Foaming composite for shoes and preparation method of foaming composite

A foaming composition and technology for shoes, applied in the field of polymer materials, can solve the problems of easy deformation, low temperature toughness, and pressure resistance, etc., and achieve low compression set, tensile quality, and high resilience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the foaming composition for shoes of the present invention, which includes the step of mixing the components of the composition.

[0043] The preparation method of the foaming composition for shoes of the present invention specifically includes the following steps:

[0044] (1) Use a high-speed mixer to mix the base material evenly, melt and blend in an internal mixer at 130-160°C for 3-10 minutes; add activator, foaming agent, crosslinking aid and filler in sequence, banbury 3 -5min, finally add the crosslinking agent and mix for 2-3min before discharging;

[0045] (2) Press out the mixed raw materials, and then process and slice them into primary embryo raw materials with a predetermined volume;

[0046] (3) Put the raw material into the mold, and perform compression foaming under the temperature conditions of 5-20MPa and 165-185°C. After 5-15 minutes, the pressure is released to obtain the foam, and the finished prod...

Embodiment 1

[0051] The base material (80 parts of ethylene-octene block copolymer (OBCs), 10 parts of ethylene-octene random copolymer (POE), 10 parts of ethylene-vinyl acetate resin (EVA)) 100 parts are used in a high-speed mixer Mix well, melt and blend in an internal mixer at 130°C for 3 minutes; add 1.0 part of activator zinc stearate and 1.5 parts of zinc oxide, 3.5 parts of azodicarbonamide (AC) as foaming agent, and crosslinking aid Triallyl isocyanurate (TAIC) 0.6 parts and filler silica 25 parts, banbury for 5 minutes, and finally add crosslinking agent 1,4-bis-tert-butylperoxycumene (BIPB) 1.2 The parts are mixed for 2 minutes and then discharged; the mixed raw materials are pressed out, and then processed and sliced into preliminary raw materials with a predetermined volume; the preliminary raw materials are placed in the mold, and under the conditions of 10MPa and 175℃, Perform molded foaming, release the pressure after 15 minutes to obtain a foam, and obtain the composition ...

Embodiment 2-4

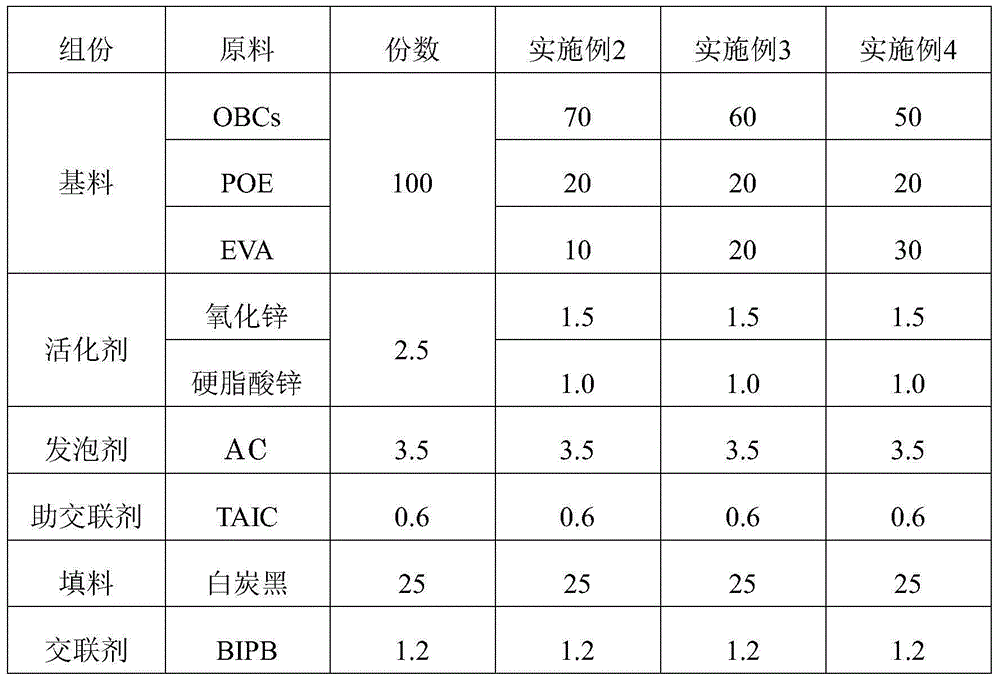

[0053] The feed ratio of the raw materials of each component is shown in Table 1. Only the different ratios of the main materials are changed, and the rest are the same as in Example 1.

[0054] Table 1 Group distribution ratio of Examples 2-4

[0055]

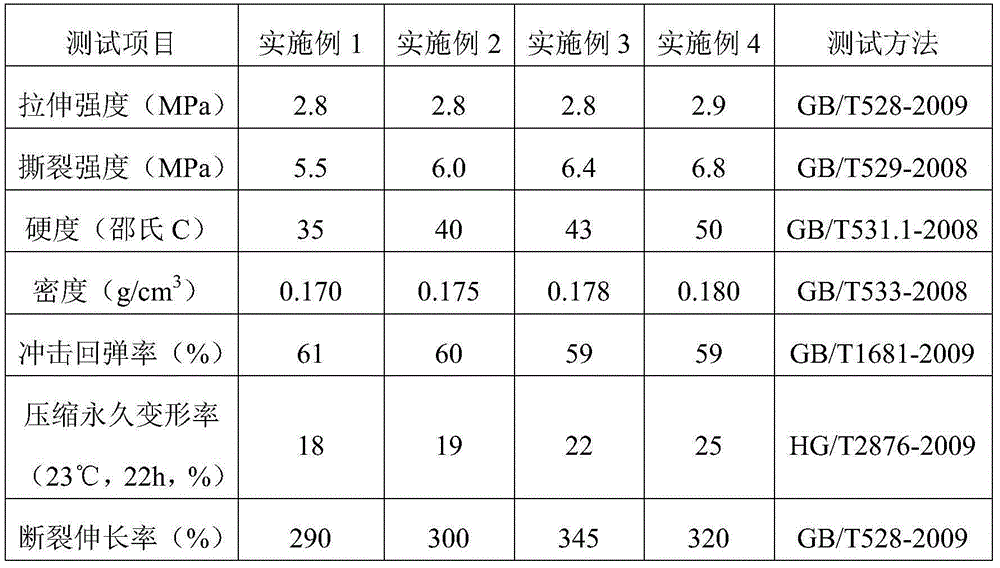

[0056] Performance tests were performed on the compositions prepared in Examples 1-4, and the results are shown in Table 2:

[0057] Table 2

[0058]

[0059] It can be seen from Table 2 that when the content of activator, foaming agent, auxiliary crosslinking agent, filler and crosslinking agent is low and the content remains unchanged, with the different addition amounts of the three base materials, the foaming material Various properties have also changed accordingly. For example, as the content of ethylene-octene block copolymers (OBCs) increases, the density of the material decreases, the tensile strength, tear strength and hardness decrease, and the impact resilience rate is significant As the content of ethylene-vinyl acetate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com