High-elasticity foaming material based on ethylene-vinyl acetate elastomers as well as preparation method and application thereof

A technology of vinyl acetate and foaming materials, applied in the field of foaming materials, can solve the problems of easy hydrolysis, high toxicity of toluene diisocyanate, easy discoloration, etc., and achieves good resilience, excellent anti-aging performance, and elongation at break. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

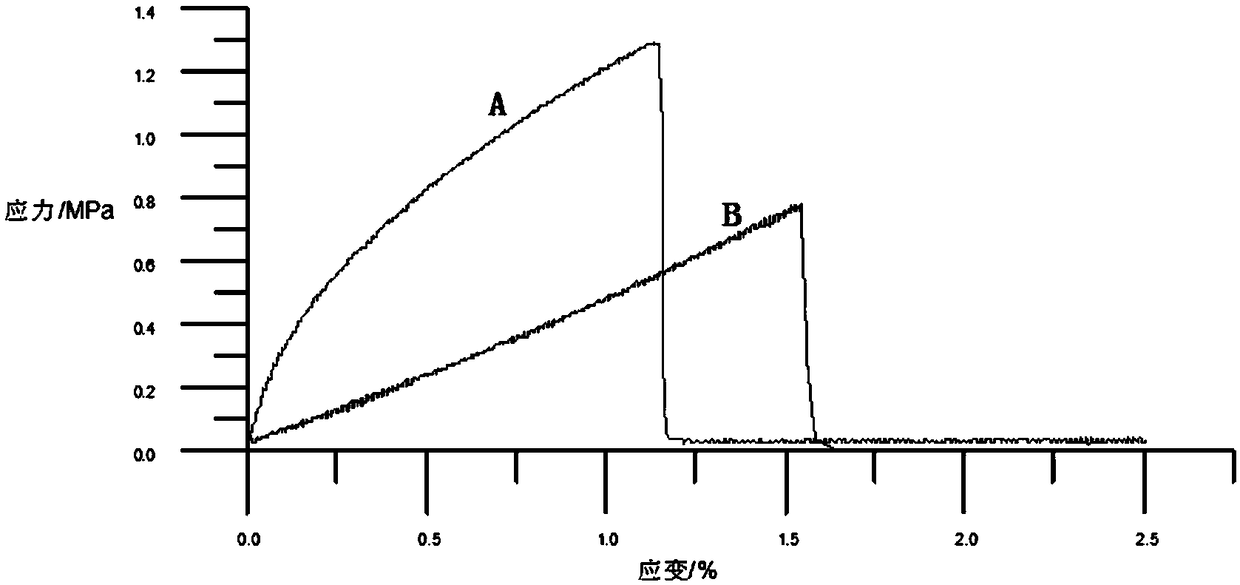

Image

Examples

Embodiment 1

[0033] A high-elasticity foaming material based on ethylene-vinyl acetate elastomer, comprising the following preparation raw materials calculated by weight: a polymer composed of 28% ethylene-vinyl acetate elastomer and low-density polyethylene LDPE with a VA content 3kg, azodicarbonamide (AC) 300g, di-tert-butylperoxycumene (BIPB) 22g, stearic acid 30g, zinc oxide 40g, talcum powder 2kg. The ethylene-vinyl acetate elastomer with a VA content of 28% is specifically selected from DuPont 265, and its mass percentage in the polymer is 100%; and its melt index is 3.0 g / 10 min.

[0034] Its preparation method is as follows: Prepare the required raw materials as needed, put them in a closed rubber mixer for mixing and plasticizing treatment, wherein the temperature in the closed rubber mixer is 135°C and plasticize for 15 minutes and discharge; The material discharged from the machine is sent to the open mill for open refining and thinning for 15 minutes; after cooling, it is cut i...

