Silicane self-crosslinked halogen-free flame retardant polyolefin foamed composite and preparation method thereof

A technology of polyolefin foaming and composite materials, which is applied in the field of silane self-crosslinking halogen-free flame-retardant polyolefin foam composite materials and its preparation, which can solve the problems of lack of flame retardancy, poor aging resistance, and broken shrinkage cavities Distortion and other problems, to achieve the effect of uniform foaming, reduce potential hidden dangers, and improve temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

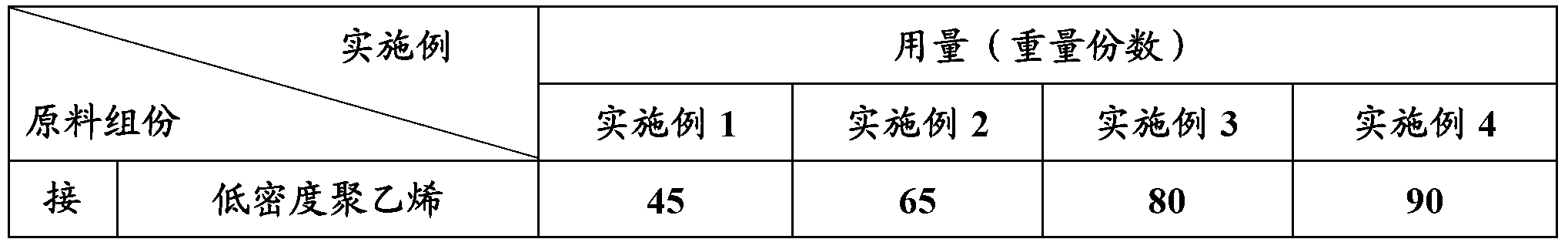

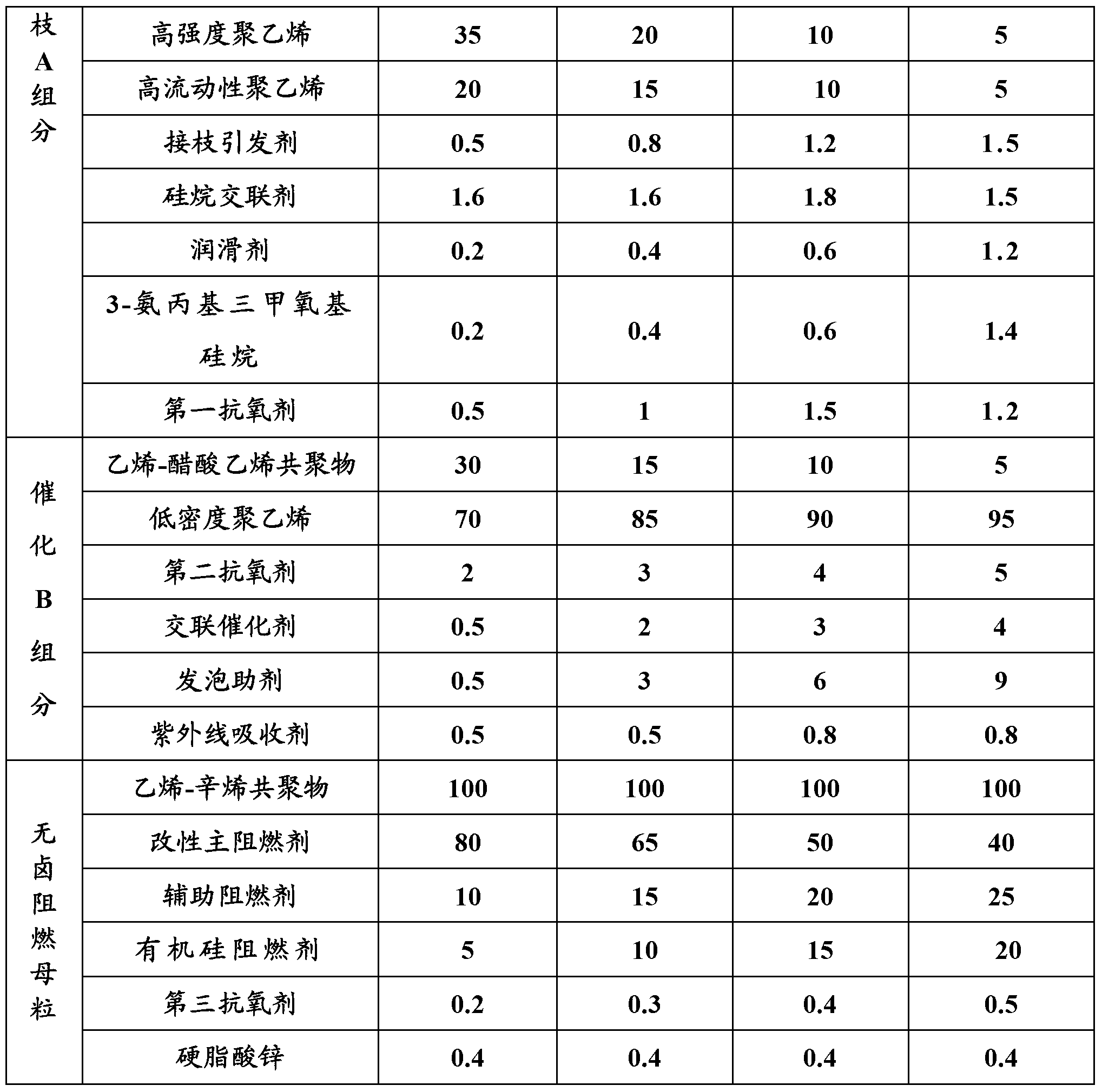

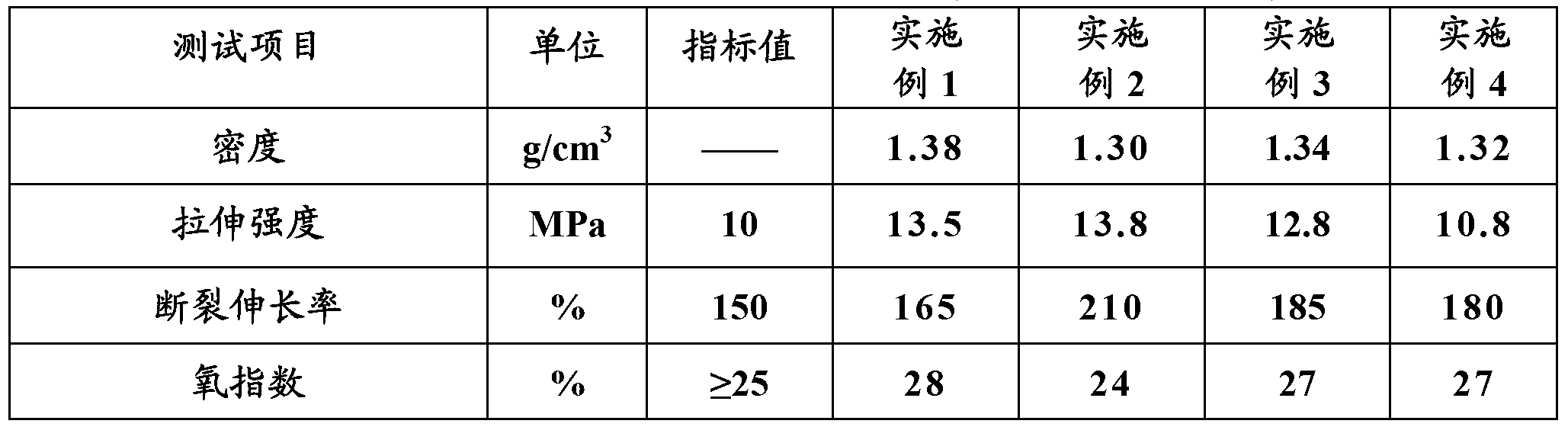

[0030] This example provides a method for preparing a silane self-crosslinking halogen-free flame-retardant polyolefin foam composite material. The raw materials and dosages used are shown in Table 1, wherein:

[0031] In component A of grafting: the melt index of low-density polyethylene is 4g / 10min; the high-strength polyethylene resin is bimodal polyethylene, its melt index is 0.3g / 10min, and the melt strength is 35MPa; Polyethylene with an index of 20g / 10min; the silane crosslinking agent is vinyltrimethoxysilane, the grafting initiator is DCP, the first antioxidant is antioxidant 300, and the lubricant is PPA;

[0032] Catalytic component B: the VA content in ethylene-vinyl acetate copolymer is 28%; the melt index of low density polyethylene is 4g / 10min; the second antioxidant is antioxidant 1010; the crosslinking catalyst is dilauric acid di Butyl tin; the foaming aid is a mixture of azodicarbonamide and monoglyceride; the ultraviolet absorber is benzotriazole;

[0033]...

Embodiment 2

[0041] This example provides a method for preparing a silane self-crosslinking halogen-free flame-retardant polyolefin foam composite material. The raw materials and dosages used are shown in Table 1, wherein:

