Air interlayer quilt and manufacturing technology thereof

An air interlayer and quilt technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, and bed sheets, can solve the problems of poor resilience, easy deformation, and poor comfort, and achieve good moisture resistance, good resilience, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

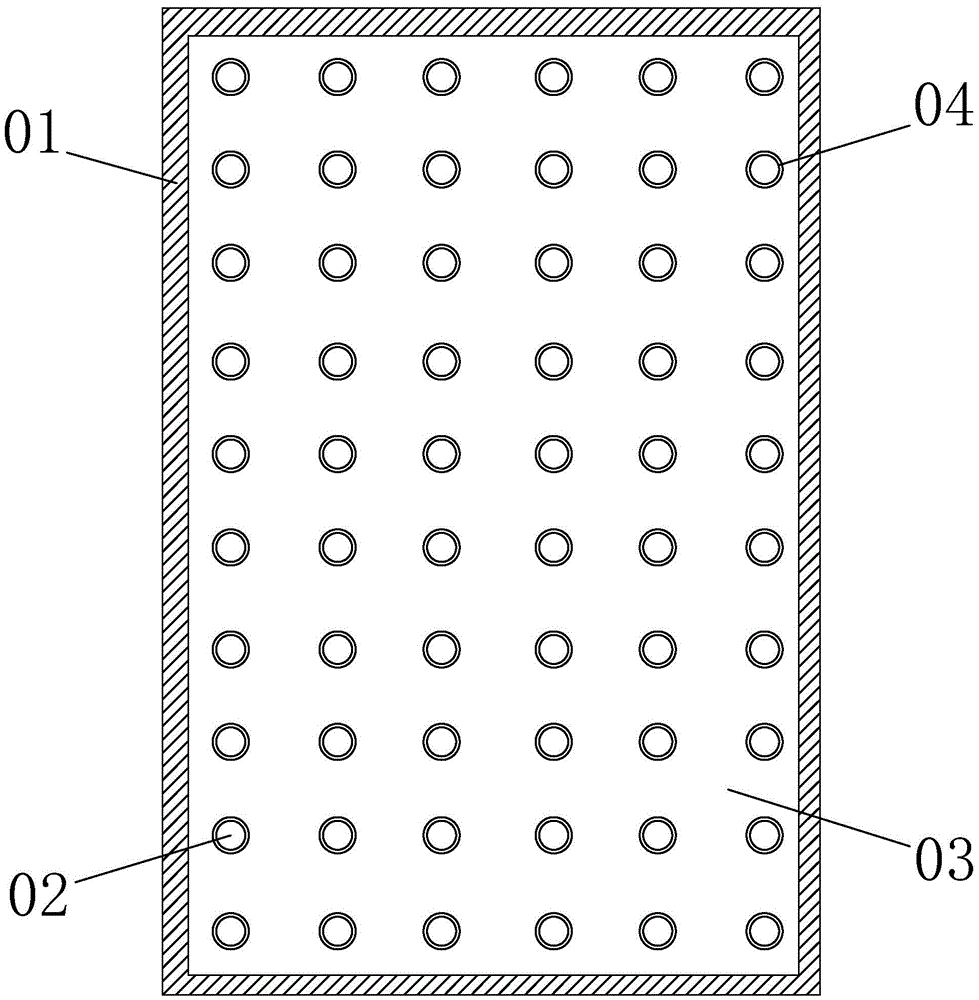

[0040] The air interlayer quilt is made by wrapping the quilt with a quilt cover. The quilt is composed of an outer wrapped cotton material layer, a supporting cotton column and a sealed film bag. The sealed film bag is filled with air and wrapped by an outer wrapped cotton material layer. The supporting cotton column runs through the outgoing hole of the sealed film bag, and its two ends are respectively fixedly connected with the inner surface of the outer wrapping cotton material layer, and the outer wrapping cotton material layer is composed of the following raw materials in parts by weight:

[0041] Raw cotton 50

[0042] Rich Fiber 15

[0043] Viscose 10

[0044] Silk 8

[0045] Spandex 5

[0046] Rabbit fur 5

[0047] sheep wool 2

[0048] Polyester 2

[0049] The supporting cotton column is composed of the following raw materials in parts by weight:

[0050] Cotton 13

[0051] Polyvinyl alcohol fiber 10

[0052] PVC fiber 8

[0053] coconut fiber5

[0054] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com