Patents

Literature

32results about How to "Increase seepage path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

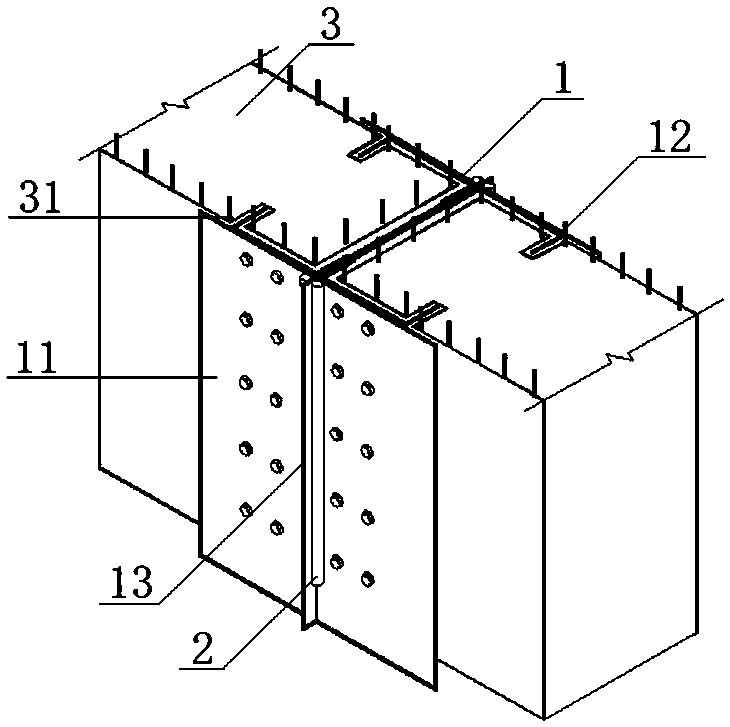

Underground diaphragm wall with anti-seepage joints and construction method of underground diaphragm wall

PendingCN109750660AIncrease stiffnessPlay a fixed roleArtificial islandsProtective foundationSlurry wallRebar

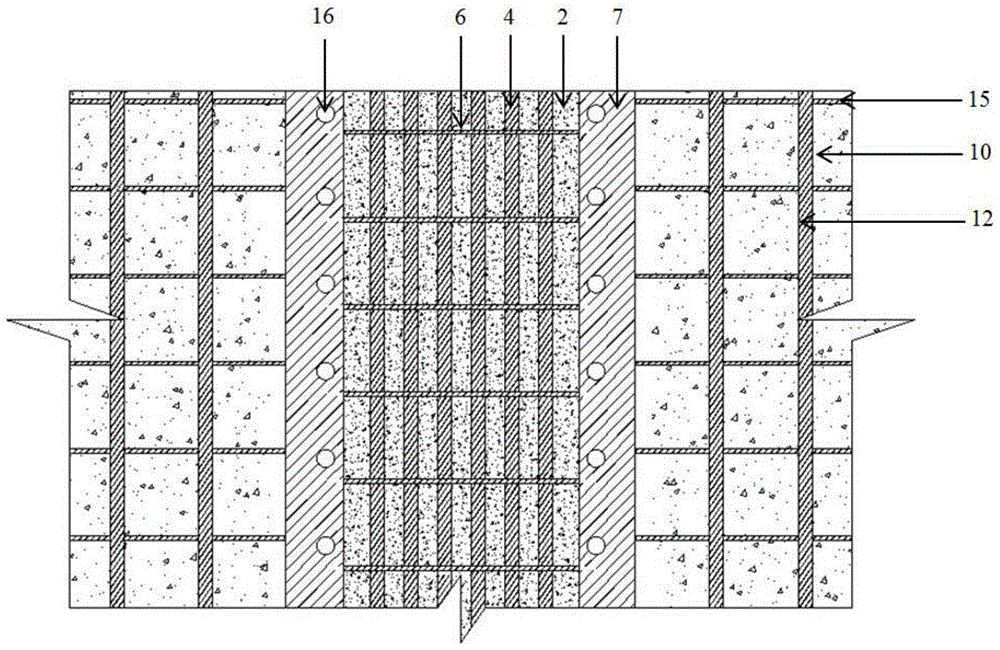

The invention relates to the technical field of engineering construction, in particular to an underground diaphragm wall with anti-seepage joints and a construction method of the underground diaphragmwall. The underground diaphragm wall comprising wall body structure continuously arranged and the anti-seepage joints connected with adjacent wall body structures, and the wall body structures are formed by pouring concrete into reinforcement cages. Each anti-seepage joint comprises I-shaped steel, a water stop steel plate and channel steel, the channel steel is located on opposite sides of two I-shaped steel flanges and corresponds to two sides of an I-shaped steel web, and a bottom groove plate of each channel steel is fixedly connected with the corresponding I-shaped steel flange. Groovesare formed in steel channel legs, corresponding to one side of each steel channel, of each reinforcement cage, and each groove is in clearance fit with the corresponding steel channel leg. The I-shaped steel and the four steel channels are connected through bolts to serve as main stress components of the anti-seepage joints, meanwhile, the steel channel legs on one of sides of the steel channels are in clearance fit with the grooves in the corresponding steel reinforcement cages, the steel reinforcement cages are fixed, and therefore the overall rigidity of the underground diaphragm wall is large, and the anti-seepage effect is good.

Owner:HEFEI UNIV OF TECH +1

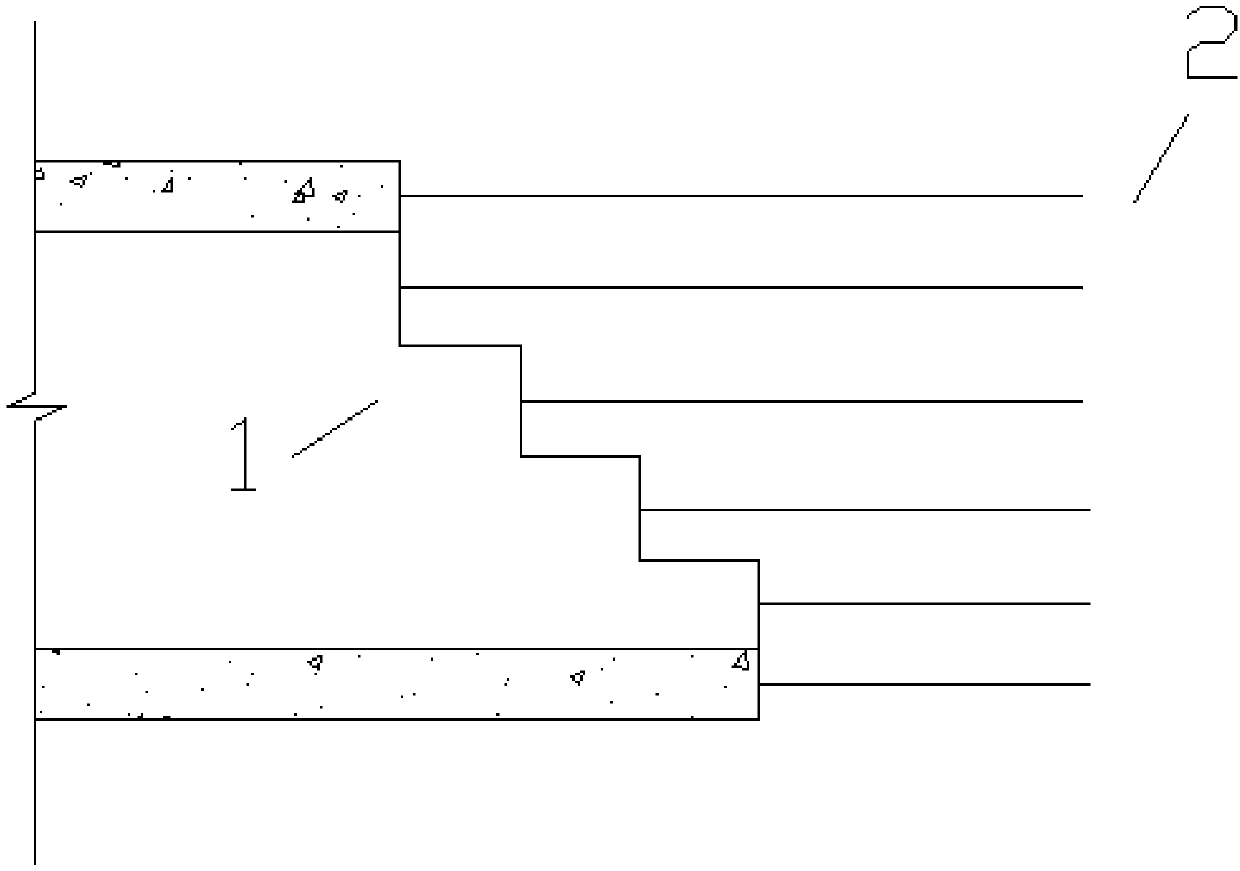

Prefabricated pipe gallery and cast-in-place pipe gallery connection waterproof structure and construction method

ActiveCN107859064AHigh strengthDelay uneven settlementArtificial islandsProtective foundationIsolation effectArchitectural engineering

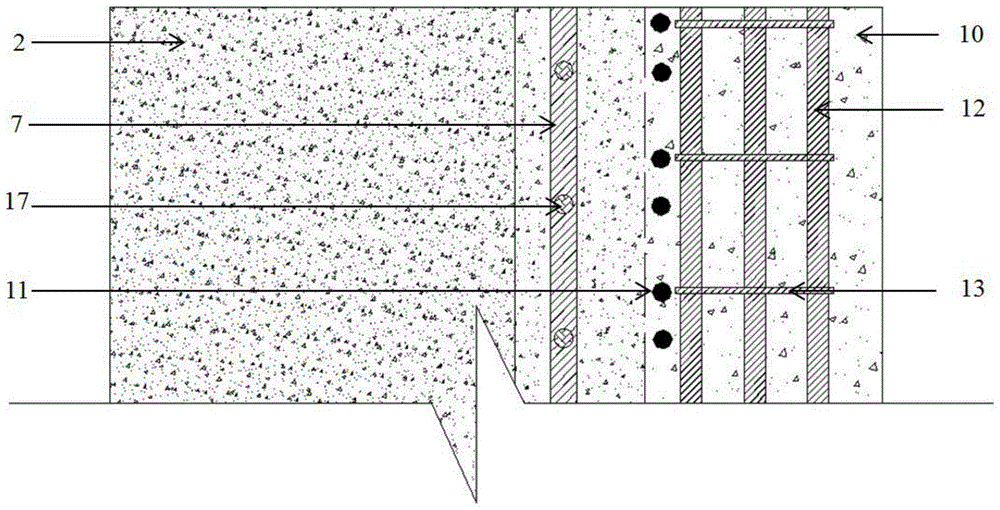

The invention relates to a prefabricated pipe gallery and cast-in-place pipe gallery connection waterproof structure. The prefabricated pipe gallery and cast-in-place pipe gallery connection waterproof structure comprises a step type tongue-and-groove, low-modulus polyurethane sealants, copper plate water stop belts, a water collection box, a slip casting main pipe, slip casting guide pipes and slip casting holes. The upper portion of a prefabricated pipe gallery is provided with a top plate, the lower portion of the prefabricated pipe gallery is provided with a bottom plate, and the middle portion of the prefabricated pipe gallery is provided with a side wall. The side wall of the connection fracture surface of the prefabricated pipe gallery and the cast-in-place pipe gallery is providedwith the step type tongue-and-groove. The surfaces of the pipe galleries are provided with grooves, the slip casting main pipe is embedded into the grooves, the two ends of the slip casting main pipeare provided with the slip casting guide pipes, and pipe body of the slip casting main pipe is provided with the slip casting holes which are distributed at equal intervals. The end openings of the inner side and the outer side of a construction joint are provided with the low-modulus polyurethane sealants, and the construction joint is internally provided with the copper plate water stop belts. The prefabricated pipe gallery and cast-in-place pipe gallery connection waterproof structure and the construction method have the beneficial effects that the multi-waterproof structure is good in water isolation effect; the strength at the joint position is higher, and differential settlement is reduced; construction of the waterproof structure is easy, time and labor are saved, and the cost is low; and when the deformation joint leaks, double guarantees of rescuing and repairing are achieved.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

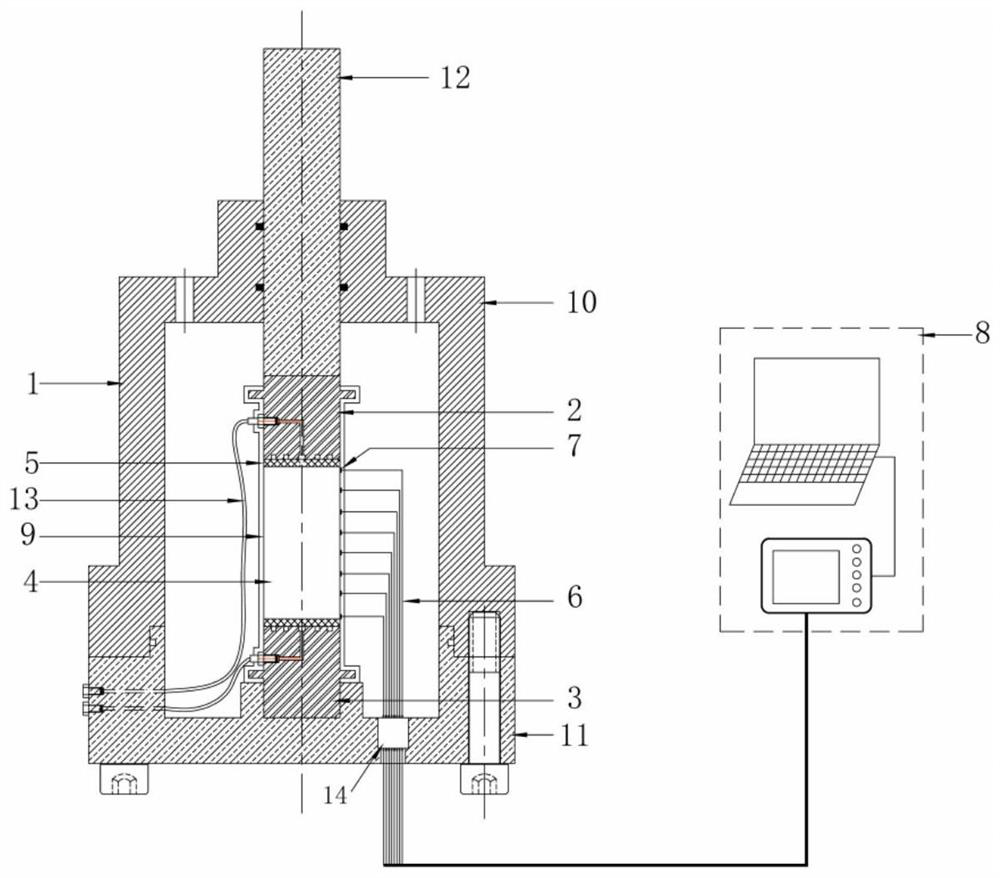

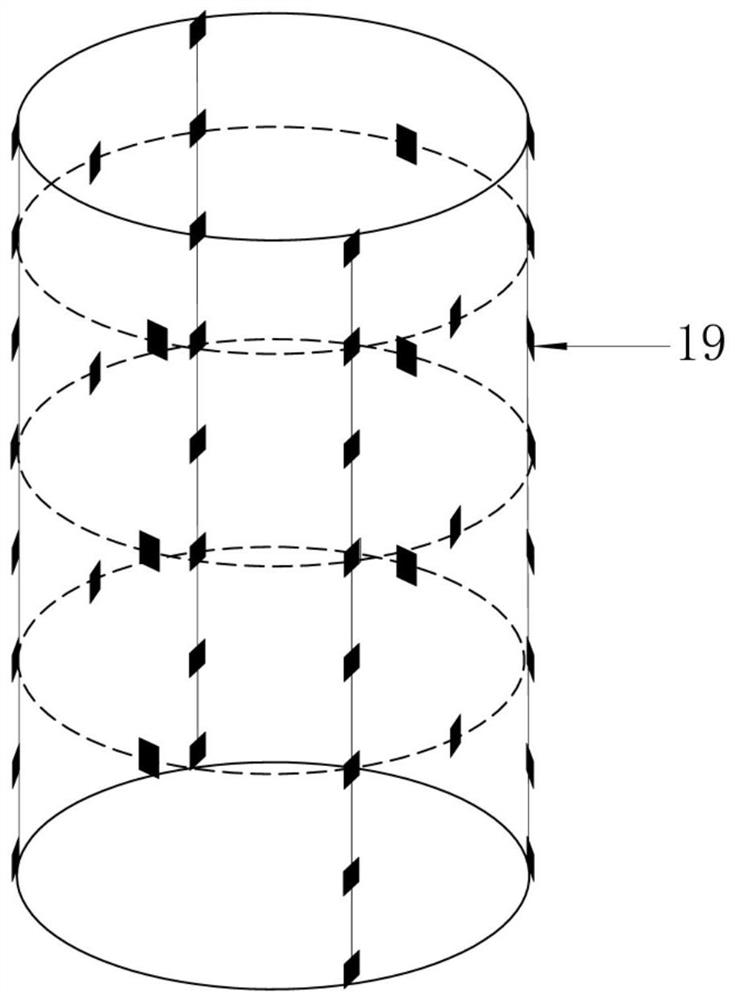

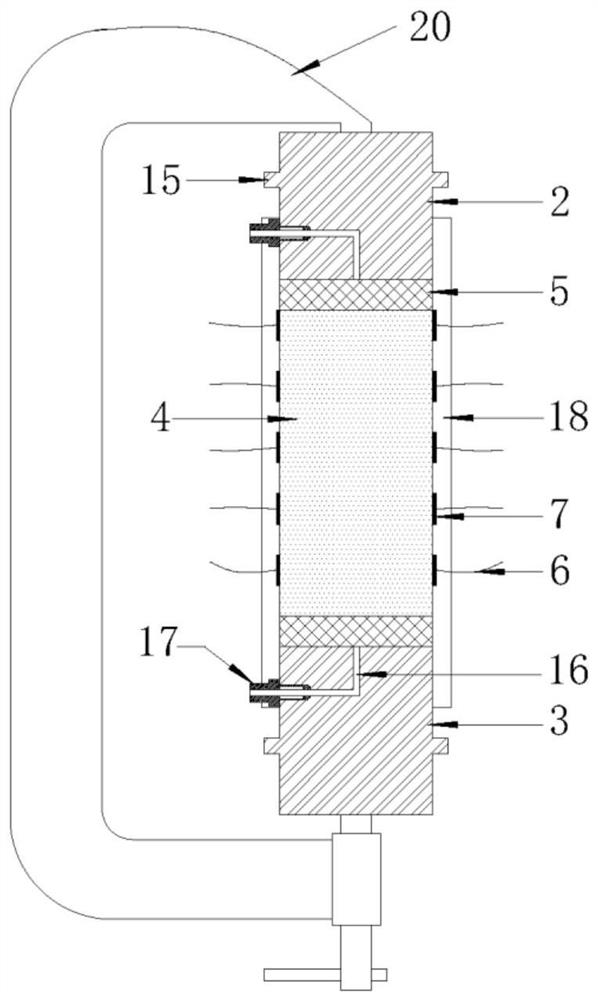

High-voltage triaxial resistivity test system and method considering chemical penetration

ActiveCN112255458AFit tightlyHigh precisionEngine sealsResistance/reactance/impedenceData acquisitionEngineering

The invention discloses a high-voltage triaxial resistivity test system and method considering chemical penetration. The system comprises a pedestal, a pressure-bearing cylinder, a sample assembly, and a data collection and processing system, wherein the sample assembly comprises an upper pressure head, a lower pressure head, a sample, a sealing layer, and detection electrodeS; the upper pressurehead, the sample and the lower pressure head are coaxially arranged in sequence from bottom to top, permeable stones are arranged between the upper pressure head and the sample and between the sampleand the lower pressure head, the lower pressure head of the sample assembly is fixed with the base, and the upper pressure head of the sample assembly is in contact with the piston rod; a plurality ofdetection electrodes are distributed on the side surface of the sample to form an electrode array; flanges are symmetrically arranged on the two sides of the upper pressure head and the two sides ofthe lower pressure head, and the sealing layer wraps and seals the upper pressure head, the lower pressure head, the sample, the flanges and the detection electrodes. The system can effectively seal the detection electrodes distributed in an electrode array on the side surface of the sample and prevent confining pressure liquid from entering the sample, so that three-dimensional resistivity measurement is carried out by using an inversion imaging method in a triaxial test, and the accuracy of a measurement result is ensured.

