Two-phase flow interface parameter distribution characteristic experiment device under swinging condition

A technology of interface parameters and distribution characteristics, which is applied in the direction of measuring devices, fluid dynamics tests, and machine/structural components testing, etc. Simulate problems such as the two-phase flow characteristics of large channels to achieve uniform foaming and more secure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

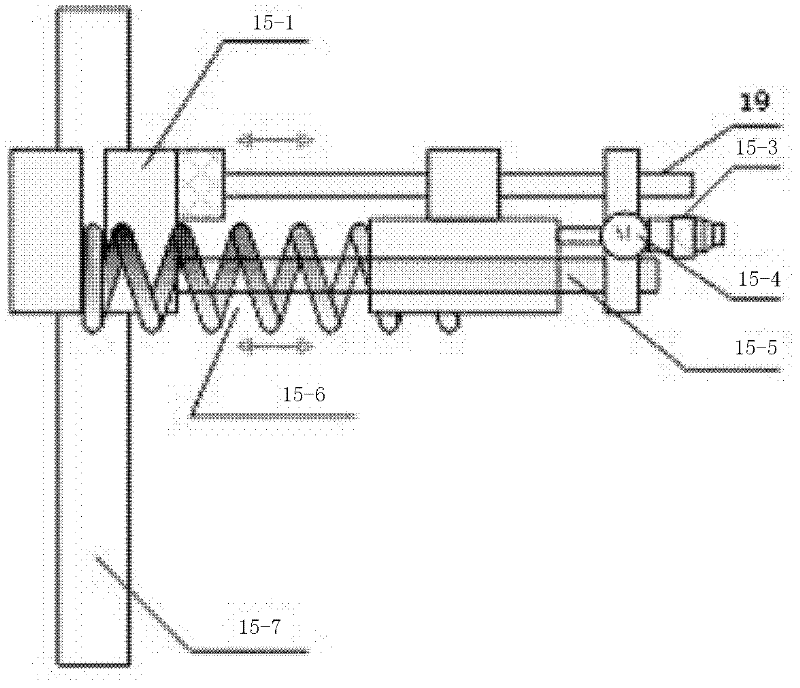

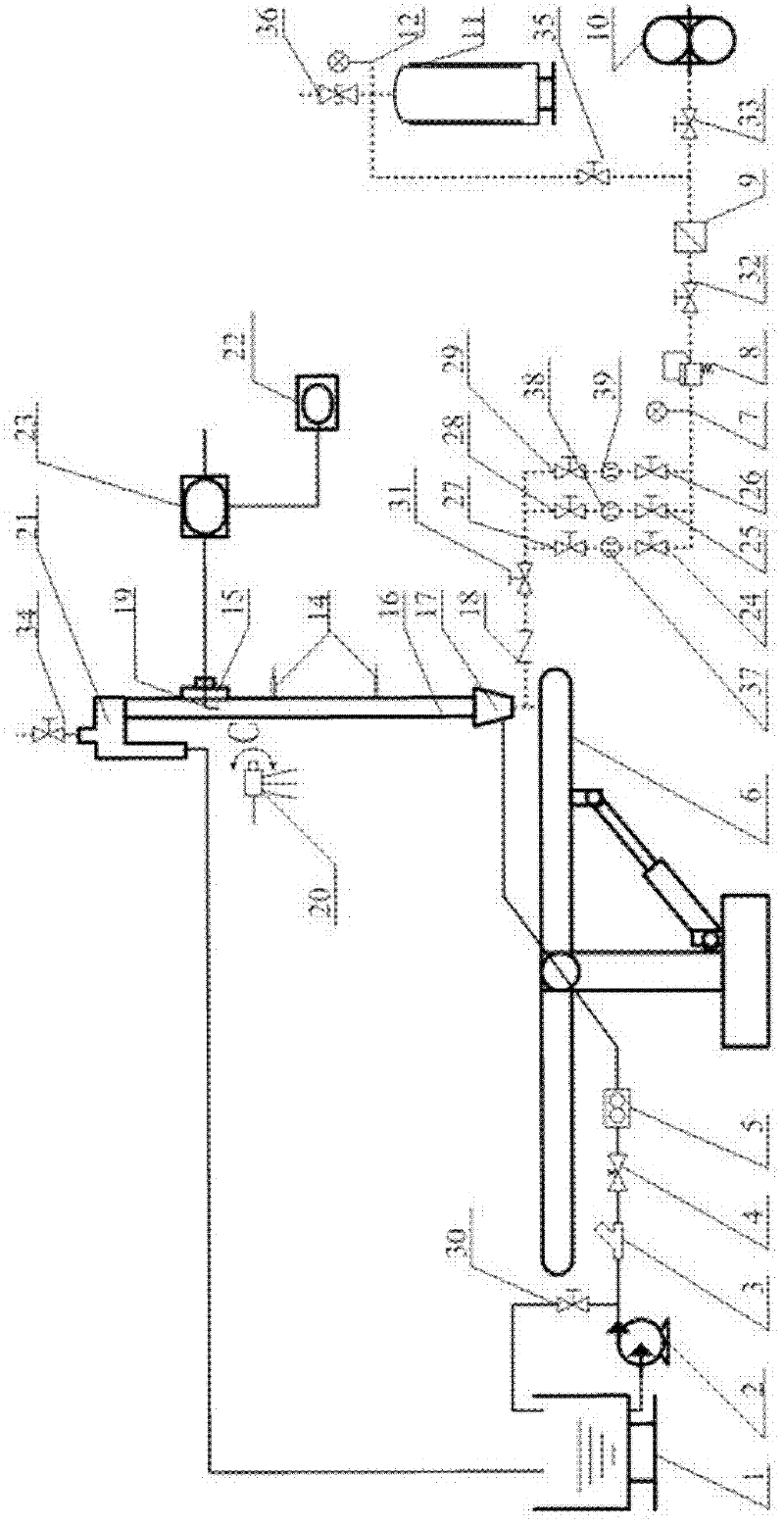

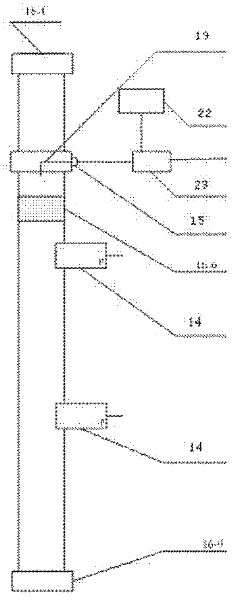

[0024] combine Figure 1~4 , an experimental device for the distribution characteristics of two-phase flow interface parameters under rocking conditions, mainly including a water storage tank 1, a circulating water pump 2, a filter 3, a water flow regulating valve 4, a mass flow meter 5, a rocking table 6, and pressure gauges 7, 12 , pressure reducing valve 8, air dryer 9, air compressor 10, air storage tank 11, computer data acquisition system 13, pressure sensor 14, probe positioning and driving mechanism 15, experimental section 16, mixing chamber 17, check valve 18. Optical fiber probe 19, high-speed camera system 20, steam-water separation device 21, laser source 22, four-channel photoelectric converter 23, various related valves 24-36, volume flow meters 37-39 and swing table console 40.

[0025] Through the control system, the swinging table makes the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com