Foam material and moulding method thereof

A foaming material and formula technology, applied in the field of foaming materials and their molding, can solve the problems of high price, rough cell structure, insufficient prevention of odor or discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

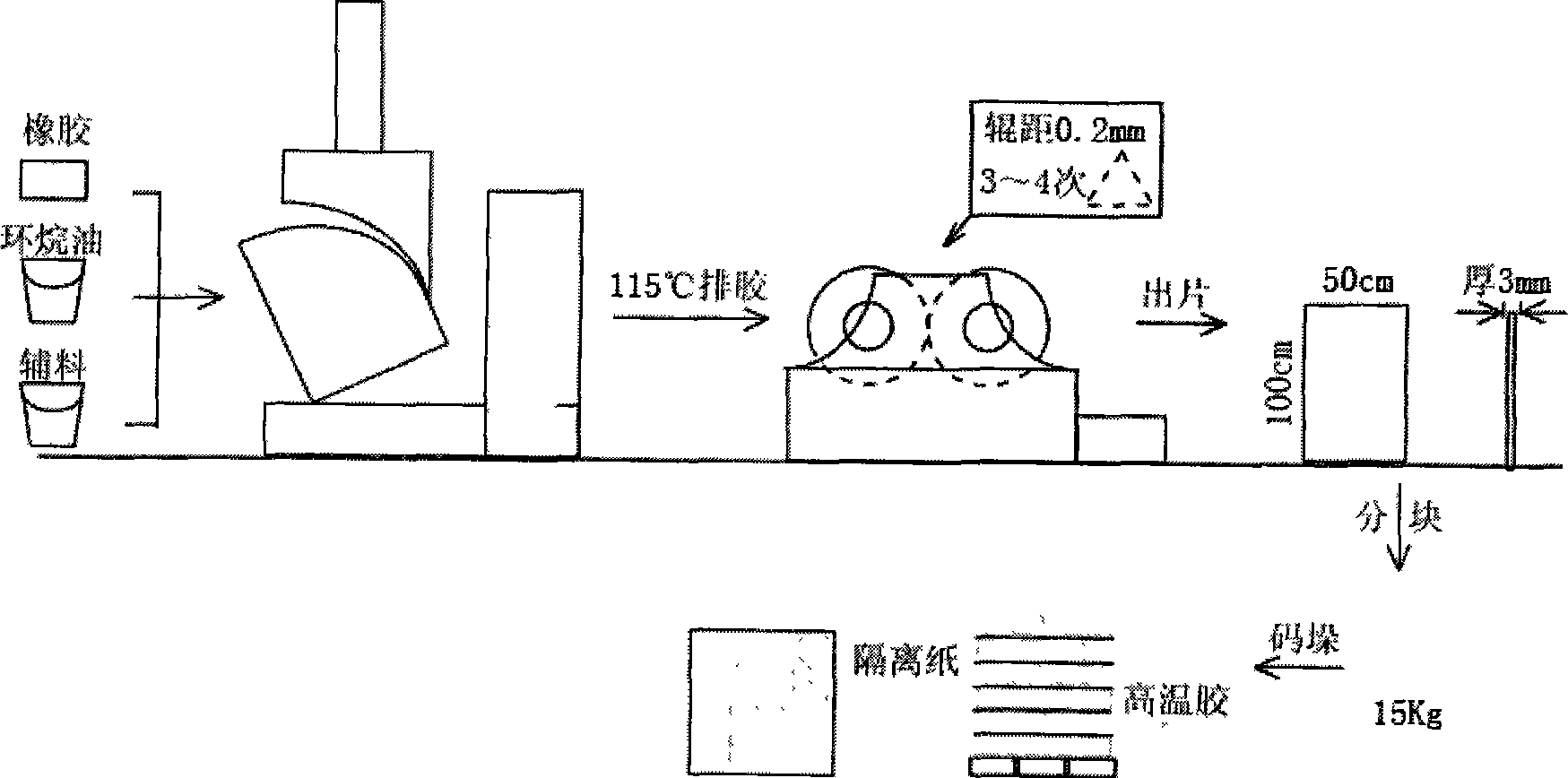

[0017] 1. Refining of high-temperature rubber compound: weigh materials according to the following formula, EPDM: 16.5Kg, chlorinated polyethylene (CPE): 4.5Kg, naphthene: 2.0Kg, ethylene glycol : 0.24Kg, paraffin: 0.15Kg, zinc diethyldithiocarbamate (promoting ZDC): 0.10Kg, zinc dibutyldithiocarbamate (promoting BZ): 0.10Kg, zinc stearate 0.03Kg, Barium stearate: 0.05Kg, stearic acid: 0.24Kg. Put the above materials into the internal mixer as a whole, mix to 115°C and then discharge the glue. Such as the simple mixing process figure 1 shown. Then adjust the roller distance of the open mill to 0.2mm to make triangular bags for 3 to 4 times, and then adjust the roller distance to 3.0mm to produce sheets of 50×100cm. Finally, the mixing sheets are stacked and stored according to 15Kg per weighing.