[0042] in:

[0043] In component A of grafting: low-density polyethylene has a melt index of 2g / 10min; high-strength polyethylene resin is metallocene polyethylene with a melt index of 3.5g / 10min and a tensile strength of 35MPa; Polyethylene with an index of 20g / 10min; the silane crosslinking agent is vinyltrimethoxysilane, the grafting initiator is DCP, the first antioxidant is antioxidant 300, and the lubricant is a fluorine-containing rheological agent;

[0044] Catalytic component B: the cross-linking catalyst is stannous octoate, the foaming aid is a mixture of N,N' dinitrosopentylene amide and monoglyceride, and the ultraviolet absorber is hindered amines;

[0045] In the halogen-free flame retardant masterbatch: the main flame retardant in the modified main fla...

Embodiment 3

[0048] This example provides a method for preparing a silane self-crosslinking halogen-free flame-retardant polyolefin foam composite material. The raw materials and dosages used are shown in Table 1, wherein:

[0049] In component A of grafting: low-density polyethylene is polyethylene with a melt index of 6g / 10min; high-flow polyethylene is polyethylene with a melt index of 50g / 10min; the silane crosslinking agent is vinyltrimethoxysilane, and the grafting initiator is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, the first antioxidant is antioxidant 300;

[0050] In the catalytic component B: the foaming aid is a mixture of modified carbonate foaming aid and monoglyceride, and the ultraviolet absorber is benzophenone;

[0051] Halogen-free flame retardant masterbatch: The main flame retardant in the modified main flame retardant is a mixture of nitrogen-phosphorus flame retardants and magnesium hydroxide at a mass ratio of 1:0.5, and the modified main flame retardant is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com