Underground diaphragm wall plate-type rigid joint and construction method thereof

An underground diaphragm wall and construction method technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of cross steel plate production and complex construction process, increasing seepage paths, large vertical loads, etc. The effect of improving the integrity of the body, increasing the seepage path, and enhancing the lateral bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

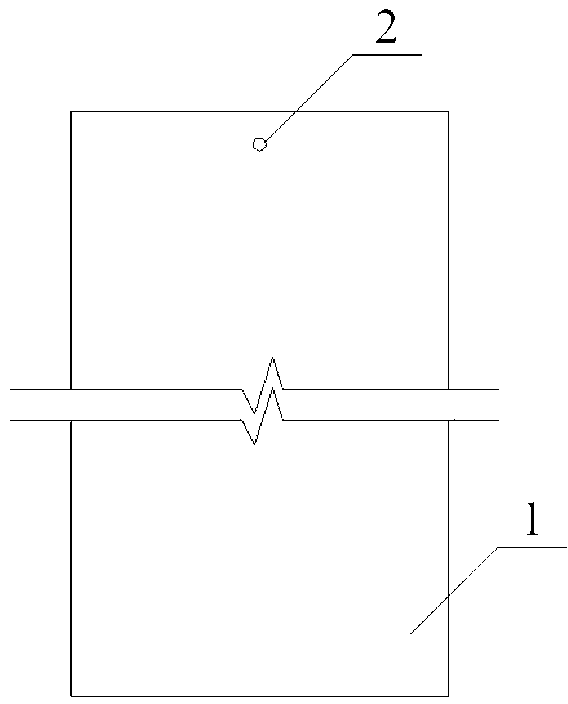

[0031] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0032] The construction method of underground diaphragm wall rigid baffle joint of the present invention, concrete implementation operation steps are as follows:

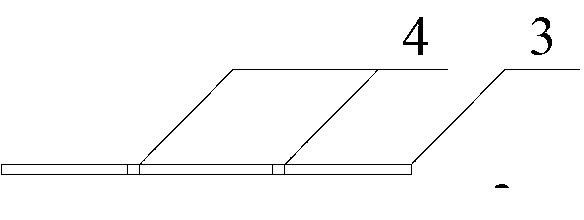

[0033] Step 1: According to the width and depth of the underground diaphragm wall, design the corresponding rigid baffle 1 and rigid base 3, including the size of the rigid baffle 1, the position and size of the connector slot 2, the size of the rigid base 3, and the reinforcement slot 4 The position and size of the locking pipe 5, the position and size of the steel bar end 6 at the bottom;

[0034] Step 2: Make rigid baffle 1, rigid bottom plate 3, and locking tube 5 according to the design;

[0035] Step 3: The fabricated rigid baffle 1 is welded to the rigid base 3 to form a rigid baffle joint 8;

[0036] Step 4: Excavate the underground diaphragm wall into grooves;

[0037] Step 5: Ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com