Ball valve

A ball valve and valve stem technology, used in the field of control valves, can solve the problems of poor sealing reliability and the control valve is not suitable for high temperature and high pressure occasions, and achieve the effects of not easy to crush, good resilience and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

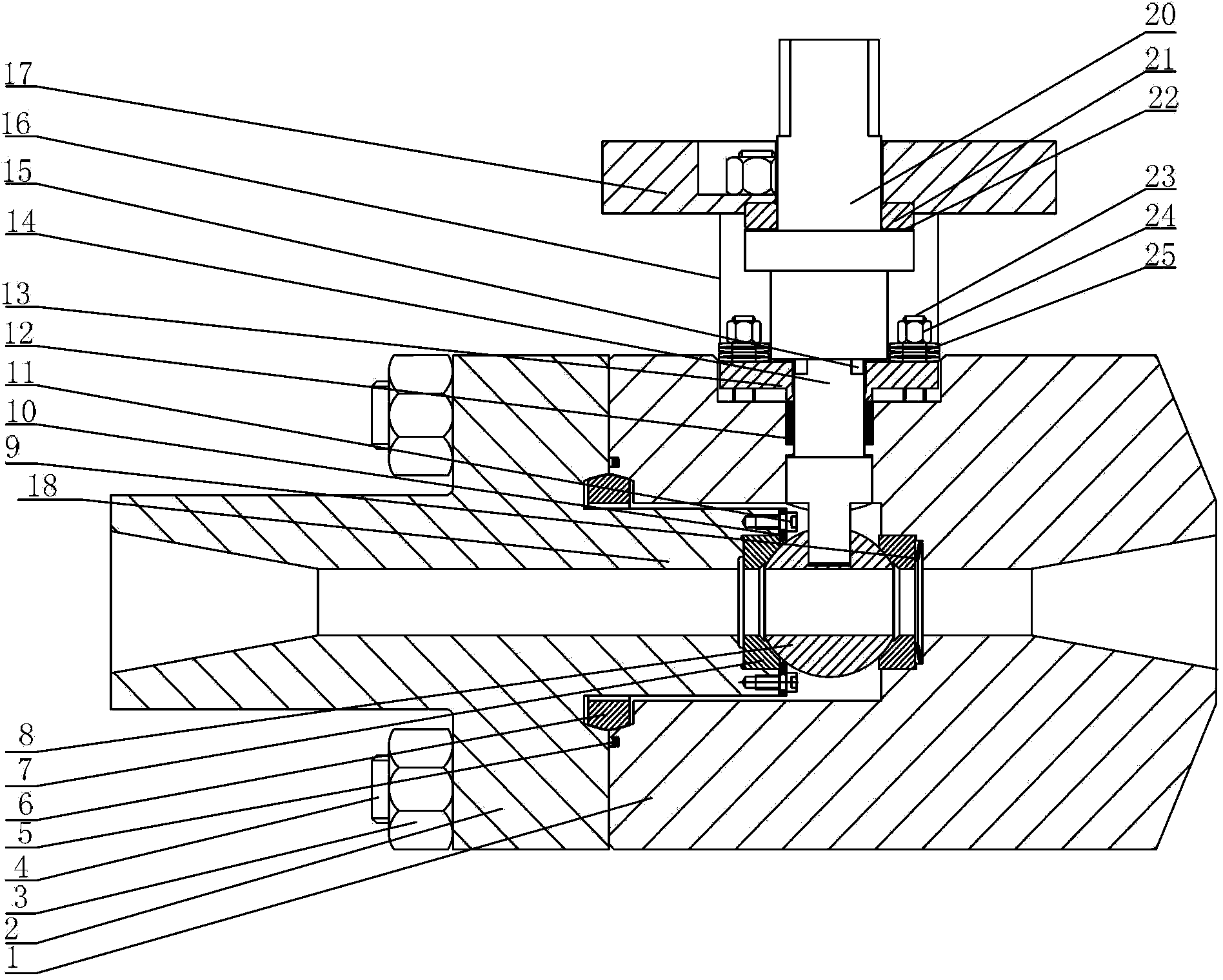

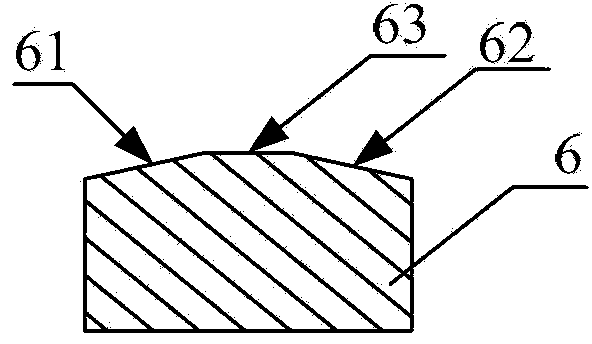

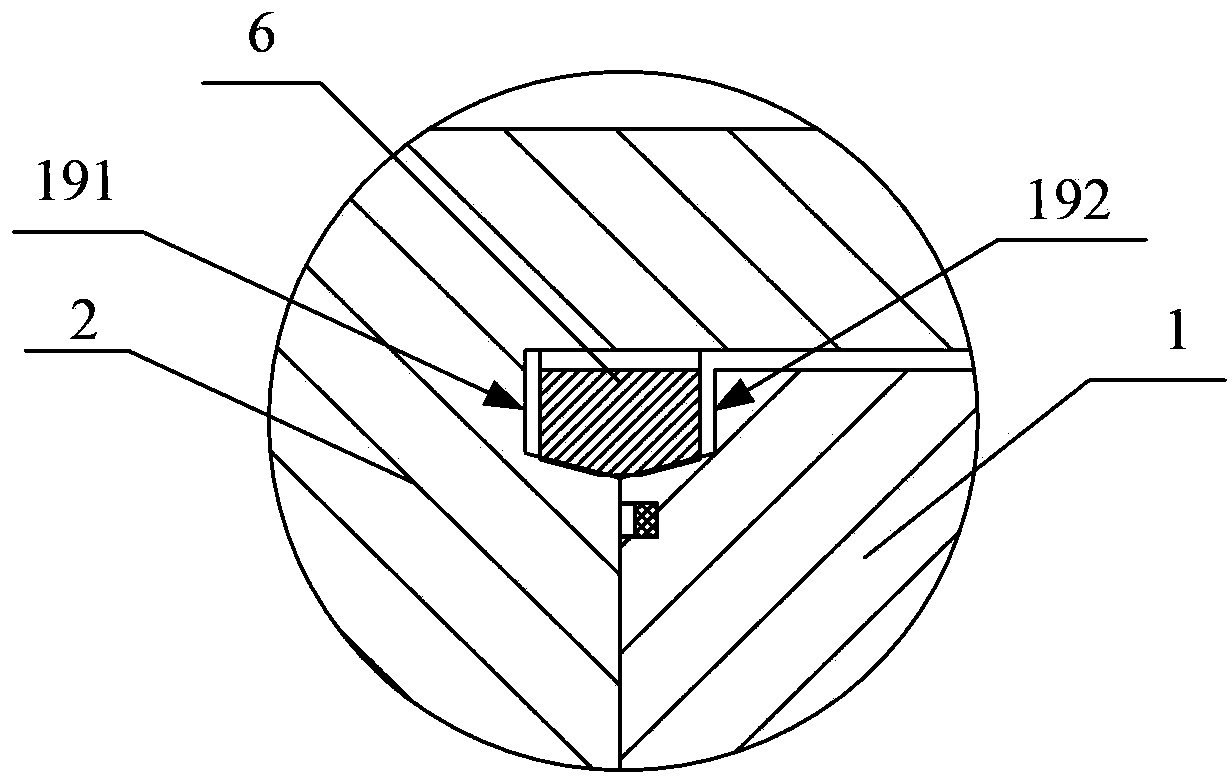

[0018] Such as figure 1 As shown, the ball valve in this embodiment includes a main valve body 1, an auxiliary valve body 2, a valve body connecting stud 4, a valve body connecting nut 3 adapted to the valve body connecting bolt column, and the lateral surface of the outer surface is trapezoidal The metal hexagonal sealing gasket 6 is provided with a first sealing groove 5 on the side of the main valve body pointing to the auxiliary valve body 2, and flexible graphite is filled in the first sealing groove 5 as the first sealing packing. The ball valve also includes a valve seat 7, a ball core 8, a valve seat load spring 9, an outlet valve seat compression ring 10, a packing assembly 12, a packing gland 13, a first valve stem section 14, a valve stem guide bearing 21, a tetrafluoroethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com