Device for improving foaming uniformity of foamed aluminum and foaming technology

A technology of uniformity and foamed aluminum, which is applied in the field of foamed aluminum processing, can solve the problems of uneven foaming of the melt, uneven foaming of foamed aluminum, small bubbles and high density, etc., so as to maintain the consistency of top and bottom and ensure foaming Uniformity, to overcome the effect of uneven foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

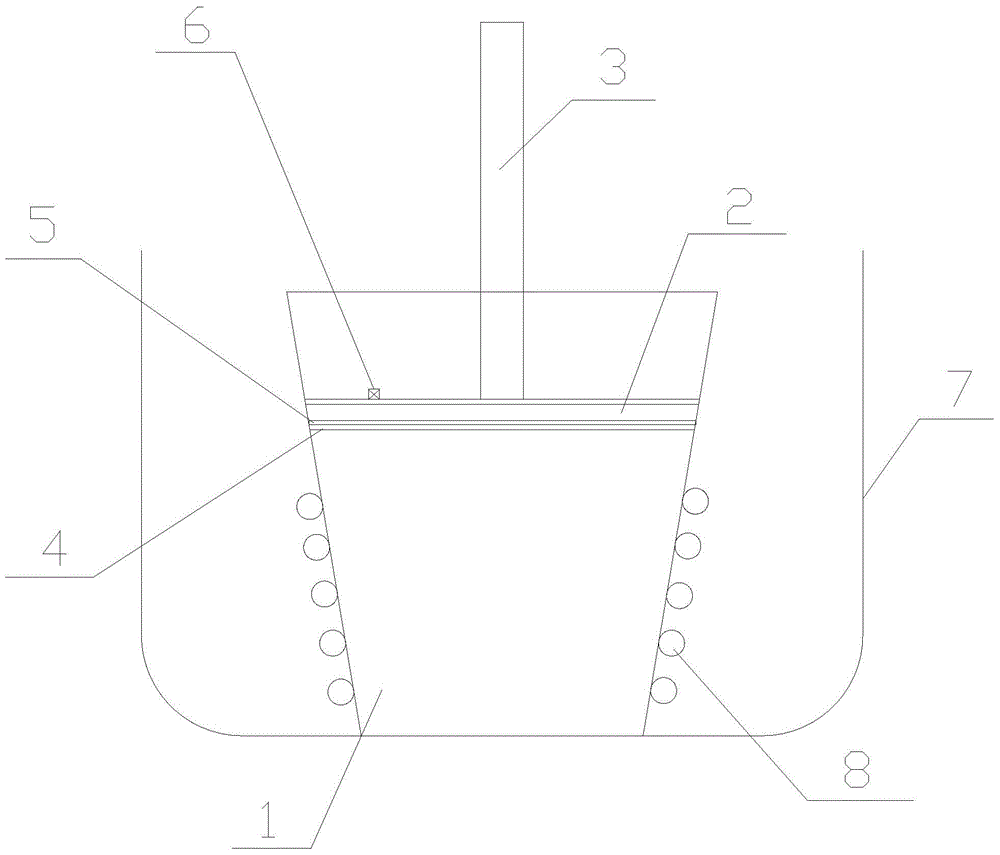

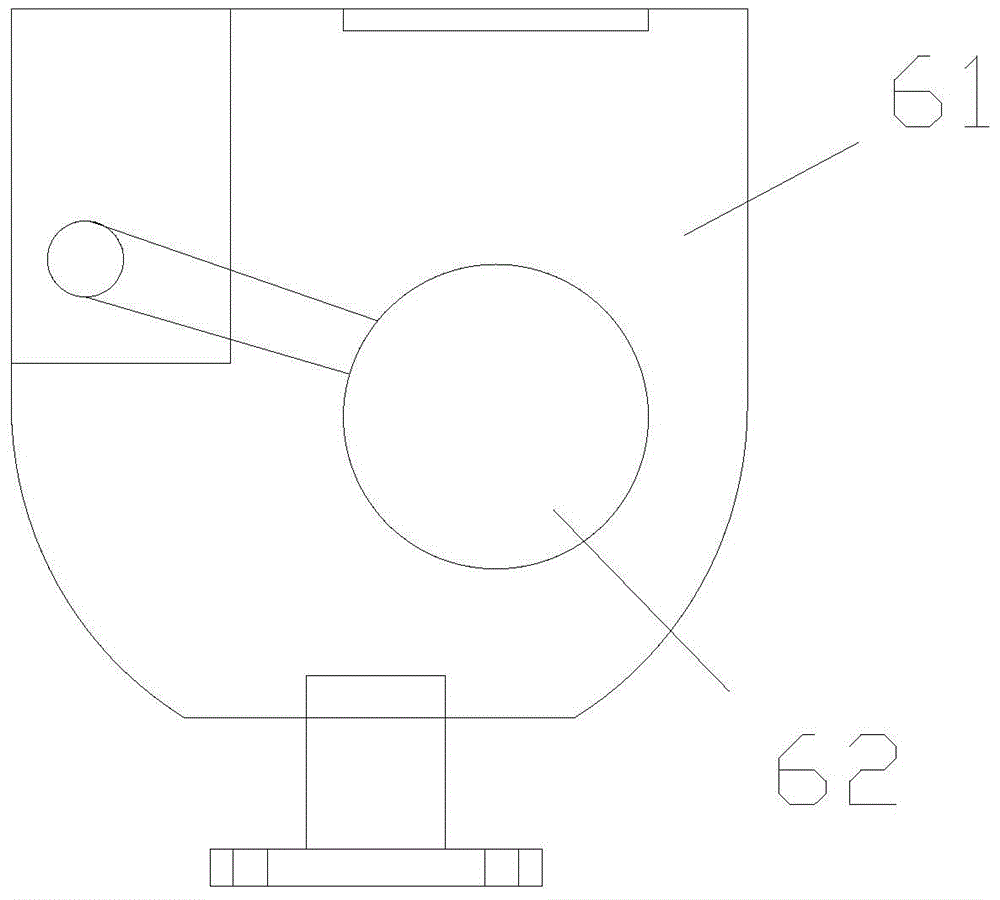

[0022] see figure 1 , figure 2 : A device for improving the foaming uniformity of foamed aluminum, including a mold box 1 with a foaming cavity. For the convenience of mold opening, the mold box 1 is usually designed as a round platform with a large upper part and a smaller open cavity structure. The mold box 1. It is equipped with pressurized cover plates 2 of various sizes and specifications (pressurized cover plates 2 of corresponding specifications can be selected according to the amount of foam, so that the pressurized cover plate 2 can form a good seal on the inside of the mold box 1), The central position of the pressurized cover plate 2 is connected to the hydraulic piston rod 3, and the surrounding edge of the pressurized cover plate 2 is provided with a sealing ring 4, and the pressurized cover plate 2 is also provided with an electric heating device 5 and one or more exhaust valves 6. The suspended piston valve in the air valve 6 can ensure that the valve is autom...

Embodiment 2

[0030] see figure 1 , figure 2 : A device for improving the foaming uniformity of foamed aluminum, including a mold box 1 with a foaming cavity. For the convenience of mold opening, the mold box 1 is usually designed as a round platform with a large upper part and a smaller open cavity structure. The mold box 1. It is equipped with pressurized cover plates 2 of various sizes and specifications (pressurized cover plates 2 of corresponding specifications can be selected according to the amount of foam, so that the pressurized cover plate 2 can form a good seal on the inside of the mold box 1), The central position of the pressurized cover plate 2 is connected to the hydraulic piston rod 3, and the surrounding edge of the pressurized cover plate 2 is provided with a sealing ring 4, and the pressurized cover plate 2 is also provided with an electric heating device 5 and one or more exhaust valves 6. The suspended piston valve in the air valve 6 can ensure that the valve is autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com