Device for vacuum packaging, particularly of food products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

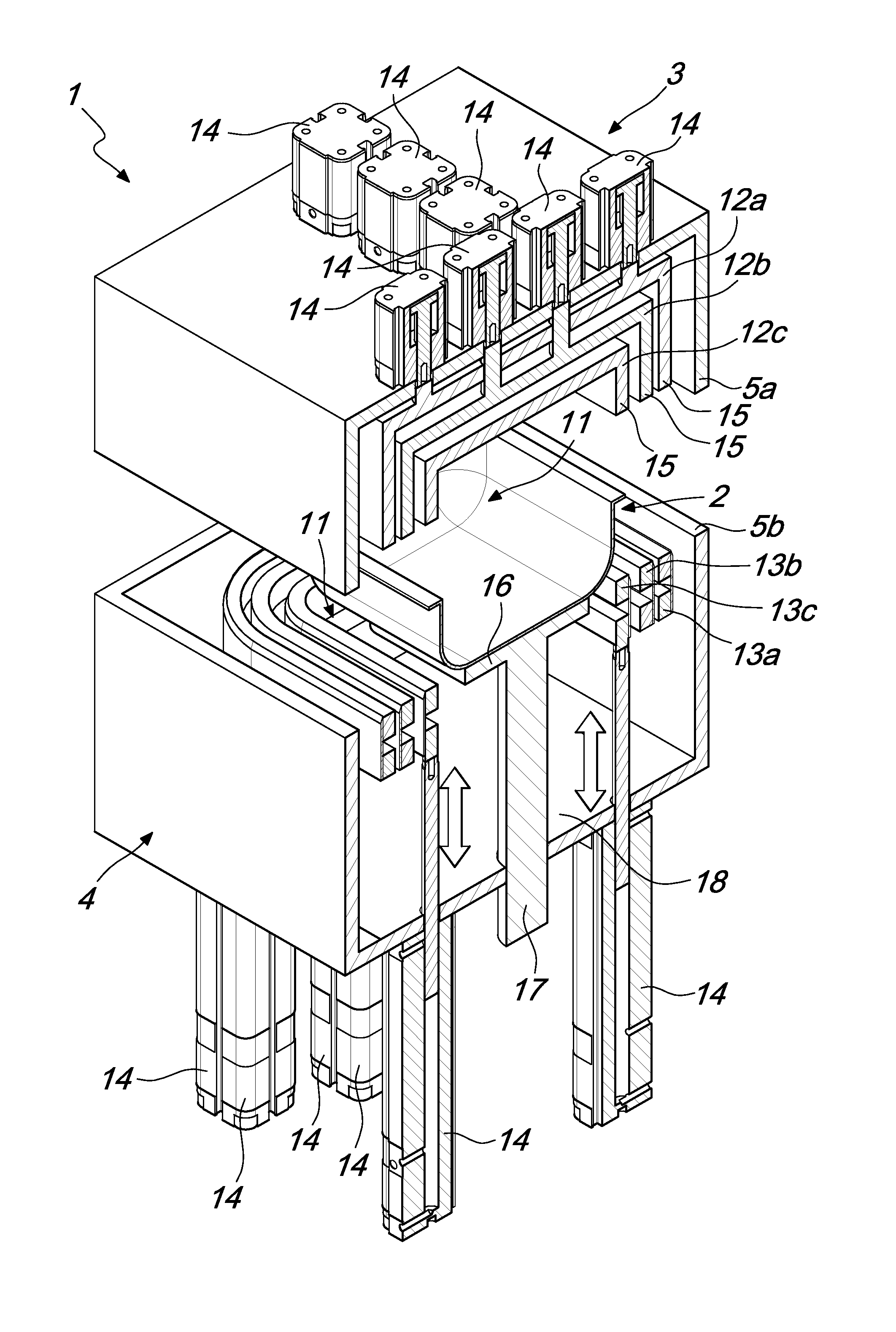

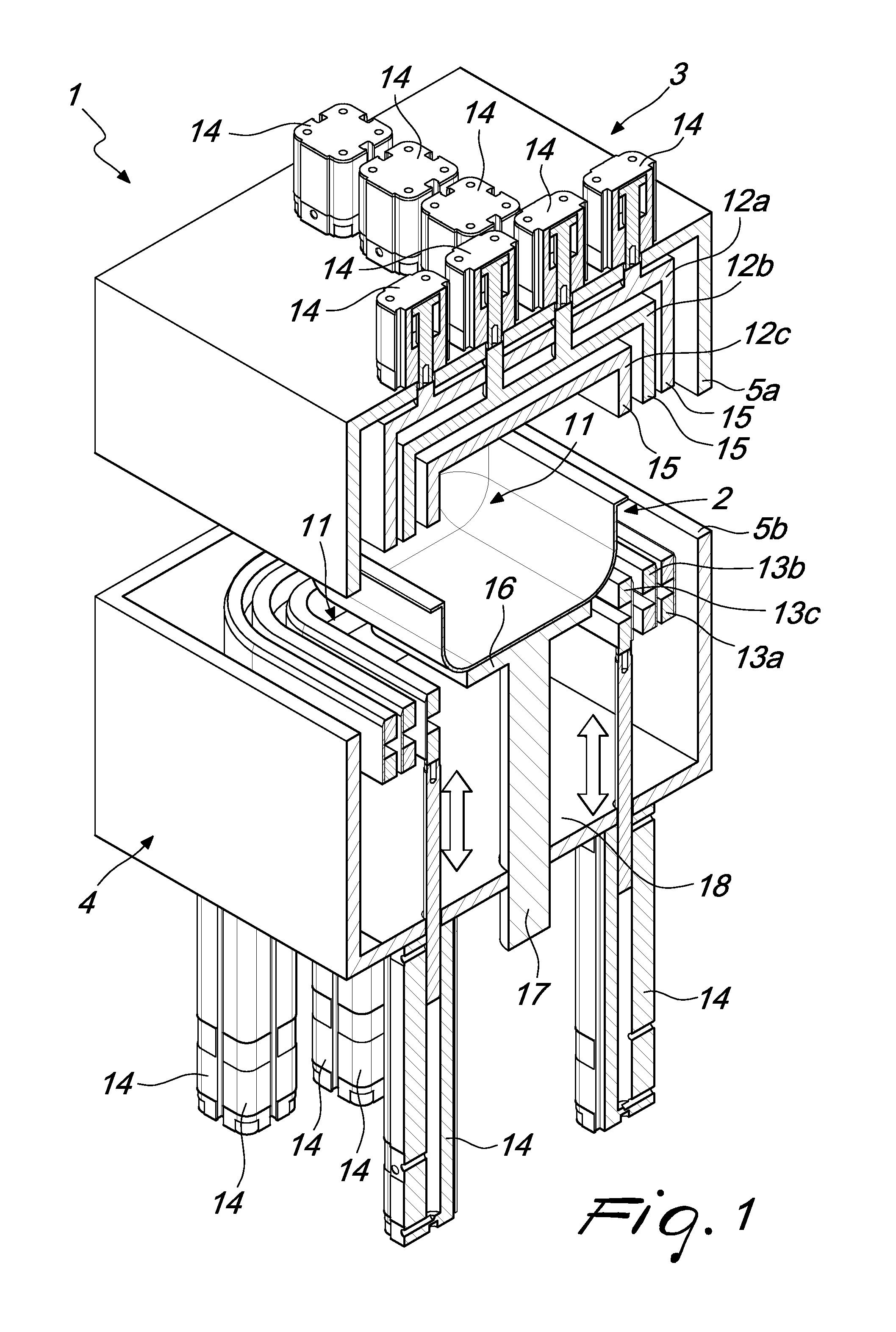

first embodiment

[0081]Therefore, differently from the first embodiment, the heat-sealing and / or cutting and / or die-cutting occurs exclusively by moving the lower chamber toward the upper chamber, without actuating for lowering the individual heat-sealing and / or cutting and / or die-cutting means of the upper chamber.