Owner:CHINA UNIV OF MINING & TECH

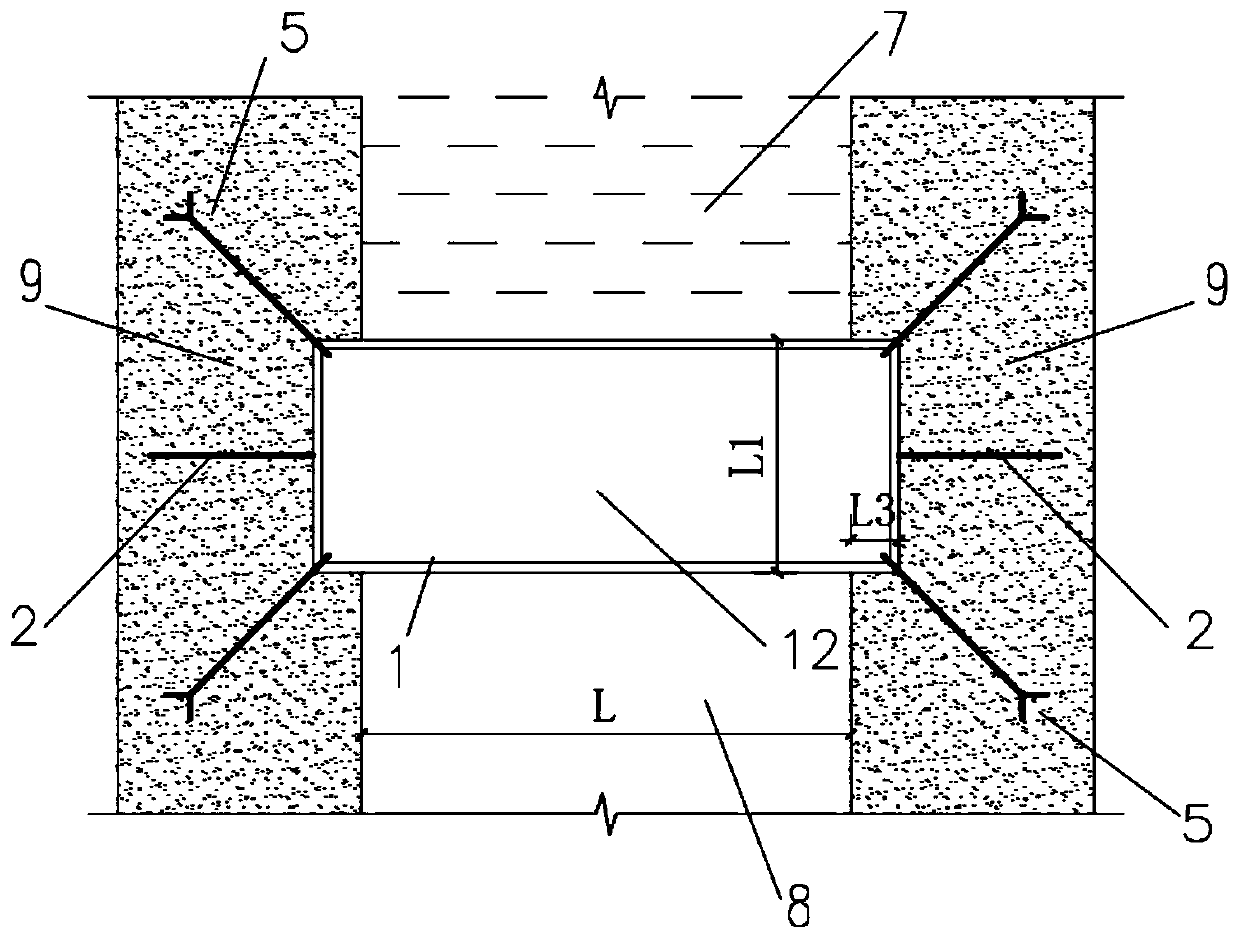

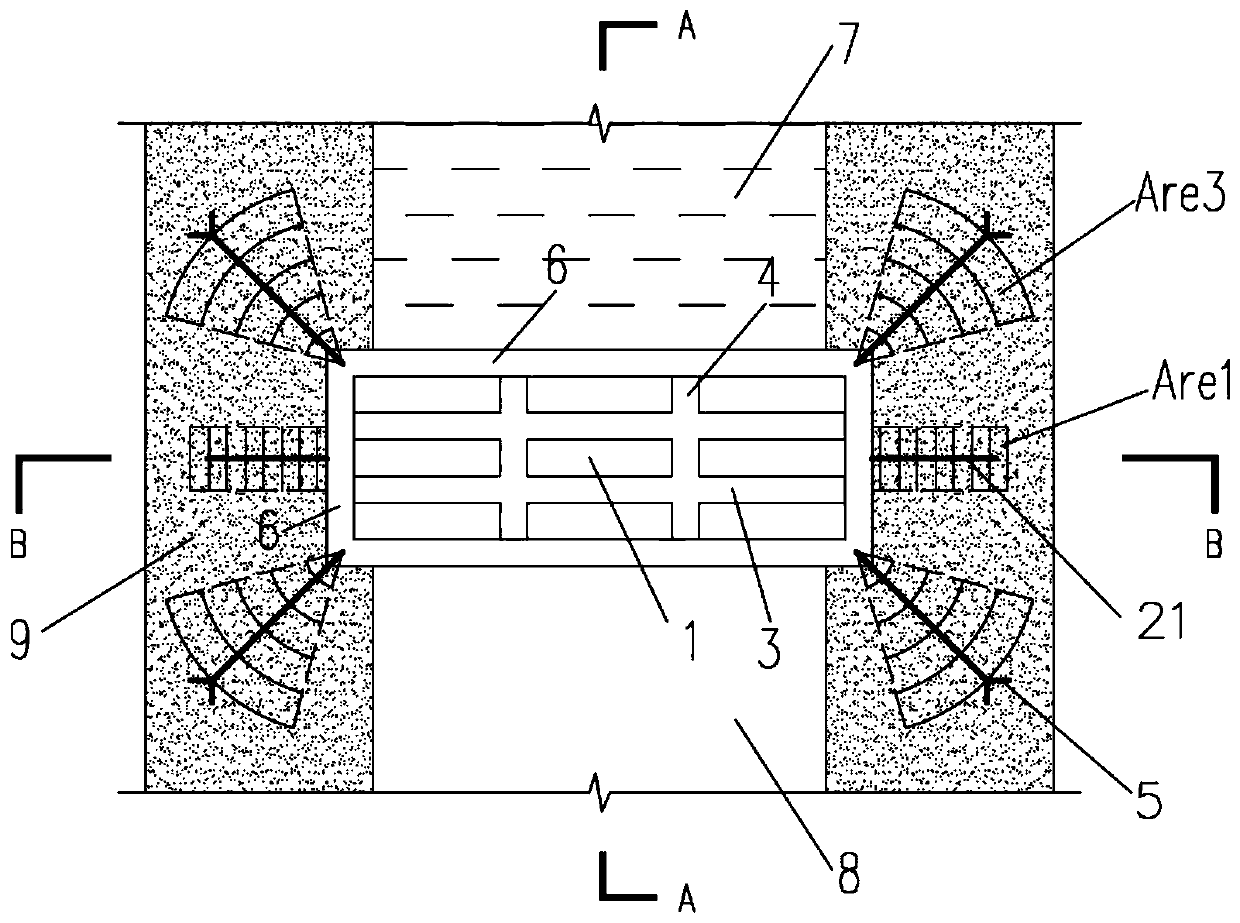

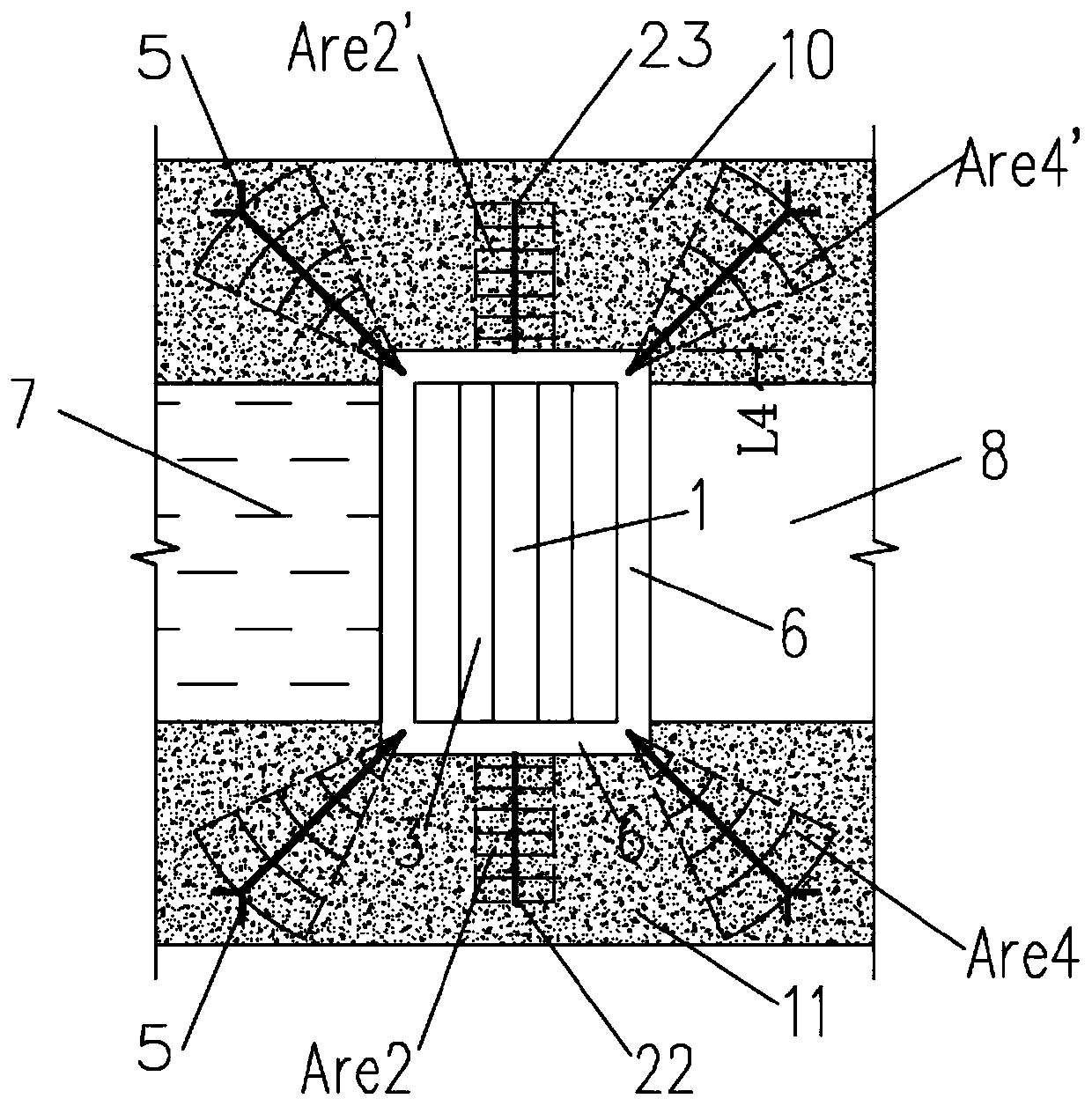

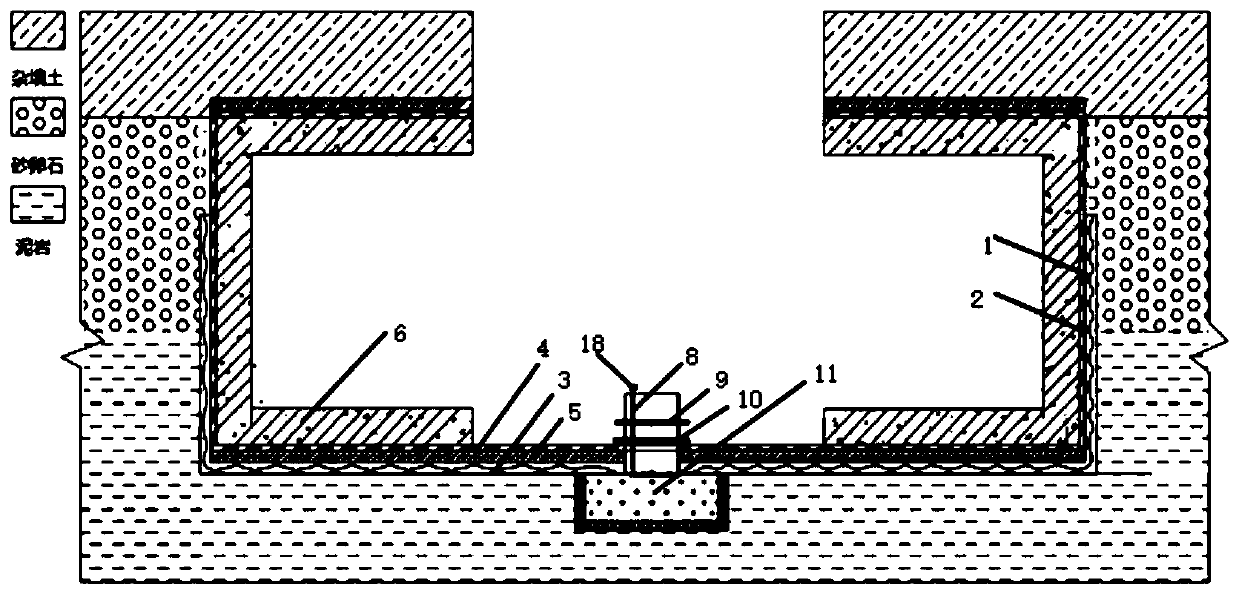

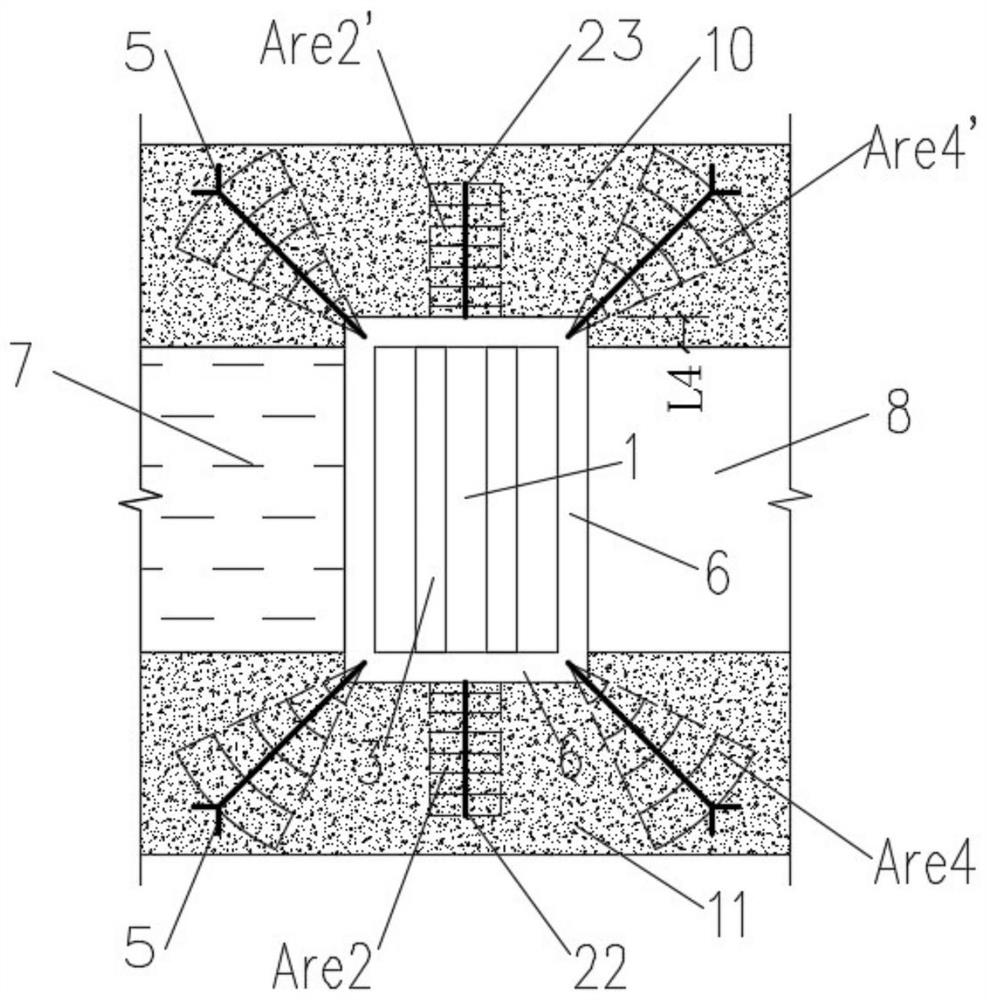

Box type water retaining dam for coal mine underground reservoir

ActiveCN110905600AIncrease the bearing areaImprove integrityBarrages/weirsMining devicesWater sourceStructural engineering

The invention discloses a box type water retaining dam for a coal mine underground reservoir. The box type water retaining dam is located between coal pillar dam bodies on the left side and the rightside of a roadway and used for isolating the underground reservoir and the roadway and blocking a water source in the underground reservoir. The box type water retaining dam comprises a main dam bodyand water retaining wings, wherein the main dam body is of a box type structure, the left side and the right side of the main dam body are embedded in the coal pillar dam bodies on the two sides, thetop of the main dam body is embedded in roadway roof surrounding rock, and the bottom of the main dam body is embedded in roadway bottom plate surrounding rock; and the water retaining wings compriseside wings, the side wings are connected with the left side and the right side of the main dam body and arranged along at least the whole height range of the main dam body, the side wings are embeddedinto the coal pillar dam bodies on the two sides to a certain depth, and thus side wing seepage prevention areas are formed. The box type water retaining dam can reduce crippling and water seepage caused by excessive local stress of the surrounding rock at the same time, adjusts differential settlement, prevents the surrounding rock from being softened due to water entering, and ensures the stability and safety of the dam bodies.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

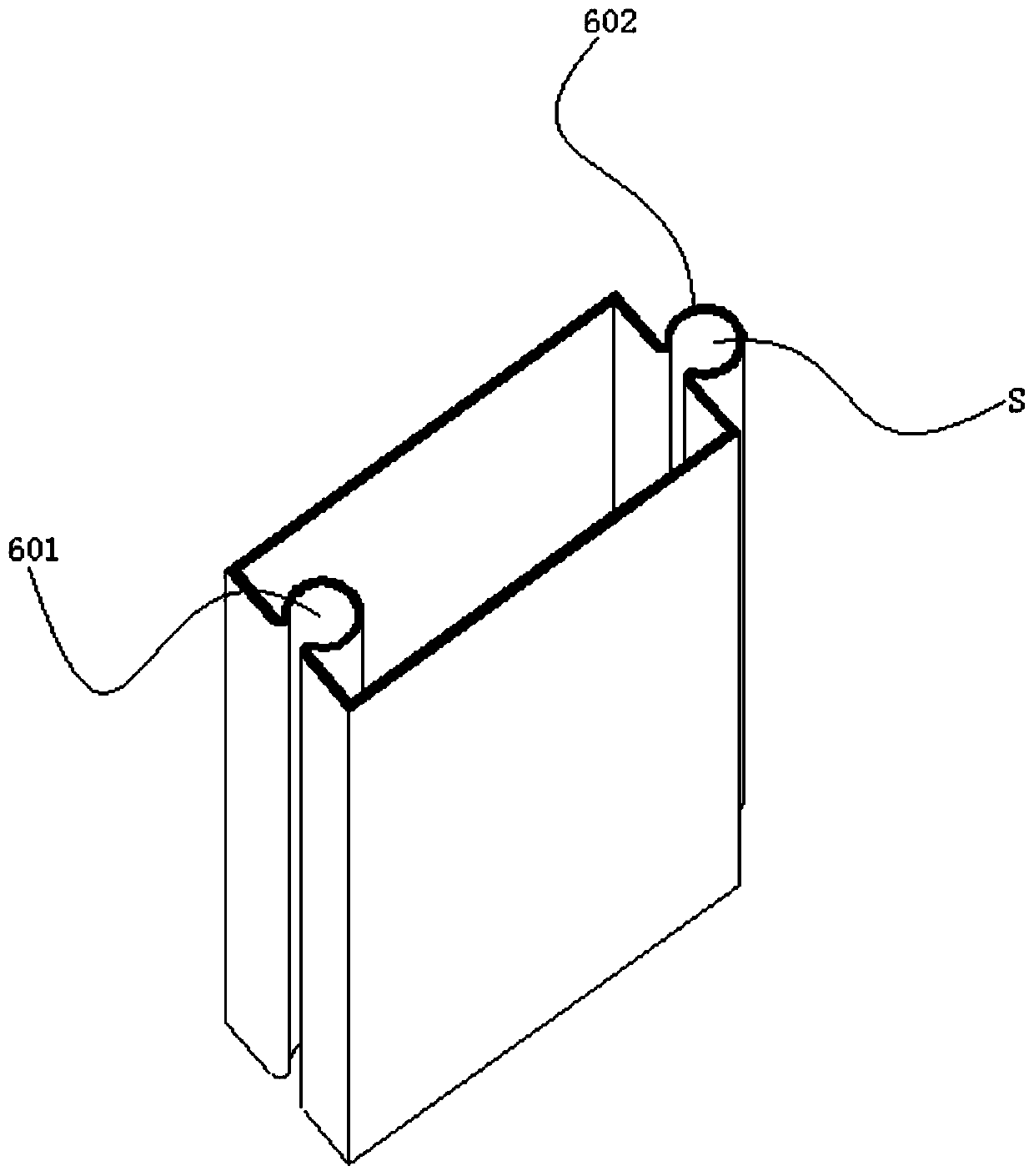

Connector box used for underground diaphragm wall steel-rubber connector and construction method

InactiveCN104929158ASolve the problem of water seepageIncrease seepage pathArtificial islandsProtective foundationSlurry wallBuilding construction

The invention relates to a connector box used for an underground diaphragm wall steel-rubber connector and a construction method, and belongs to the technical field of building construction. The connector box and the construction method are used for solving the problems that as for a circular connector pipe, an excavation dark region exists or the wall brushing technology needs to be additionally arranged, and therefore the number of construction technologies is increased. The connector box comprises a horseshoe fore shaft pipe capable of being lifted in a pit of a construction trough section. An arc-shaped end face is formed at the end, close to the front portion of the construction trough section, of the horseshoe fore shaft pipe in the width direction of the construction trough section, and a rectangular end face is formed at the end, close to the back portion of the construction trough section, of the horseshoe fore shaft pipe in the width direction of the construction trough section. A groove is formed in the end, close to the front portion of the construction trough section, of the horseshoe fore shaft pipe in the length direction of the construction trough section, and a rubber water stop sheet is embedded into the groove. The construction method includes the steps of 1, excavating the front portion of the construction trough section, and placing the connector box; 2, placing a steel reinforcing cage, and pouring the cage with concrete; 6, excavating the back portion of the construction trough section; 4, removing the horseshoe fore shaft pipe in a pulling mode.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

