PE film and preparation method thereof

A technology of film and quality parts, applied in the field of packaging materials, can solve problems such as poor shelf effect, poor film movement, and poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application also provides a preparation method of PE film, comprising the following steps:

[0040] co-extruding the corona layer resin, the middle layer resin and the inner layer resin to obtain a melted film, the melted film comprising the corona layer, the middle layer and the inner layer arranged in sequence;

[0041] The molten film is inflated, cooled and shaped, and then the corona layer is subjected to corona treatment to obtain a PE film;

[0042] The corona layer includes 60 parts by mass to 80 parts by mass of metallocene linear low density polyethylene resin and 20 parts by mass to 40 parts by mass of medium density polyethylene resin;

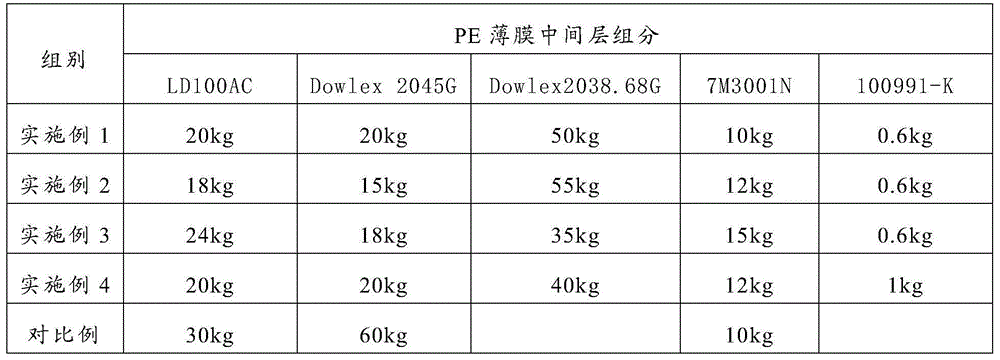

[0043] The intermediate layer comprises 15 to 25 parts by mass of low density polyethylene resin, 15 to 25 parts by mass of linear low density polyethylene resin and 35 to 60 parts by mass of medium density polyethylene resin;

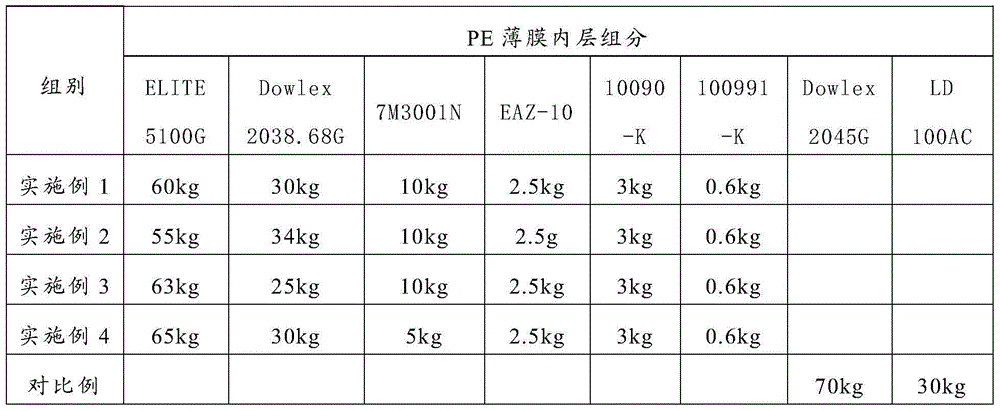

[0044] The inner layer includes 55 parts by mass to 75 parts by mass of metallocene linear l...

Embodiment 1

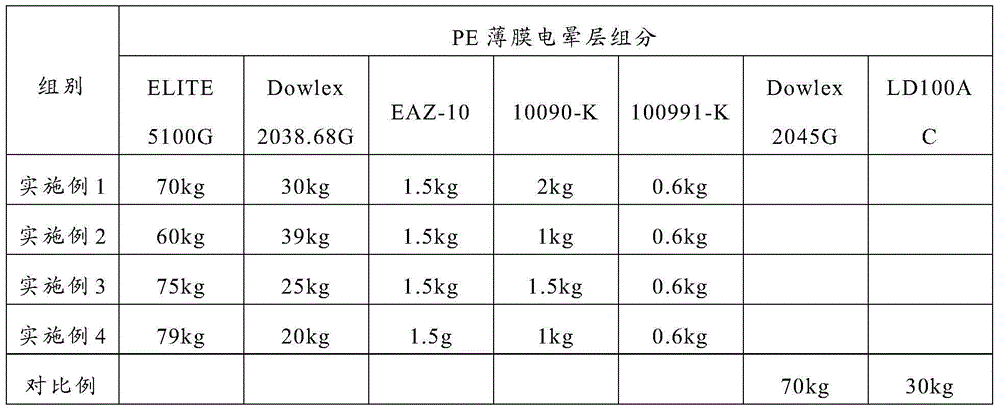

[0058] Add the outer layer resin raw material, the middle layer resin raw material and the inner layer resin raw material respectively into the three hoppers of the co-extrusion machine, and the formulas of each resin raw material are listed in Table 1.

[0059] After the raw materials in the three barrels are co-extruded, they are blown, cooled, and shaped by the wind ring. The temperature of the three barrels of the extruder is set to be 170°C for the first stage, 180°C for the second stage, and 190°C for the third stage. °C, die head temperature: 195 °C; set the air inlet temperature inside and outside the air ring to 20 °C, the rotating traction cooling temperature to 35 °C, the air volume of the air cushion roller to 50%, and the inflation ratio to 2.

[0060] Corona treatment is performed on the outer layer of the film after inflation, cooling and shaping, and the corona treatment power is set to 3KW. After corona treatment, a PE film for hygiene product packaging is obta...

Embodiment 2

[0062] The preparation procedure of the PE film of this example is the same as that of Example 1. The raw material formula is listed in Table 1, and the process parameters are listed in Table 2. The total thickness of the film prepared in this example is 50 μm, wherein the outer layer, middle layer and inner layer of the film The layer thickness ratio is 1:2:1. The performance of the PE film prepared in this example was tested, and the test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com