Design method for nano-film thermal rectifier with asymmetric embedded structure

A nano-film, thermal rectifier technology, applied in the field of design, to achieve the effect of improving flexibility and controllability, reducing production design costs, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

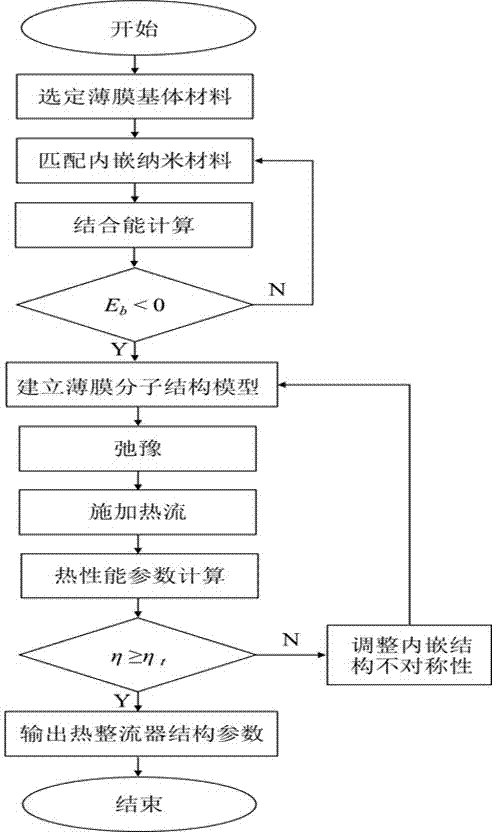

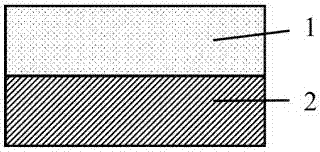

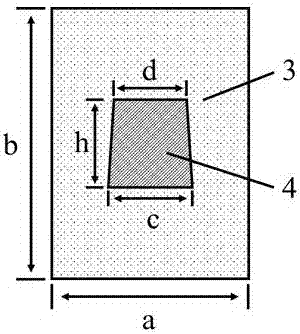

[0022] see figure 1 , select two materials respectively, one is the nano-film matrix material, and the other is the asymmetric embedded structure material, wherein the thermal conductivity of the nano-film matrix material is greater than 200W / mK, and the asymmetric embedded structure material The thermal conductivity should be less than 10W / mK. In the Materials Studio software, the models of the two material blocks and the model of the contact between the two material block models are respectively established, such as figure 2 The shown model of the nanofilm matrix material block 1 model and the asymmetric embedded material block 2 model in contact with each other.

[0023] Use the CASTEP module in the Materials Studio software to first calculate the energy of the nano-film matrix material block 1 E 1 and the energy of the asymmetric embedded material block 2 E 2 , and then calculate the energy of the block after the nano-film matrix material block 1 and the asymmetric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com