Novel protective shoe upper and production technique thereof

A technology for manufacturing crafts and protective shoes, which is applied to shoe uppers, footwear, boot legs, etc. It can solve the problems of not having the function of rebounding external impact protection, and cannot effectively protect the feet, so as to save cumbersome procedures and high market promotion. Foreground, the effect of reducing collision damage

Inactive Publication Date: 2013-09-04

泉州泰亚鞋业有限公司

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides a new type of protective vamp and the manufacturing process of the vamp, the main purpose of which is to overcome the defects that the vamp of existing shoes does not have the function of rebounding external impact protection and cannot effectively protect the instep

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

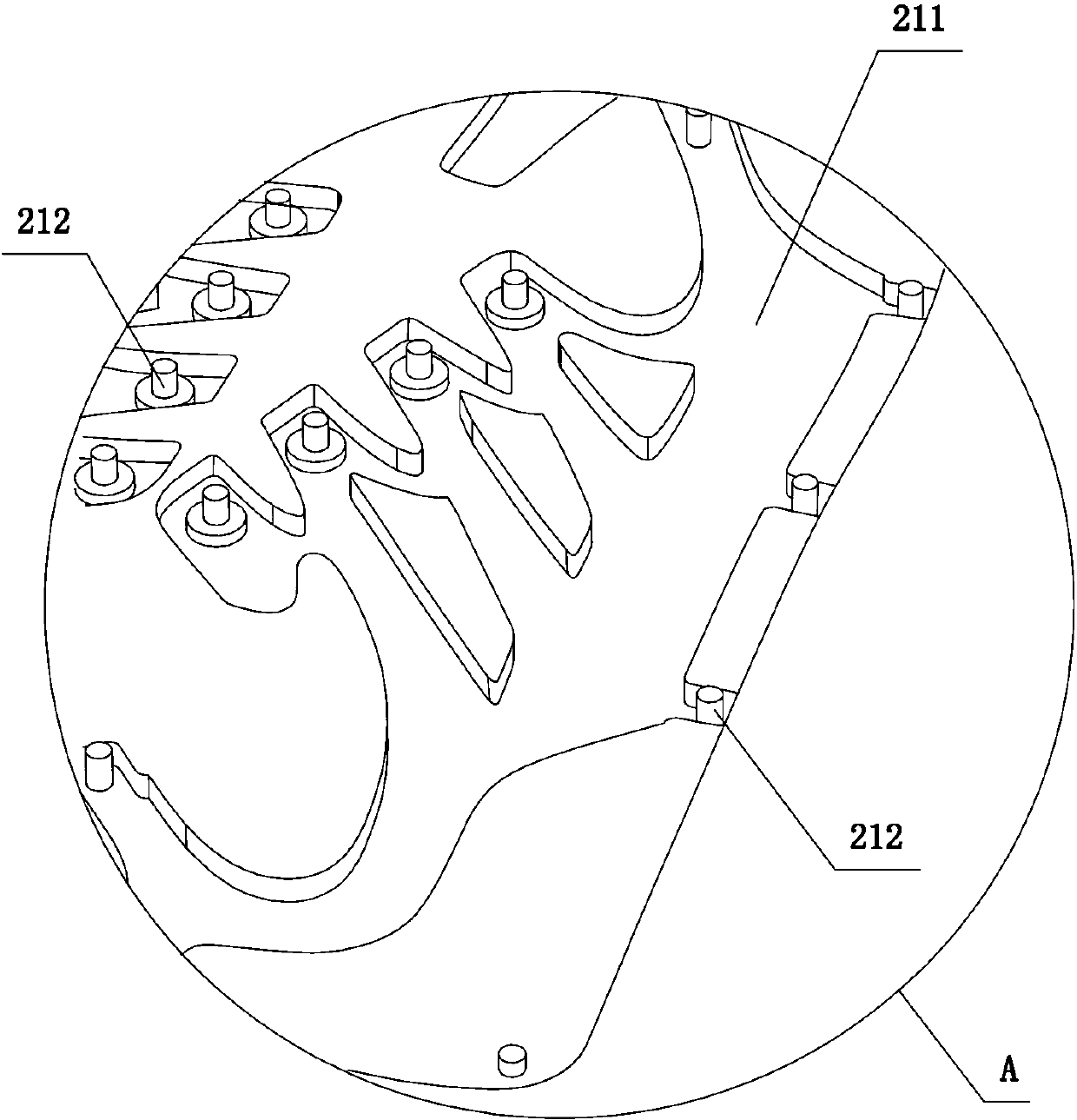

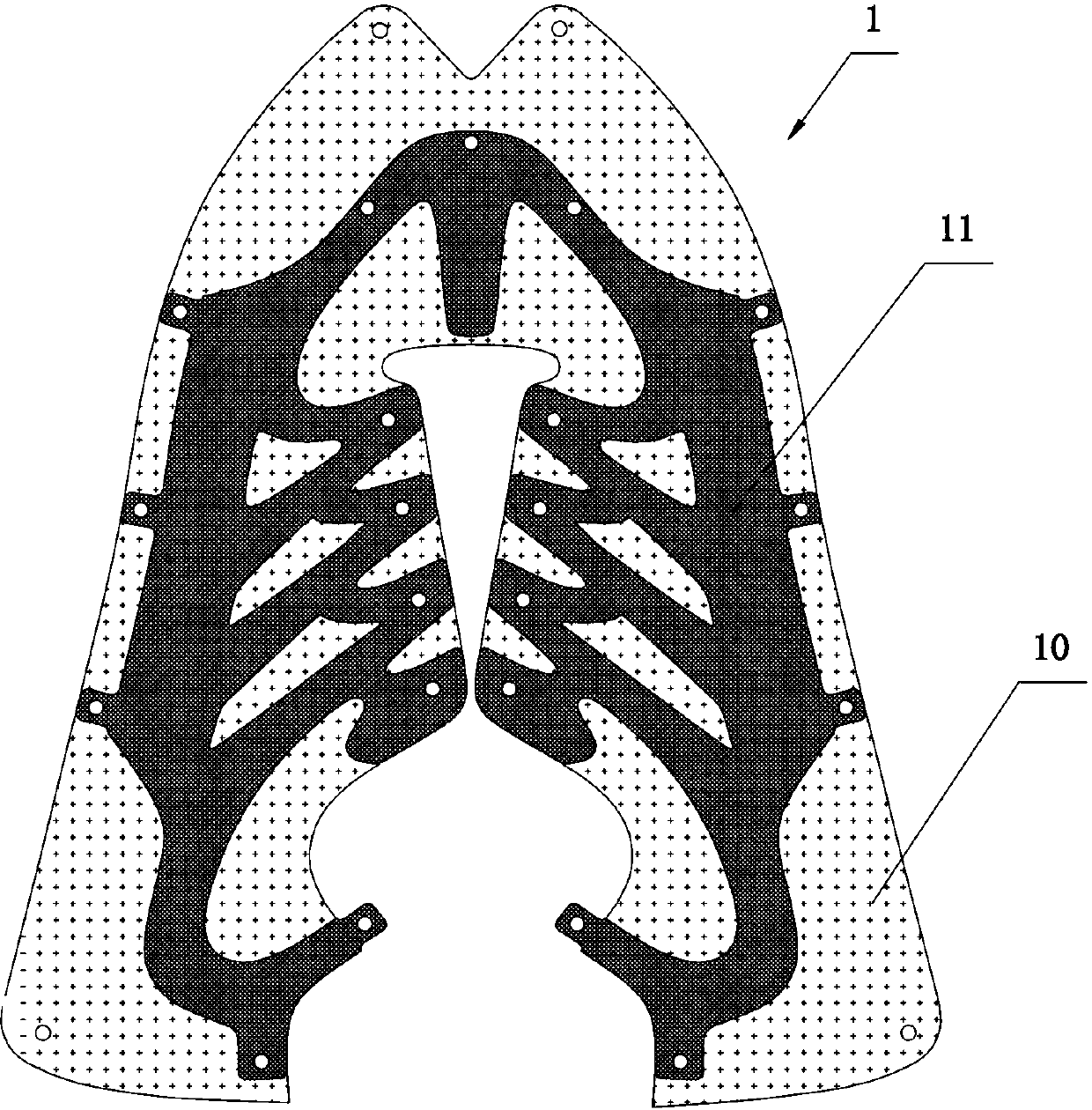

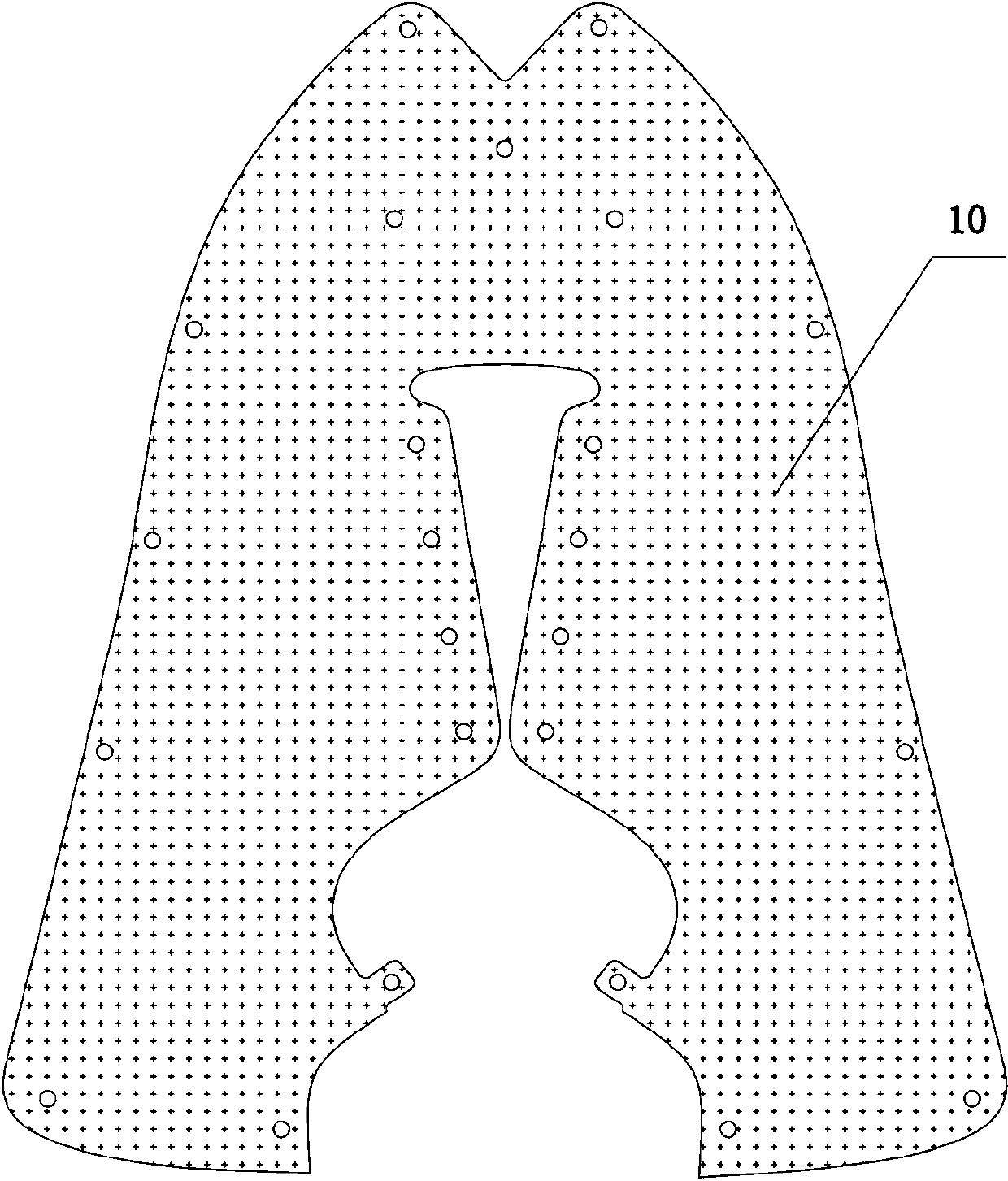

