H-shaped steel sheet pile with bidirectional locking openings for combined steel sheet pile

A combined steel sheet pile and two-way locking technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of single combined steel sheet pile and cannot adapt to structural walls, etc., to improve the anti-seepage performance and increase the seepage path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

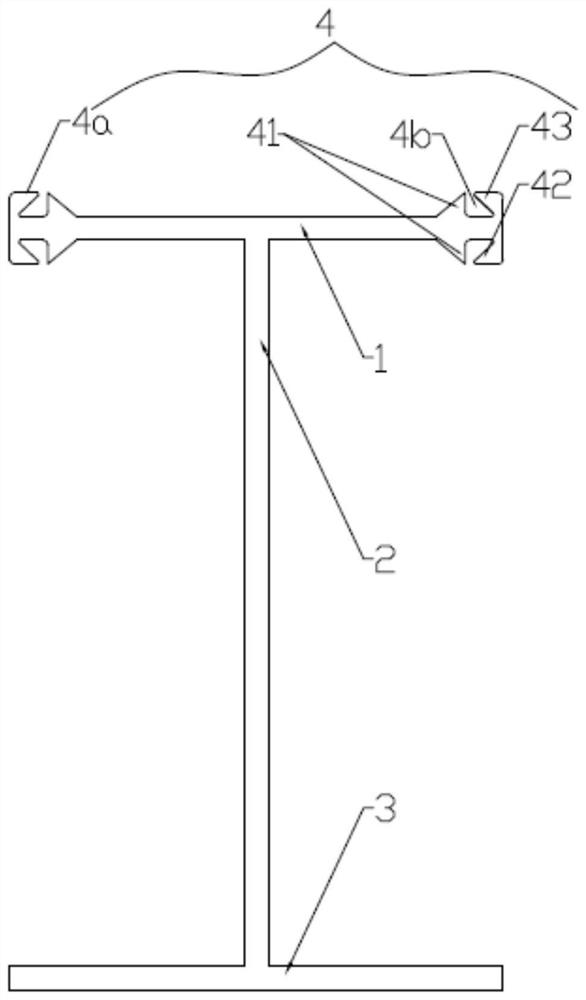

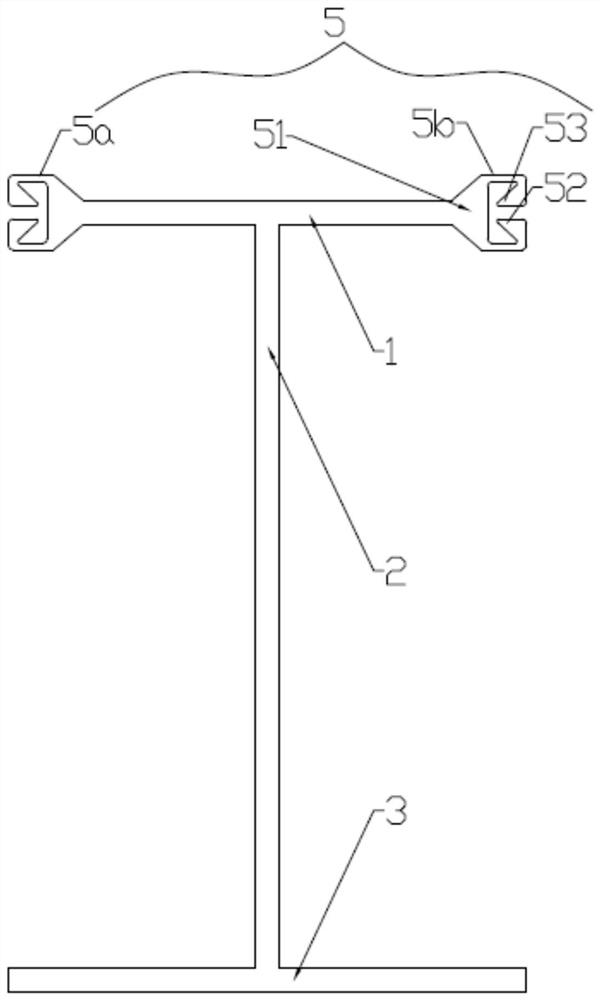

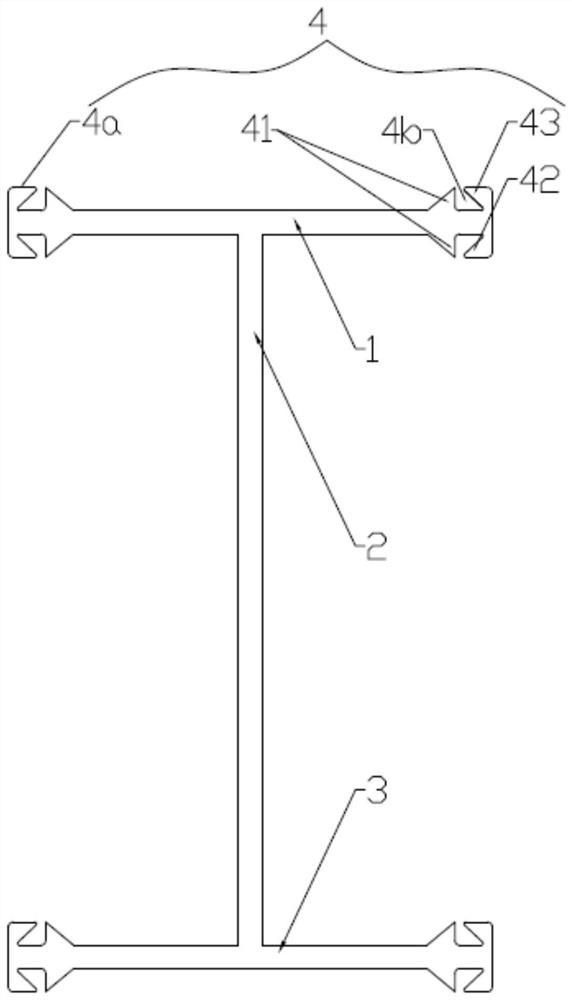

[0029] In this embodiment, an H-shaped steel sheet pile for a combined steel sheet pile with two-way locking includes an upper wing plate 1, a web plate 2 and a lower wing plate 3, and both ends of the upper wing plate 1 are provided with locks, and the locks are made of The ends of the upper wing plate 1 are respectively bent upwards and downwards to form a hook-shaped structure.

[0030] In this case, two-way locks are provided at both ends of the upper wing 1 of the H-shaped steel sheet pile. There are at least four locks, and the two-way locks can increase the seepage path of water flow, thereby improving the anti-seepage performance. When connecting with the Larsen steel sheet pile 6, the H-shaped steel of the above-mentioned two-way lock structure can also be used alone or in combination in the two installation methods of positive buckle and reverse buckle, and then extend more new forms of combined steel sheet pile structures.

[0031] Among them, according to differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com