Polyvinyl alcohol nonwoven fabric and preparation method thereof

A technology of polyvinyl alcohol and non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, textile materials processing and other directions, can solve the problems of instability, intensified decomposition, low processing efficiency, etc., to achieve a softer and more comfortable feel, break The effect of elongation improvement and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

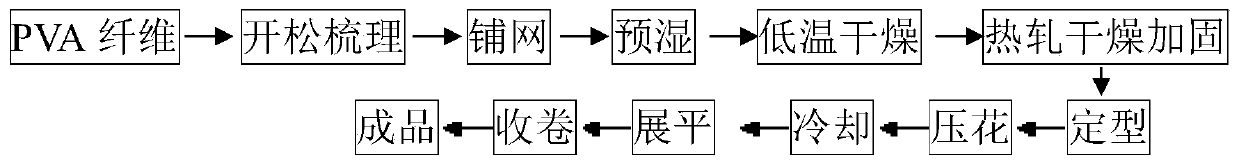

[0040] A preparation method of polyvinyl alcohol nonwoven fabric, comprising the steps of:

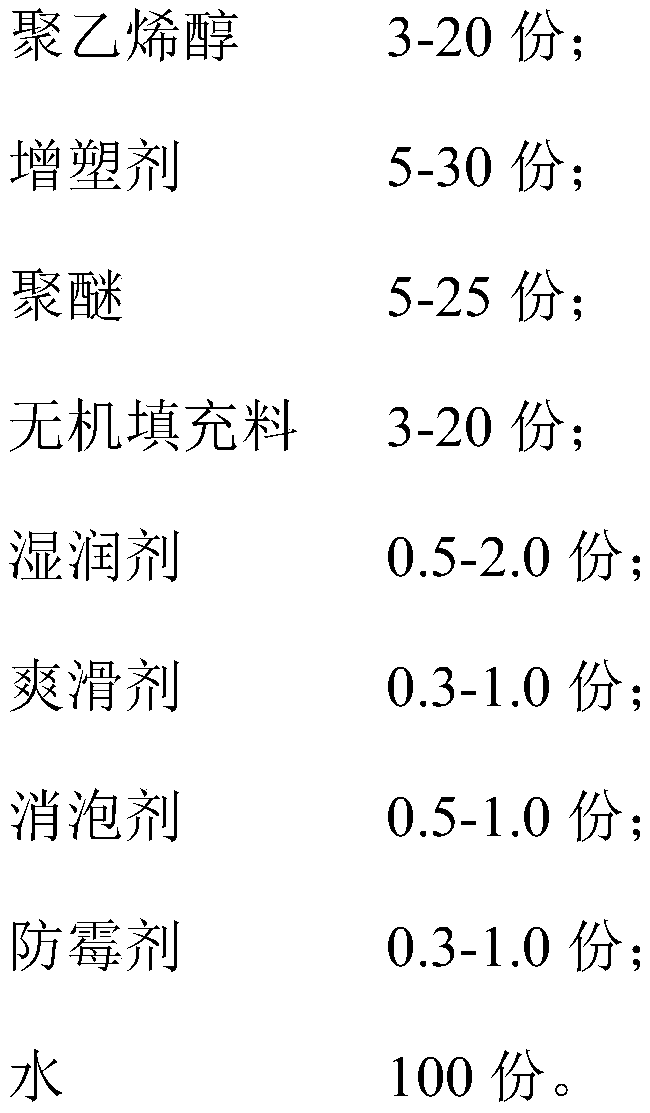

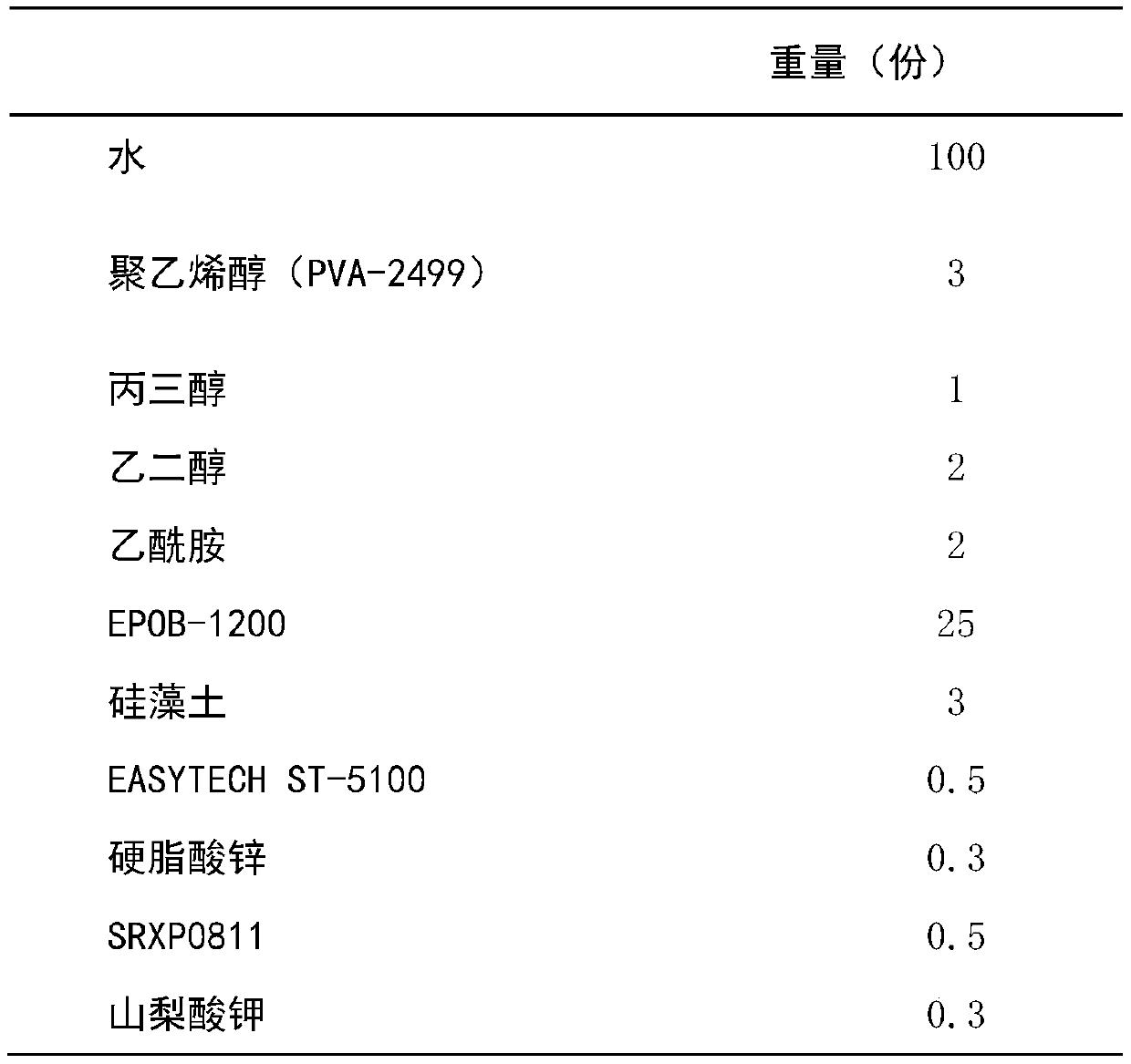

[0041] (1) Preparation of a modifying solution for polyvinyl alcohol nonwoven fabrics, the modified solution for polyvinyl alcohol nonwoven fabrics includes the following components (as shown in Table 1) in parts by weight.

[0042] Table 1

[0043]

[0044] After the above-mentioned components are measured separately, they are respectively added into the dissolution container with a stirring and heating device, and the stirring is started at a stirring rate of 60 rpm, and the heating is started, and the temperature is raised to a temperature range of 95°C. Keep it under high temperature for 2 hours to ensure that the polyvinyl alcohol is completely dissolved, cool down to 90°C and keep it warm for 0.5 hours, then cool to room temperature and discharge for later use to obtain a polyvinyl alcohol non-woven fabric modification solution;

[0045] (2) Use step (1) described polyvinyl a...

Embodiment 2

[0053] A preparation method of polyvinyl alcohol non-woven fabric, specifically comprising the steps of:

[0054] (1) Preparation of a modifying solution for polyvinyl alcohol nonwoven fabrics, the modified solution for polyvinyl alcohol nonwoven fabrics includes the following components in parts by weight (as shown in Table 3).

