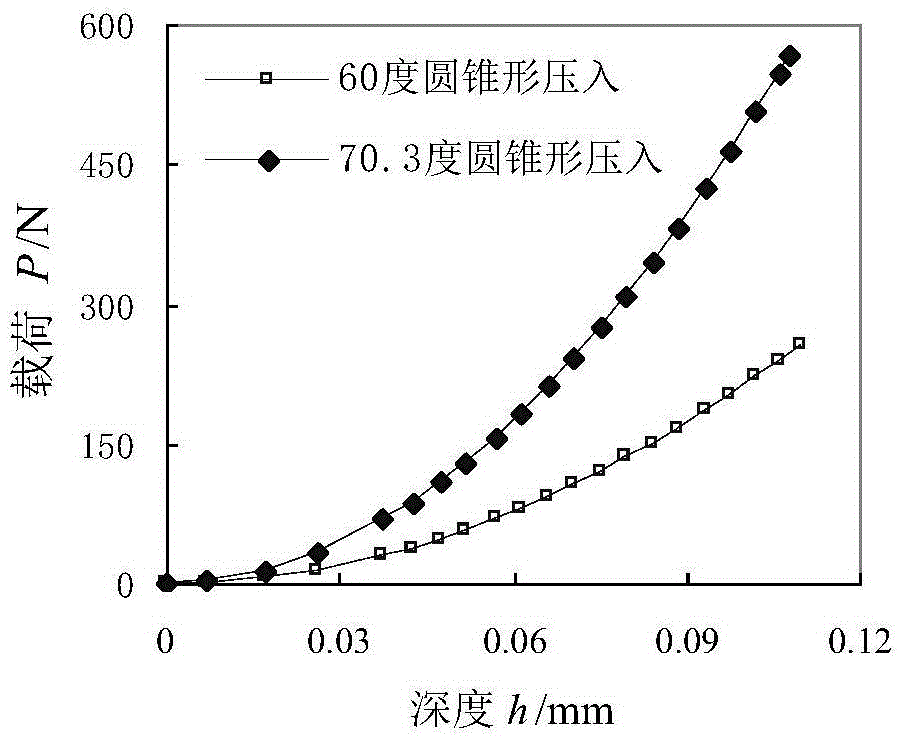

[0058] The quasi-static indentation test of nuclear power pipeline T225NG titanium alloy was carried out by diamond conical or quadrilateral pyramidal indenter, and its uniaxial constitutive relation curve was obtained. image 3 The load-depth curves obtained from the conical indentation test of minimally invasive small cylindrical specimens are given. The data processing process is as follows: firstly, the test load-depth curves under the two angles are zero-point corrected according to the format satisfied by Kick’s law, and then regression is obtained to obtain the loading curvature C θ1 , C θ2 . Finally, substitute the obtained loading curva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com