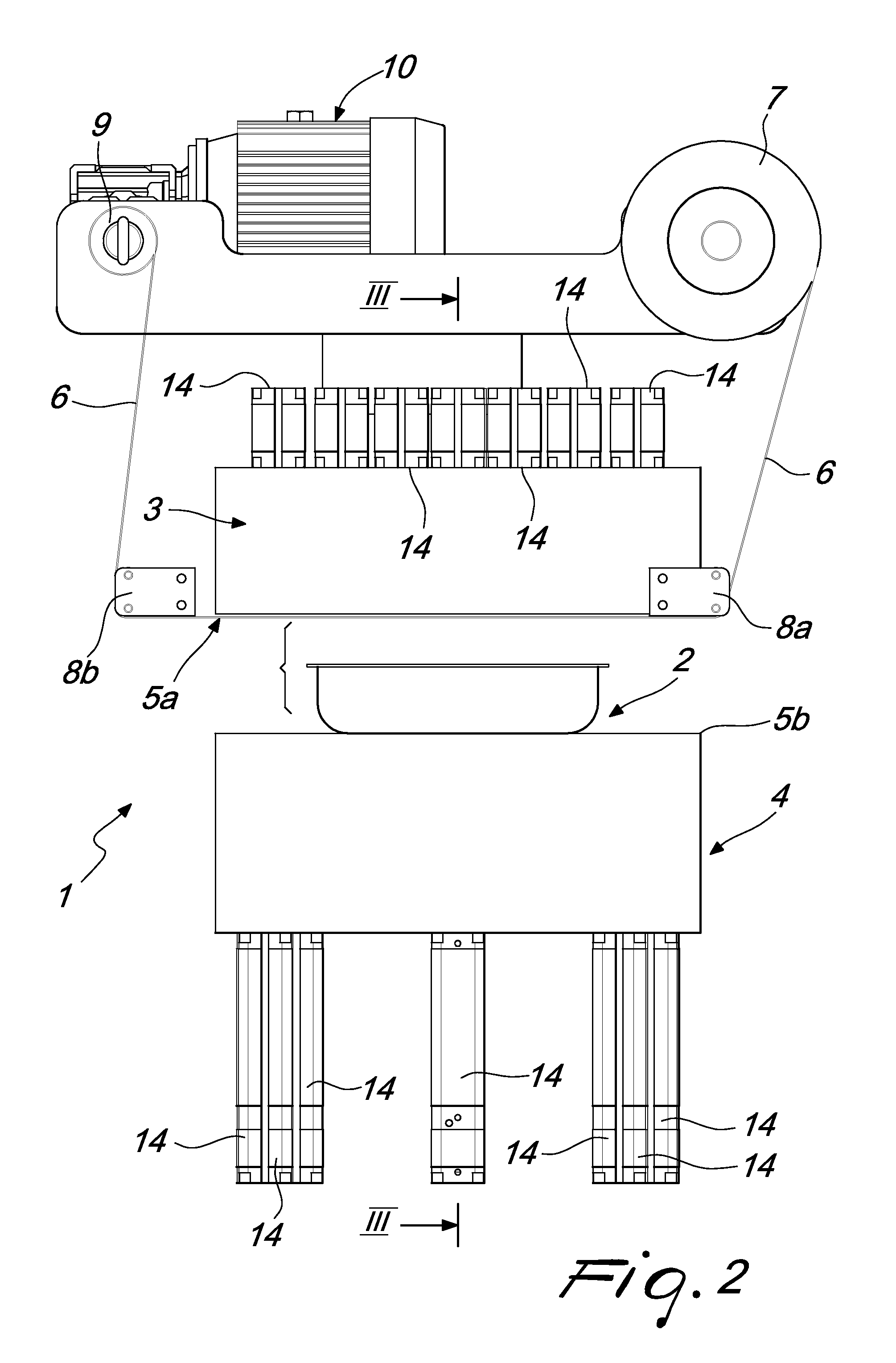

second embodiment

[0082]Essentially, in this second embodiment there are no presser means at the upper chamber.

[0083]The film used can be both of the single-folded type and of the flat sheet type.

[0084]The materials used, as well as the dimensions that constitute the individual components of the invention, may of course be more pertinent according to specific requirements.

[0085]The various means for performing certain different functions need not certainly coexist only in the illustrated embodiment, but can be present per se in many embodiments, including ones that are not illustrated.

[0086]The characteristics indicated as advantageous, convenient or the like may also be omitted or be replaced with equivalents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com