[0055] table 3

[0056]

[0057]

[0058] After the above-mentioned components are measured separately, they are respectively added into the dissolution container with a stirring and heating device, the stirring is started, the stirring rate is 120 rpm, and the heating is started, and the temperature is raised to a temperature range of 100°C. Keep it under high temperature for 2 hours to ensure that the polyvinyl alcohol is completely dissolved, cool down to 90°C and keep it warm for 1.0 hour, then cool to room temperature and discharge it for later use to obtain a polyvinyl alcohol non-woven fabric modification solution;

[0059] (2) Use step...

Embodiment 3

[0066] A preparation method of polyvinyl alcohol non-woven fabric, specifically comprising the steps of:

[0067] (1) Preparation of a modifying solution for polyvinyl alcohol nonwoven fabrics, the modified solution for polyvinyl alcohol nonwoven fabrics includes the following components in parts by weight (as shown in Table 5).

[0068] table 5

[0069]

[0070]

[0071] After the above-mentioned components are measured separately, they are respectively added into a dissolution container with a stirring and heating device, and the stirring is started at a stirring rate of 100 rpm, and heating is started to raise the temperature to a temperature range of 96°C. Keep it under high temperature for 2 hours to ensure that the polyvinyl alcohol is completely dissolved, cool down to 90°C and keep it warm for 0.6 hours, then cool to room temperature and discharge for later use to obtain a polyvinyl alcohol non-woven fabric modification solution.

[0072] (2) Use step (1) descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com