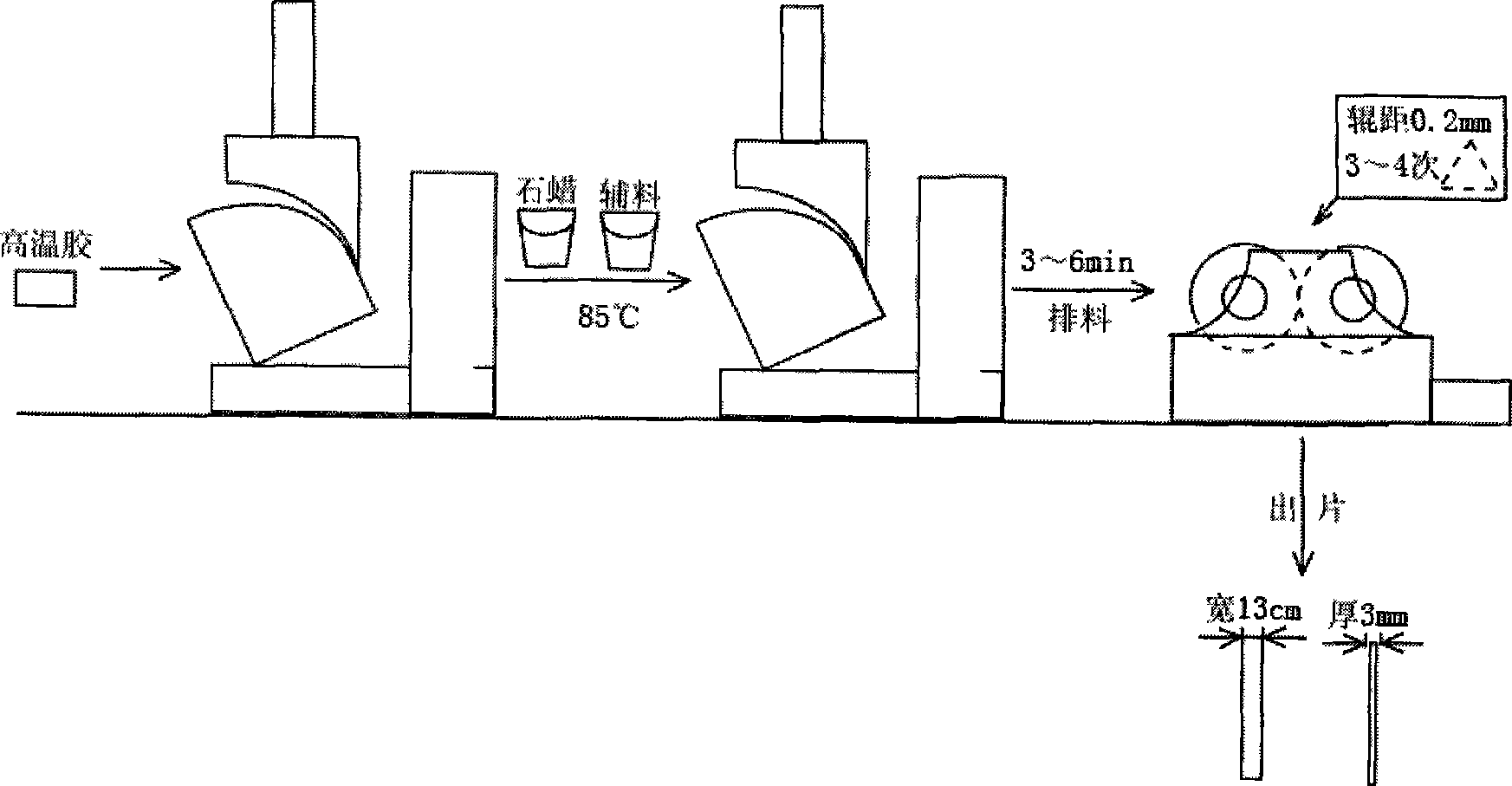

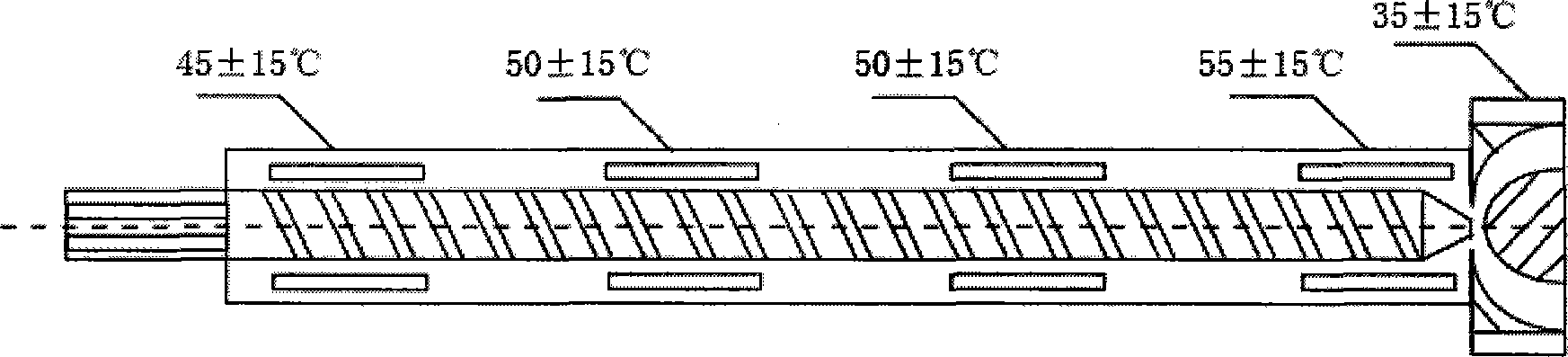

[0018] 2. Refining of low-temperature rubber compound: weigh materials according to the following formula, high-temperature rubber: 15Kg, chlorinated paraffin: 7.0Kg, talcum powd...

Embodiment 2

[0034] 1. The formula of high temperature glue is as follows: EPDM: 16.5Kg, chlorinated polyethylene (CPE): 4.5Kg, naphthene: 2.0Kg, ethylene glycol: 0.20Kg, paraffin: 0.18Kg, two Zinc ethyl dithiocarbamate (promoting ZDC): 0.15Kg, zinc dibutyldithiocarbamate (promoting BZ): 0.12Kg, zinc stearate 0.03Kg, barium stearate: 0.02Kg, stearin Acid: 0.30Kg. The mixing process of high-temperature glue is as in Example 1. 2. The formula of low-temperature compounded glue High-temperature glue: high-temperature glue: 15Kg, chlorinated paraffin: 7.0Kg, talcum powder: 2.0Kg, aluminum hydroxide: 6.0Kg, trioxide Antimony: 2.0Kg, non-polluting high stretch semi-reinforcing carbon black (N774): 2.0Kg, azodicarbonamide (foaming agent AC): 2.5Kg, urea foaming agent (DAK) 0.23Kg , 2-mercaptobenzothiazole (accelerator M): 0.20Kg, zinc oxide: 1.5Kg, sulfur: 0.10Kg, zinc dibutyldithiocarbamate (accelerator BZ): 0.20Kg, tetrathio Bis(1,5-pentylidene)thiuram (promoter DPTT): 0.26Kg. The mixing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com