Rectangular square pyramid bolt ball grid multi-point supporting high-altitude separate assembling method

A technology of multi-point support and quadrangular pyramid, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of low efficiency and achieve the effect of cost reduction and efficiency increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

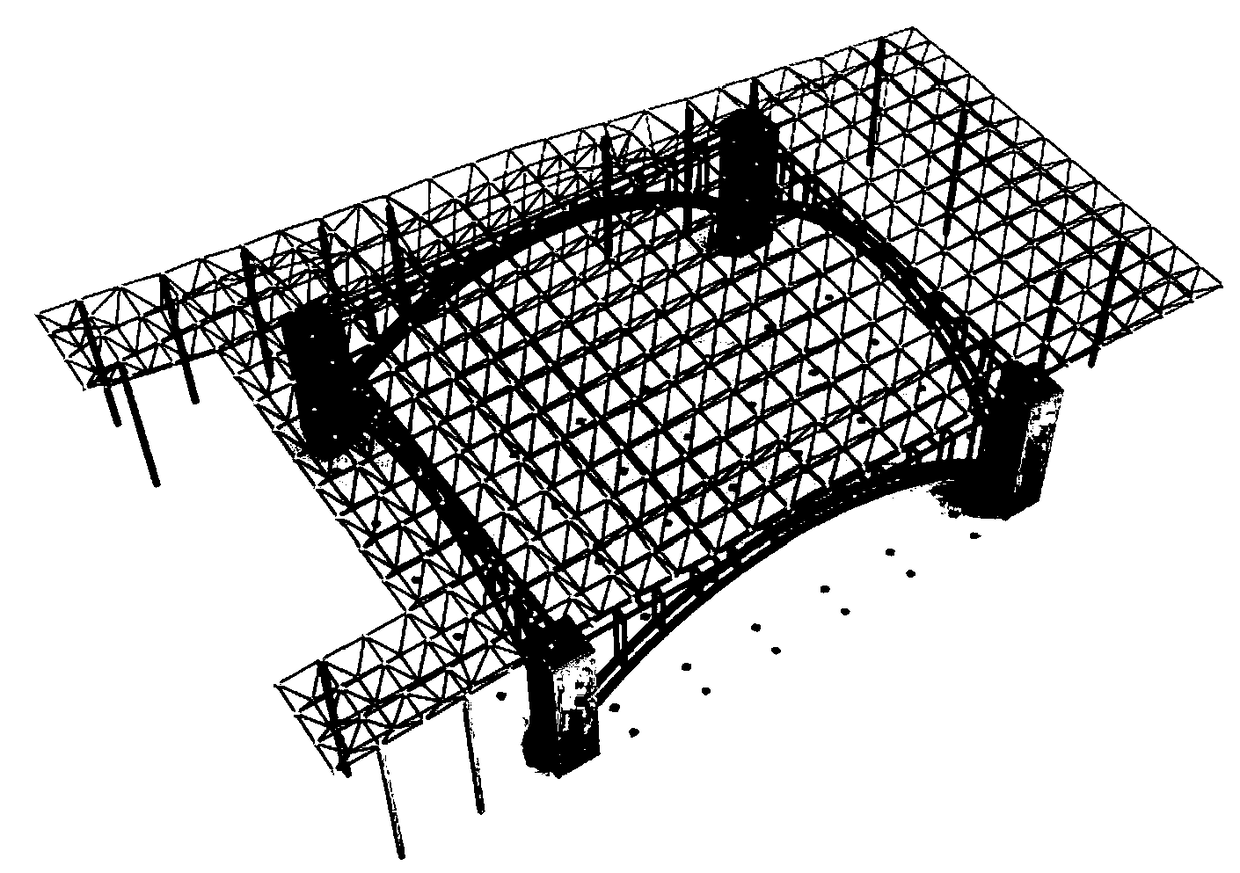

[0026] The preferred embodiment of the multi-point support high-altitude loose assembly method of the regular quadrangular pyramid bolt ball grid frame of the present invention is as follows:

[0027] Include steps:

[0028] A. The starting frame of the grid frame is hoisted by a small hoisting unit assembled on the ground;

[0029] B. After the starting frame is installed, the remaining parts are assembled at high altitude;

[0030] Before the step B, firstly, MIDAS is used to accept and analyze the wire formwork of the grid, find out where the deformation may be large during the assembly process, and set up supports. The supports are designed to be a structure that can adjust the elevation at any time.

