Nanocellulose/sulfonated polyaryletherketone composite film as well as preparation method and application of nanocellulose/sulfonated polyaryletherketone composite film

A technology of sulfonated polyaryletherketone and nanocellulose, which is applied in the field of nanocellulose/sulfonated polyaryletherketone composite proton conduction membranes for fuel cells and its preparation, can solve the problem of mechanical property stability decline and proton conductivity low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

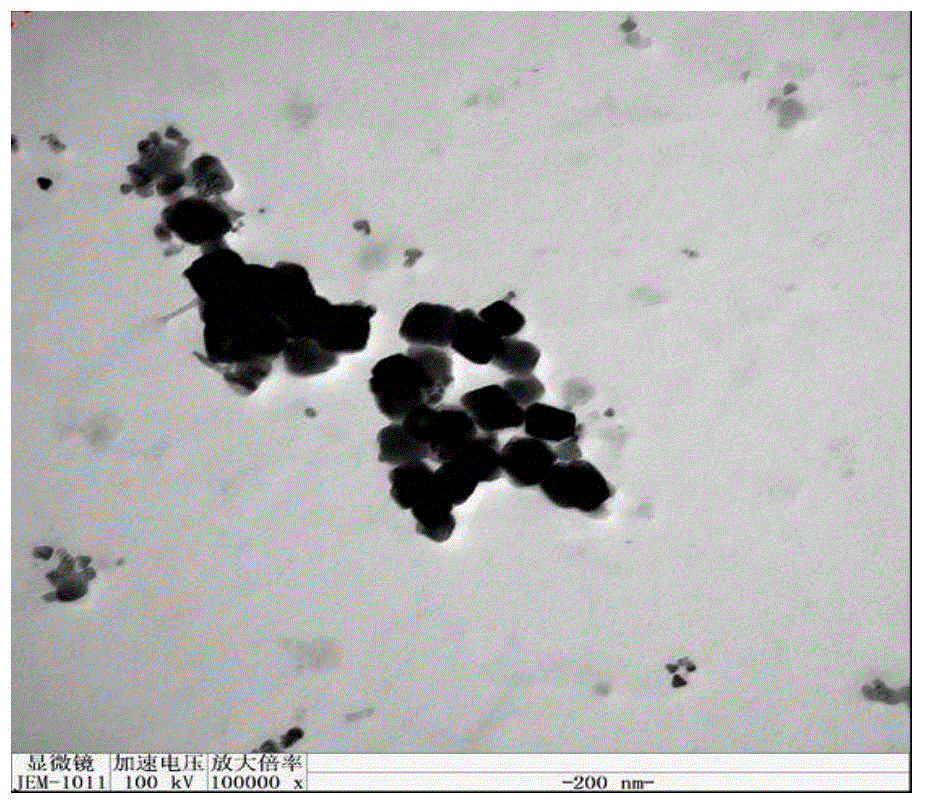

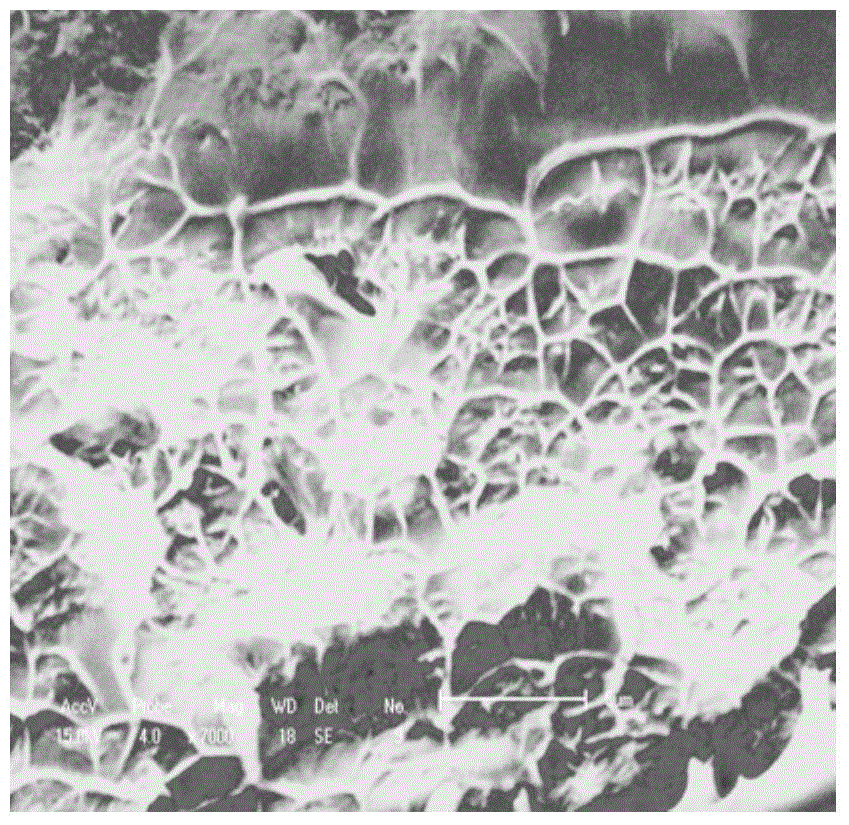

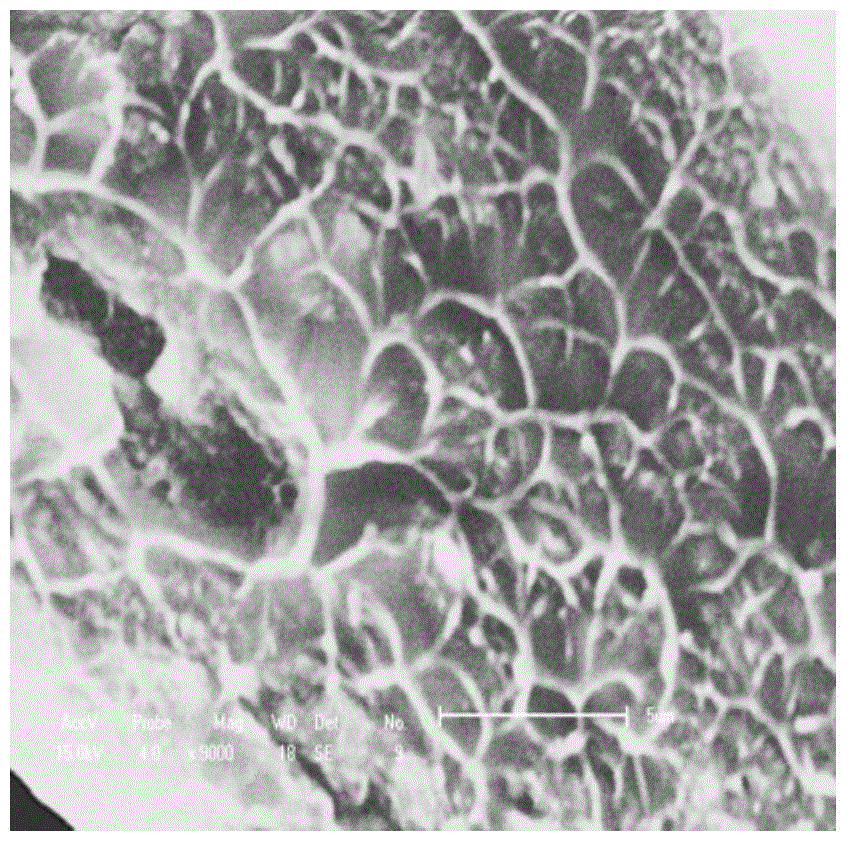

Image

Examples

Embodiment 1

[0034] Select a 100ml three-necked flask, and install a stirring device, a nitrogen through hole, a water carrier, and a spherical condenser, and feed continuous and stable nitrogen gas into the three-necked flask, and put 2.8795g (0.015mol) of benzene pendant diphenol into the three-necked flask. , 4.8345g (0.015mol) of difluorodiketone, 2.2770g of anhydrous potassium carbonate, 24ml of sulfolane, and 12ml of toluene, reflux for three hours, and take out as much toluene as possible. Then the reaction system was heated to 180°C. After 11 hours, the solution became viscous, and 8 ml of sulfolane was added thereto. After 1 hour, the polymerization reaction was complete. Then pour the viscous liquid into 800ml of deionized water under the stirring state of a glass rod to obtain a white filamentous solid. Salts and solvents, and then dried in a vacuum oven at 120°C for 24 hours. Weigh 6.8 g of the product obtained in the previous step and add 100 ml of concentrated sulfuric acid...

Embodiment 2

