Antistatic type high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and antistatic technology, applied in the field of thermoplastic elastomer preparation, can solve the problems of poor flame retardancy and other problems, and achieve the effects of reduced mechanical properties, low hardness, and low addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

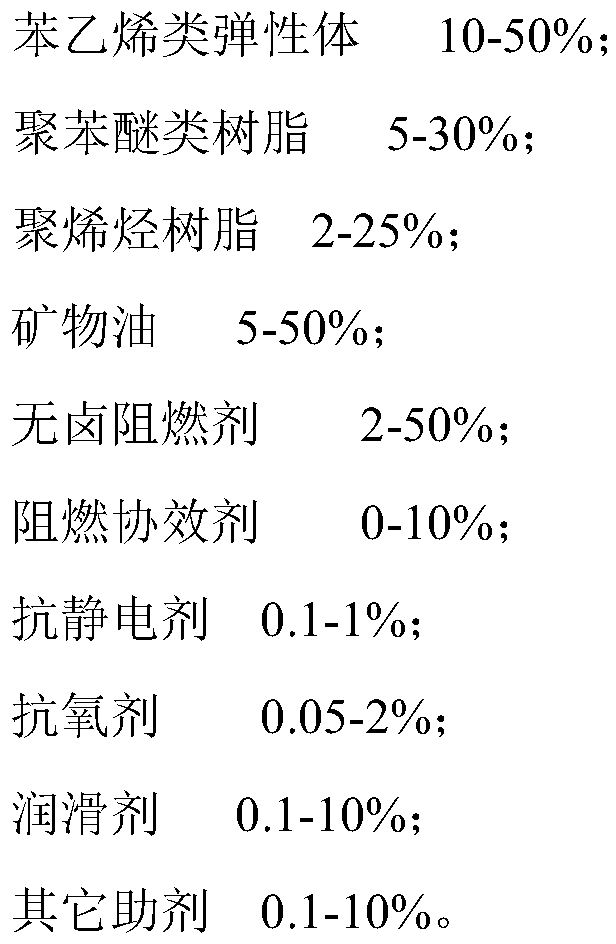

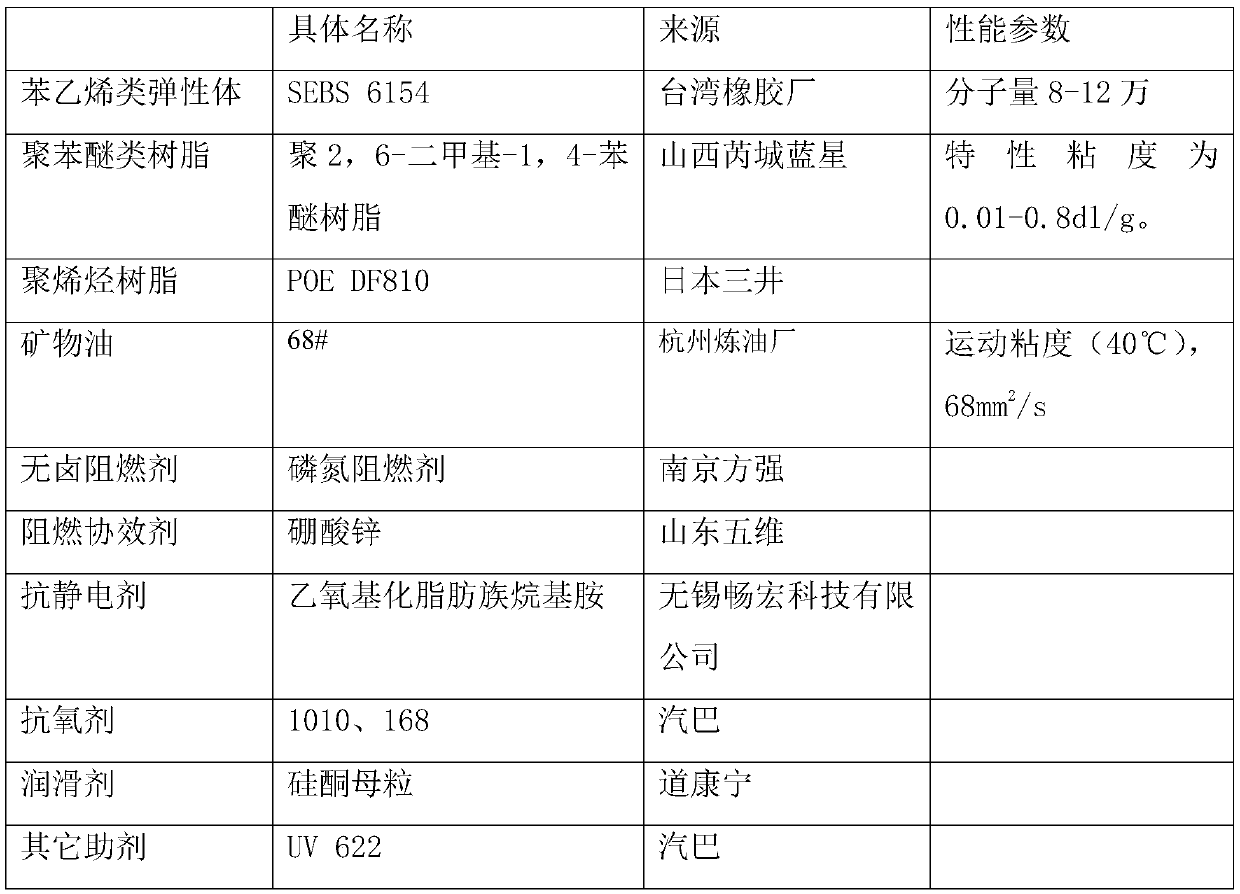

Method used

Image

Examples

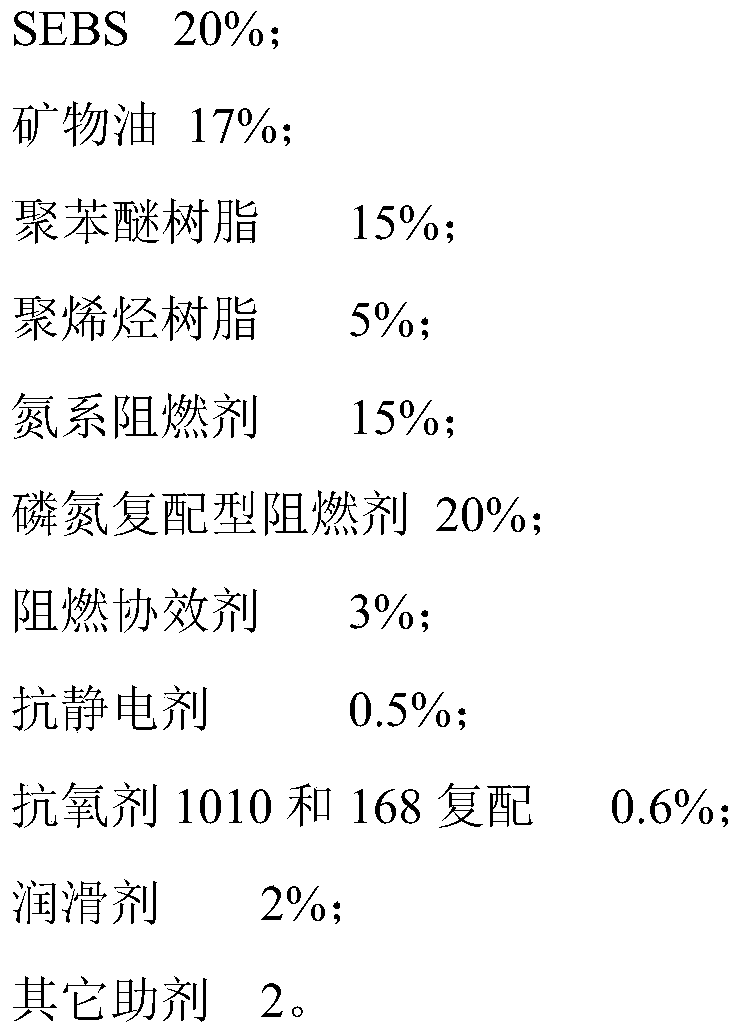

Embodiment 1

[0037] A preparation method of the antistatic type high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer comprises the following steps:

[0038] 1) Prepare various raw materials according to the weight percentage composition recorded in Table 1, wherein the antistatic agent is a 1:1 mixture of sodium dodecylsulfonate and ethoxylated C12-14 tertiary alkylamine;

[0039] 2) After mixing the styrene-based elastomer with the filler oil and stirring evenly, let it stand for 8 hours;

[0040] 3) Add other raw materials, stir for 3 minutes, make the raw materials mix evenly, and discharge;

[0041] 4) Put the mixed raw materials into a twin-screw extruder to extrude and granulate. The screw speed is 400r / min, and the processing temperature is 200°C. Extrude and granulate, which is the final antistatic high-efficiency halogen-free Flame retardant thermoplastic elastomer.

Embodiment 2

[0043] A preparation method of the antistatic type high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer comprises the following steps:

[0044] 1) Various raw materials are prepared according to the weight percentage composition recorded in Table 1, wherein the antistatic agent is a 1:1 mixture of ethoxylated C12-14 tertiary alkylamine and ethoxylated lauramide;

[0045] 2) After mixing the styrene-based elastomer with the filler oil and stirring evenly, let it stand for 8 hours;

[0046] 3) Add other raw materials, stir for 3 minutes, make the raw materials mix evenly, and discharge;

[0047] 4) Put the mixed raw materials into a twin-screw extruder to extrude and granulate. The screw speed is 400r / min, and the processing temperature is 200°C. Extrude and granulate, which is the final antistatic high-efficiency halogen-free Flame retardant thermoplastic elastomer.

Embodiment 3

[0049] A preparation method of the antistatic type high-efficiency low-smoke halogen-free flame-retardant thermoplastic elastomer comprises the following steps:

[0050] 1) Prepare various raw materials according to the weight percentage composition recorded in Table 1, wherein the antistatic agent is a 1:1 mixture of sodium diethyldithiocarbamate and ethoxylauramide;

[0051] 2) After mixing the styrene-based elastomer with the filler oil and stirring evenly, let it stand for 8 hours;

[0052] 3) Add other raw materials, stir for 3 minutes, make the raw materials mix evenly, and discharge;

[0053] 4) Put the mixed raw materials into a twin-screw extruder to extrude and granulate. The screw speed is 400r / min, and the processing temperature is 200°C. Extrude and granulate, which is the final antistatic high-efficiency halogen-free Flame retardant thermoplastic elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com