Double-layer clay liner for preventing seepage and resisting compression at bottom of refuse landfill

A landfill and clay technology, applied in layered products, natural mineral layered products, infrastructure engineering, etc., can solve the problems of blocking heavy metal ions and volatile organic compounds, polluting groundwater, etc., to protect groundwater, reduce Settling and compressibility reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

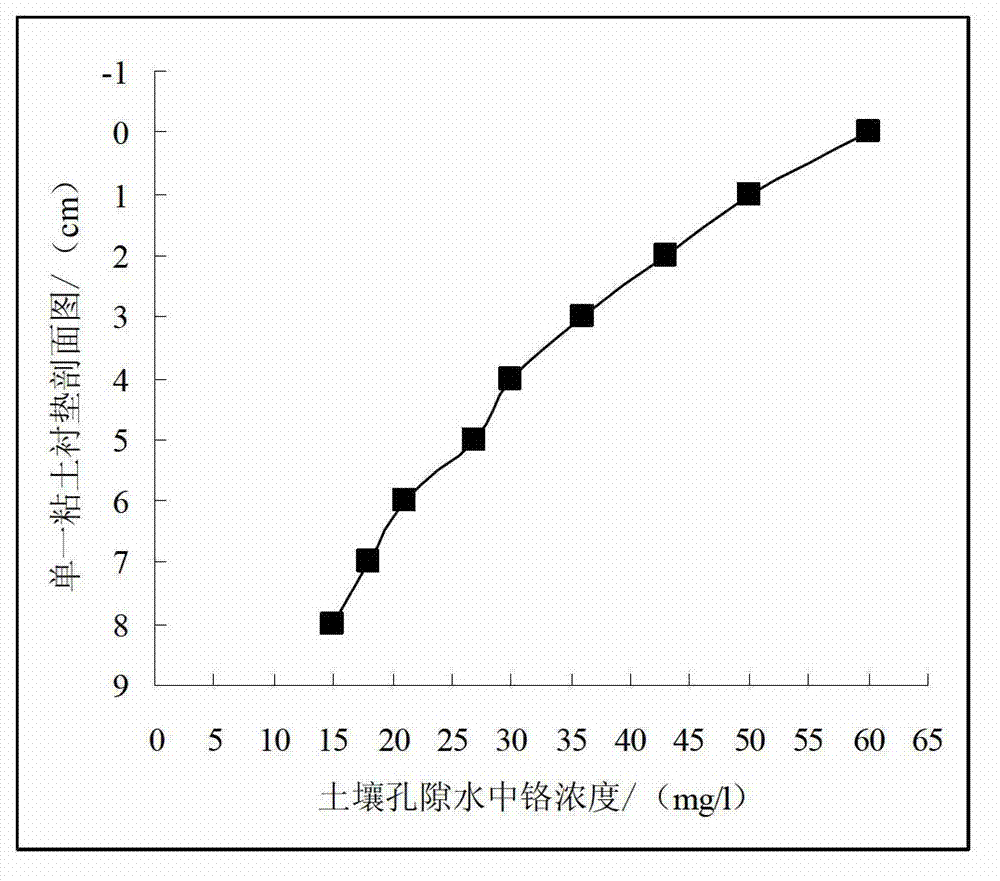

[0015] The clay used in this experiment was taken from a landfill, and was dried, crushed, and screened to obtain particles with a particle size of less than 1 mm. The optimal water content of the clay was determined to be 18.8%. Take part of the clay and add water accounting for 22% of the dry ingredients, mix and stir evenly, and prepare a single-layer clay liner with a thickness of 8cm through ordinary compaction.

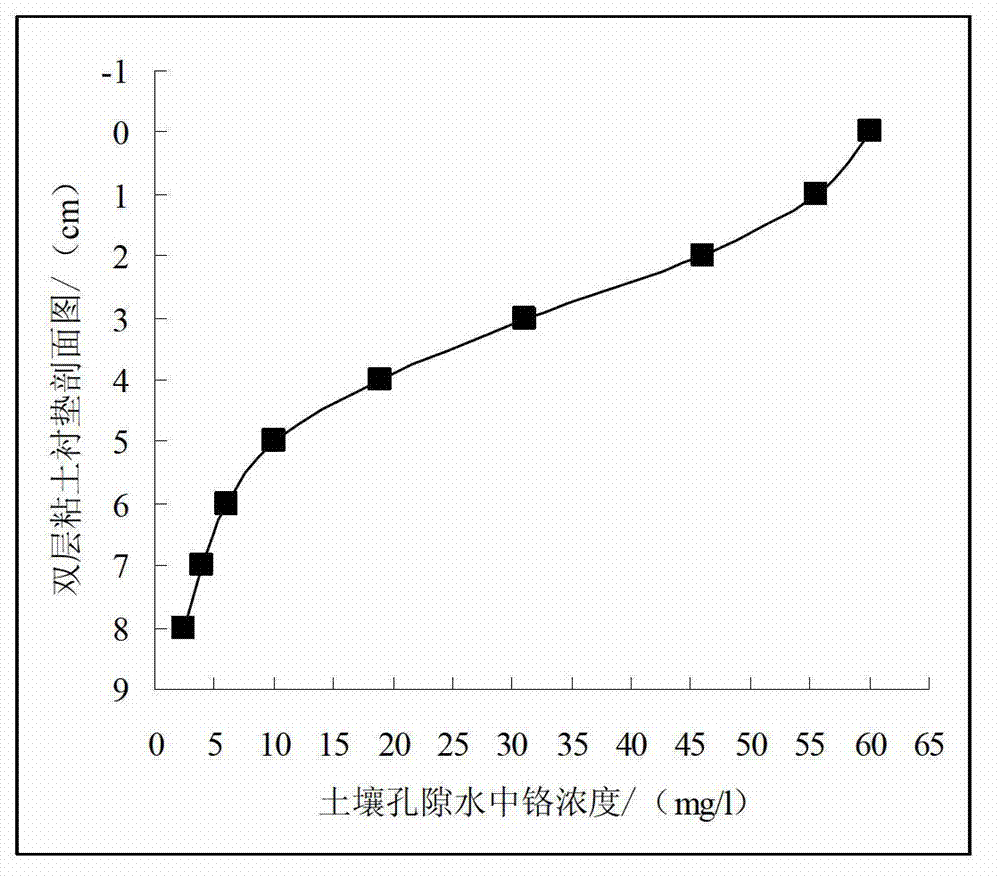

[0016] The preparation of the upper layer of clay liner is to mix 90% by mass of clay and 10% of lime evenly. The optimal water content of the measuring point is 25.2% by using the compaction test method. Add water accounting for 28.2% of the mass of dry ingredients and mix well. , formed by ordinary compaction, the thickness of the upper clay liner is 4cm. The preparation of the lower layer of clay liner is to mix 94% clay and 6% granular activated carbon powder evenly by mass percentage, and use the compaction test method to determine the optimal water content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com