Blown rubber for thick product and variable temperature mould pressing preparation method thereof

A technology for foaming rubber and thick products, which is applied in the field of foam rubber for thick products and its variable temperature molding preparation. It can solve the problems affecting product appearance and quality, inconsistent cell structure, and insufficient porosity, and achieve high strength, Uniform foaming and low compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

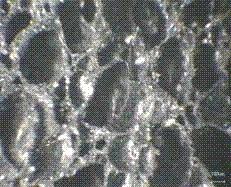

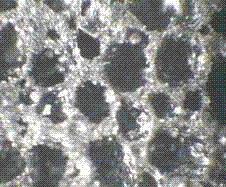

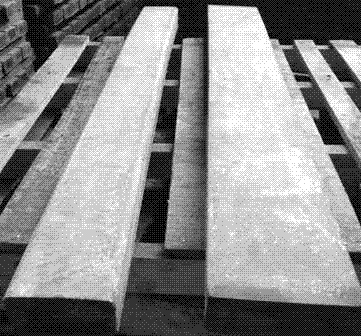

Image

Examples

Embodiment 1

[0040] The components and mass parts are: 100 parts of 1# smoked sheet glue, 5 parts of active zinc oxide, 5 parts of stearic acid, 2 parts of foaming agent H, 8 parts of sodium bicarbonate, 30 parts of calcium carbonate, 300# paraffin wax 20 parts of oil, 10 parts of carbon black N774, 10 parts of fumed silica, 1.5 parts of anti-aging agent RD, 1.5 parts of anti-aging agent MB 1.5, 1.5 parts of anti-aging agent 4010NA, 1.5 parts of paraffin wax, 2 parts of microcrystalline wax, 2 parts of accelerator DM, Accelerator TMTD 0.5 parts, accelerator PZ 1.2 parts, sulfur 0.8 parts.

[0041] The preparation process of Example 1 is as follows: on the 16-inch open type rubber mixing machine, the natural rubber is thinly passed 30 times with the minimum roller distance; after being fully parked, the natural rubber is thinly passed 10 times, and then the roller distance is increased to about 5mm before wrapping and feeding , and then add carbon black, plasticizer, filler, foaming agent, ...

Embodiment 2

[0044] The components and parts by mass are: 100 parts of EPDM rubber 2340A, 5 parts of activated zinc oxide, 3 parts of stearic acid, 4 parts of foaming agent OBSH, microencapsulated urea AF (produced by Zhenjiang Thorpe Group) 2 6 parts of sodium bicarbonate, 40 parts of talcum powder, 20 parts of calcium carbonate, 40 parts of 150s engine oil, 10 parts of carbon black N990, 10 parts of fumed silica, 1 part of anti-aging agent RD, 1 part of anti-aging agent 4020, promote 2 parts of accelerator DM, 1.5 parts of accelerator CZ, 0.8 parts of accelerator TMTD, 1.5 parts of accelerator PZ, 0.8 parts of accelerator M, and 1.5 parts of sulfur.

[0045] The preparation process of embodiment 2 is: on the 16-inch open-type rubber mixing machine, the low Mooney EPDM rubber is thinly passed 10 times with the minimum roll distance; then raw rubber, carbon black, plasticizer, filler, Foaming agent and anti-aging agent are added to the closed rubber mixer in proportion and mixed evenly, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com