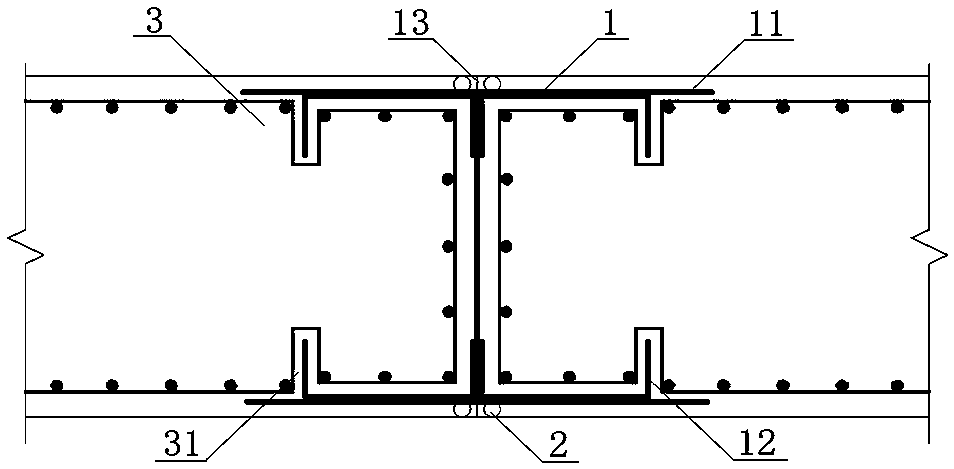

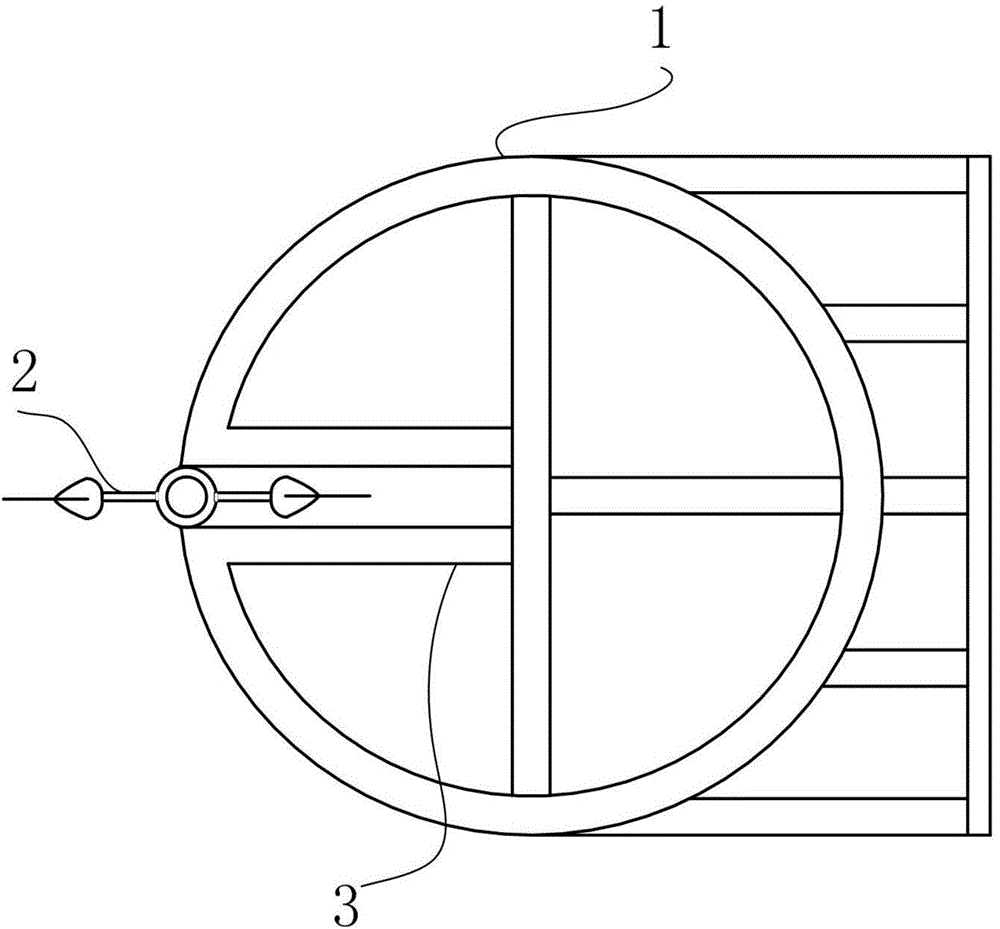

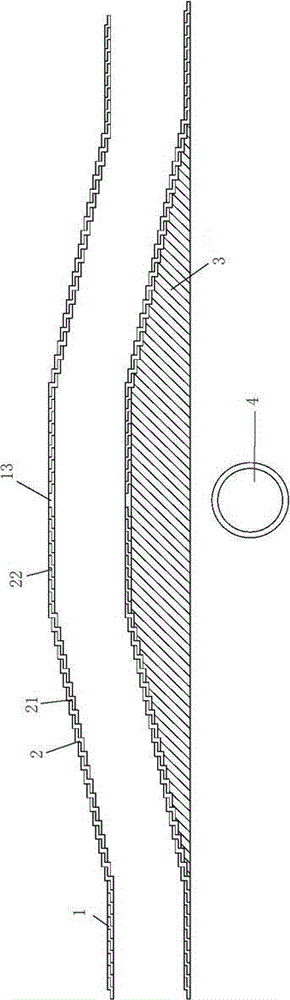

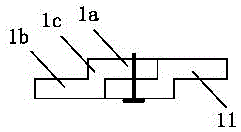

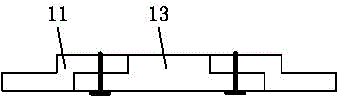

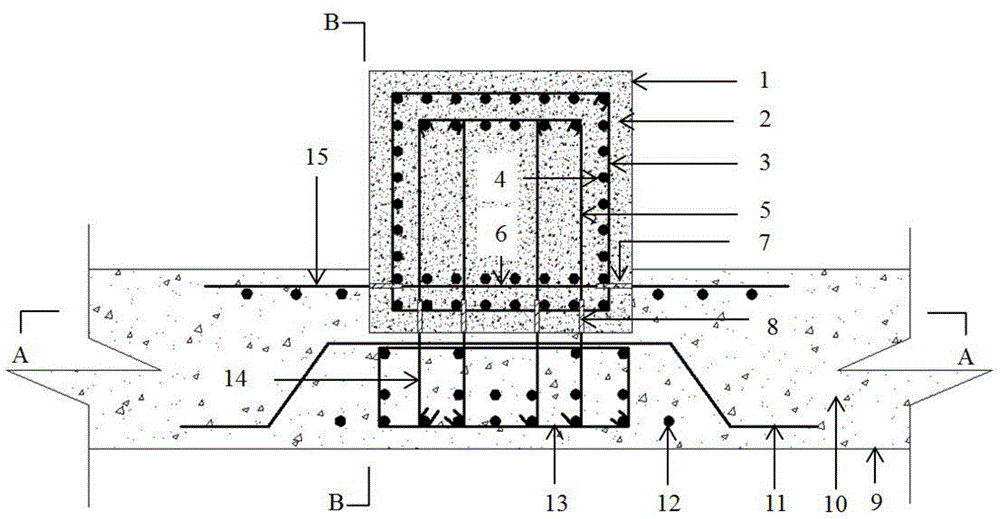

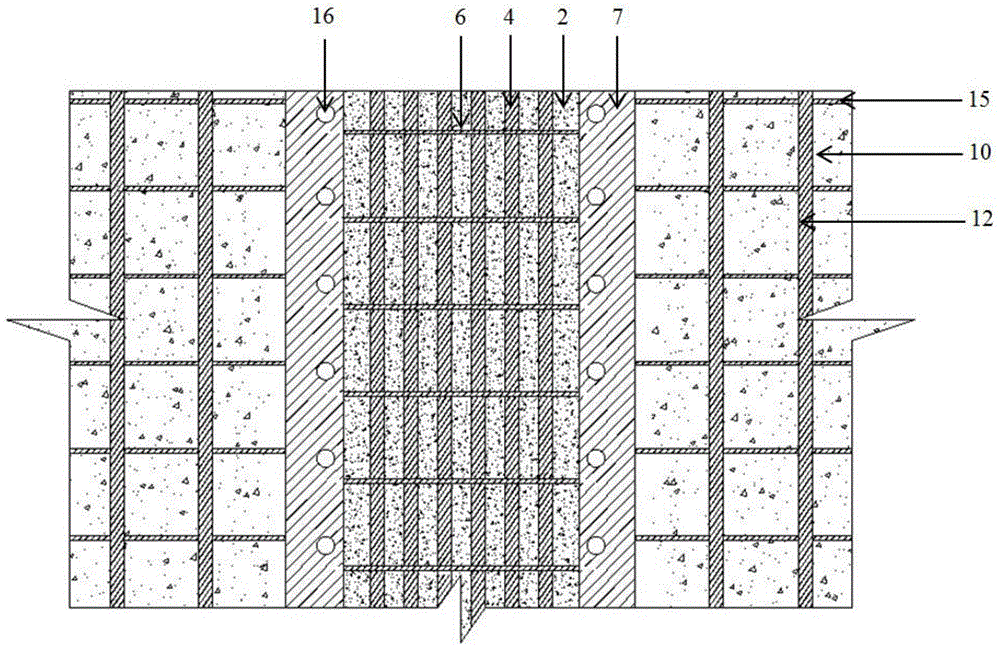

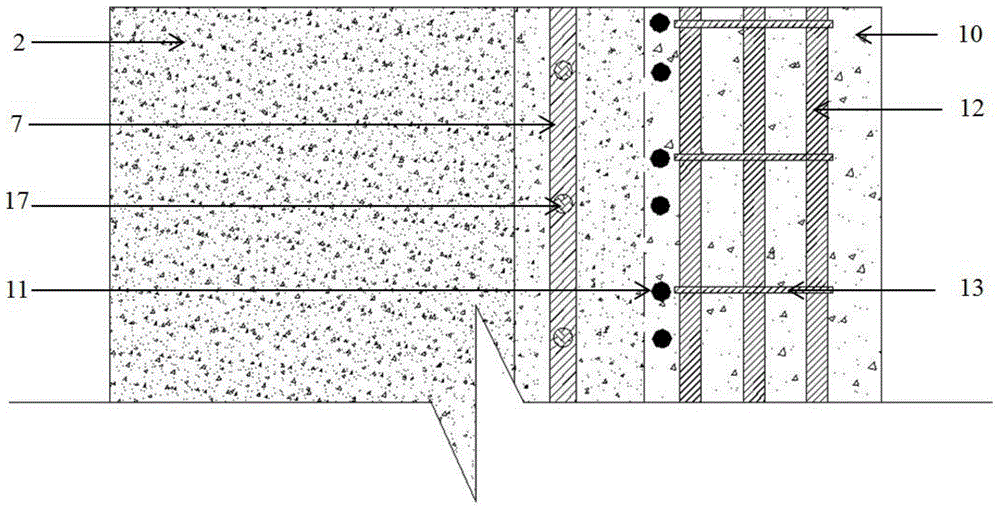

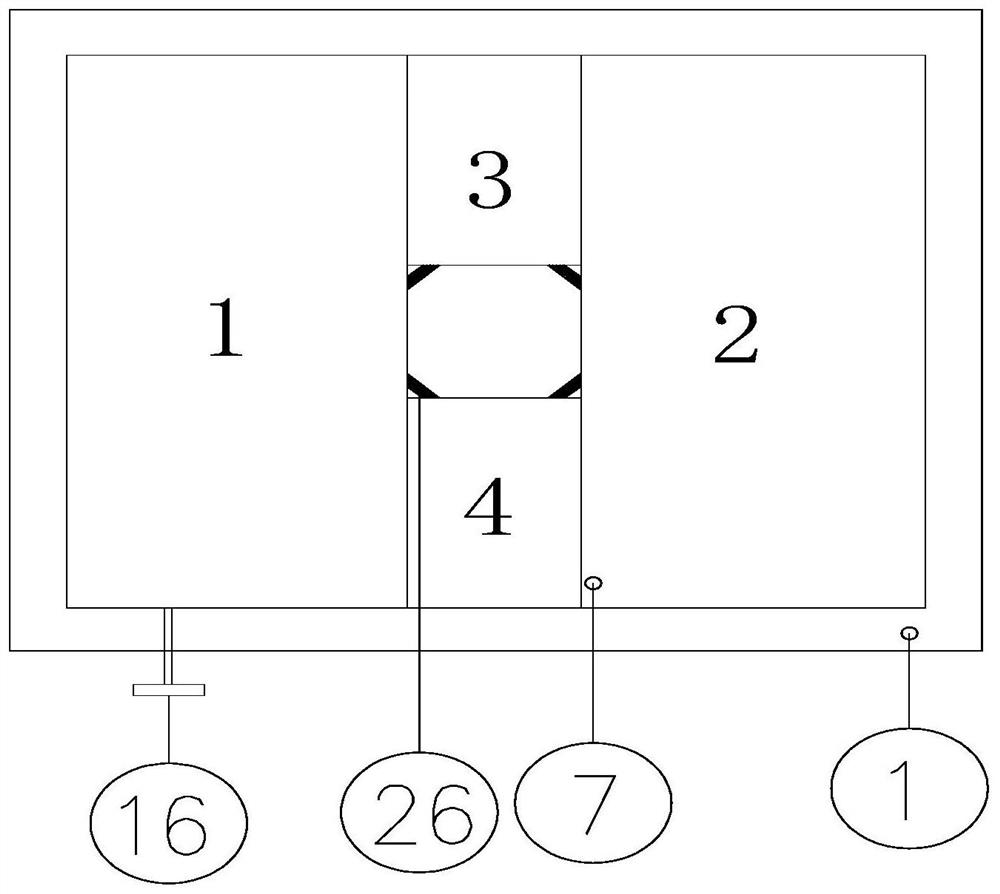

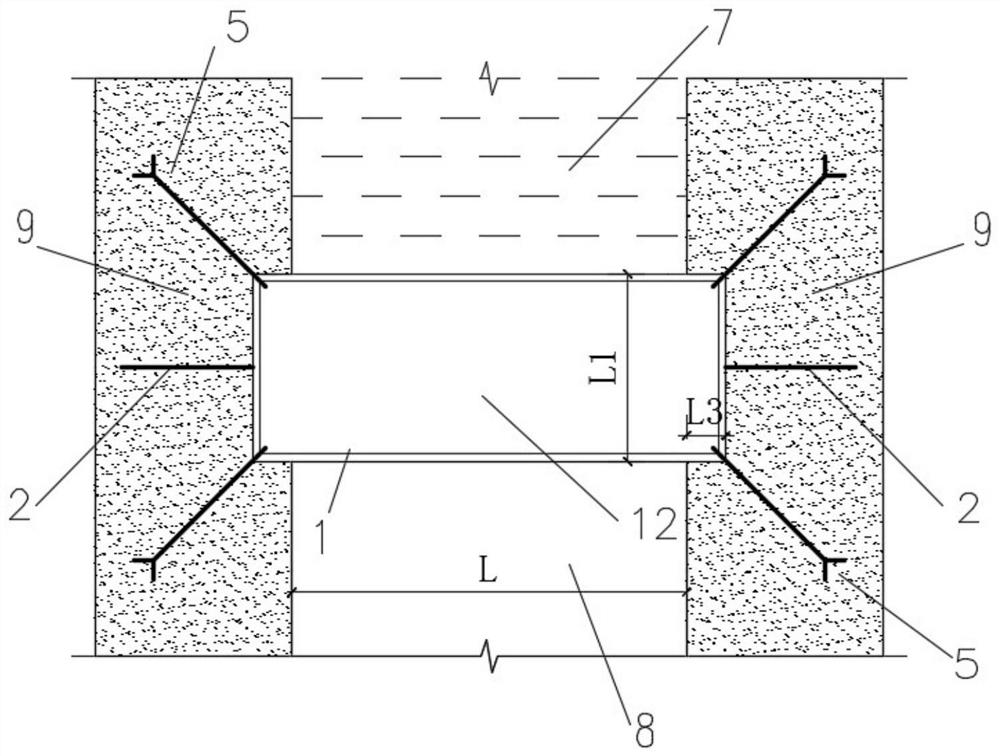

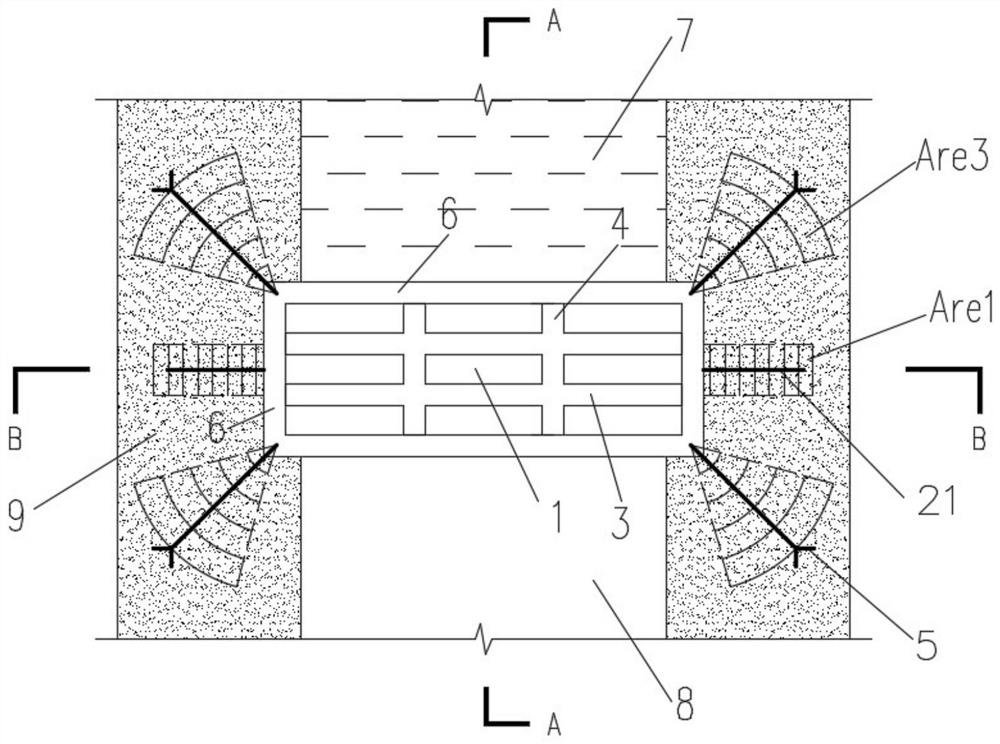

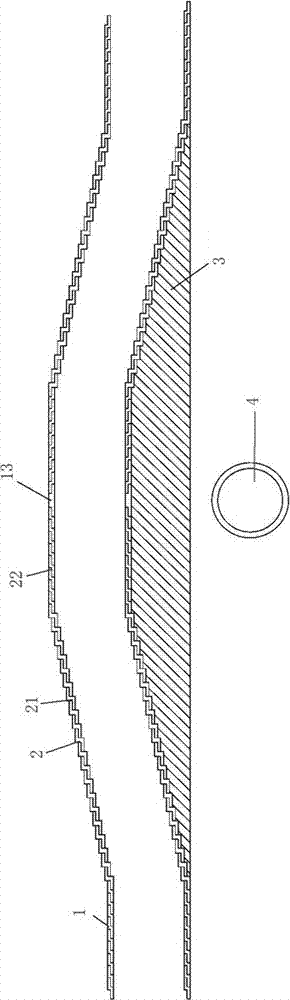

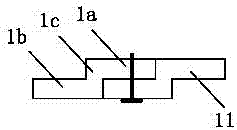

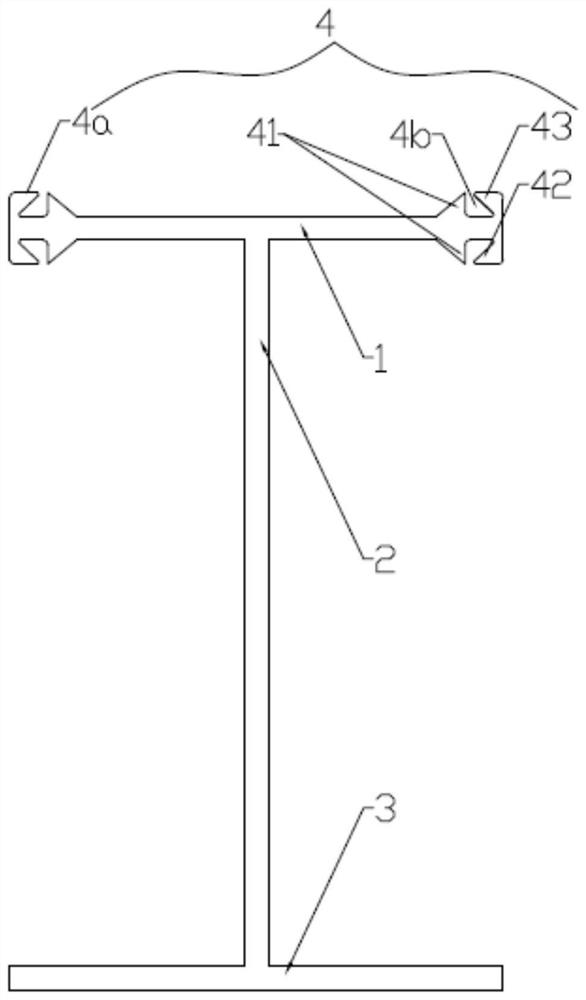

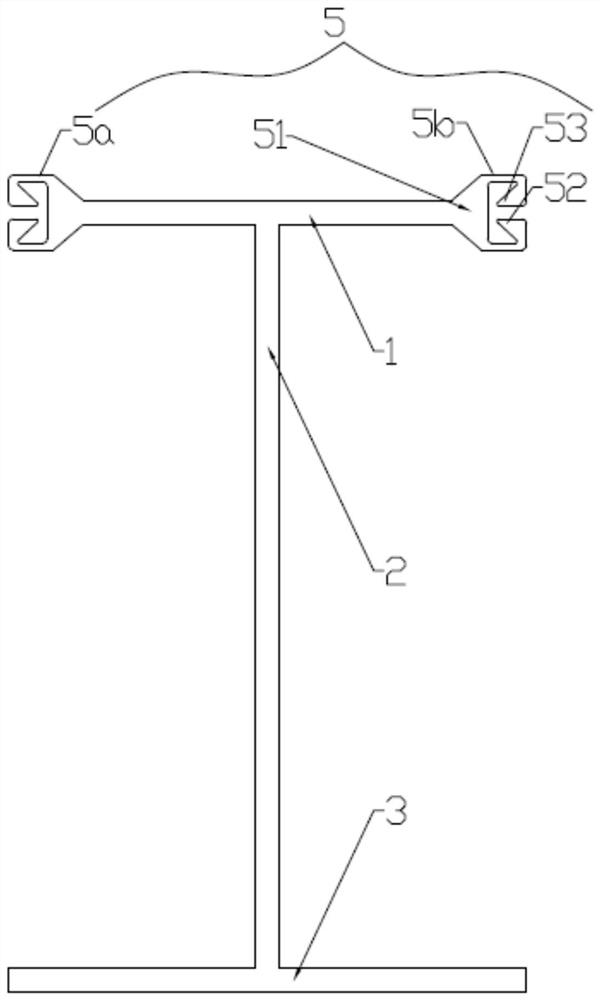

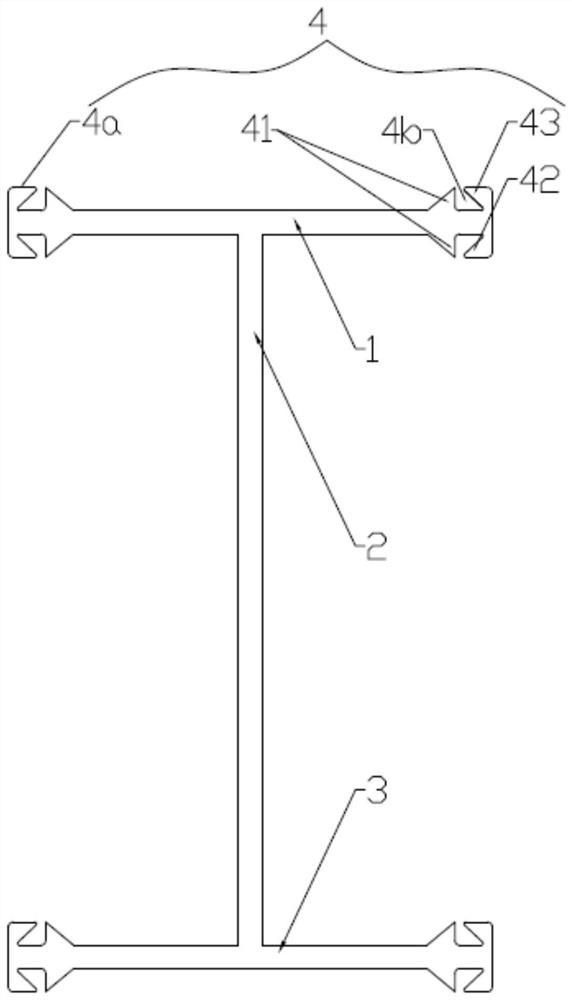

Underground diaphragm wall plate-type rigid joint and construction method thereof

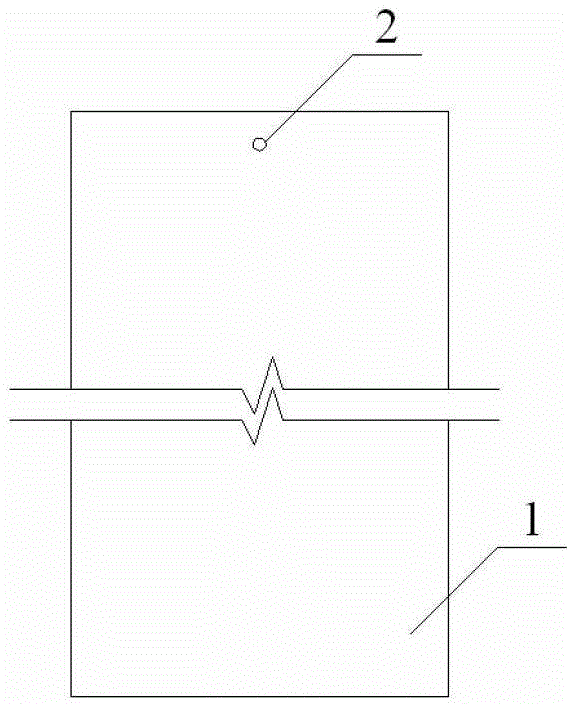

ActiveCN103306312AEnhanced lateral bending resistanceSimple designArtificial islandsUnderwater structuresSlurry wallEngineering

The invention discloses an underground diaphragm wall rigid baffle joint and a construction method thereof, and relates to a rigid baffle joint mode and a construction method thereof. The rigid baffle joint (8) consists of two rigid baffles (1) and a rigid bottom plate (3), wherein a latch pipe (5) is arranged between the two rigid baffles (1); second connecting piece clamping grooves (7) are formed in the side surface of the latch pipe (5); first connecting piece clamping grooves (2) are formed in the side surfaces of the rigid baffles (1); the two rigid baffles (1) are connected with the latch pipe (5) by the first connecting piece clamping grooves (2) and the second connecting piece clamping grooves (7); steel bar end sockets (6) are arranged on the bottom surface of the latch pipe (5); steel bar clamping grooves (4) are formed in the rigid bottom plate (3); and the steel bar ends are fitted with the steel bar clamping grooves (4) to connect the latch pipe (5) with the rigid bottom plate (3). The rigid baffle joint is simple to design and manufacture; accurate contraposition of steel bar cages of adjacent walls is realized; the wall integrity is improved; the lateral bending resistance of the joint is improved; and a percolation path is increased.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

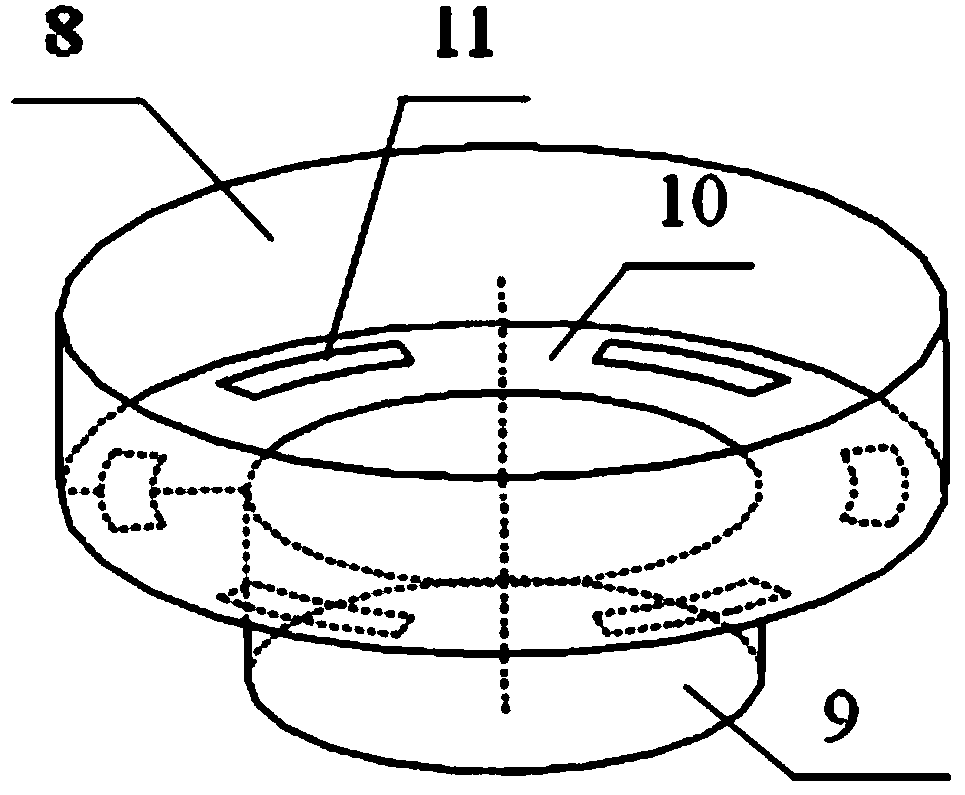

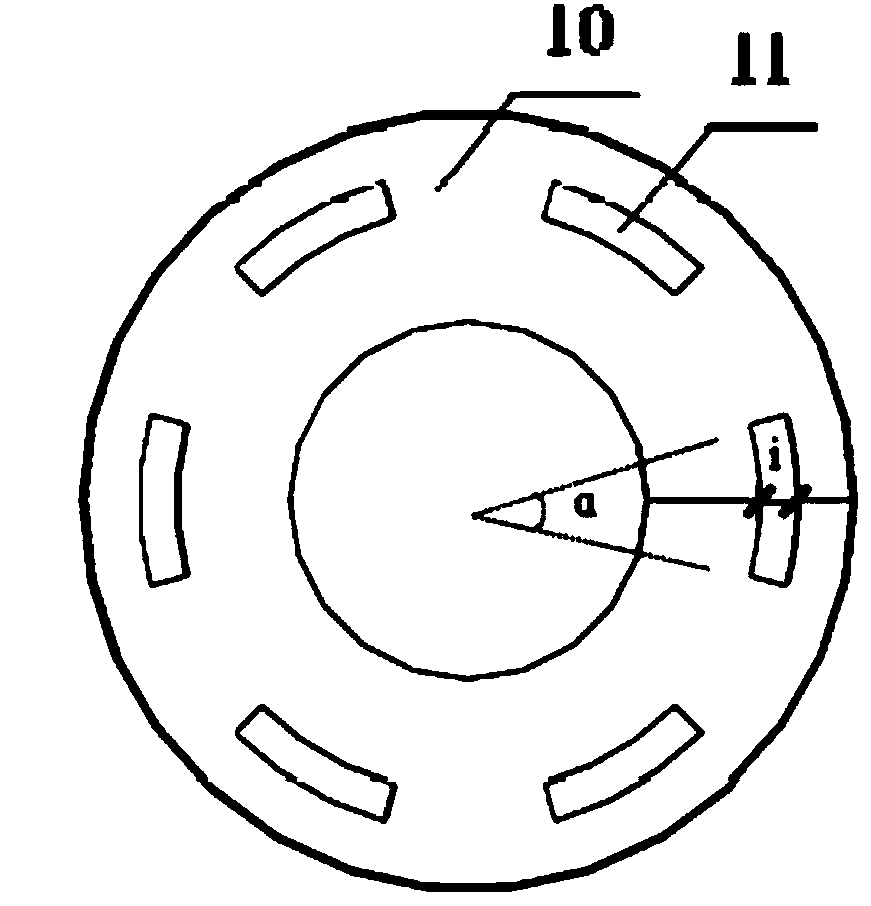

Water plugging seepage-proofing method for recharge well

ActiveCN103526780APrevent upwellingIncrease the safety reserve of water blocking and anti-seepageProtective foundationDrinking water installationButt jointMeasuring instrument

The invention discloses a water plugging seepage-proofing method for a recharge well. The method includes the steps that firstly, a steel disc ring is premade, and a clamping groove is welded on a well casing in advance; a rubber balloon is placed in the clamping groove and pressurized, so that the clamping groove is filled with the rubber balloon, a sediment tube of the recharge well, a filter and the well casing are connected in a butt joint mode, fixed and then submerged in a well hole, and a gravel filter layer and a clay ball water resisting layer are constructed; the well casing is sleeved with the steel disc ring, the steel disc ring is submerged to the well hole, when the reading number of a pressure measuring instrument is synchronously increased along with the submergence of the steel disc ring, deflation and pressure reduction are conducted on the rubber balloon, the steel disc ring is quickly submerged until the steel disc ring can not continue submerging, the lower portion of the steel disc ring is pressed in the clamping groove, the rubber balloon is extruded in the gap between the clamping groove and the steel disc ring, and eventually a concrete water plugging layer is constructed. According to the method, plugging failure of the filter layer caused by inevitable well casing disturbance in the well completion construction process and recharge water upwelling in the running process of the recharge well can be effectively avoided, even inclination of the well casing can be reduced or avoided, and by the cooperation of other recharge water preprocessing measures, eventually normal working of the recharge well can be guaranteed.

Owner:TIANJIN UNIV

Prefabricated composite member and production method thereof, and prefabricated composite wall and construction method thereof

ActiveCN111236499AHigh degree of industrializationReduce wet workWallsHeat proofingHeat conservationRebar

The invention belongs to the field of building outer walls, and discloses a prefabricated composite member and a production method thereof, and a prefabricated composite wall and a construction methodthereof. The prefabricated composite member comprises a veneer and an insulation board which are connected with each other, a reinforcement cage connected with an inner board, and a plurality of connecting assemblies used for mutually connecting the insulation board and the inner board, wherein a cavity is formed between the insulation board and the inner board, and the reinforcement cage is partially located in the cavity; each connecting assembly comprises a built-in component arranged in the insulation board and an assembly component connected with the built-in component; each assembly component is partially arranged in the inner plate and partially located in the cavity; and each assembly component further comprises a first connecting section connected with the built-in component andan inner side limiting piece connected with the first connecting section, wherein each inner side limiting piece is located in the cavity and abuts against the insulation board, and the diameter of each inner side limiting piece is larger than the diameters of the parts connected with the two sides of the inner side limiting piece. According to the scheme, the problem of heat preservation and exterior facing integration of a double-faced composite outer wall is solved, and the production and construction process is simple and efficient.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

