Polyethylene (PE) film and preparation method thereof

A polyethylene film and polyethylene technology, which is applied in the field of washing product packaging, can solve the problems of easy bag breakage, low tensile strength, easy liquid leakage, etc., to achieve good environmental protection, high tensile strength, and ensure leakage prevention. The effect of resistance and drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

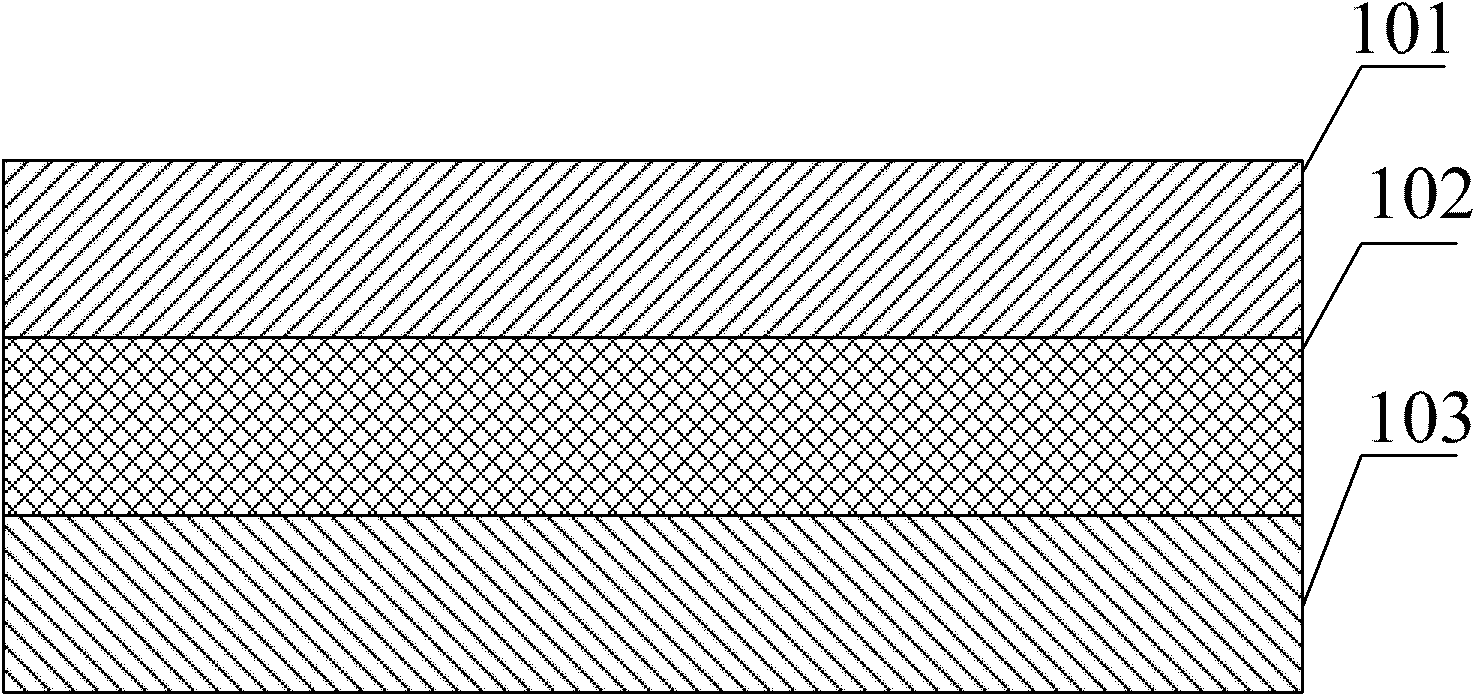

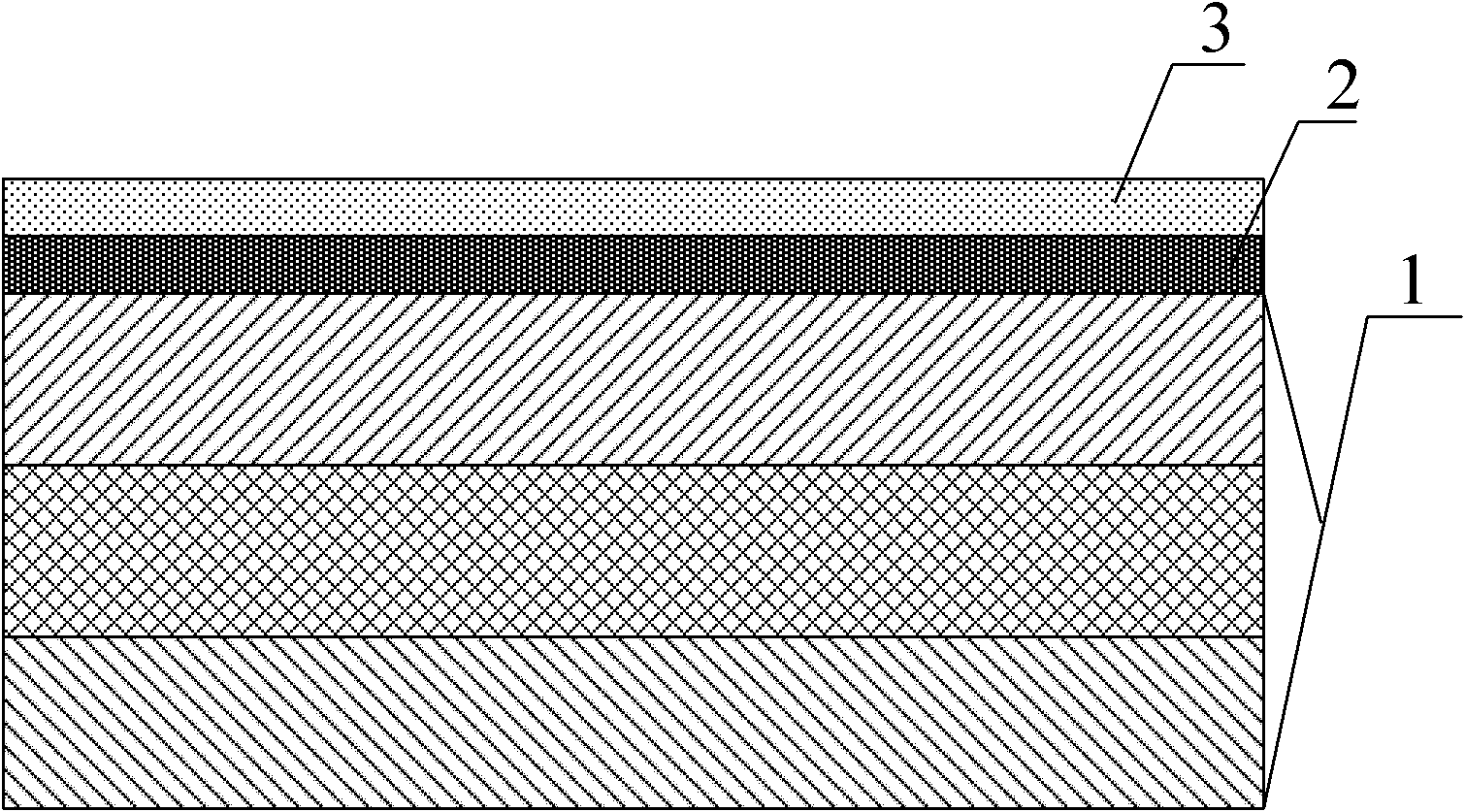

[0035] Correspondingly, the present invention provides a method for preparing the aforementioned PE film, comprising: co-extruding and blow molding the raw materials of the aforementioned composite layer, intermediate layer and heat-sealing layer at 120°C to 160°C.

[0036] In the present invention, the composite layer resin, the intermediate layer resin and the heat-sealing layer resin are preferably respectively added to the three barrels of the extruder, and each barrel is heated in three stages. ℃, the heating temperature of the second stage is 130℃~140℃, the heating temperature of the third stage is 140℃~150℃, the temperature of the die head is set at 140℃~160℃, and the extrusion melt pressure is controlled to be less than 45Mpa. The polymer particles in the above three barrels are melted by the extruder to form a tube blank. After the tube blank is stretched, compressed air is blown out from the center of the die head of the extruder to blow the tube blank into a bubble-l...

Embodiment 1

