Foamed plastic pad as well as preparation method and production line

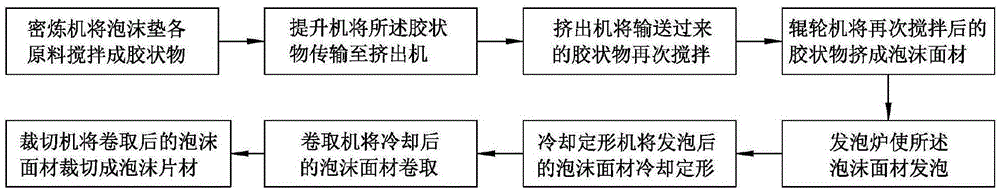

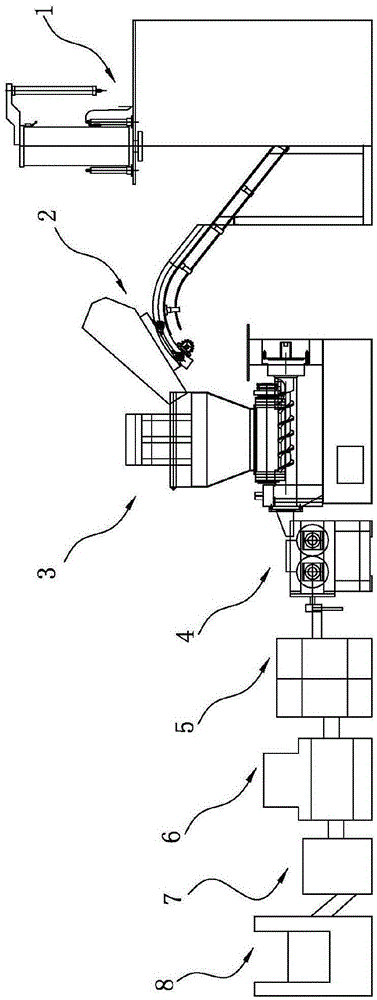

A foam pad and production line technology, which is applied in the field of foam plastics, can solve the problems of low production line efficiency, uneven foam pads, and easy sliding of foam pads, and achieve the effects of continuous foaming with high efficiency, good anti-skid performance, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A foam pad of the present invention is made of the following raw materials in weight percentage: ethylene-vinyl acetate copolymer 20%, polyethylene 45%, calcium carbonate 25%, crosslinking agent 2%, auxiliary agent 5%, toner 3% %.

Embodiment 2

[0069] A foam pad of the present invention is made of the following raw materials in weight percentage: ethylene-vinyl acetate copolymer 10%, polyethylene 50%, calcium carbonate 35%, crosslinking agent 1%, auxiliary agent 3%, toner 1% %.

Embodiment 3

[0071] A foam pad of the present invention is made of the following raw materials in weight percentage: ethylene-vinyl acetate copolymer 15%, polyethylene 40%, calcium carbonate 40%, crosslinking agent 1%, auxiliary agent 3%, toner 1% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com