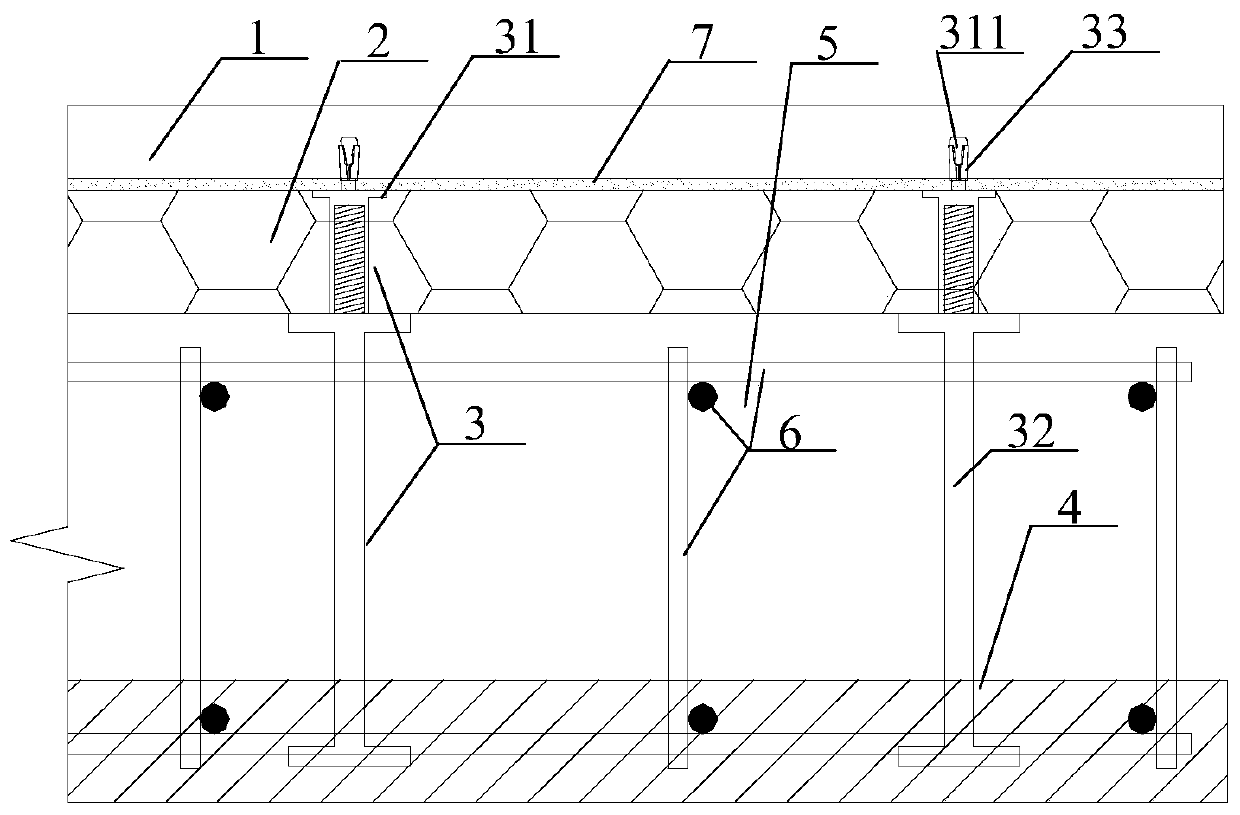

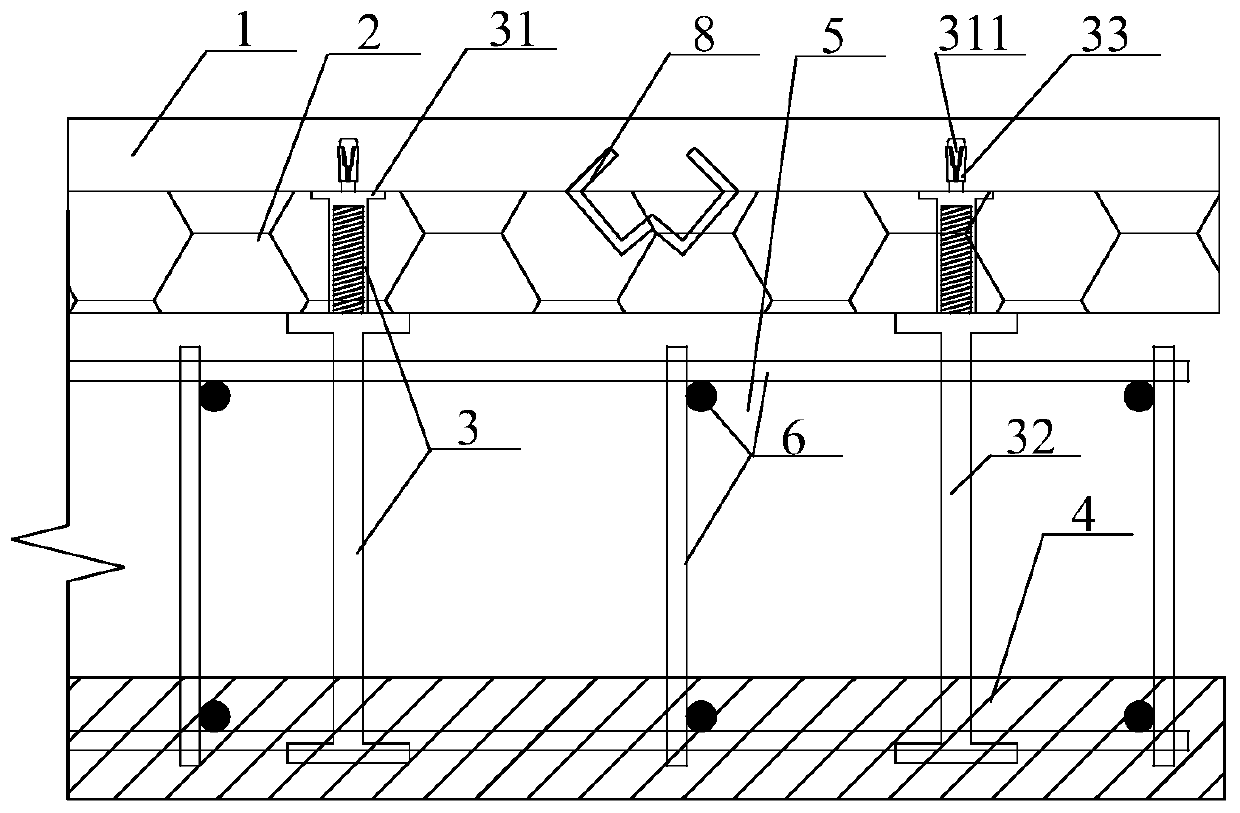

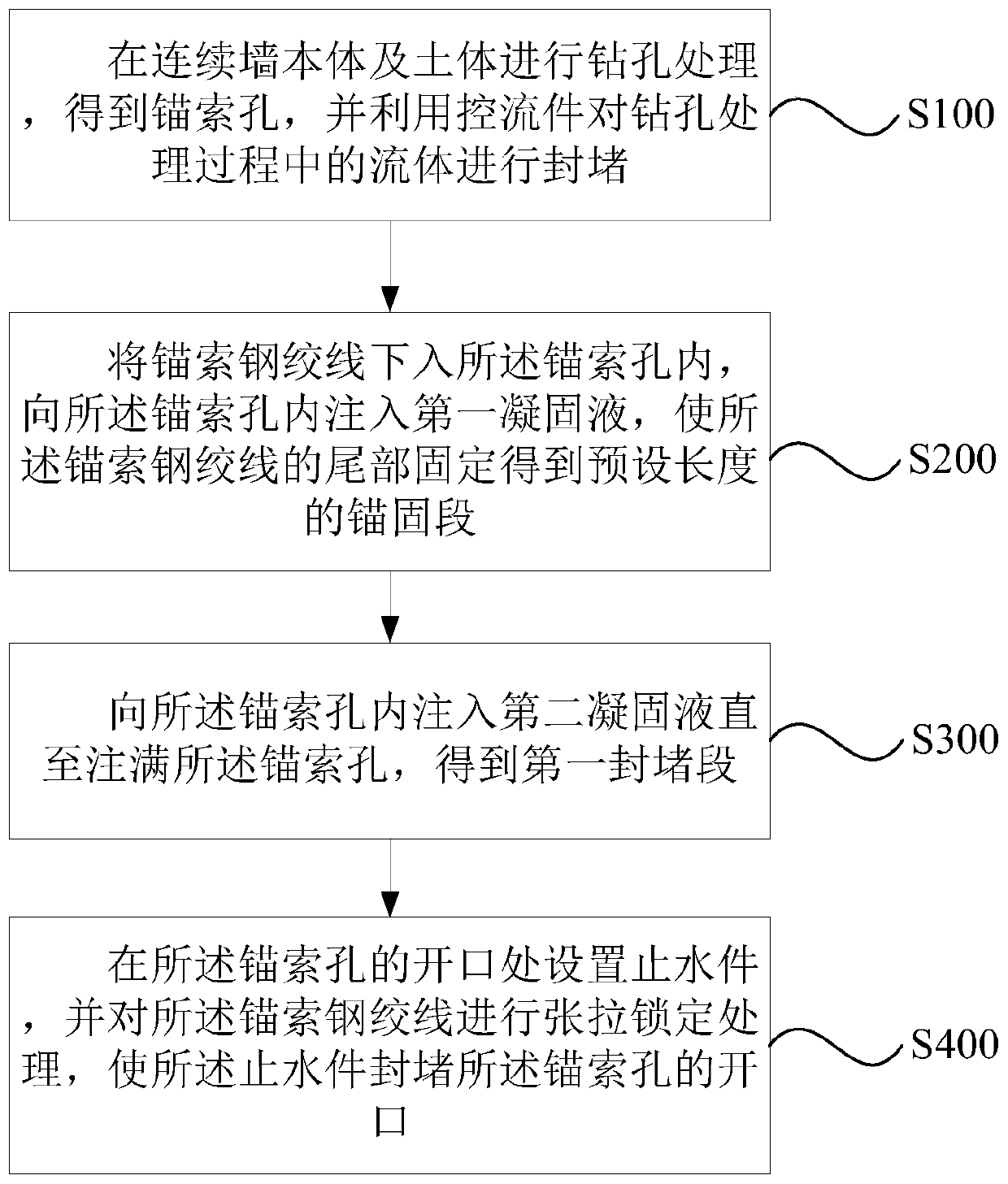

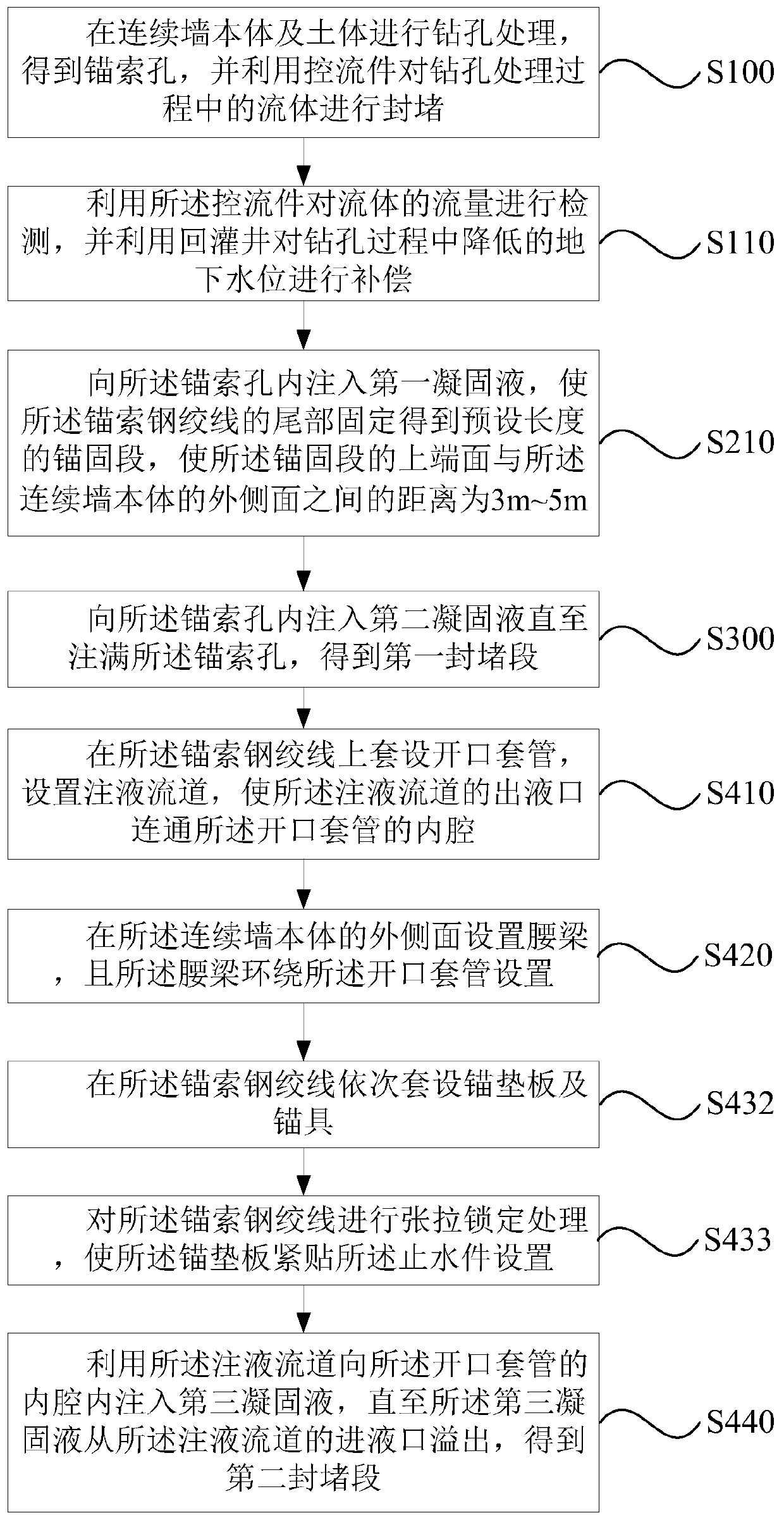

Sealing water method and sealing water structure of anchor cable hole of water-rich stratum underground diaphragm wall

PendingCN110158589AWater sealing is effectivePrevent collapseProtective foundationBulkheads/pilesSlurry wallEngineering

The invention discloses a sealing water method and a sealing water structure of an anchor cable hole of a water-rich stratum underground diaphragm wall. The sealing water method comprises the following steps: drilling a diaphragm wall body and a soil body to obtain an anchor cable hole, and adopting a flow control piece to block fluid during the drilling treatment process; putting an anchor cablesteel strand in the anchor cable hole, and filling first solidification solution in the anchor cable hole to fix the tail part of the anchor cable steel strand so as to obtain an anchorage section with a preset length; filling second solidification solution in the anchor cable hole until the anchor cable hole is full to obtain a first blocking section; arranging a waterstop piece at the opening ofthe anchor cable hole, and stretching, drawing and locking the anchor cable steel strand to enable the waterstop piece to block the opening of the anchor cable hole. The sealing water method and thesealing water structure can effectively carry out sealing water treatment on the anchor cable hole to ensure the construction quality.

Owner:中铁建华南建设有限公司 +2

Damping structure of up-down cross tunnel and construction method thereof

ActiveCN105003283AImprove seismic performanceImprove clearanceUnderground chambersTunnel liningStructure of the EarthHeight difference

The invention discloses a damping structure of up-down cross tunnels. The structure comprises a lining segment structure surrounding the inner layer of an under-construction tunnel. The lining segment structure is formed by overlaying dwarf Z-shaped duct pieces, high-type Z-shaped duct pieces, and T-shaped transfer duct pieces. When the under-construction tunnel is constructed to the position where a certain distance is between the under-construction tunnel and an original tunnel, the high-type Z-shaped duct pieces are used to overlay to make the under-construction tunnel generate small inclination strike, and clear height difference between the under-construction tunnel and the original tunnel is increased. When the under-construction tunnel is constructed to the position where a certain distance is between the under-construction tunnel and the original tunnel, a damping layer is arranged close to the side of the original tunnel. The damping structure is advantaged by high anti-seismic property and high security, and reducing vibration influence of transport vehicles on the tunnel structure.

Owner:NANJING GEOTECHNICAL & UNDERGROUND SPACE TECH CO LTD

Connecting method of foundation pit precast pile and cast-in-situ superposed lining wall through stirrups

ActiveCN105040677AHigh strengthImprove bending abilityBulkheads/pilesStructural engineeringUltimate tensile strength

The invention discloses a connecting method of a foundation pit precast pile and a cast-in-situ superposed lining wall through stirrups. The method includes the following steps that after the size of the precast pile is determined according to design, a main rib and the stirrups of the pile are arranged, a connecting steel plate is arranged on the joint of the pile stirrups and the wall stirrups along a pile body, and pile connecting holes and wall connecting holes are formed in the connecting steel plate; connecting ribs of the pile stirrups are fixedly connected with the connecting steel plate through the pile connecting holes, and the wall connecting holes are plugged through plugging materials; pile concrete is poured, the precast pile is beaten into the designed position of a foundation pit after the designed strength is achieved through curing, the plugging materials are removed after excavation of the foundation pit is completed, and the wall connecting holes are exposed; and according to the design requirement, the main rib, the stirrups and a bent rib are arranged at the corresponding positions of a cast-in-situ wall, connecting ribs of the wall stirrups in the cast-in-situ wall are fixedly connected with the connecting steel plate through the wall connecting holes, concrete of the cast-in-situ wall is poured after connection is completed, and connection of the precast pile and the cast-in-situ superposed wall is completed.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Water plugging seepage-proofing method for recharge well

ActiveCN103526780BPrevent upwellingIncrease the safety reserve of water blocking and anti-seepageProtective foundationDrinking water installationButt jointMeasuring instrument

The invention discloses a water plugging seepage-proofing method for a recharge well. The method includes the steps that firstly, a steel disc ring is premade, and a clamping groove is welded on a well casing in advance; a rubber balloon is placed in the clamping groove and pressurized, so that the clamping groove is filled with the rubber balloon, a sediment tube of the recharge well, a filter and the well casing are connected in a butt joint mode, fixed and then submerged in a well hole, and a gravel filter layer and a clay ball water resisting layer are constructed; the well casing is sleeved with the steel disc ring, the steel disc ring is submerged to the well hole, when the reading number of a pressure measuring instrument is synchronously increased along with the submergence of the steel disc ring, deflation and pressure reduction are conducted on the rubber balloon, the steel disc ring is quickly submerged until the steel disc ring can not continue submerging, the lower portion of the steel disc ring is pressed in the clamping groove, the rubber balloon is extruded in the gap between the clamping groove and the steel disc ring, and eventually a concrete water plugging layer is constructed. According to the method, plugging failure of the filter layer caused by inevitable well casing disturbance in the well completion construction process and recharge water upwelling in the running process of the recharge well can be effectively avoided, even inclination of the well casing can be reduced or avoided, and by the cooperation of other recharge water preprocessing measures, eventually normal working of the recharge well can be guaranteed.

Owner:TIANJIN UNIV

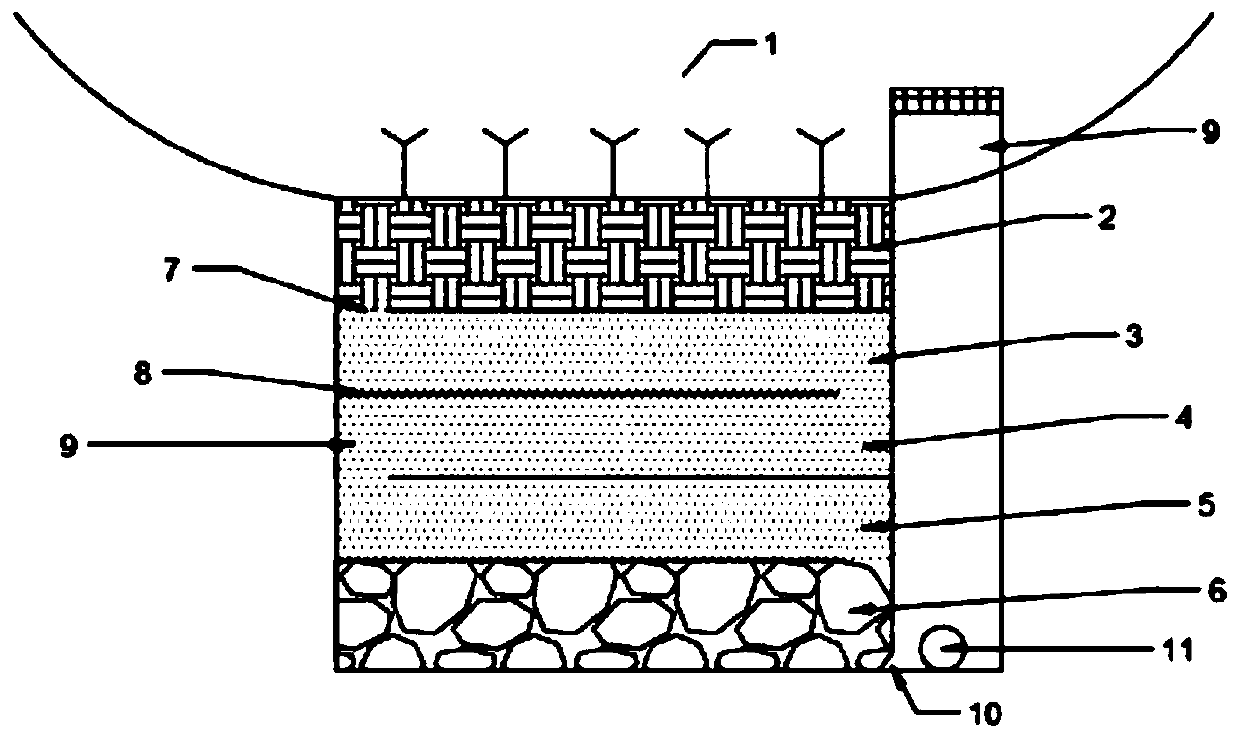

Biological detention pond for improving ability of nitrogen and phosphorus removal

InactiveCN109809632AImprove removal efficiencyImprove adsorptionWater contaminantsMultistage water/sewage treatmentSoil horizonStormwater

The invention provides a biological detention pond for improving the ability of nitrogen and phosphorus removal. The biological detention pond includes a water reserve and a detention pond body structure arranged on the lower part of the water reserve, the detention pond body structure includes a planting soil layer, a packing area and a pebble bed from top to bottom, wherein the packing area is internally provided with a plurality of layers of impermeable geotechnical cloths, the detention pond body structure is divided into a plurality of layers of corridors, one ends of the impermeable geotechnical cloths are connected to the inner wall of the detention pond body structure, the other ends of the impermeable geotechnical cloths are free ends, a serpentine water seepage passageway is formed among the multiple layers of corridors, and the multiple layers of corridors are filled with different fillers correspondingly; and the pebble bed communicates with the water seepage passageway, and a perforated drainage pipe is arranged in the pebble bed. According to the biological detention pond for improving the ability of nitrogen and phosphorus removal, through design of the multiple layers of corridors, the hydraulic retention time of rainwater in the detention pond can be increased, phosphorus removal is facilitated, entering of oxygen can be isolated, an anoxic zone and an anaerobic zone are arranged on the lower part of the biological detention pond, and nitrogen removal is facilitated.

Owner:JIANGSU UNIV

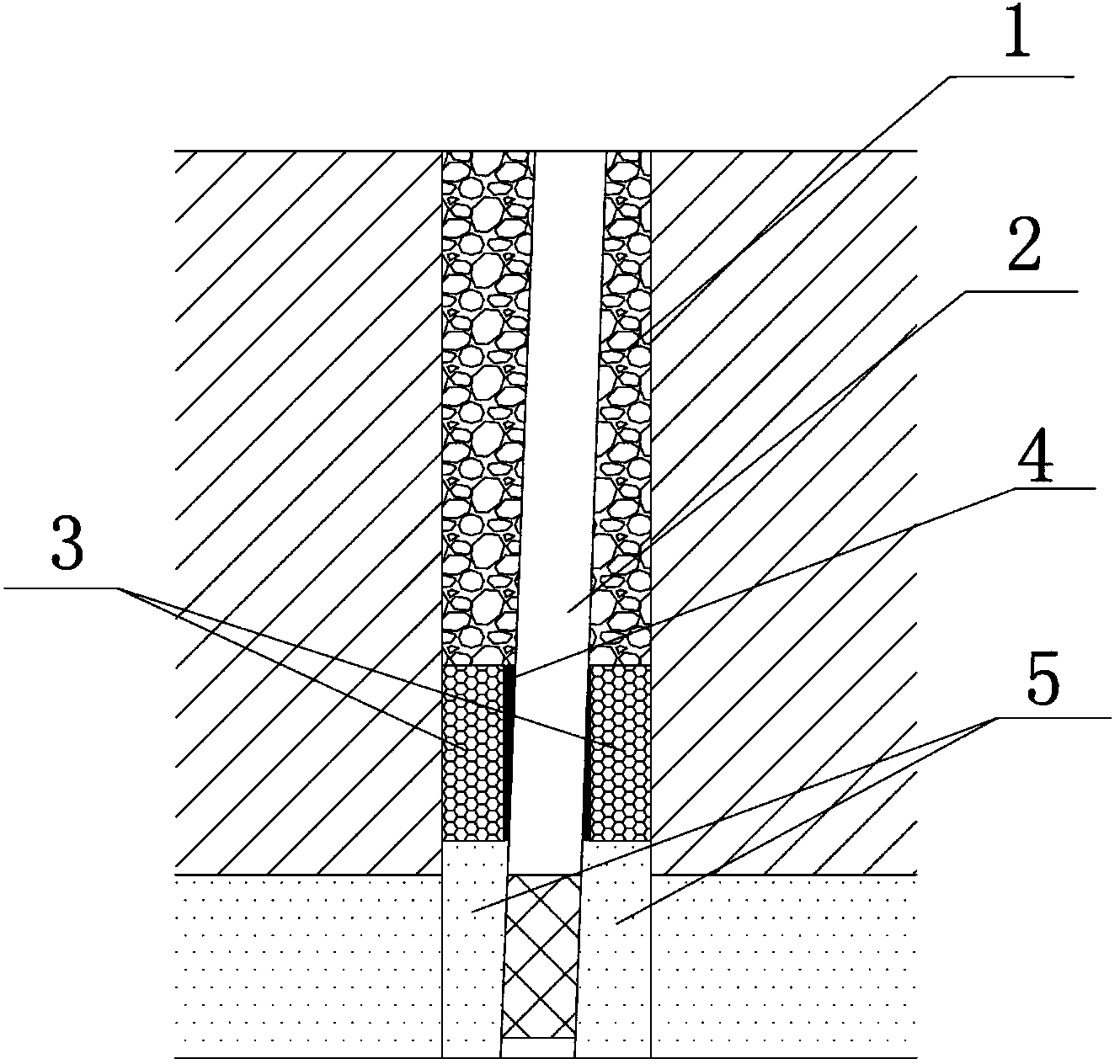

Foundation pit base face water-free construction structure under sandy gravel and mudstone geological conditions

The invention discloses a foundation pit base face water-free construction structure under sandy gravel and mudstone geological conditions. The structure comprises a foundation pit drainage system, awater collecting well and a water pumping and draining system, wherein 1) the foundation pit drainage system comprises a foundation pit side wall drainage system and a foundation pit bottom drainage system, and the foundation pit side wall drainage system communicates with the foundation pit bottom drainage system; 2) the water collecting well is arranged at the bottom of a foundation pit, and thewater collecting well communicates with the foundation pit bottom drainage system so as to collect water at the bottom of the foundation pit into the water collecting well; and 3) the water pumping and draining system is arranged at the water collecting well and is used for draining the water in the water collecting well. The structure is easy to install and operate, the underground water is effectively prevented from permeating into the foundation pit, the defects of a well point dewatering method are effectively overcome, and the potential safety hazard of water-carrying construction of thefoundation pit is reduced; construction of the foundation pit is not affected while the water is pumped and drained, and water-free construction of the base face of the foundation pit is truly achieved; and when the centralized water pumping and draining device system is sealed, a water pump is recovered from the device, and the investment cost of a project is also saved.