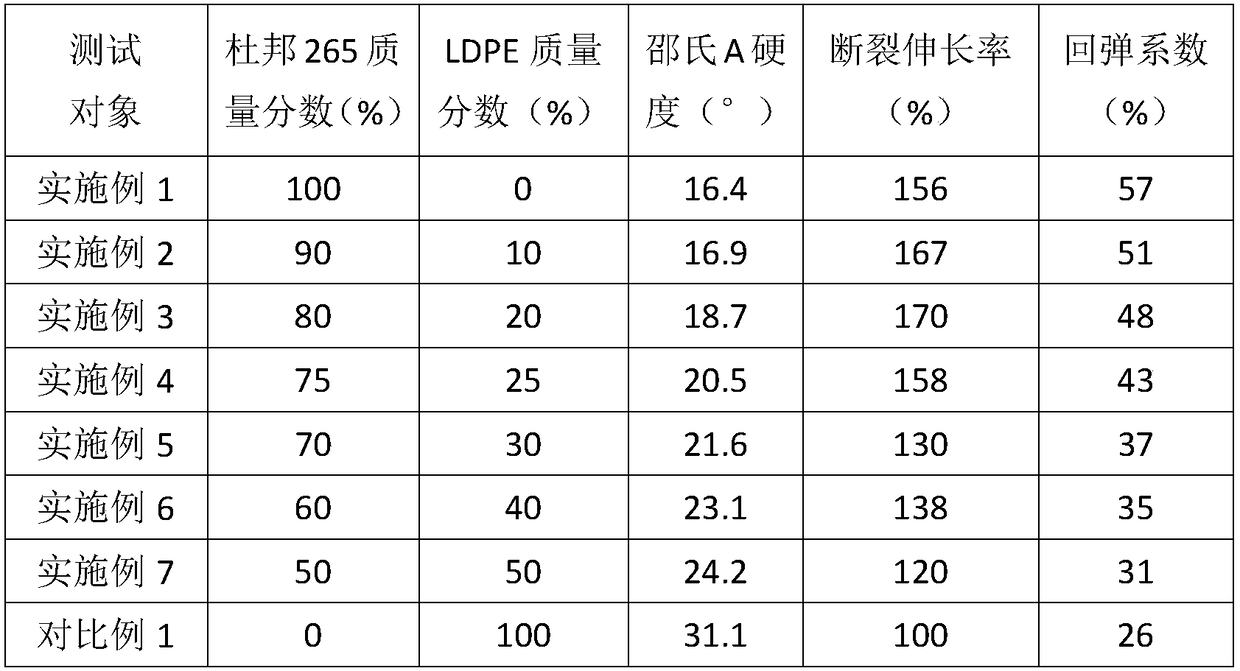

Embodiment 2- Embodiment 7

[0036] Except that the mass percent content of DuPont 265 in the polymer is different, the kind and dosage of other preparation raw materials are all the same as in Example 1; and the preparation method is also the same as in Example 1, and the specific mass of DuPont 265 in the polymer The percentages are 90%, 80%, 75%, 70%, 60%, 50% in turn.

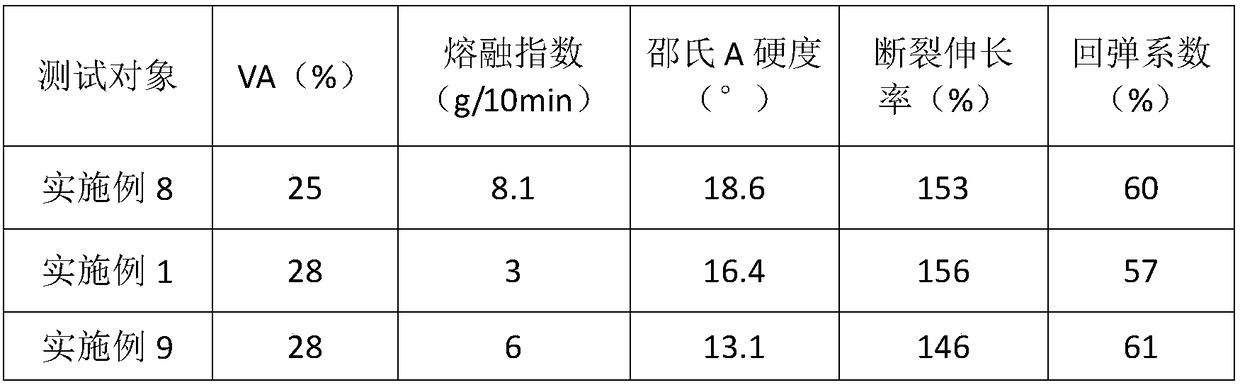

Embodiment 8

[0041] A kind of highly elastic foaming material based on ethylene-vinyl acetate elastomer, comprising following preparation raw materials calculated by weight: VA content is 25% ethylene-vinyl acetate elastomer 3kg, azodicarbonamide (AC) 380g , di-tert-butylperoxycumene (BIPB) 25g, stearic acid 30g, zinc oxide 40g, talcum powder 1.75kg. The ethylene-vinyl acetate elastomer with a VA content of 25% is specifically selected from DuPont 265, and its melt index is 8.1 g / 10 min.

[0042] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com