A foamed polypropylene material

A foaming polypropylene and foaming agent technology, applied in the field of medical PP modified materials, can solve the problems of consumption of polypropylene raw materials, environmental pollution, etc., and achieve the effects of protecting the environment, reducing costs, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

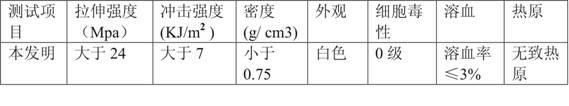

Examples

Embodiment 1

[0028] Weigh 0.8 kg of azodimethamide with a particle size of 4 μm and 0.5 kg of zinc oxide, mix them evenly, and grind them into a fine powder passing through a 100-mesh sieve, which is the modified foaming agent.

[0029] Add 80kg of PP: T30S, 5kgPE, 0.2kg of talc powder with a particle size of 5000 mesh, 0.2kg of dicumyl peroxide, 0.5kg of divinylbenzene and the modified foaming agent obtained in the previous steps into a high mixing pot and mix 10 minutes, the rotating speed is 600 r / min. Mix evenly to obtain the foamed polypropylene material of the present invention.

Embodiment 2

[0031] Weigh 1.2 kg of azodicarboxamide with a particle size of 4 μm and 0.8 kg of zinc oxide, mix them evenly, and grind them into a fine powder passing through a 100-mesh sieve, that is, the modified foaming agent.

[0032] Add 88kg of PP: T30S, 13kgPE, 0.35kg of talc powder with a particle size of 5000 mesh, 0.5kg of dicumyl peroxide, 0.8kg of divinylbenzene and the modified foaming agent obtained in the previous steps into a high mixing pot and mix 10 minutes, the rotating speed is 600 r / min. Mix evenly to obtain the foamed polypropylene material of the present invention.

Embodiment 3

[0034] Weigh 1.5 kg of azodimethamide with a particle size of 4 μm and 1 kg of zinc oxide, mix them uniformly, and grind them into a fine powder passing through a 100-mesh sieve, that is, the modified blowing agent.

[0035] Add 95kg of PP: T30S, 20kgPE, 0.5kg of talc powder with a particle size of 5000 mesh, 0.8kg of dicumyl peroxide, 1.2kg of divinylbenzene and the modified foaming agent obtained in the previous steps into the high mixing pot Mix for 10 minutes at a speed of 600 r / min. Mix evenly to obtain the foamed polypropylene material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com