Composite retaining structure of foundation pit project and construction method thereof

A technology of enclosure structure and construction method, which can be applied in basic structure engineering, excavation, construction, etc., can solve the problems of enclosure structure deformation and pit bottom uplift, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: In this embodiment, the floor area is 16,400 m 2 Taking the construction of a certain foundation pit project as an example, the foundation pit was excavated according to the design depth of the two underground floors and the underground diaphragm wall was constructed. After that, according to the owner's requirements, the two underground floors were adjusted to three underground floors to improve the utilization of underground space Therefore, it is necessary to carry out effective reinforcement design and construction on the original underground enclosure structure to meet the requirements of the construction code, combined with the following Figure 1 to Figure 8 Illustrate the construction method of the compound enclosure structure of foundation pit project of this embodiment, concrete steps are as follows:

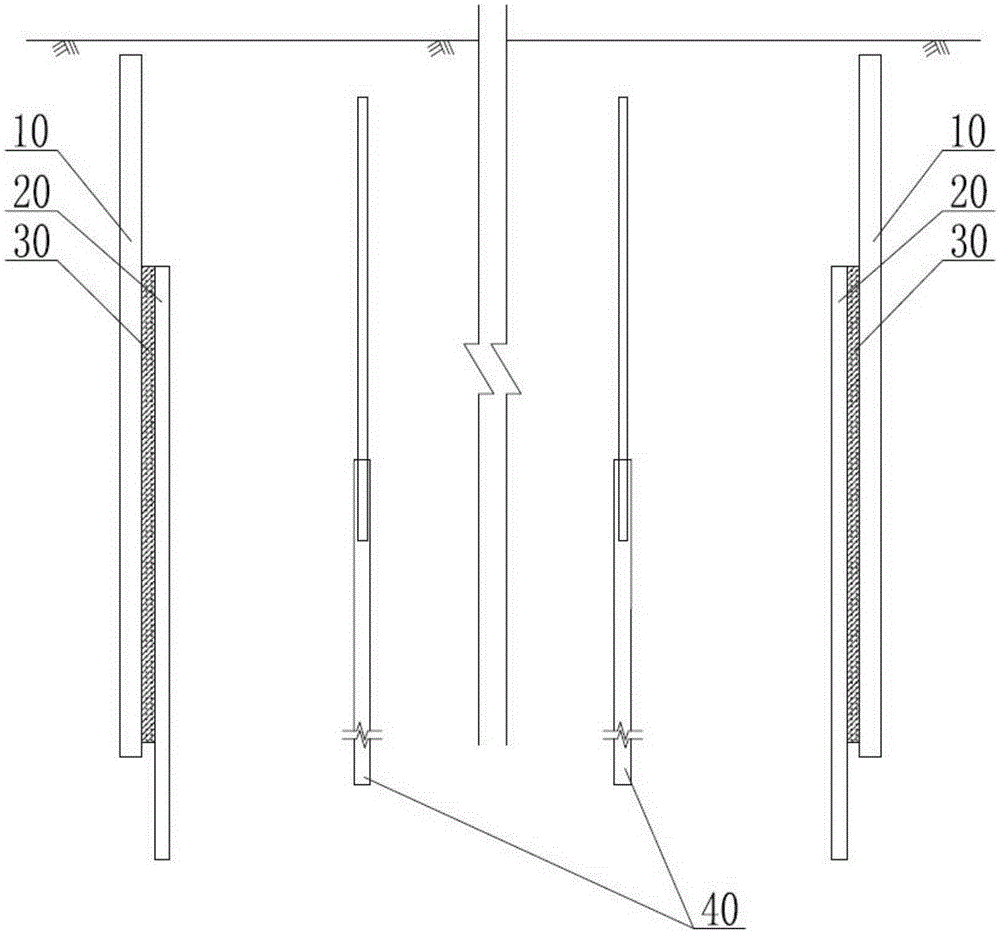

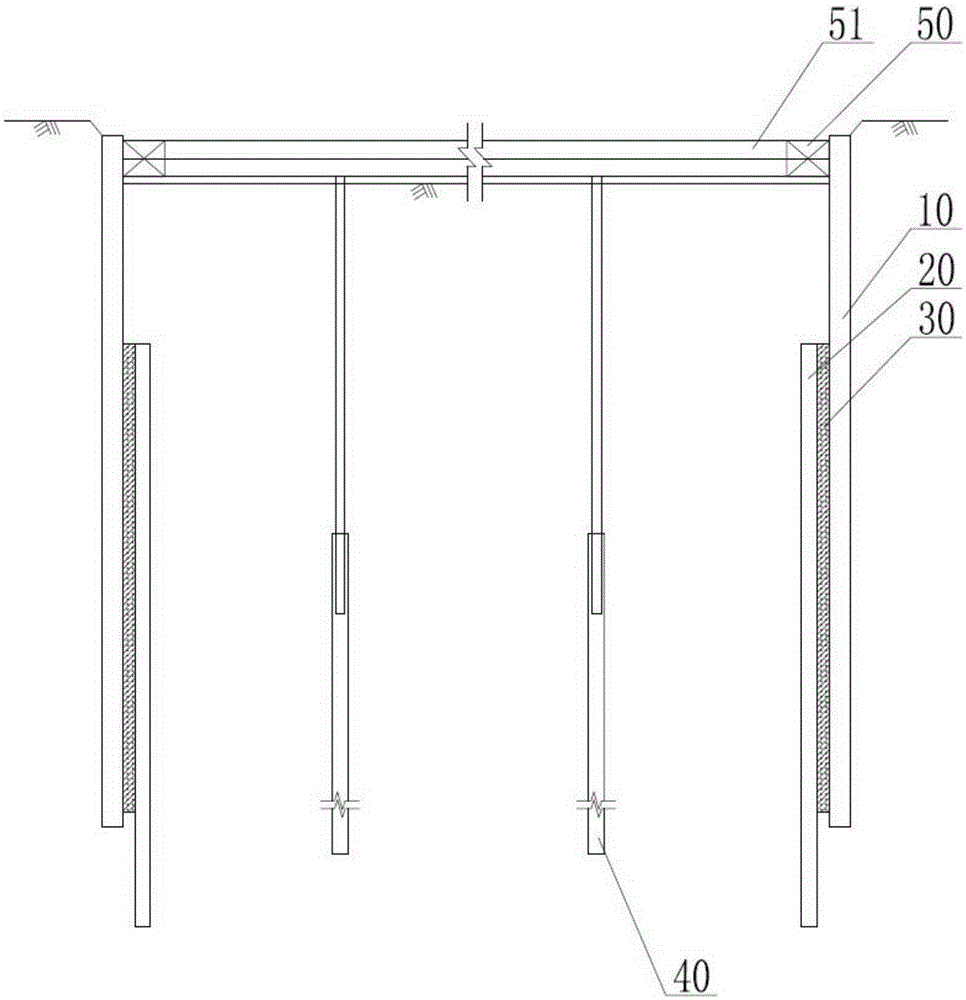