Owner:中铁隧道局集团建设有限公司 +2

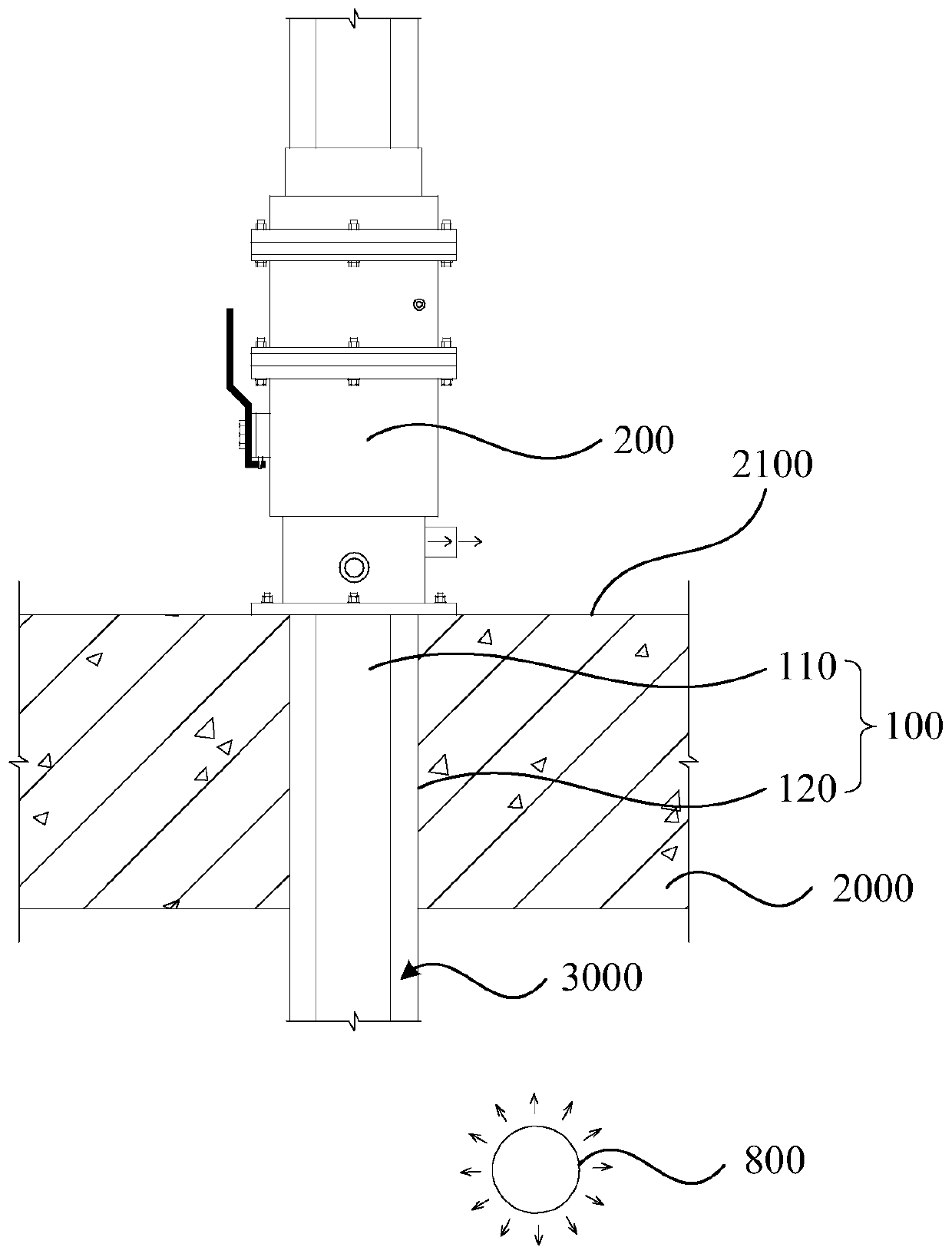

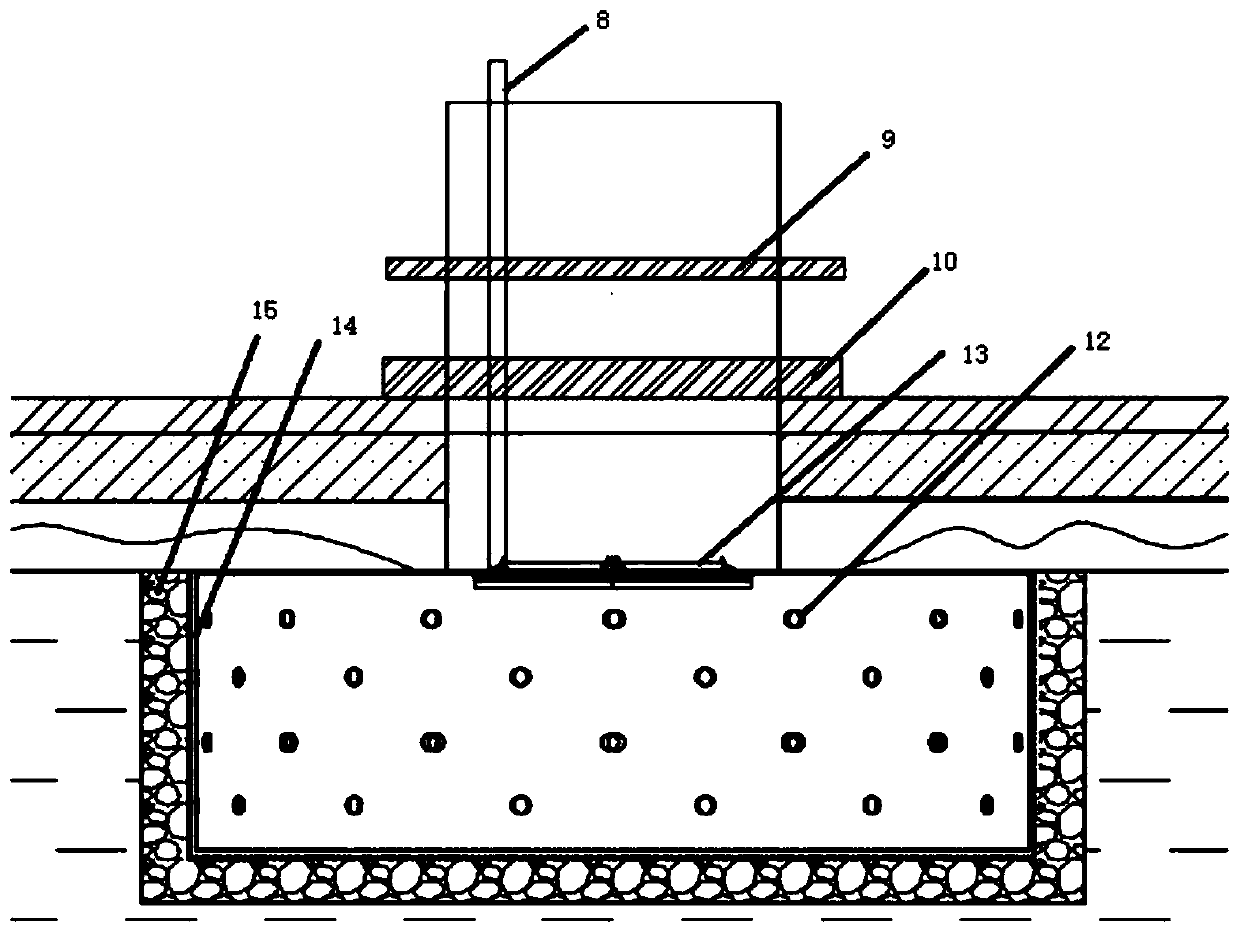

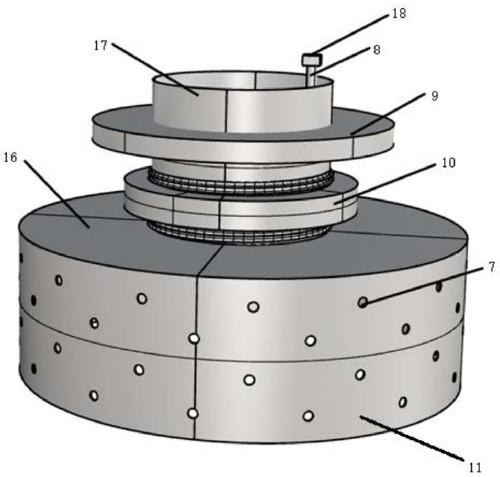

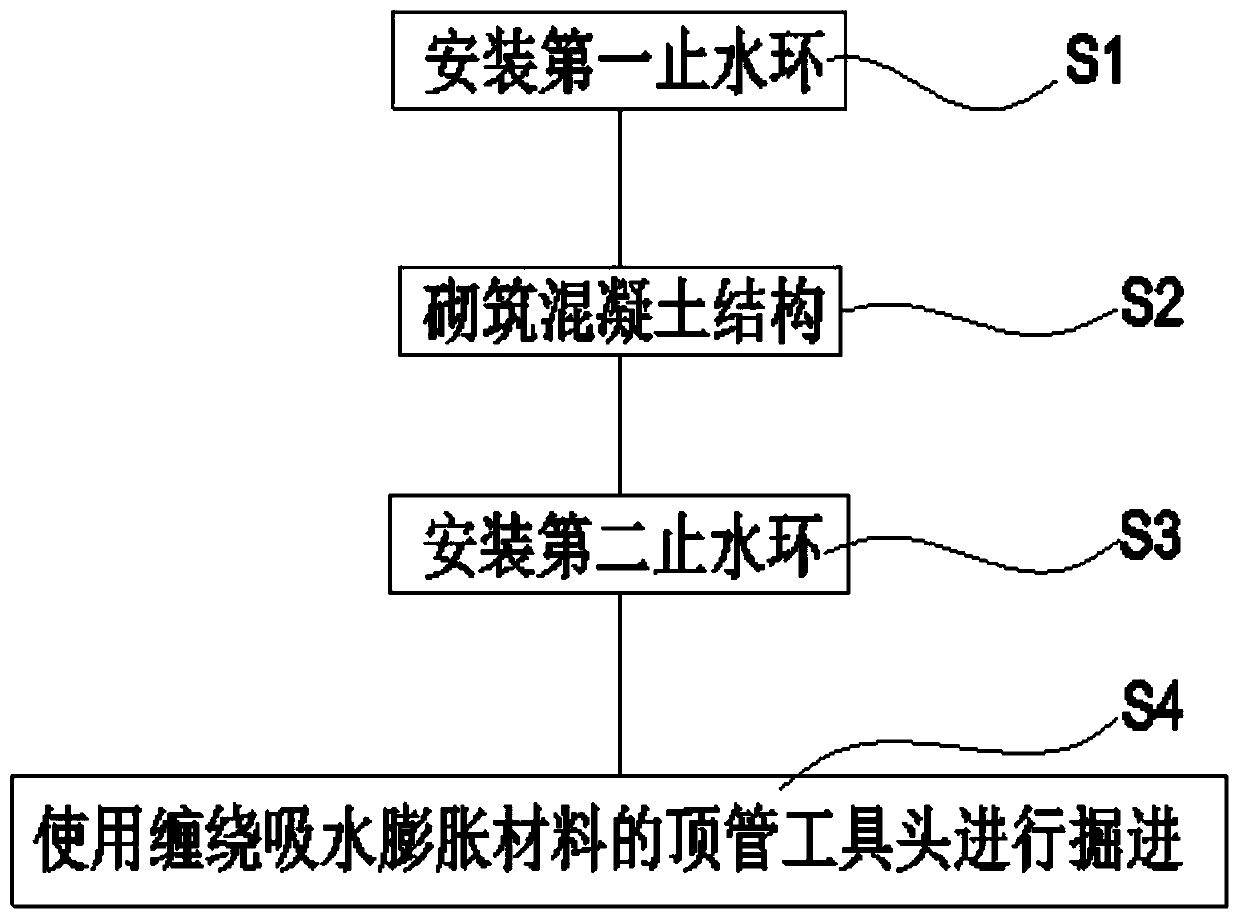

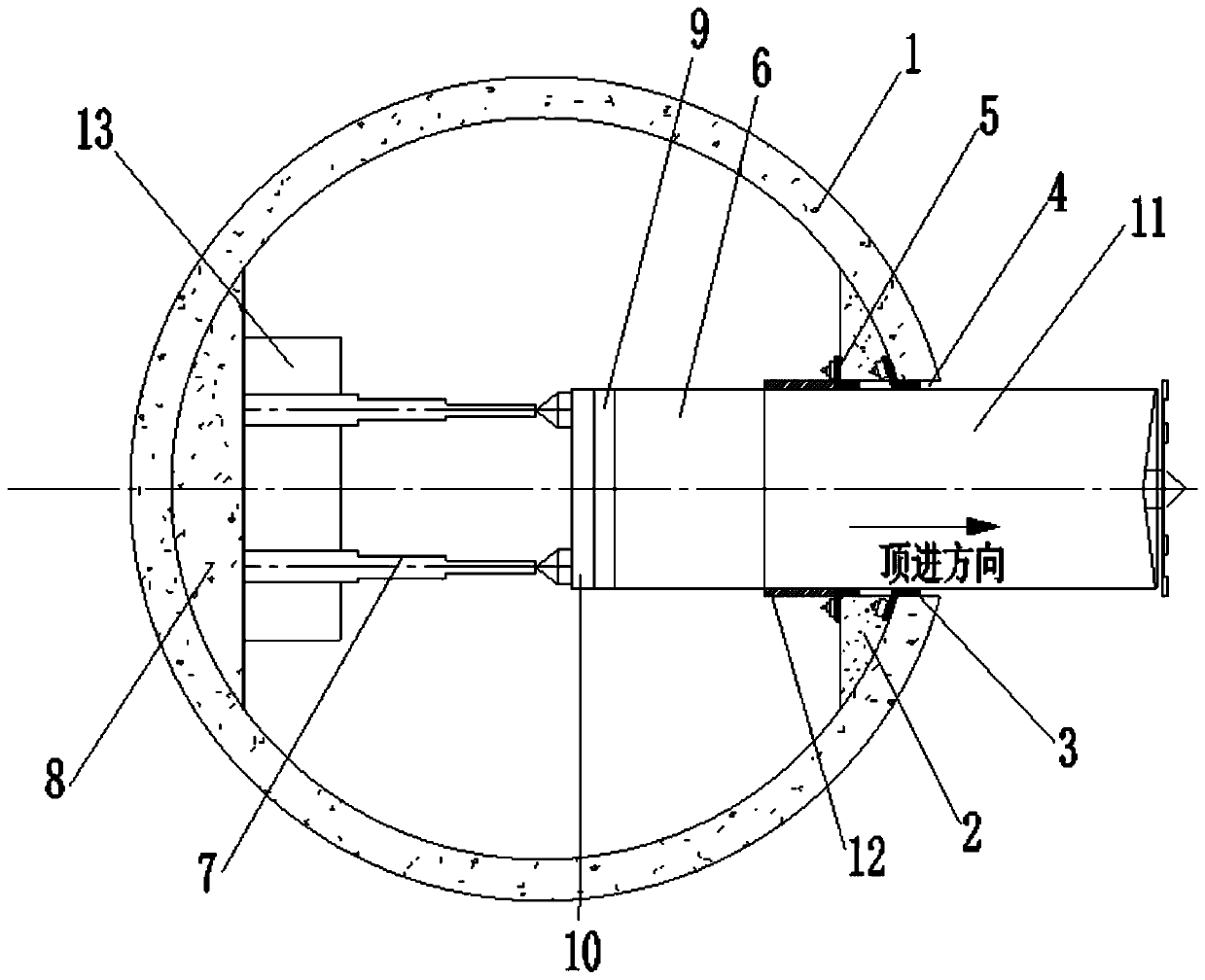

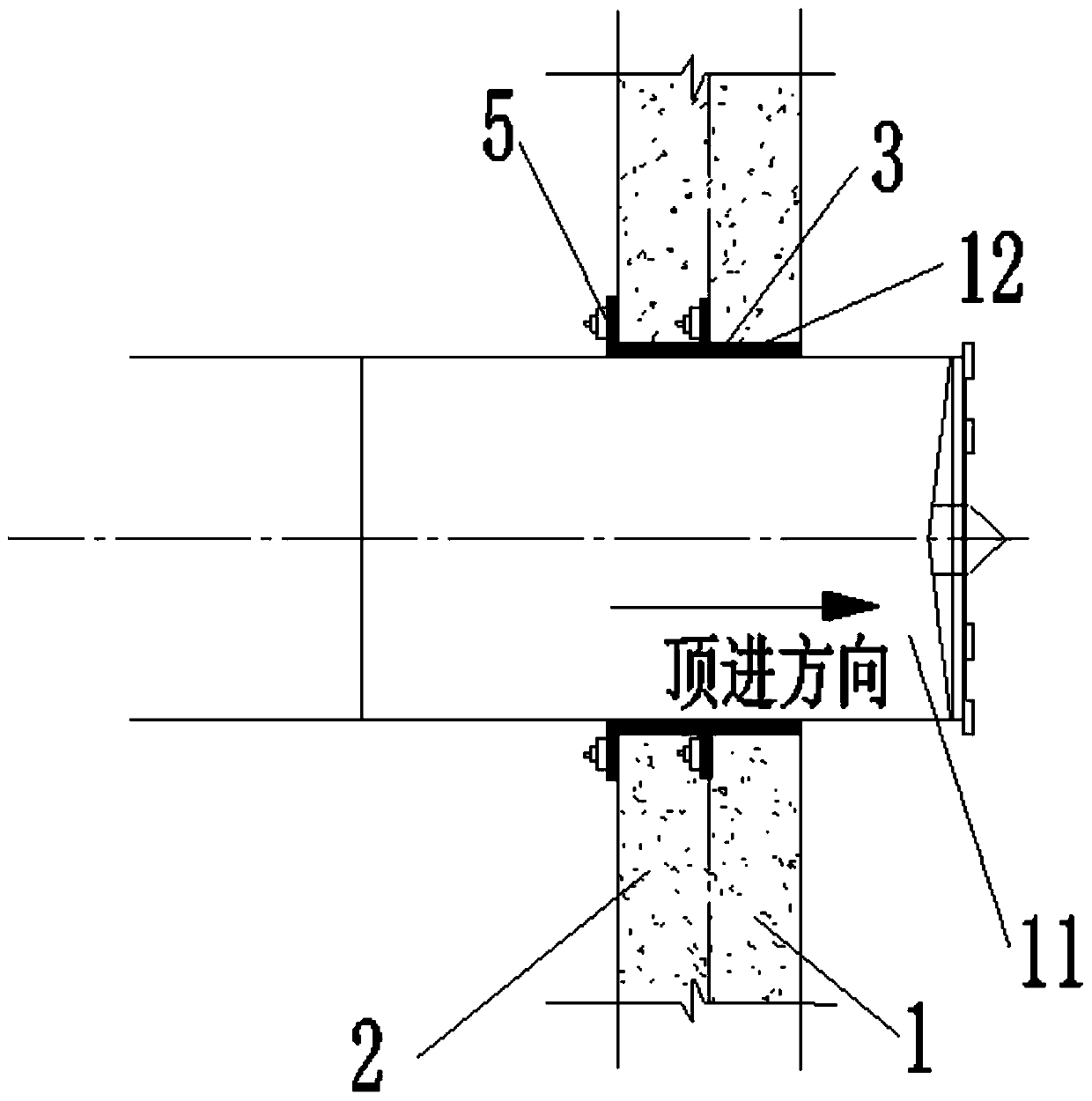

A water-stopping method and device for pipe-jacking entry and exit holes suitable for areas with deep, thick, water-rich sand layers

ActiveCN108266207BIncrease seepage pathPrevent water leakage and sand leakageUnderground chambersTunnel liningWater stopWater flow

Owner:GUANGZHOU MUNICIPAL ENG GROUP

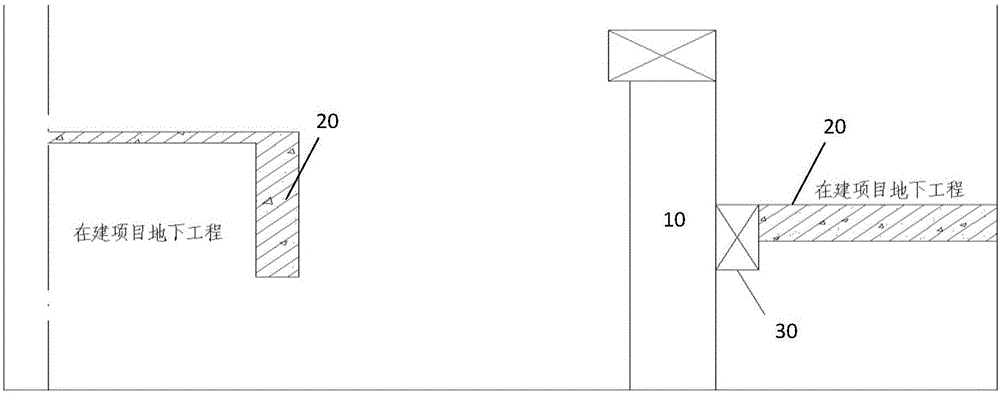

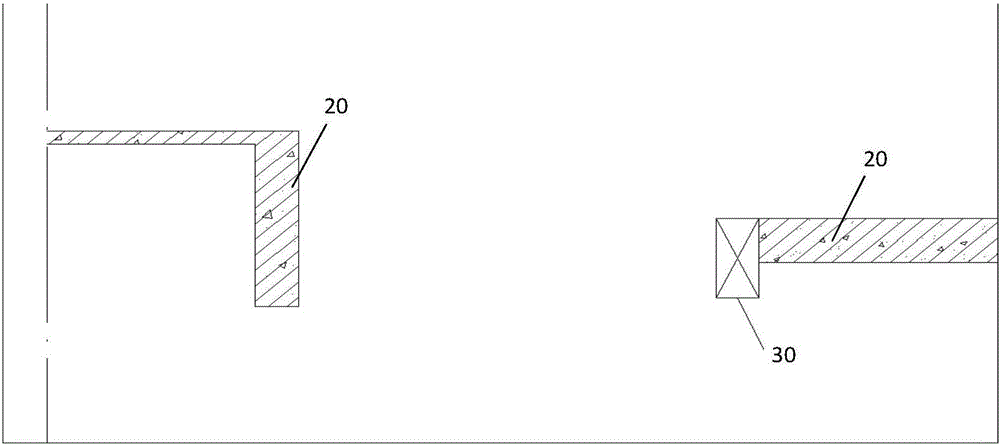

Basement communication method

The invention discloses a basement communication method. The basement communication method comprises the steps that firstly, a temporary structural beam (30) is arranged between a lining wall (20) of one basement and an enclosing wall (10); secondly, the enclosing wall (10) between lining walls (20) of two basements is dismantled; thirdly, part of the temporary structural beam (30) is dismantled; and fourthly, a connecting channel top plate (40) is constructed between the lining walls (20) of the two basements and fixedly connected with the temporary structural beam (30). By adoption of the basement communication method, the temporary structural beam (30) is incompletely dismantled, so that structural floors of the basements are not overhung, the safety of the structural floors is improved, and environmental-friendly construction requirements are met.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

