Novel temperature measuring cable

An optical cable and a new type of technology, applied in the field of optical fiber temperature measurement, can solve the problems of weak strength, slow response, poor accuracy, etc., and achieve the effects of improving strength, long service life, and improving temperature transfer speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

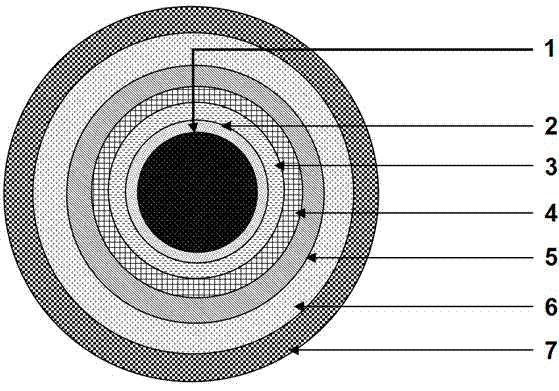

[0048] see figure 1 , a new type of temperature measuring optical cable, from the inside to the outside is the core layer 1, the cladding layer 2, the coating layer 3, the buffer layer 4, the metal armor cladding layer 5, the strengthening layer 6 and the outer sheath layer 7; the core layer 1 is a solid structure, the outer wall of the core layer 1 is wrapped with a cladding layer 2, the outer wall of the cladding layer 2 is wrapped with a coating layer 3, the outer wall of the coating layer 3 is wrapped with a buffer layer 4, and the outer wall of the buffer layer 4 is wrapped with Metal armor cladding 5, the outer wall of the metal armor cladding 5 is wrapped with a reinforcement layer 6, and the outer wall of the reinforcement layer 6 is wrapped with an outer sheath 7;

[0049] The manufacturing material of the core layer 1 is homogeneously doped quartz glass or pure quartz glass, the refractive index of the core layer 1 is 1.43-1.49, and the diameter of the core layer 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com