[0049] Embodiment 1 prepares PE film

[0050] Add composite layer resin raw materials, intermediate layer resin raw materials and heat-sealing layer resin raw materials to the three barrels of the co-extrusion machine respectively. The formula of each resin raw material is as follows:

[0051] Composite layer: 32wt% LDPE, 32wt% LLDPE and 36wt% modified m-LLDPE;

[0052] Middle layer: 30wt% LDPE, 60wt% LLDPE and 10wt% white masterbatch;

[0053] Heat seal layer: 31wt% LDPE and 69wt% LLDPE.

[0054] The polymer particles in the above three barrels are melted by the extruder to form a tube blank. After the tube blank is stretched, compressed air is blown out from the center of the die head of the extruder to blow the tube blank into a bubble-like film. The shaped film was cooled and shaped by the air ring cooling air to obtain a PE film. The process parameters of the extruder equipment are shown in Table 1.

Embodiment 2

[0055] Embodiment 2 prepares PE film

[0056] The difference between this embodiment and Example 1 lies in the resin raw materials of the composite layer, the middle layer and the heat-sealing layer. The resin raw material formulations of each layer of this embodiment are as follows:

[0057] Composite layer: 28wt% LDPE, 29wt% LLDPE and 43wt% modified m-LLDPE;

[0058] Middle layer: 26wt% LDPE, 58wt% LLDPE and 16wt% white masterbatch;

[0059] Heat seal layer: 35wt% LDPE and 65wt% LLDPE.

[0060] Setting extruder equipment process parameter is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com