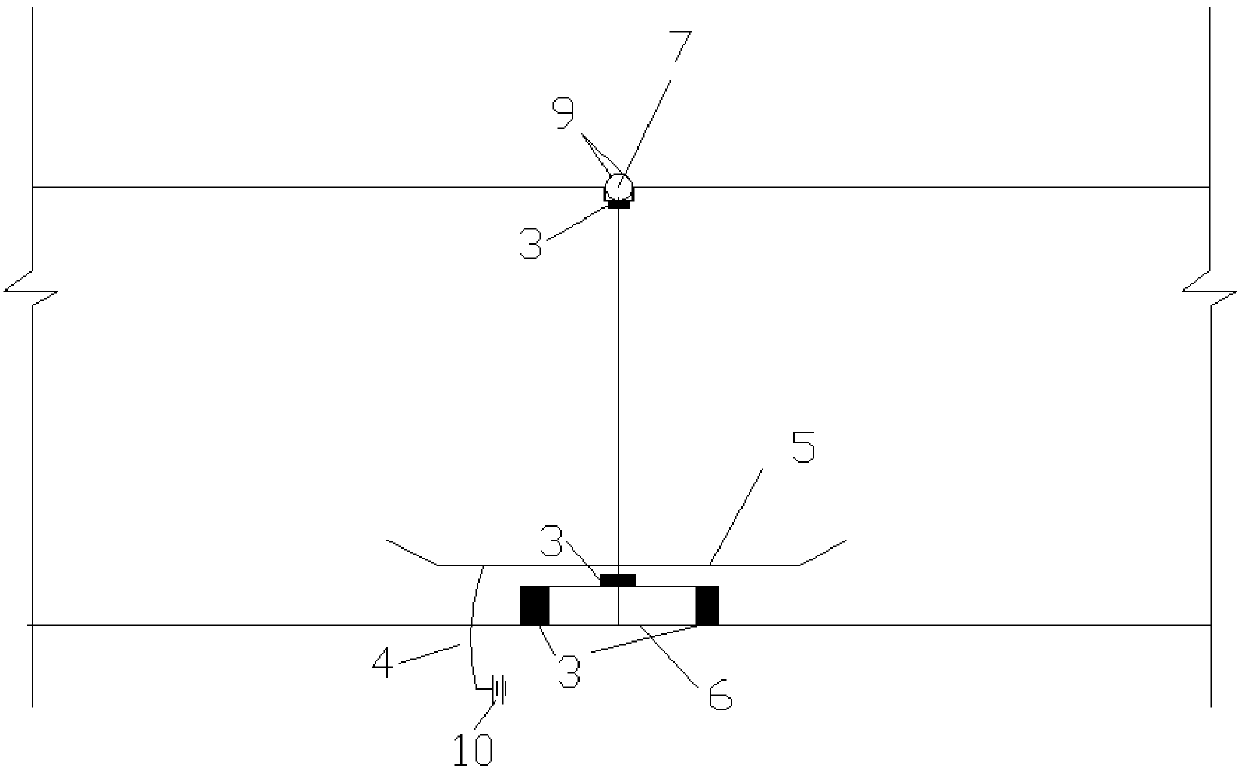

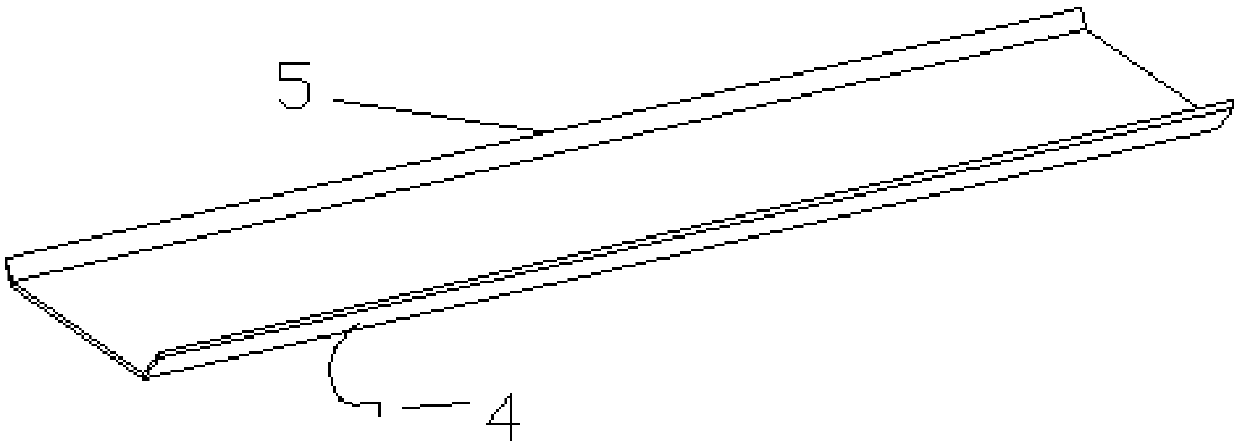

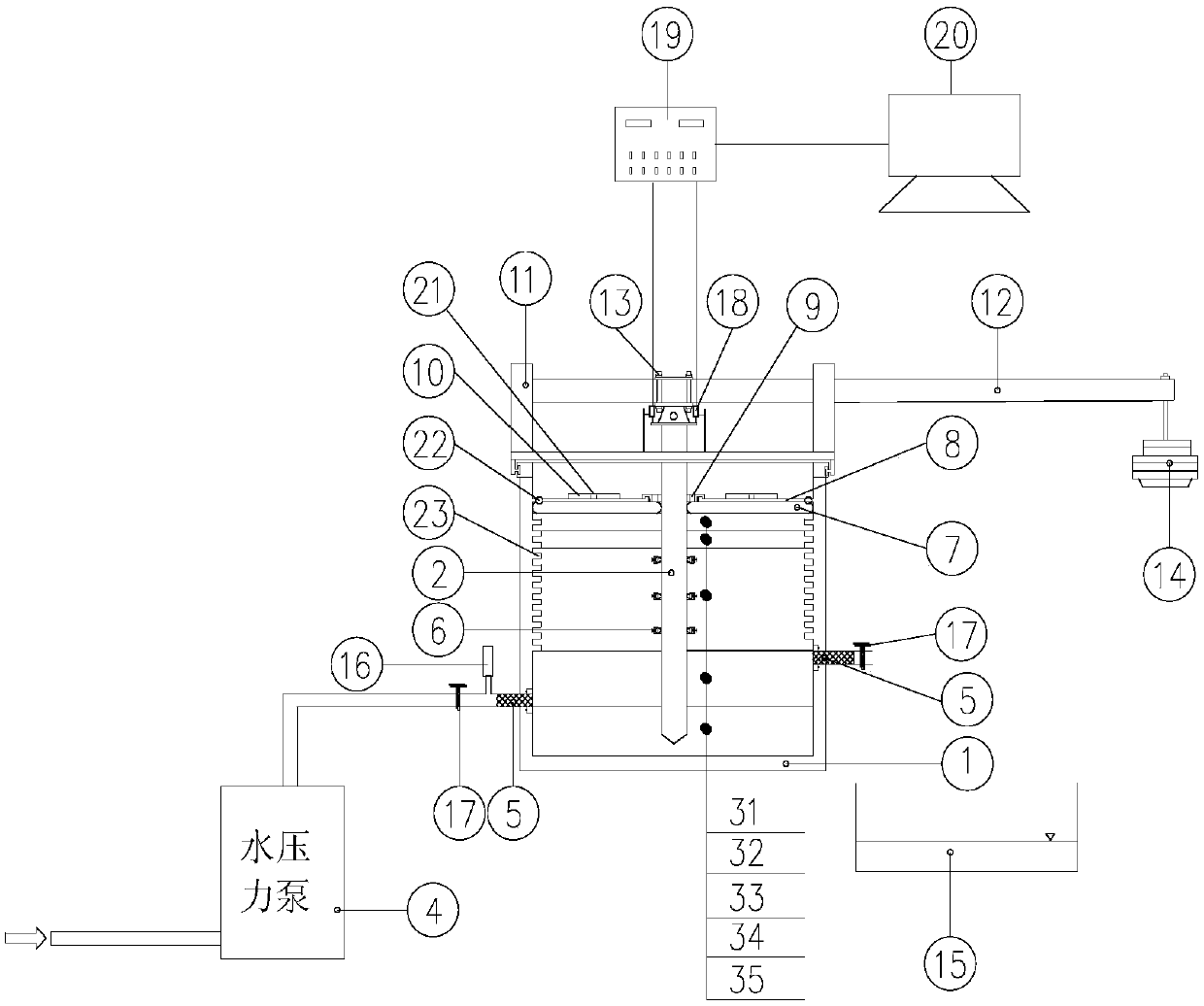

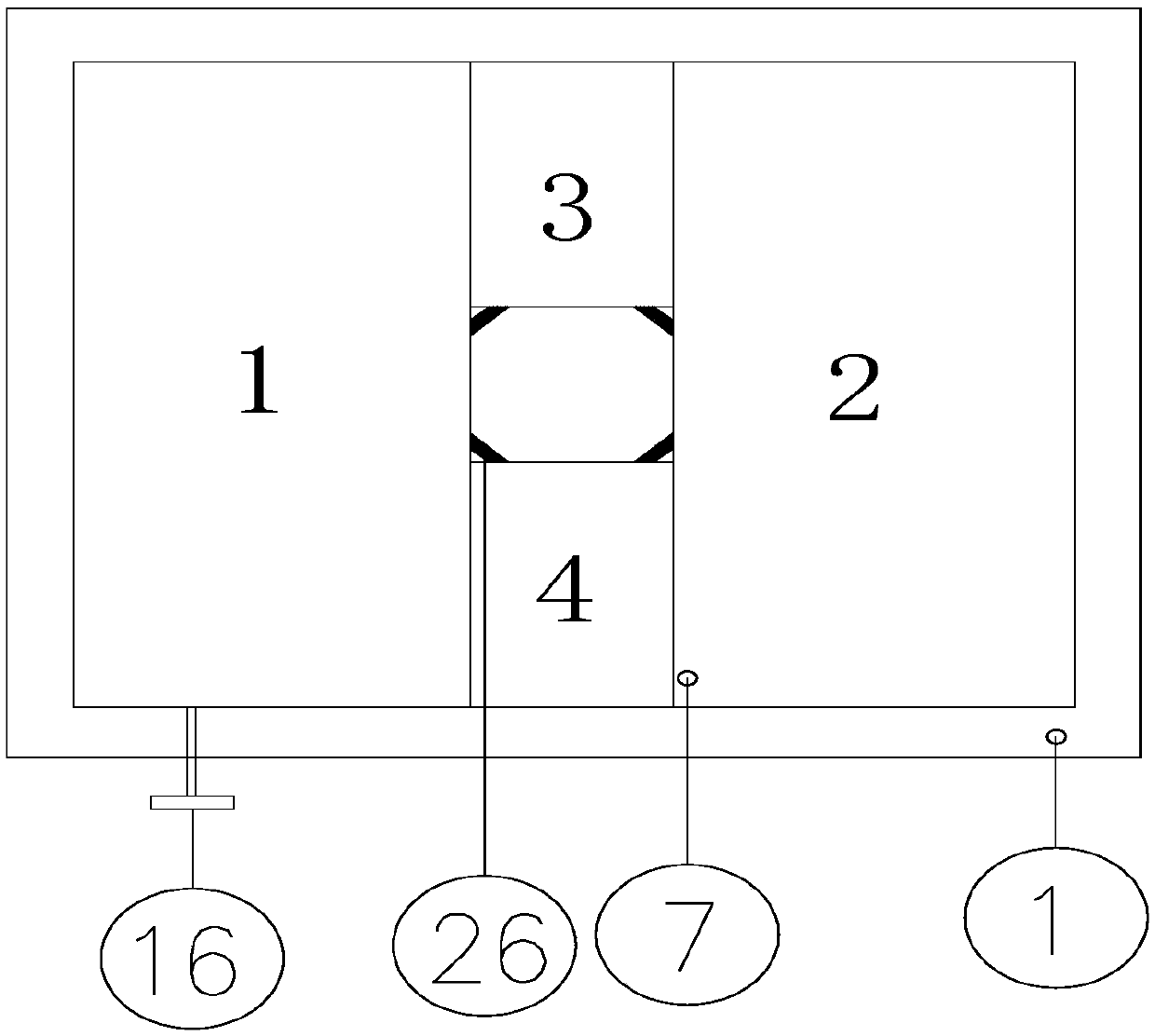

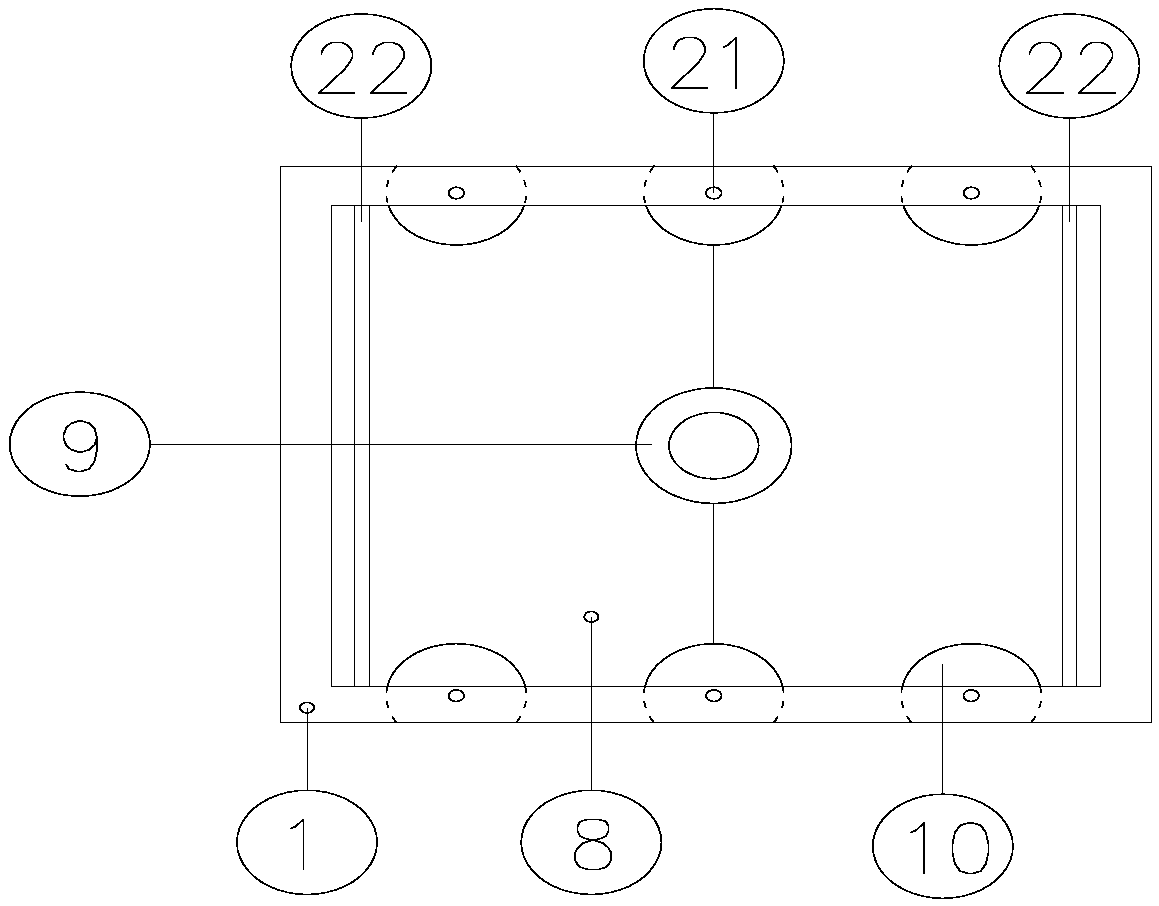

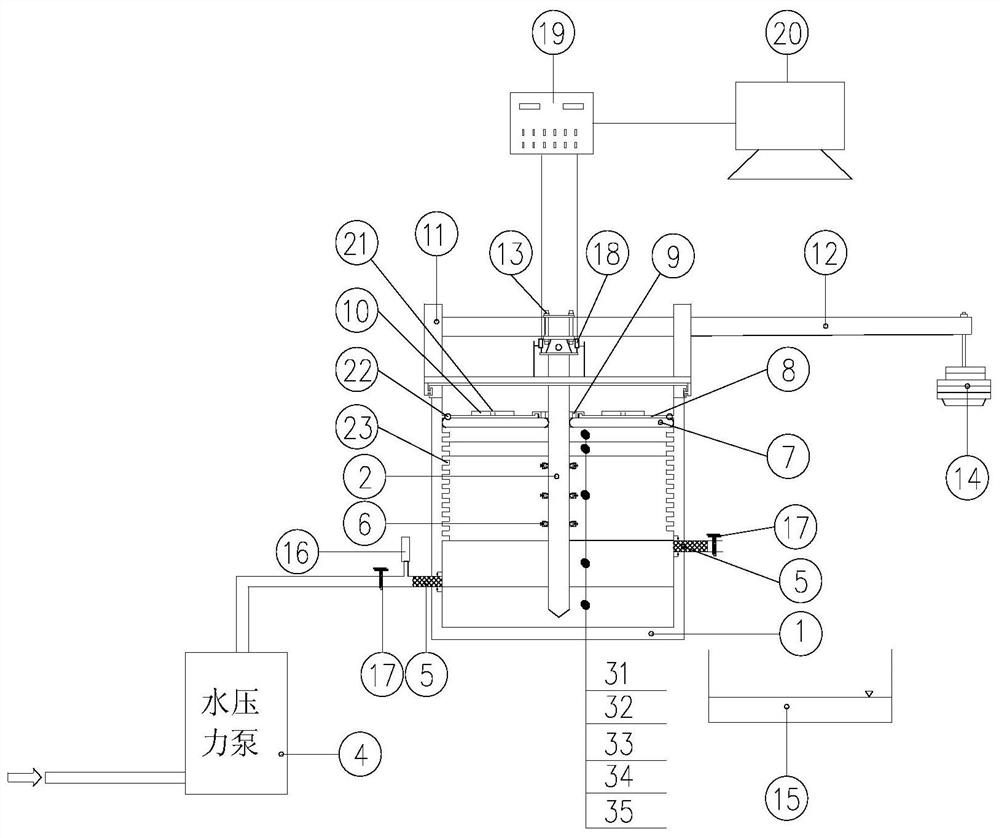

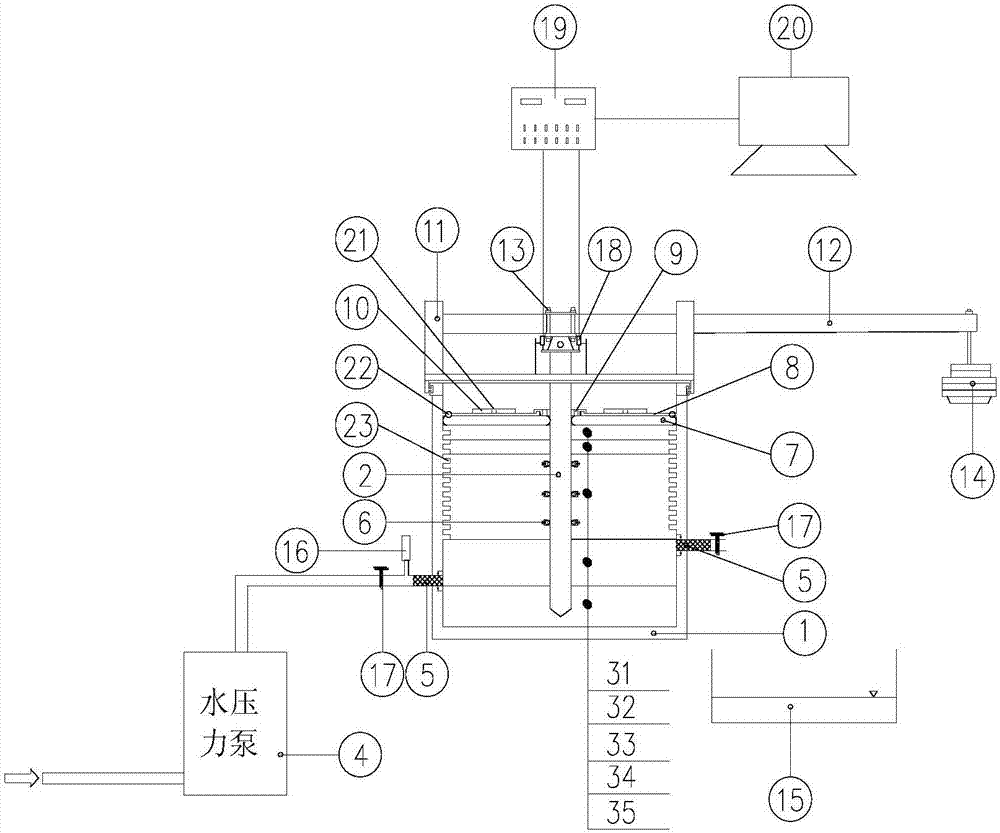

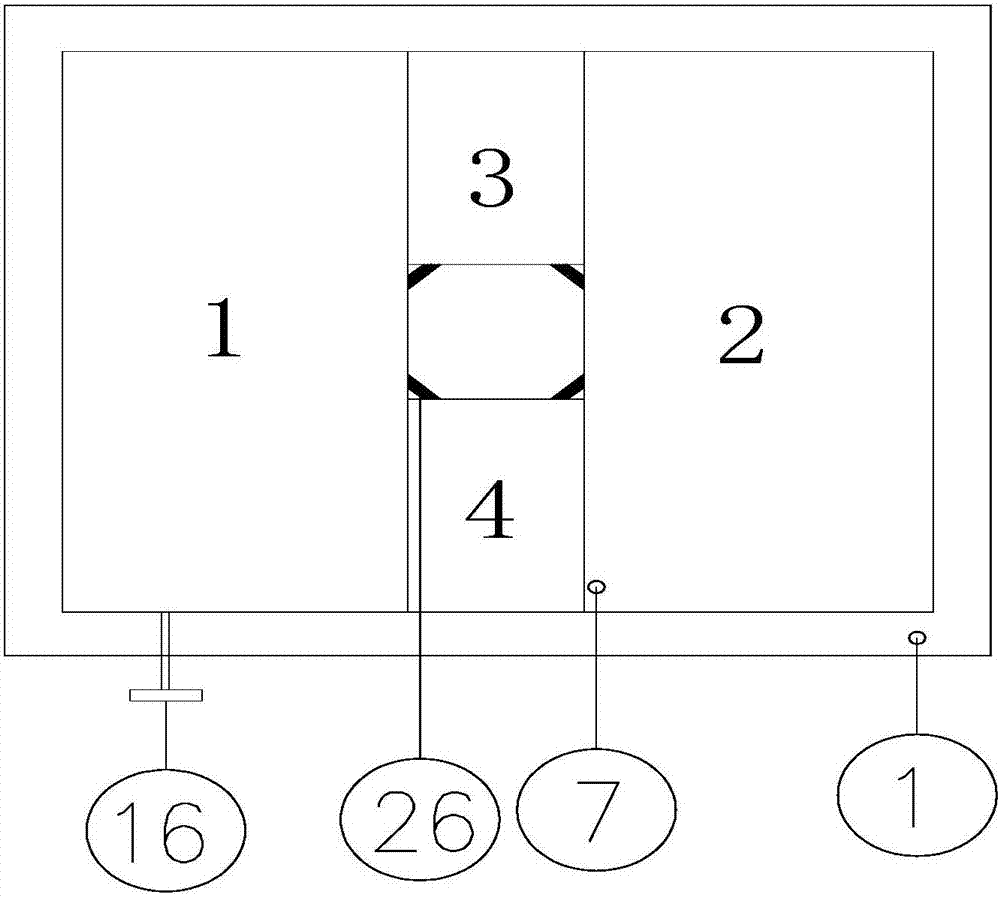

A Test Method for Vertical Static Load Test of Single Pile Under Stable Confined Water Conditions

ActiveCN107165203BIncrease seepage pathAvoid bump damageFoundation testingConfined waterData acquisition

The invention discloses a test method for a single pile vertical static load test under the stable confined water condition. The test method comprises the following steps that (1) the size of a model pile and the thicknesses of soil bodies in a box are determined; (2) the water pressure of a pressure bearing layer is determined; (3) soil layers are paved by layers, and the model pile is buried; (4) force transferring water bags are placed; (5) back pressure plates are placed; (6) a vertical loading system and a data acquisition system are placed; (7) the water pressure of the pressure bearing layer is loaded; (8) the loading level is determined, and graded loading is implemented; (9) the pile top is vertically loaded; (10) the vertical compressive ultimate bearing capacity of the model pile is determined; (11) a test device is disassembled; (12) the vertical bearing capacity characteristic value of the single pile is determined; and (13) the pressure of a confined water layer is adjusted, the water pressure of the pressure bearing layer is increased to the next level, and the steps (2) to (12) are repeated to obtain the characteristic values of the pile foundation vertical bearing capacity under different confined water pressure conditions. The test method is good in effect, convenient to operate, low in cost and short in time.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

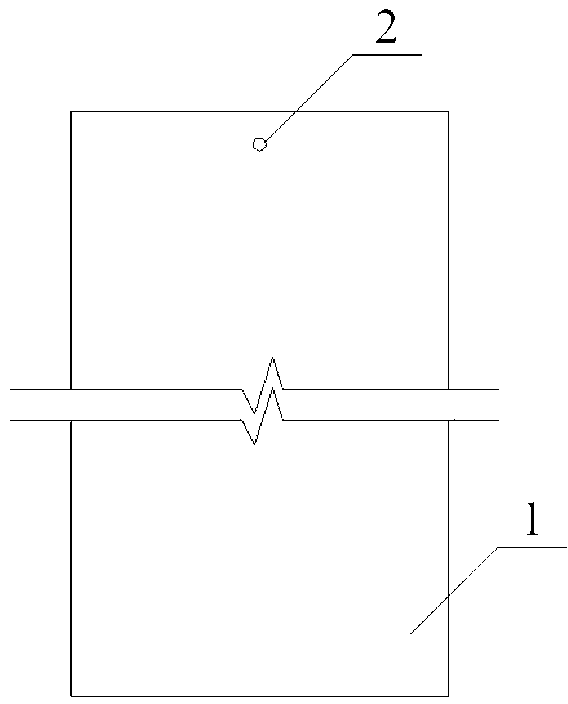

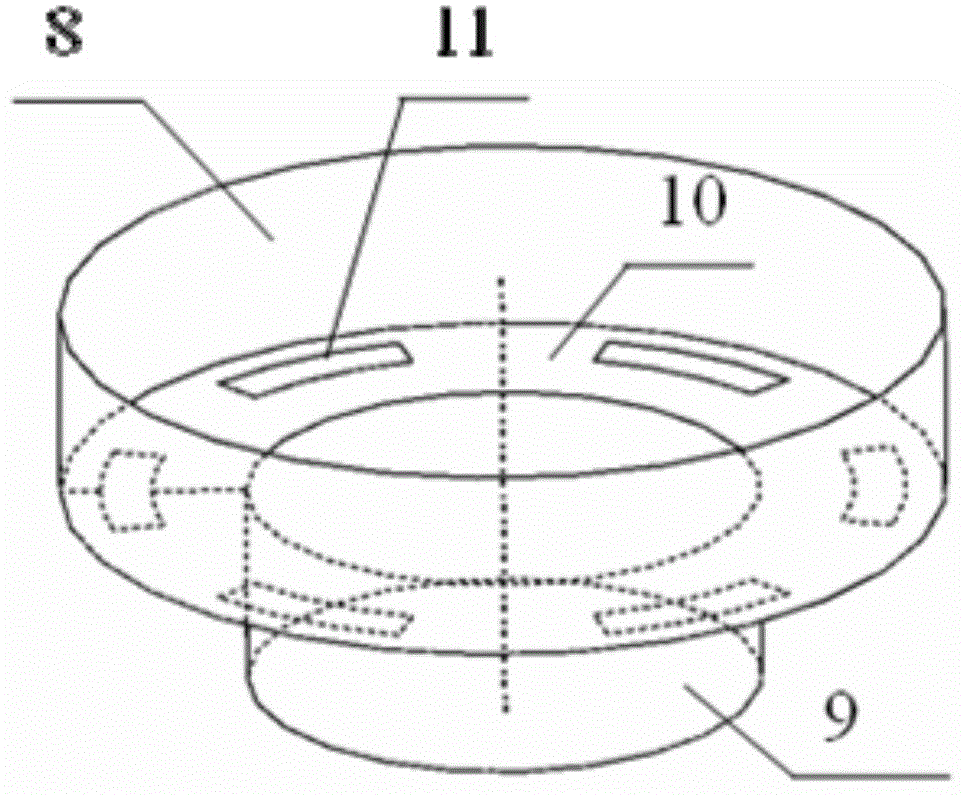

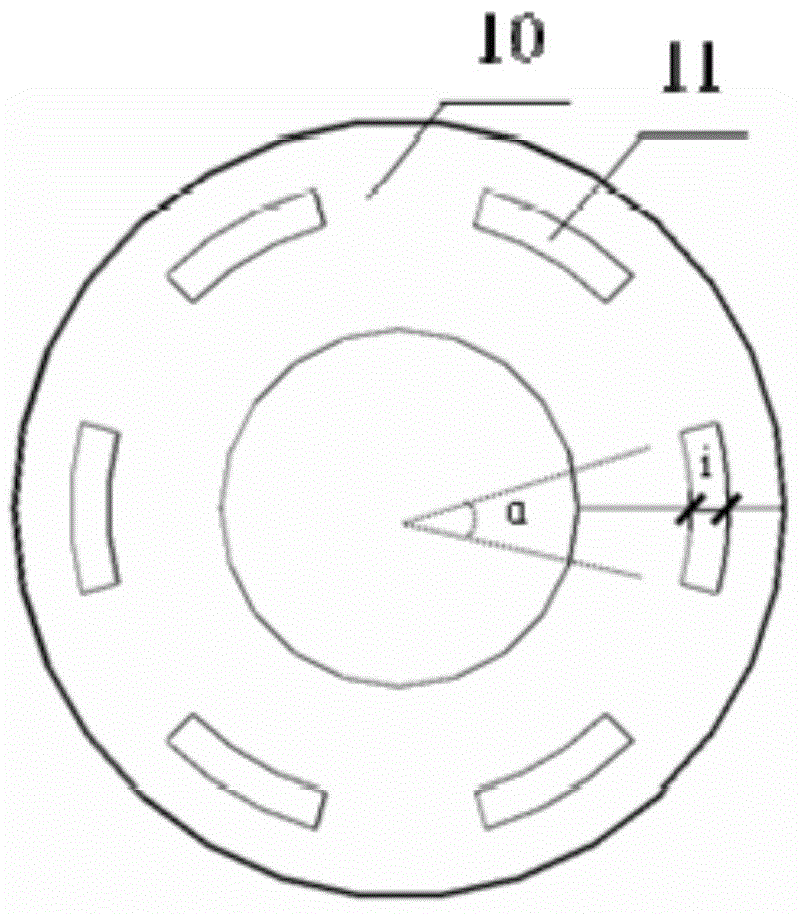

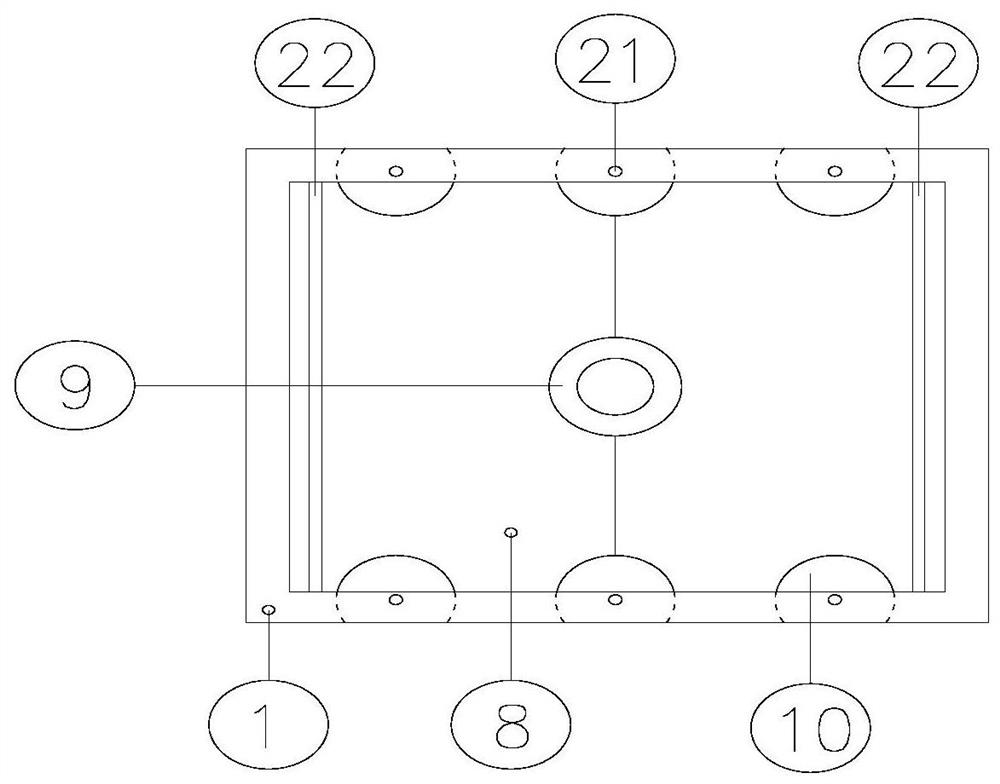

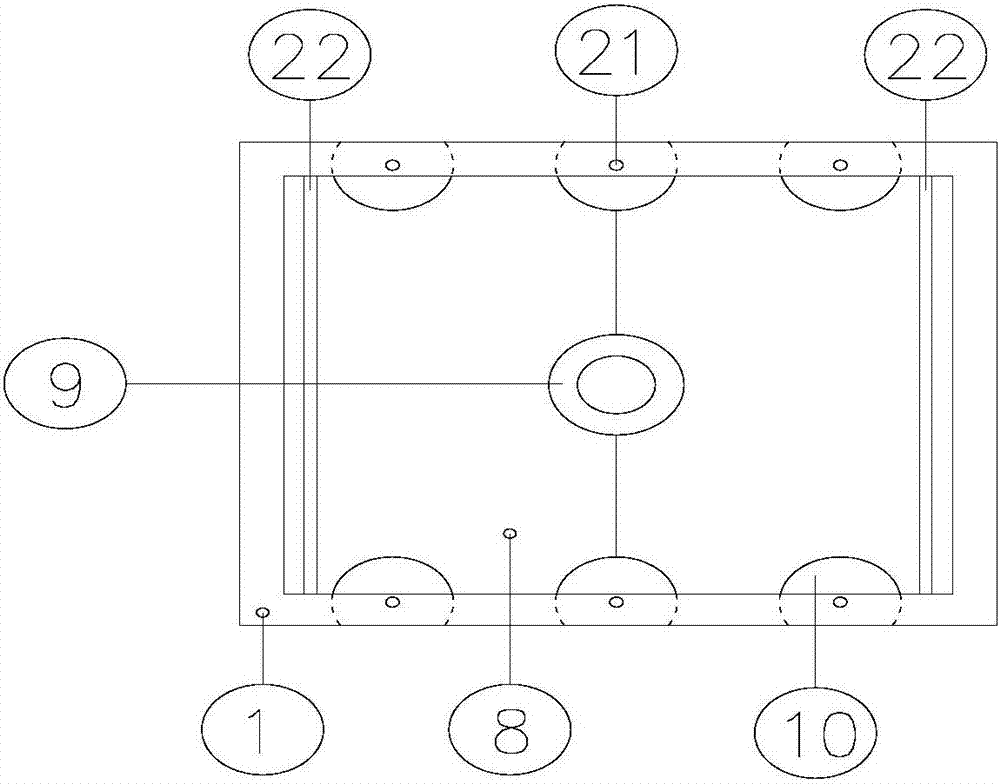

Test device for stabilizing pressure under the condition of single pile vertical static load test

