ECC-concrete interface treating method

A treatment method and concrete technology, which is applied to artificial islands, underwater structures, protective devices, etc., can solve problems such as water seepage, achieve the effects of increasing seepage paths, enhancing cohesive force, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

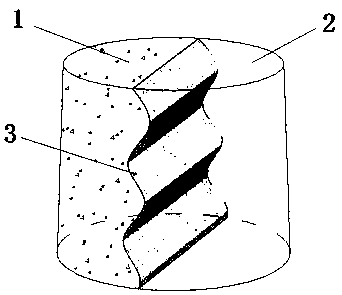

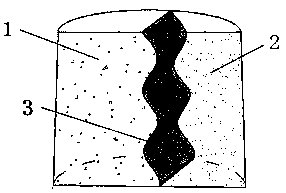

[0017] Embodiment 1: as Figure 1-2 As shown, the preferred strength grade of the concrete layer 1 in this embodiment is C30, and the mixing ratio is calculated by mass ratio, cement: Class II fly ash: fine aggregate: coarse aggregate: water: water reducing agent = 1:0.20: 3.0:4.2:0.66:0006. The preferred mixing ratio of the ECC layer 2 is in terms of mass ratio, cement: Class I fly ash: quartz sand: water: superplasticizer: fiber = 1: 1.20: 0.72: 0.57: 0.003: 0.0379. Both the concrete layer 1 and the ECC layer 2 adopt semicircular platform test blocks, the upper and lower bottom surfaces are semicircular, the diameters are 175mm and 185mm respectively, and the height is 150mm. Before pouring, use the corrugated formwork to separate the round platform mold, etc., pour the concrete first, and remove the formwork after 24 hours. Within 24 hours after demoulding, the corrugated interface 3 shall be treated and interface agent shall be applied, and the ECC layer 2 shall be poure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com