[0031] In the step A, first assemble the starting frame of the net frame into 6 pieces on the ground, hoist it to the designated position on the top of the net frame with a truck crane, and weld and fix it with the supports at both ends after checking that it is correct.

...

specific Embodiment

[0044] First, carry out the grid construction simulation calculation

[0045] There is a margin when setting the support displacement in the horizontal direction to avoid deformation of the lateral support. The support in this part is a concealed structure, which cannot be seen after on-site construction, so it is not known whether there is a downward deflection phenomenon behind, so consider setting a margin.

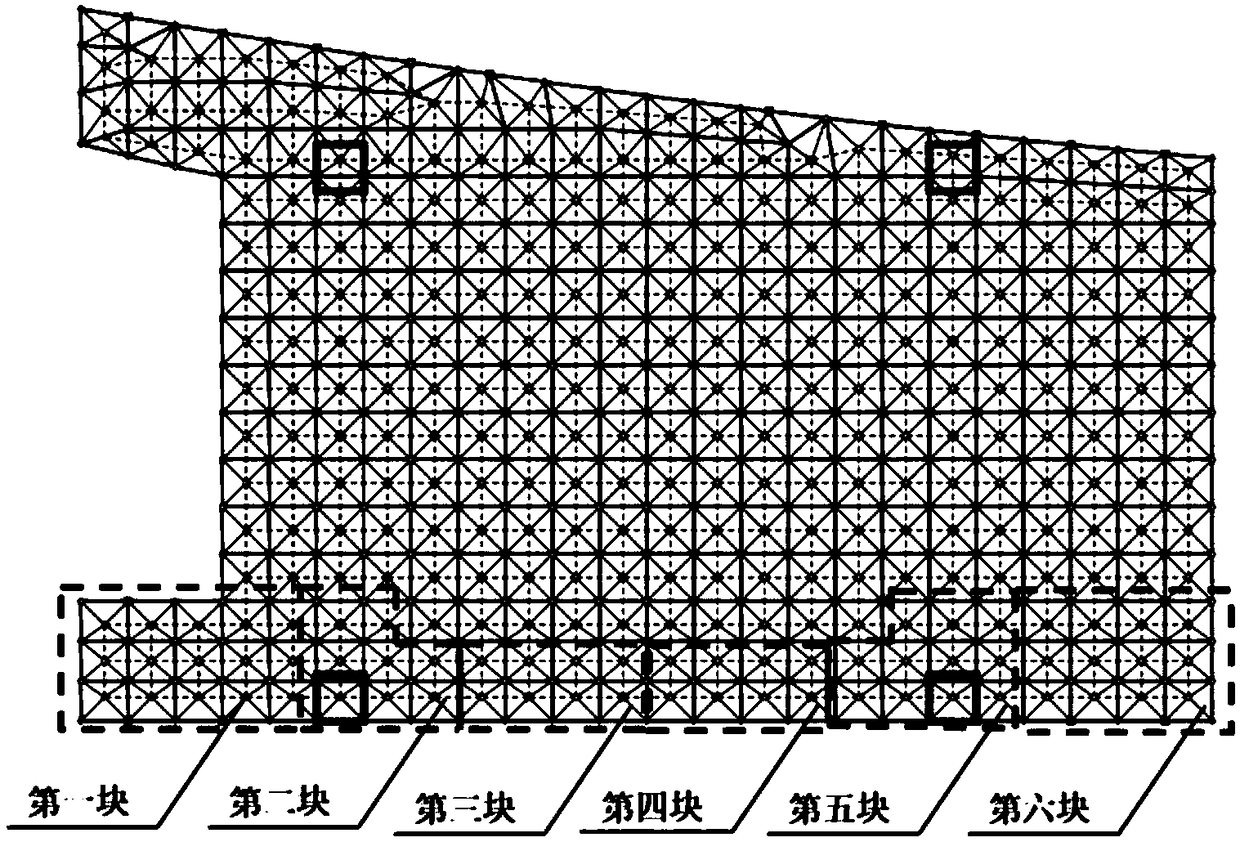

[0046] Grid installation sequence:

[0047] The first step: (such as figure 2 ) First assemble the net frame into blocks (6 pieces in total) on the ground, and then hoist it to the designated position on the top of the net frame with a truck crane. After checking, it is welded and fixed with the supports at both ends.

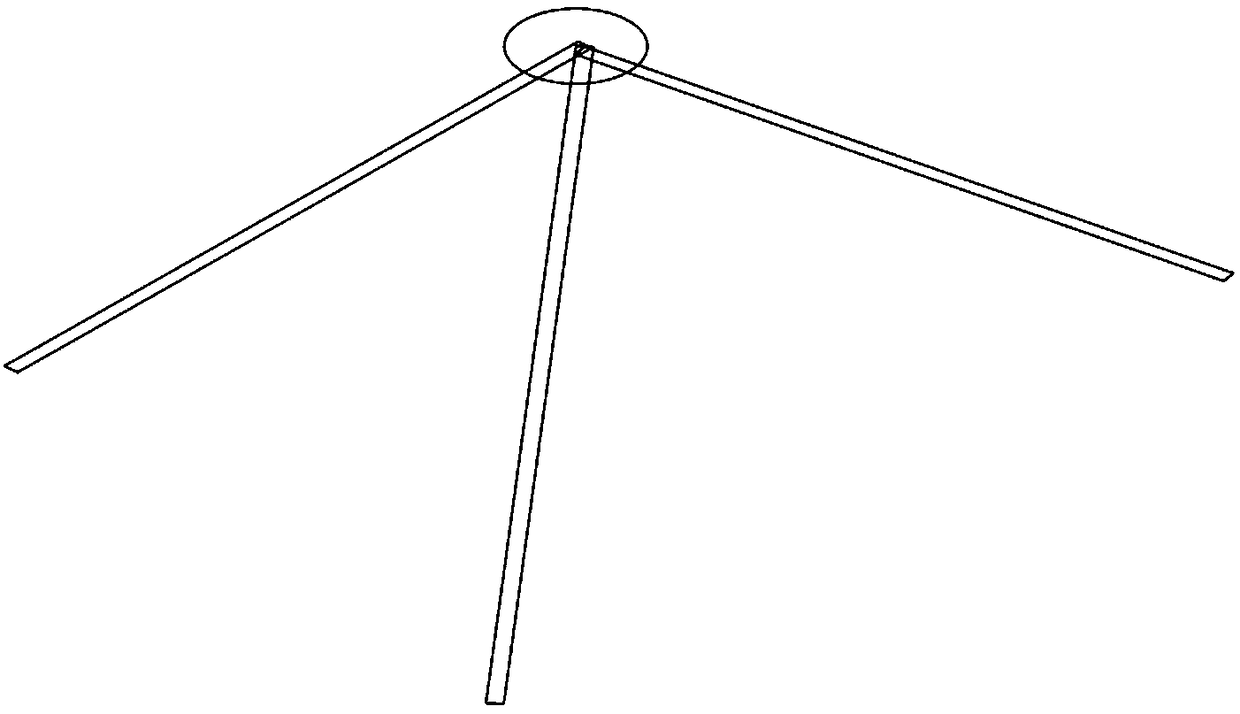

[0048] The second step (such as image 3 ): Assemble upwards from the installed starting frame on the basis of the grid frame assembled in the previous step. The order is: extend a grid forward and install the upper string of the grid frame from left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com