ActiveCN107012898BIncrease seepage pathAvoid bump damageFoundation testingConfined waterData acquisition

A test device for the vertical static load test of a single pile under the condition of stable pressurized water. A model box is laid with soil in the box to simulate a site, and a test single pile is buried in the soil in the box. The vertical loading system includes a reaction force frame, a lever , pile driver and weights, the hydraulic loading system includes a water pump, an inlet anti-filter cartridge, an outlet anti-filter cartridge, a force transfer water bag and a counter-pressure plate, the water outlet of the pump is connected to the anti-filter cartridge, and the imported anti-filter cartridge is installed in the model. On the water inlet of the wall of the box, the outlet anti-filter cartridge is installed on the water outlet of the wall of the model box, the top surface of the soil body in the box is laid with a force-transmitting water bag, and a counter-pressure plate is set on the force-transmitting water bag, and the counter-pressure plate is divided into left and right. Some of them are connected to the rotating shaft, and the left and right counter-pressure plates are connected by a screw cap, and the screw cap passes through the test single pile; the data acquisition system includes a displacement meter, which is located on the top of the test single pile, and the displacement meter is connected with the data acquisition instrument. . The invention has good effect, convenient operation, low cost and short time.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

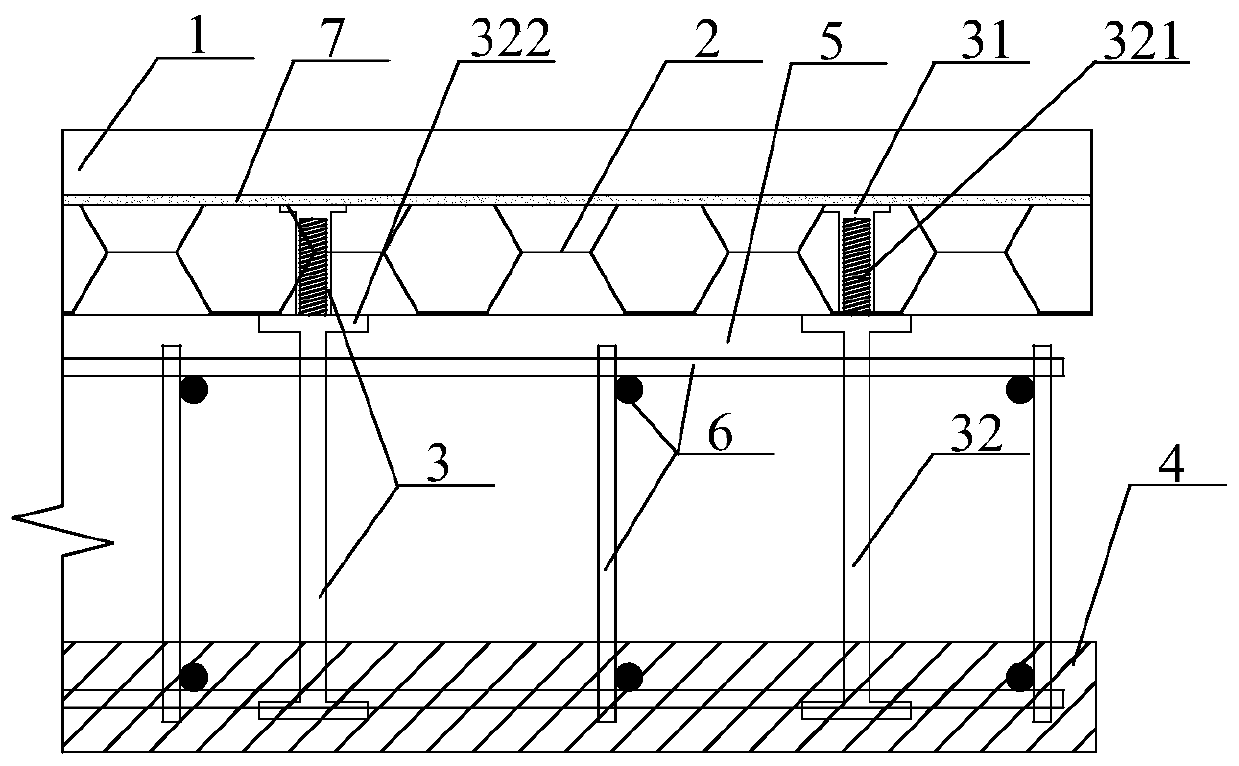

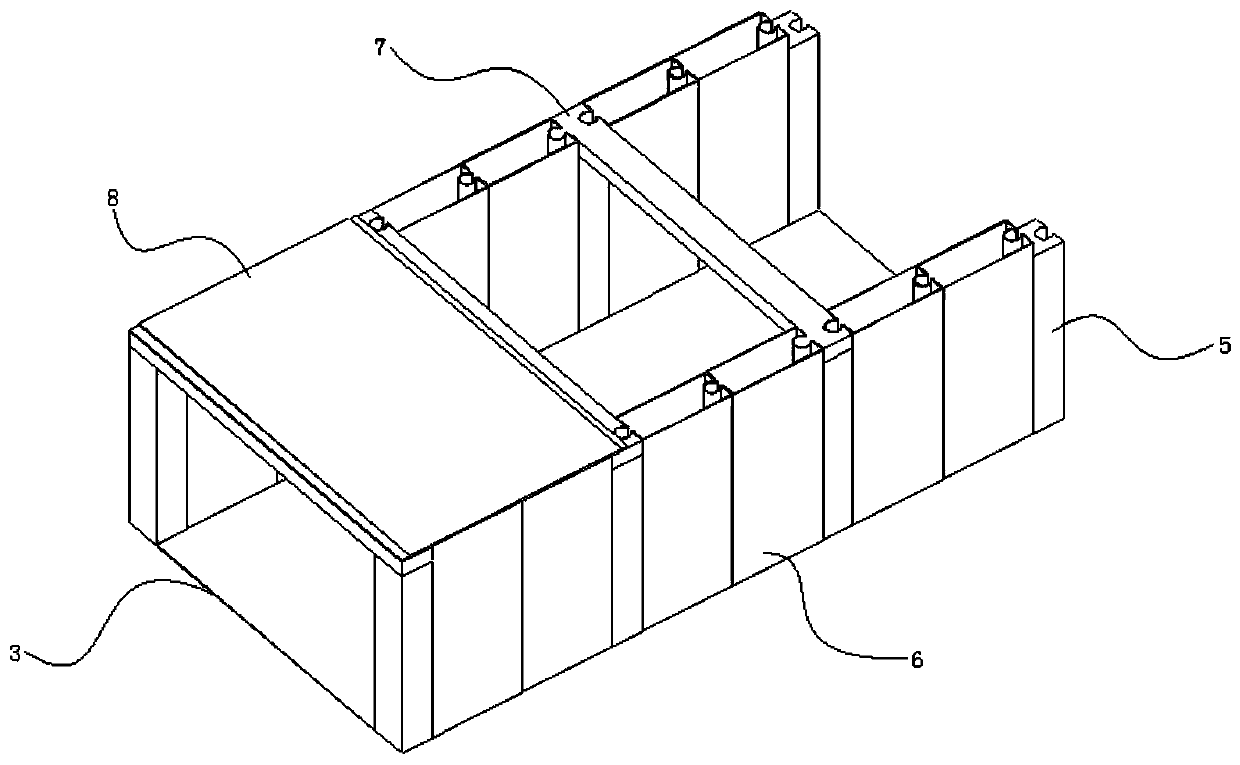

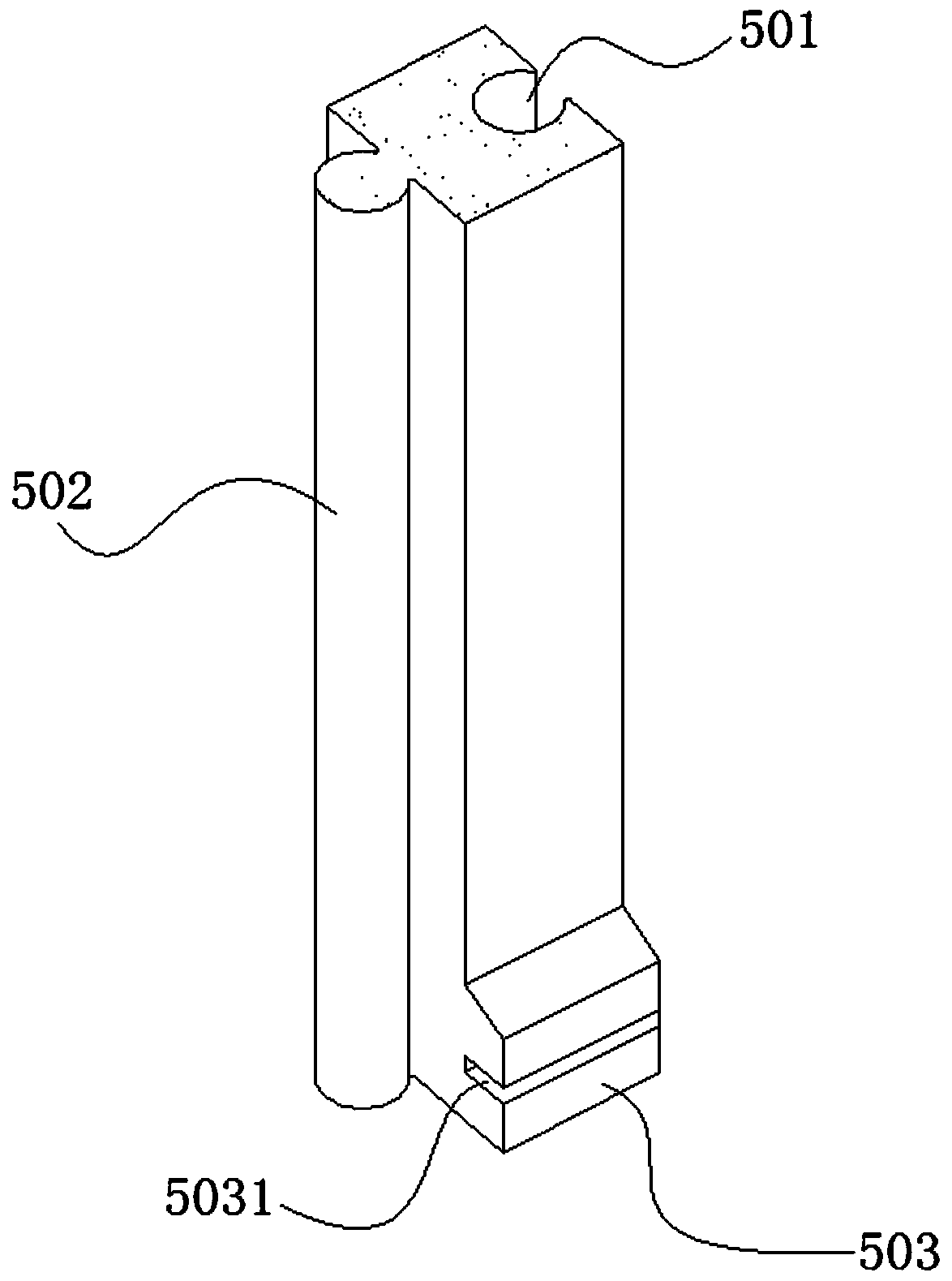

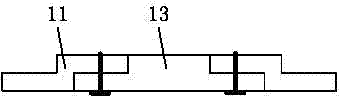

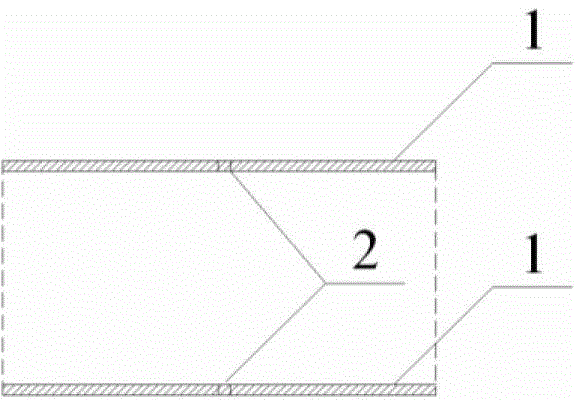

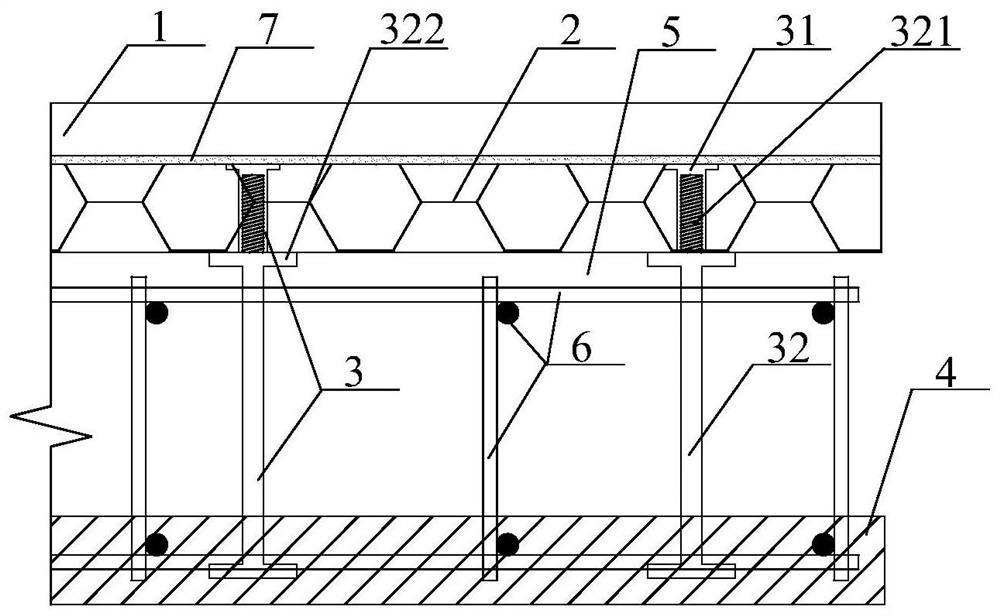

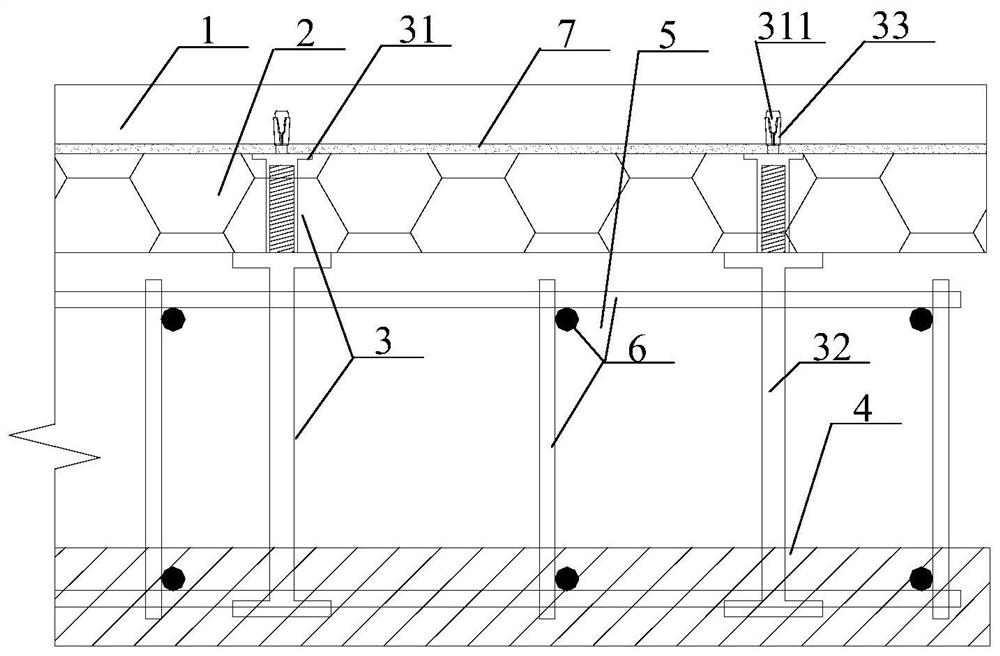

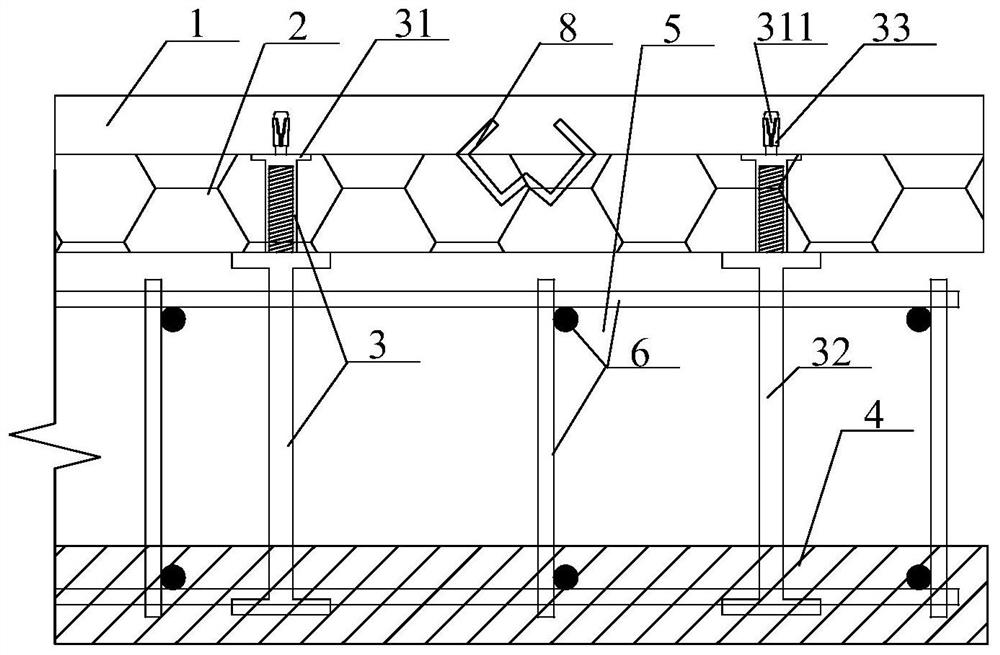

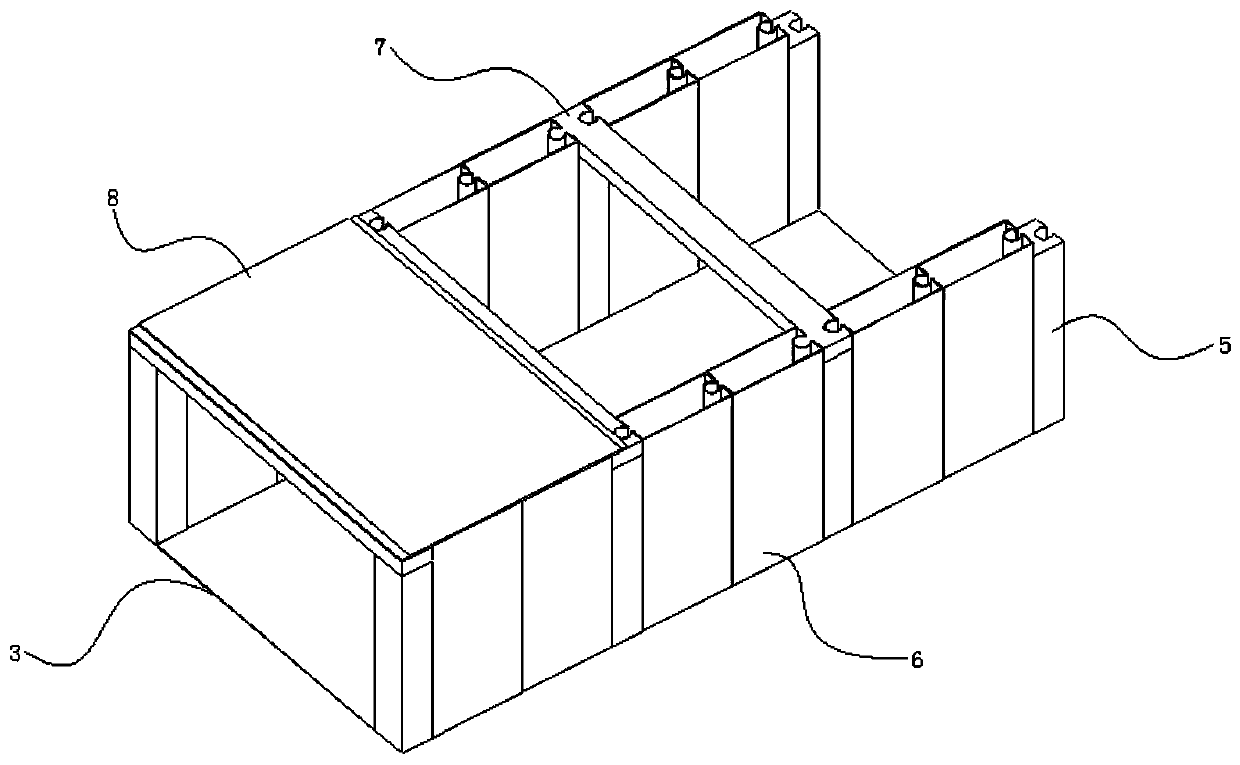

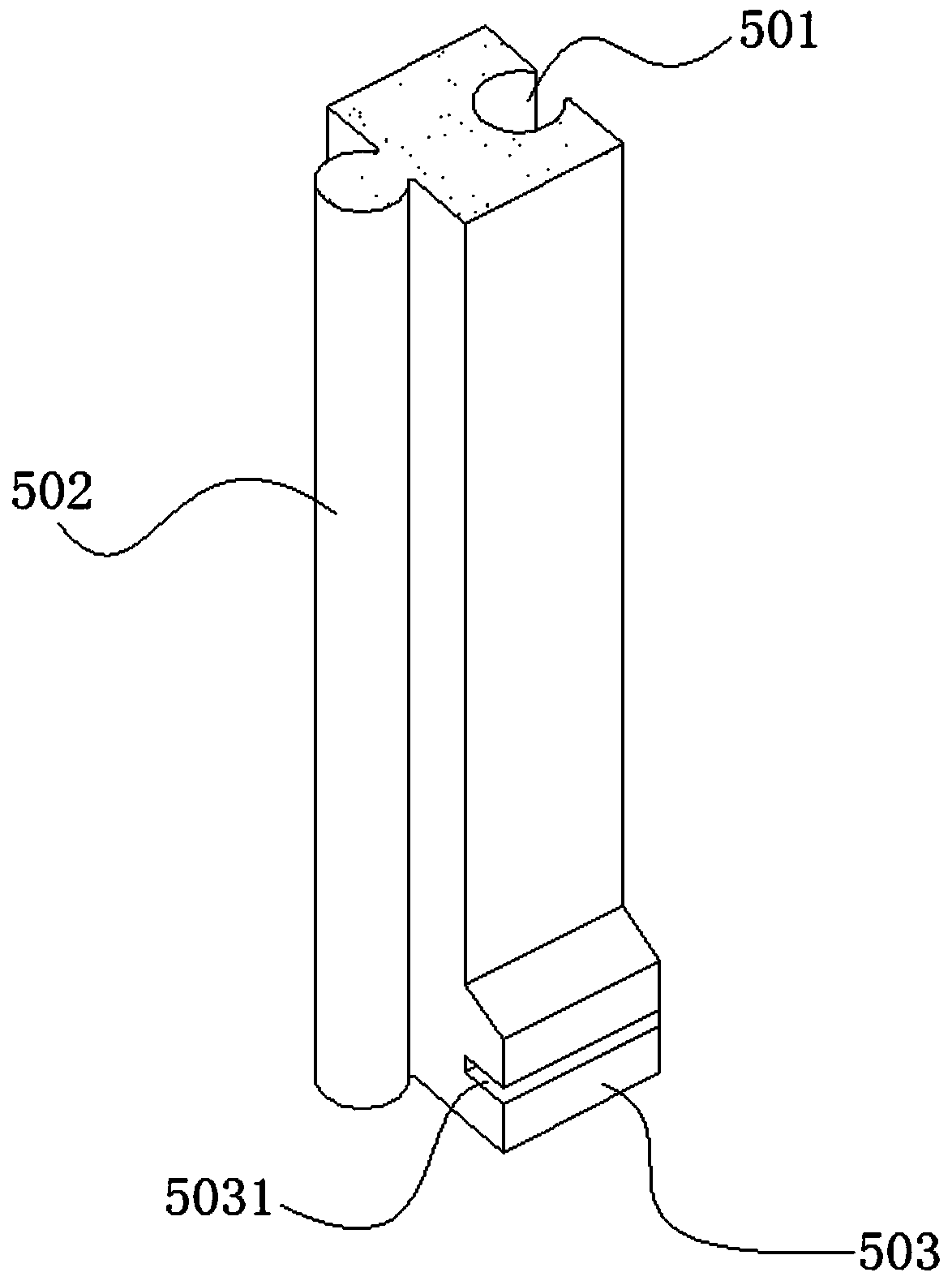

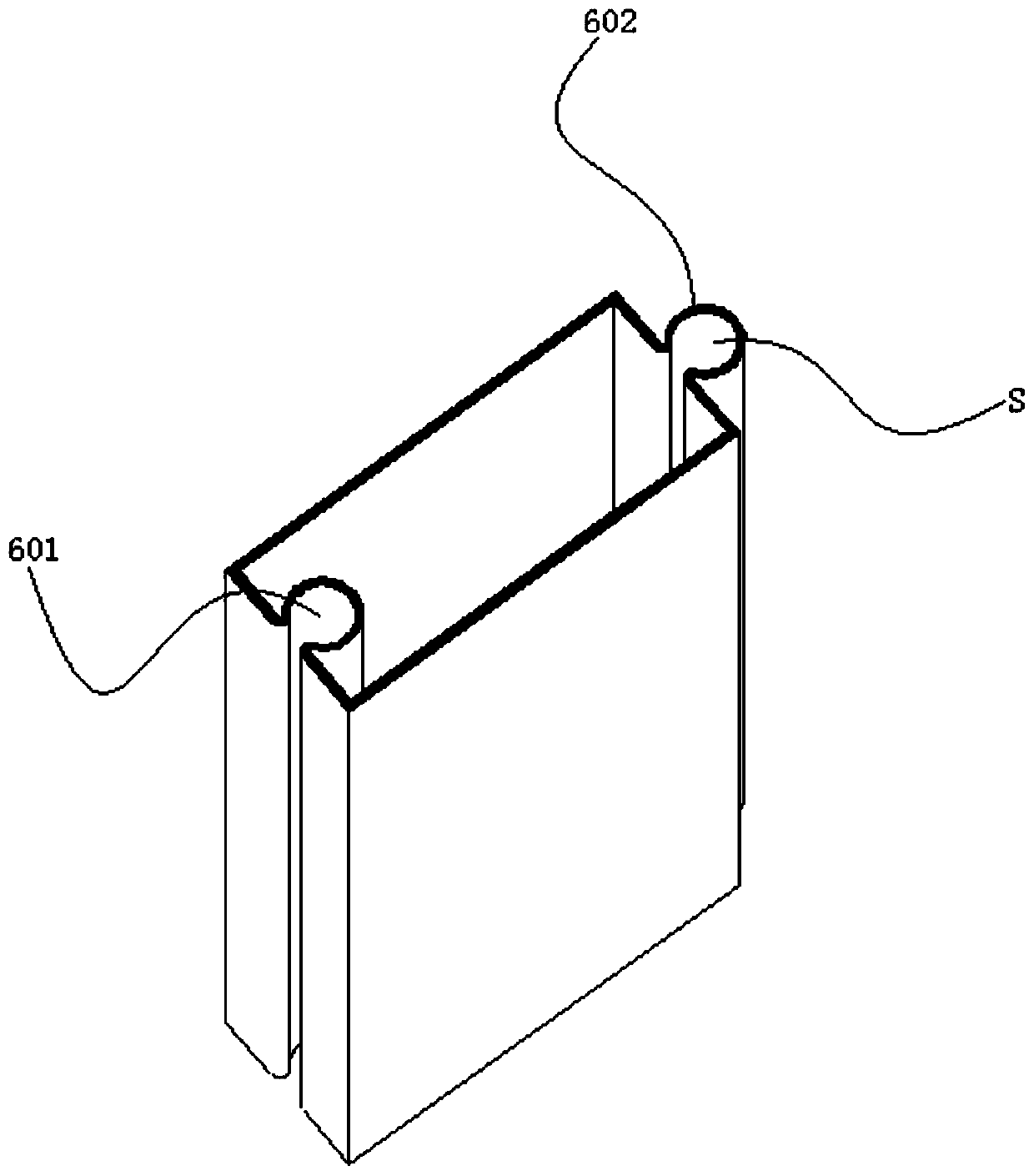

A polymer plastic assembled pipe gallery and its construction method

ActiveCN109914473BHigh strengthReduce weightArtificial islandsUnderwater structuresArchitectural engineeringPipe

The invention provides a high-molecular plastic assembly type pipe gallery and a construction method thereof. The assembly type pipe gallery comprises a bottom plate, a top plate and a plurality of frame components arranged between the bottom plate and the top plate. The bottom plate is paved on a cushion layer at the bottom of the pipe gallery. The top plate is arranged above the bottom plate inparallel. The frame components, the bottom plate, side plates and the top plate define a pipe gallery channel. The construction method of the assembly type pipe gallery comprises the steps of site leveling, foundation pit excavation, cushion layer construction, bottom plate installation, stand column construction, side plate installation, cross beam installation, top plate installation, water stoptreatment, soil mass backfilling and the like. The assembly type pipe gallery adopts industrialized large-scale production and mechanized construction, and is high in efficiency, short in construction period and low in construction cost. The pipe gallery is good in structural integrity, a seepage path is additionally arranged, and thus the good seepage prevention performance is achieved.

