High-reflectivity backplate material of photovoltaic module

A photovoltaic module and high reflection technology, applied in photovoltaic power generation, electronic equipment, electrical components, etc., can solve the problems of photovoltaic module safety hazards and other problems, and achieve the effects of high photoelectric conversion efficiency, high water vapor barrier performance, and high partial discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In the manufacturing process, firstly, 100 parts of polyethylene terephthalate, 10 parts of inorganic filler titanium dioxide, 3 parts of hydrolysis stabilizer monomer carbodiimide, anti-thermal oxygen aging agent 1,3,5-tri( 0.05 parts of 4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) were uniformly mixed by a high-speed mixer, melt-processed at 230-270 ° C, and cast into a film to obtain a 250 μm thick polymer basement membrane layer.

[0054] Then 100 parts of inorganic filler hollow glass microspheres, 5 parts of auxiliary filler nano-titanium dioxide and 20 parts of silane coupling agent vinyltrimethoxysilane are added to the high-speed mixer, and stirred at a speed of 20000r / min until the temperature of the mixer rises to 130 The stirring was completed at ℃, and the product was dried in a vacuum oven at 100℃ overnight. 20 parts of the modified hollow glass microspheres and 100 parts of the ethylene-propylene copolymer are uniformly mixed with a high-speed mixer, and t...

Embodiment 2

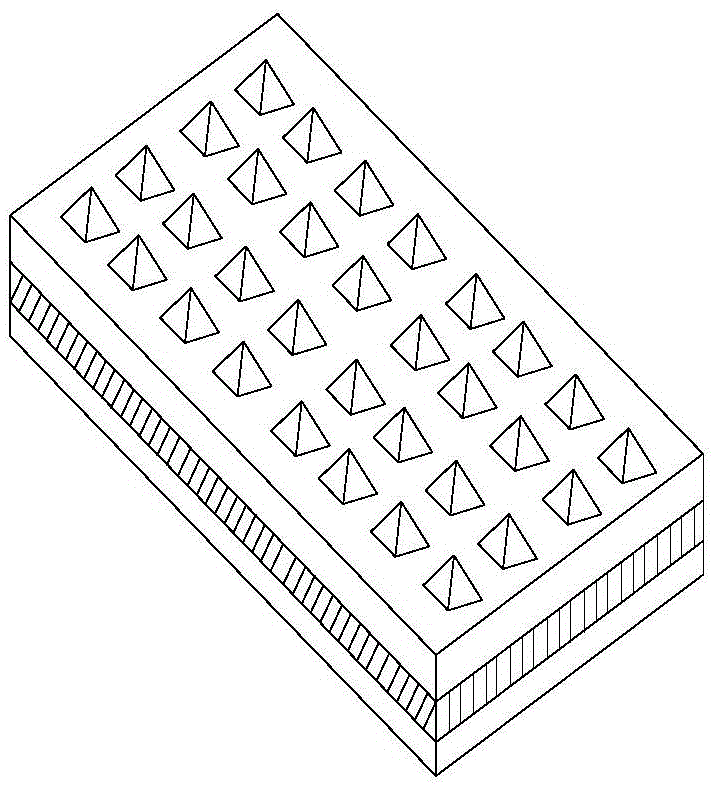

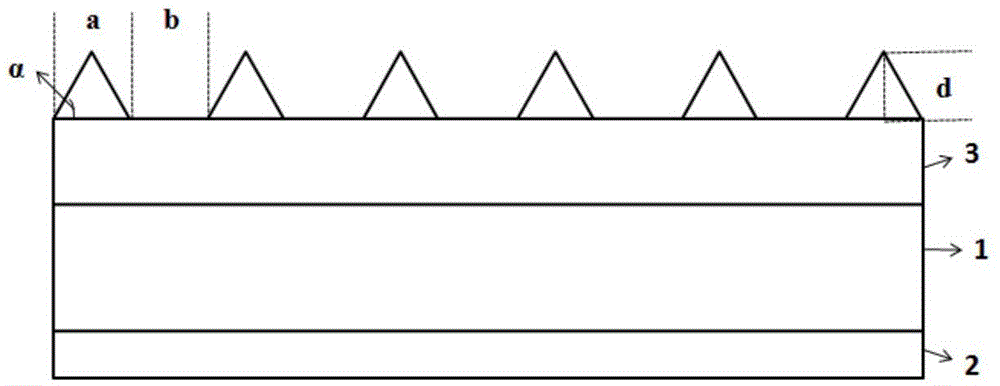

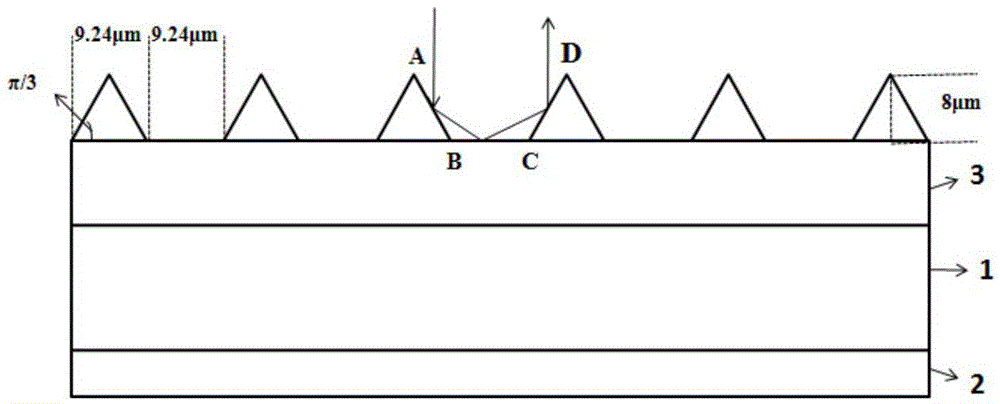

[0057] In Example 2, the thickness and composition of each layer are the same as in Example 1, but the polyolefin layer in Example 2 has a uniformly distributed regular pyramid structure.

Embodiment 3

[0059] In the manufacturing process, firstly, 100 parts of polyethylene terephthalate, 10 parts of inorganic filler titanium dioxide, 3 parts of hydrolysis stabilizer monomer carbodiimide, anti-thermal oxygen aging agent 1,3,5-tri( 0.05 parts of 4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) were uniformly mixed by a high-speed mixer, melt-processed at 230-270 ° C, and cast into a film to obtain a 250 μm thick polymer basement membrane layer.

[0060] Then add 100 parts of inorganic filler hollow glass microspheres, 5 parts of auxiliary filler nano-titanium dioxide and 20 parts of silane coupling agent vinyltrimethoxysilane into a high-speed mixer, and stir at 20,000 r / min until the temperature of the mixer rises to 130°C to end the stirring. The product was dried overnight in a vacuum oven at 100°C. 10 parts of the modified hollow glass microspheres and 100 parts of the ethylene-propylene copolymer are uniformly mixed with a high-speed mixer, and then granulated and dried in a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com