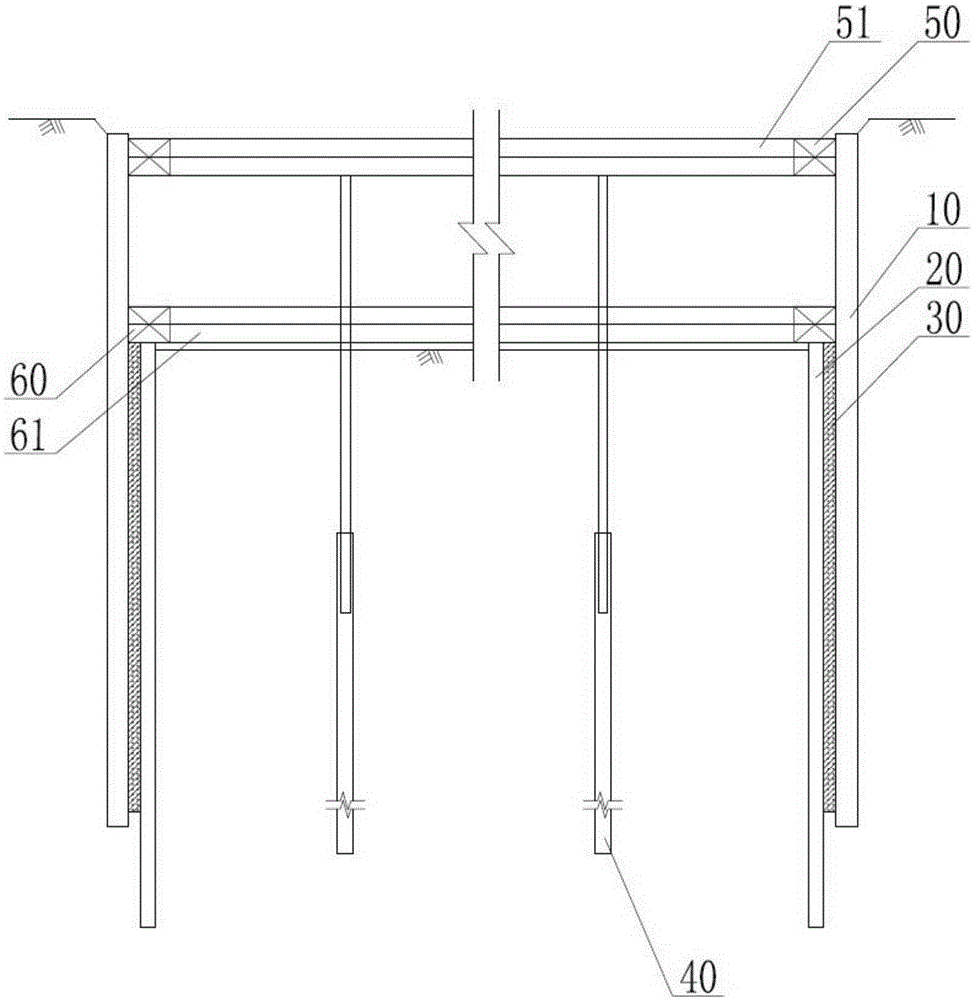

[0024] 1. In order to meet the requirements of excavation for foundation pit safety and environmental protection, such as figure 1 As shown, alon...

Embodiment 2

[0031] Embodiment 2: Combination Figure 9 and Figure 10 The composite enclosure structure of the foundation pit project of present embodiment is illustrated, and it comprises the underground diaphragm wall 10 that is enclosed in foundation pit outside; Along the inner side of underground diaphragm wall 10, some bored cast-in-place piles 20 that are arranged continuously, and bored cast-in-situ piles The depth of 20 is greater than the depth of underground diaphragm wall 10; the gap between underground diaphragm wall 10 and bored pile 20 is filled by high-pressure rotary grouting pile 30; The foundation bottom plate 80, and the foundation bottom plate 80 is offset with the underground continuous wall 10 located on its side, and the edge of the bottom surface of the foundation bottom plate 80 is also provided with a turn-down corbel 82, and the end of the turn-down corbel 82 is offset with the bored pile 20.

[0032] The composite enclosure structure of the foundation pit pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com