Owner:CHONGQING UNIV

Coal mine underground reservoir box type retaining dam

ActiveCN110905600BIncrease the bearing areaImprove integrityBarrages/weirsMining devicesWater sourceStructural engineering

The invention discloses a box type water retaining dam for a coal mine underground reservoir. The box type water retaining dam is located between coal pillar dam bodies on the left side and the rightside of a roadway and used for isolating the underground reservoir and the roadway and blocking a water source in the underground reservoir. The box type water retaining dam comprises a main dam bodyand water retaining wings, wherein the main dam body is of a box type structure, the left side and the right side of the main dam body are embedded in the coal pillar dam bodies on the two sides, thetop of the main dam body is embedded in roadway roof surrounding rock, and the bottom of the main dam body is embedded in roadway bottom plate surrounding rock; and the water retaining wings compriseside wings, the side wings are connected with the left side and the right side of the main dam body and arranged along at least the whole height range of the main dam body, the side wings are embeddedinto the coal pillar dam bodies on the two sides to a certain depth, and thus side wing seepage prevention areas are formed. The box type water retaining dam can reduce crippling and water seepage caused by excessive local stress of the surrounding rock at the same time, adjusts differential settlement, prevents the surrounding rock from being softened due to water entering, and ensures the stability and safety of the dam bodies.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

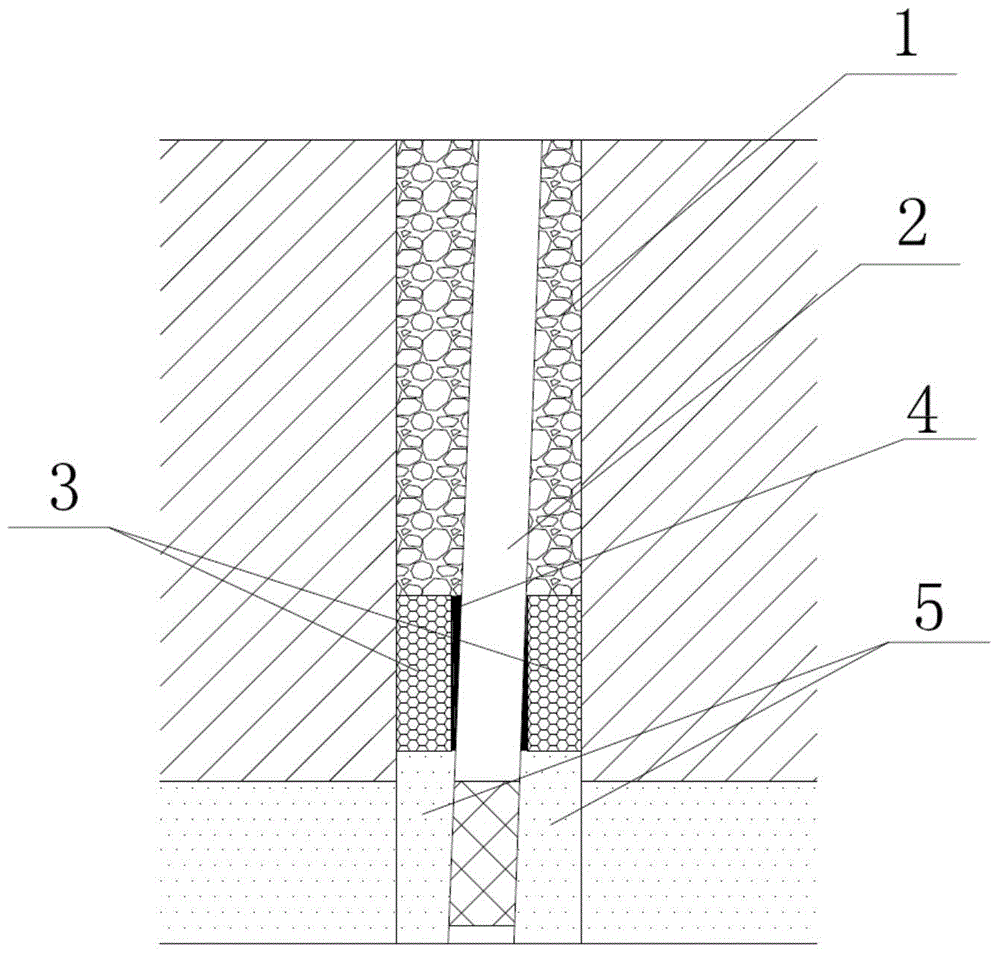

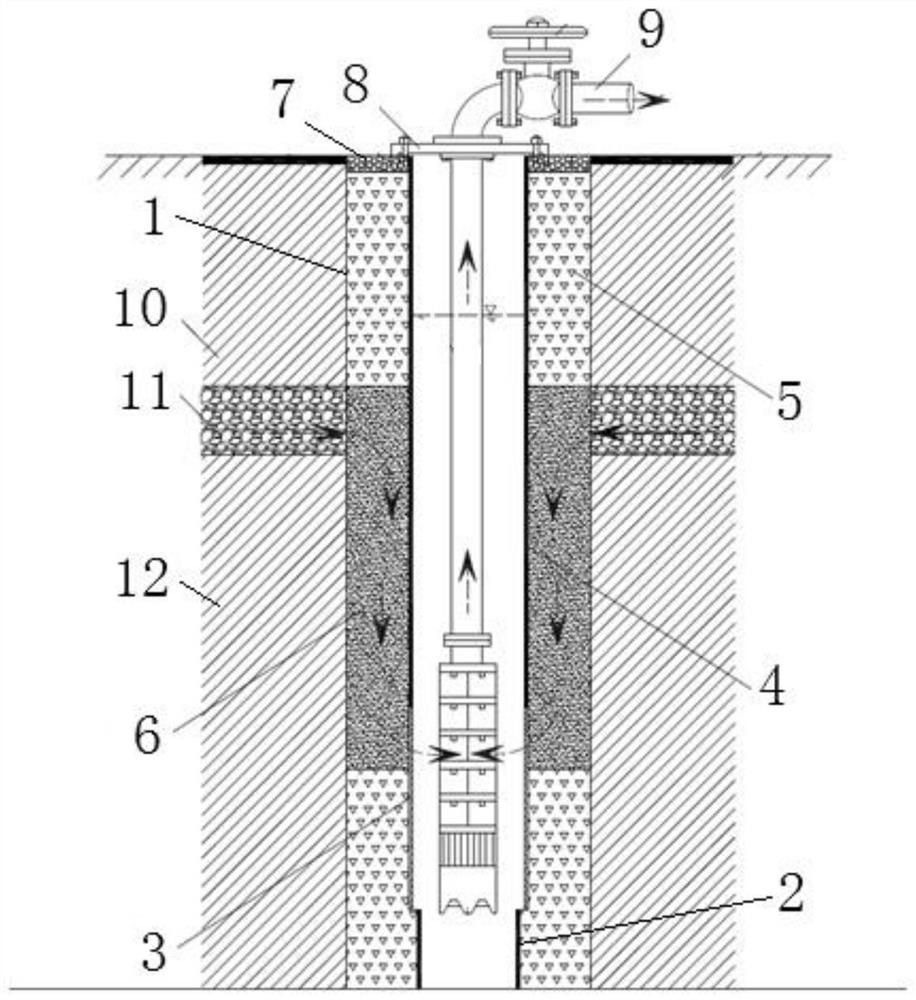

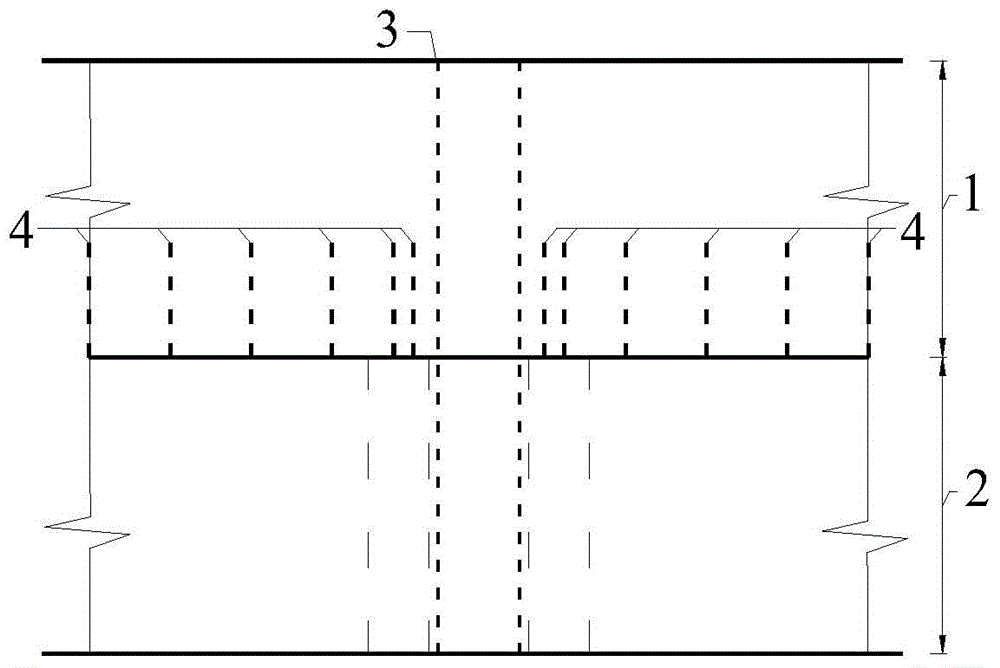

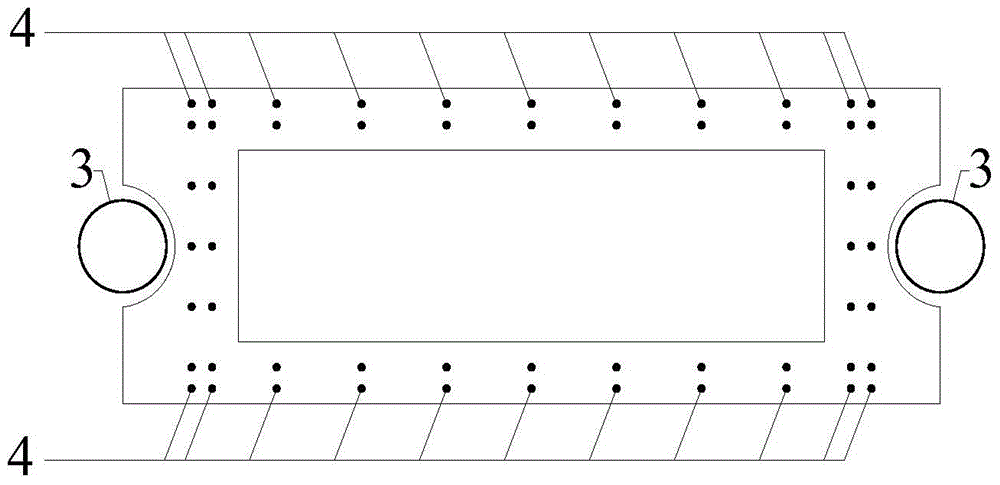

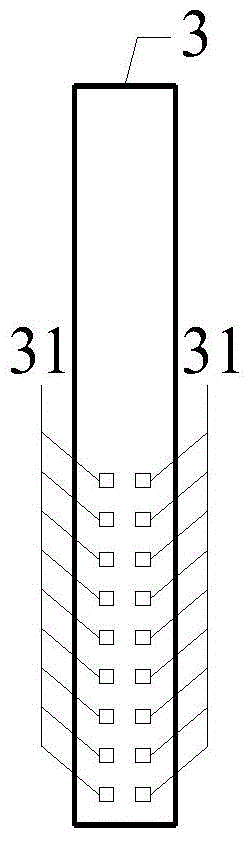

Underground water in-situ remediation device and method for enlarging seepage path

PendingCN114524533AIncrease seepage pathWater contaminantsContaminated soil reclamationSolid wallWater filter

The invention provides an underground water in-situ remediation device capable of enlarging a seepage path. The underground water in-situ remediation device comprises an outer wall pipe, a lower solid wall pipe, a water filtering pipe and an upper solid wall pipe, wherein the space between the outer wall pipe and the lower solid wall pipe is filled with a filter material, the space between the outer wall pipe and the lower half part of the water filter pipe is filled with a filter material, the space between the outer wall pipe and the upper half part of the water filter pipe is filled with a PRWB material, and the space between the outer wall pipe and the lower half part of the upper solid wall pipe is filled with a PRWB material. And a filter material is filled between the outer wall pipe and the upper half part of the upper solid wall pipe.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

A semi-prefabricated underground diaphragm wall and its construction method

InactiveCN104895093BAvoid prone to disadvantagesAvoid Serious Quality IssuesExcavationsBulkheads/pilesSlurry wallReinforced concrete

Owner:SOUTHEAST UNIV

An upper and lower cross tunnel shock absorption structure and construction method thereof

ActiveCN105003283BImprove seismic performanceImprove clearanceUnderground chambersTunnel liningCushioningStructure of the Earth

The invention discloses a shock-absorbing structure for an up and down crossing tunnel, which includes a lining segment structure surrounding the inner layer of the tunnel under construction, and the lining segment structure consists of a short Z-shaped segment, a tall Z-shaped segment and a T The tunnel under construction is stacked at a certain distance from the original tunnel, and the high Z-shaped segment is stacked to make the tunnel under construction produce a small inclination angle and increase the distance between the tunnel under construction and the original tunnel. Clear height difference, a shock-absorbing layer is set on the side close to the original tunnel at a certain distance from the construction of the tunnel under construction to the original tunnel. The invention has the advantages of strong anti-seismic performance, high safety, and can reduce the vibration influence of traffic vehicles on the tunnel structure.

Owner:NANJING GEOTECHNICAL & UNDERGROUND SPACE TECH CO LTD

Connection method of prefabricated piles in foundation pit and stirrups of cast-in-place laminated lining walls

ActiveCN105040677BIncreased shear strengthSolve quality problemsBulkheads/pilesStructural engineeringEngineering

The invention discloses a connecting method of a foundation pit precast pile and a cast-in-situ superposed lining wall through stirrups. The method includes the following steps that after the size of the precast pile is determined according to design, a main rib and the stirrups of the pile are arranged, a connecting steel plate is arranged on the joint of the pile stirrups and the wall stirrups along a pile body, and pile connecting holes and wall connecting holes are formed in the connecting steel plate; connecting ribs of the pile stirrups are fixedly connected with the connecting steel plate through the pile connecting holes, and the wall connecting holes are plugged through plugging materials; pile concrete is poured, the precast pile is beaten into the designed position of a foundation pit after the designed strength is achieved through curing, the plugging materials are removed after excavation of the foundation pit is completed, and the wall connecting holes are exposed; and according to the design requirement, the main rib, the stirrups and a bent rib are arranged at the corresponding positions of a cast-in-situ wall, connecting ribs of the wall stirrups in the cast-in-situ wall are fixedly connected with the connecting steel plate through the wall connecting holes, concrete of the cast-in-situ wall is poured after connection is completed, and connection of the precast pile and the cast-in-situ superposed wall is completed.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Underground diaphragm wall plate-type rigid joint and construction method thereof

ActiveCN103306312BEnhanced lateral bending resistanceSimple designArtificial islandsUnderwater structuresSlurry wallEngineering

The invention discloses an underground diaphragm wall rigid baffle joint and a construction method thereof, and relates to a rigid baffle joint mode and a construction method thereof. The rigid baffle joint (8) consists of two rigid baffles (1) and a rigid bottom plate (3), wherein a latch pipe (5) is arranged between the two rigid baffles (1); second connecting piece clamping grooves (7) are formed in the side surface of the latch pipe (5); first connecting piece clamping grooves (2) are formed in the side surfaces of the rigid baffles (1); the two rigid baffles (1) are connected with the latch pipe (5) by the first connecting piece clamping grooves (2) and the second connecting piece clamping grooves (7); steel bar end sockets (6) are arranged on the bottom surface of the latch pipe (5); steel bar clamping grooves (4) are formed in the rigid bottom plate (3); and the steel bar ends are fitted with the steel bar clamping grooves (4) to connect the latch pipe (5) with the rigid bottom plate (3). The rigid baffle joint is simple to design and manufacture; accurate contraposition of steel bar cages of adjacent walls is realized; the wall integrity is improved; the lateral bending resistance of the joint is improved; and a percolation path is increased.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

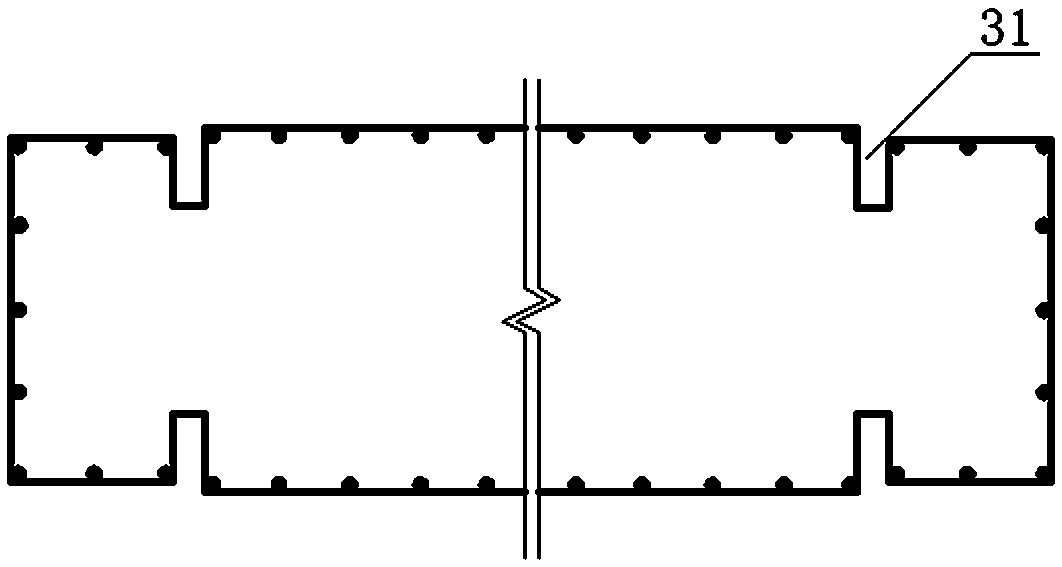

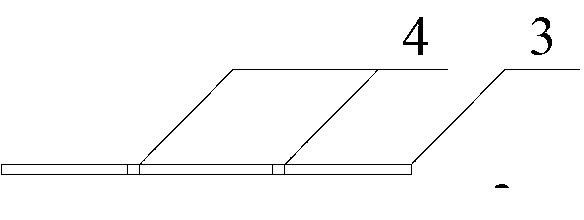

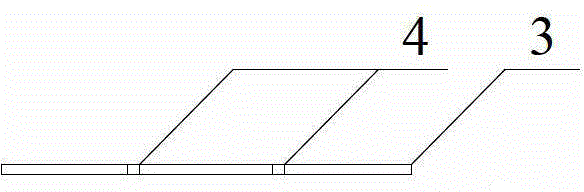

H-shaped steel sheet pile with bidirectional locking openings for combined steel sheet pile

PendingCN113638400AIncrease seepage pathImprove anti-seepage performanceBulkheads/pilesSteel platesFoundation engineering

The invention provides an H-shaped steel sheet pile with bidirectional locking openings for a combined steel sheet pile, and belongs to the technical field of sheet pile walls, piles or other structural components for steel foundation engineering. The H-shaped steel sheet pile comprises a web and a wing plate mounted at the end of the web, and is characterized in that inner hooks or outer hooks are arranged at two ends of the wing plate, and the tail end of the wing plate is bent upwards and downwards to form a hook-shaped structure. The H-shaped steel sheet pile is applied to machining of sheet pile walls and the like, and has the advantages of high rigidity, flexible combination modes and the like.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD +1

Test device of single-pile vertical static test under stable pressure bearing water condition

Disclosed is a test device of a single-pile vertical static test under the stable pressure bearing water condition. In-box soil in a simulation site is laid in a model box, a test single pile is embedded in the in-box soil, a vertical loading system comprises a reaction frame, a lever, a pile pressing device and weights, a water pressure loading system comprises a water pump, an inlet inverse filtering core cylinder, an outlet inverse filtering core cylinder, a force transmission water bag and a back pressure plate, a water outlet of the water pump is connected with the inverse filtering core cylinder, the inlet inverse filtering core cylinder is mounted on a water inlet in the wall face of the model box, the outlet inverse filtering core cylinder is mounted on a water outlet of the wall face of the model box, the force transmission water bag is laid on the top face of the in-box soil, the back pressure plate is arranged on the force transmission water bag, and comprises a left portion and a right portion, the left portion and the right portion are both connected with a rotating shaft, the left portion and the right portion of the back pressure plate are connected through a rotating cover, and the rotating cover penetrates a test single pile. A data collection system comprises a displacement meter, the displacement meter is located on the top of the test single pile, the displacement meter is connected with a data collection instrument, and the device is good in effect, convenient to operate, low in cost and short in time.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

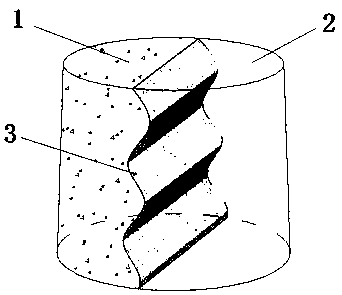

ECC-concrete interface treating method

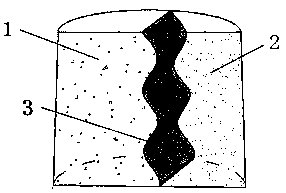

InactiveCN108914980AAvoid crackingImprove impermeabilityArtificial islandsClimate change adaptationHydraulic structureCementitious composite

The invention discloses an ECC (Engineering Fiber Reinforced Cementitious Composites)-concrete interface treating method and belongs to the field of tunnel and underground concrete structure and hydraulic structure engineering technology. An interface is parallel to a water penetration direction, and an ECC-concrete sample is partitioned by a corrugated plate during pouring, so that an ECC-concrete interface is corrugated. The ECC-concrete interface is brushed with an interface agent, so that the ECC-concrete bonding area is increased, a longer penetration path is obtained, and accordingly, the interface penetration performance is improved. By adoption of the ECC-concrete interface treating method, the durability of tunnel and underground concrete structures and hydraulic concrete structures can be effectively improved.

Owner:KUNMING UNIV OF SCI & TECH

Prefabricated laminated member and production method thereof, and prefabricated laminated wall and construction method thereof

ActiveCN111236499BHigh degree of industrializationReduce wet workWallsHeat proofingThermal insulationRebar

The invention belongs to the field of building exterior walls, and discloses a prefabricated laminated member and a production method thereof, as well as a prefabricated laminated wall and a construction method thereof. A prefabricated composite component, comprising: a decorative panel and a thermal insulation board connected to each other; a reinforcing bar cage connected with an inner leaf plate; a plurality of connecting components connecting the thermal insulation board and the inner leaf A cavity is formed, and the reinforcement cage is partially located in the cavity; the connecting component includes a built-in component arranged in the thermal insulation board, and an assembled component connected with the built-in component; the assembled component is partially arranged inside the inner blade and partially located in the cavity The assembly part also includes a first connecting segment connected with the built-in part; and an inner limiting piece connected with the first connecting segment, the inner limiting piece is located in the cavity and abuts against the insulation board, and the diameter of the inner limiting piece is larger than the diameter of the inner limiting piece. part of the side connection. The solution of the invention solves the problem of heat preservation and exterior decoration integration of the double-sided laminated exterior wall, and the production and construction processes are simple and efficient.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

High-molecular plastic assembly type pipe gallery and construction method thereof

ActiveCN109914473AImprove integrityIncrease seepage pathArtificial islandsUnderwater structuresStructural integrityCushion

The invention provides a high-molecular plastic assembly type pipe gallery and a construction method thereof. The assembly type pipe gallery comprises a bottom plate, a top plate and a plurality of frame components arranged between the bottom plate and the top plate. The bottom plate is paved on a cushion layer at the bottom of the pipe gallery. The top plate is arranged above the bottom plate inparallel. The frame components, the bottom plate, side plates and the top plate define a pipe gallery channel. The construction method of the assembly type pipe gallery comprises the steps of site leveling, foundation pit excavation, cushion layer construction, bottom plate installation, stand column construction, side plate installation, cross beam installation, top plate installation, water stoptreatment, soil mass backfilling and the like. The assembly type pipe gallery adopts industrialized large-scale production and mechanized construction, and is high in efficiency, short in construction period and low in construction cost. The pipe gallery is good in structural integrity, a seepage path is additionally arranged, and thus the good seepage prevention performance is achieved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com