A process for manufacturing a novel protective shoe upper comprises the following steps: adding a processing adjuvant, a bridging agent, a foaming agent, an active agent, and pigment in EVA raw materials, forming EVA foaming body after fully mixing, finally cutting into an EVA foaming body layer; covering a bonding layer on the EVA foaming body layer, then blanking into a preset pattern modeling; placing the blanked EVA foaming body layer in a bottom die; coating a cloth-skin treatment agent on the bonding surface of the bottom layer of a shoe upper and placing on the bottom die of the die, closing a die cover, firstly pressurizing and heating and then pressurizing and cooling and fetching an end product. The protective shoe upper manufactured by the invention can effectively improve protective strength of the shoe upper, reduce collision harm from external impact force to an instep, and play a protective role for a user in outdoor activities.

Description

technical field The invention relates to a shoe upper and a manufacturing method thereof, in particular to a novel protective shoe upper and a manufacturing process of the shoe upper. Background technique For now, the uppers of traditional shoes are generally made of materials such as nylon, polyester, foam, leather or cotton textiles, and the manufacturing process is generally made by stitching single or multiple materials or hot pressing with high-frequency molds. . However, when the user is doing outdoor activities, the upper of the shoe will inevitably encounter hard objects such as mountain gravel, dead branches of shrubs, etc. The upper of traditional shoes does not have the function of rebounding external impact protection, which will cause damage to the shoe body, or even damage the It reaches the instep, which brings troubles to the user in outdoor activities. Contents of the invention The present invention provides a new type of protective vamp and the manufac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A43B23/02

Inventor 林松柏张红生龙再坛何海

Owner 泉州泰亚鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com