Stretch-proof polyethylene winding film and preparation method thereof

A polyethylene and stretch film technology, applied in the field of packaging materials, can solve the problems of poor resilience of stretch films, and achieve the effects of good resilience, smooth appearance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

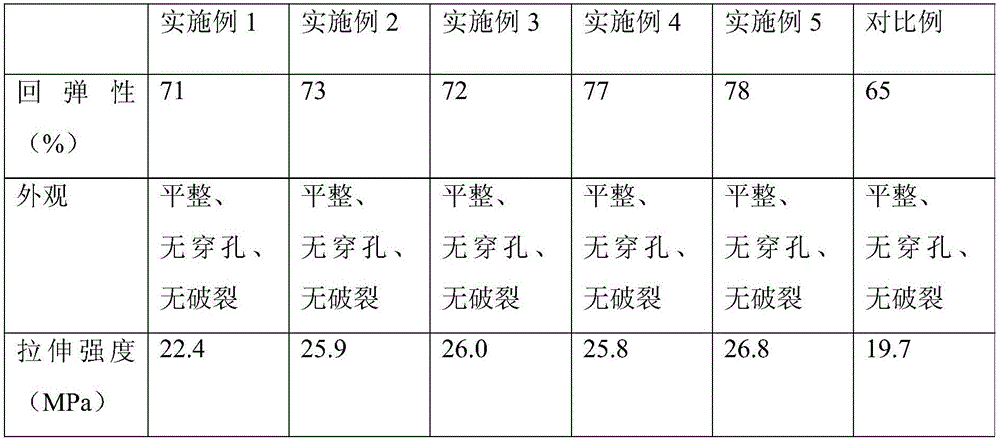

Examples

Embodiment 1

[0016] A stretch-resistant polyethylene stretch film, consisting of the following components in parts by mass: 35 parts of polyethylene resin, 9 parts of polyisobutylene, 2 parts of o-hydroxybenzophenone, 5 parts of triallyl cyanurate, formaldehyde 3 parts of triacetoxysilane, 1 part of propylene glycol alginate, 7 parts of diisopropyl phosphite, 4 parts of antioxidant 168, and 5 parts of calcium stearate.

[0017] Preparation:

[0018] (1) According to the above mass parts, polyethylene resin, polyisobutylene, o-hydroxybenzophenone, triallyl cyanurate, methyltriacetoxysilane, propylene glycol alginate, diisopropyl phosphite, After the antioxidant 168 and calcium stearate are mixed, put them in a blender, stir evenly at 180°C to obtain a mixture, wherein the pressure of the blender is 0.8MPa;

[0019] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature of the first zone is 155°C, the temperature of the second zone is 160°C, the ...

Embodiment 2

[0022] A stretch-resistant polyethylene stretch film, consisting of the following components in parts by mass: 45 parts of polyethylene resin, 21 parts of polyisobutylene, 11 parts of o-hydroxybenzophenone, 17 parts of triallyl cyanurate, methyl 15 parts of triacetoxysilane, 9 parts of propylene glycol alginate, 15 parts of diisopropyl phosphite, 13 parts of antioxidant 168, and 13 parts of calcium stearate.

[0023] Preparation:

[0024] (1) According to the above mass parts, polyethylene resin, polyisobutylene, o-hydroxybenzophenone, triallyl cyanurate, methyltriacetoxysilane, propylene glycol alginate, diisopropyl phosphite, After the antioxidant 168 and calcium stearate are mixed, place them in a blender, stir evenly at 230°C to obtain a mixture, and the pressure of the blender is 1.2MPa;

[0025] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature in the first zone is 170°C, the temperature in the second zone is 175°C, the ...

Embodiment 3

[0028] A stretch-resistant polyethylene stretch film, consisting of the following components in parts by mass: 37 parts of polyethylene resin, 12 parts of polyisobutylene, 4 parts of o-hydroxybenzophenone, 8 parts of triallyl cyanurate, formaldehyde 7 parts of triacetoxysilane, 2 parts of propylene glycol alginate, 9 parts of diisopropyl phosphite, 6 parts of antioxidant 168, and 7 parts of calcium stearate.

[0029] Preparation:

[0030] (1) According to the above mass parts, polyethylene resin, polyisobutylene, o-hydroxybenzophenone, triallyl cyanurate, methyltriacetoxysilane, propylene glycol alginate, diisopropyl phosphite, After the antioxidant 168 and calcium stearate are mixed, place them in a blender, and stir evenly at 190°C to obtain a mixture, wherein the pressure of the blender is 0.9MPa;

[0031] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature of the first zone is 160°C, the temperature of the second zone is 165...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com