[0049] The sulfonated polymer was prepared according to the steps in Example 1. Weigh 0.48 g of sulfonated phenyl side group polyether ether ketone ketone and dissolve it in 6 ml of dimethyl sulfoxide. Weigh 0.02 g of nanocellulose with sulfonic acid groups and hydroxyl groups into 6 ml of dimethyl sulfoxide, and ultrasonicate at room temperature for 24 hours.

[0050] Blend the sulfonated benzene side group polyether ether ketone ketone solution with the nanocellulose solution of sulfonic acid group and hydroxyl group, filter the blended solution with a 300-mesh nylon mesh, pour the filtrate on a glass plate, and heat it at 60°C Dry for 48 hours, then raise the temperature to 80°C and dry for 48 hours. Continue to dry the formed soft film in a vacuum oven at 100°C for 24 hours, and then remove the film after cooling. The mass fraction of nanocellulose is 4%.

[0051] The mass ratio of nanocellulose with sulfonic acid group and hydroxyl group to sulfonated phenyl side group...

Embodiment 3

[0055] In Example 1, the feeding ratio of sulfonated polyaryletherketone and nanocellulose was set to 0.47:0.03, and the feeding ratios of other components were kept unchanged, and Example 1 was repeated. A nanocellulose / sulfonated phenyl side group polyetheretherketoneketone composite membrane with sulfonic acid groups and hydroxyl groups having a mass fraction of nanocellulose of 6% is obtained.

[0056] The sulfonic acid group and hydroxyl nanocellulose / sulfonated benzene side group PEEK composite membrane prepared by this method has a proton conductivity of 0.17 S / cm and a water absorption rate of 44.06% at 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com