Water plugging seepage-proofing method for recharge well

A technology for refilling wells and well pipes, which is applied to water supply devices, drinking water installations, protection devices, etc., can solve the problems of clogging failure of the filter layer of the refilling well, failure of the refilling well, and tilting of the well tube, so as to prevent the filter layer from being blocked. The effect of plugging failure, extending seepage path, extending hydraulic path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

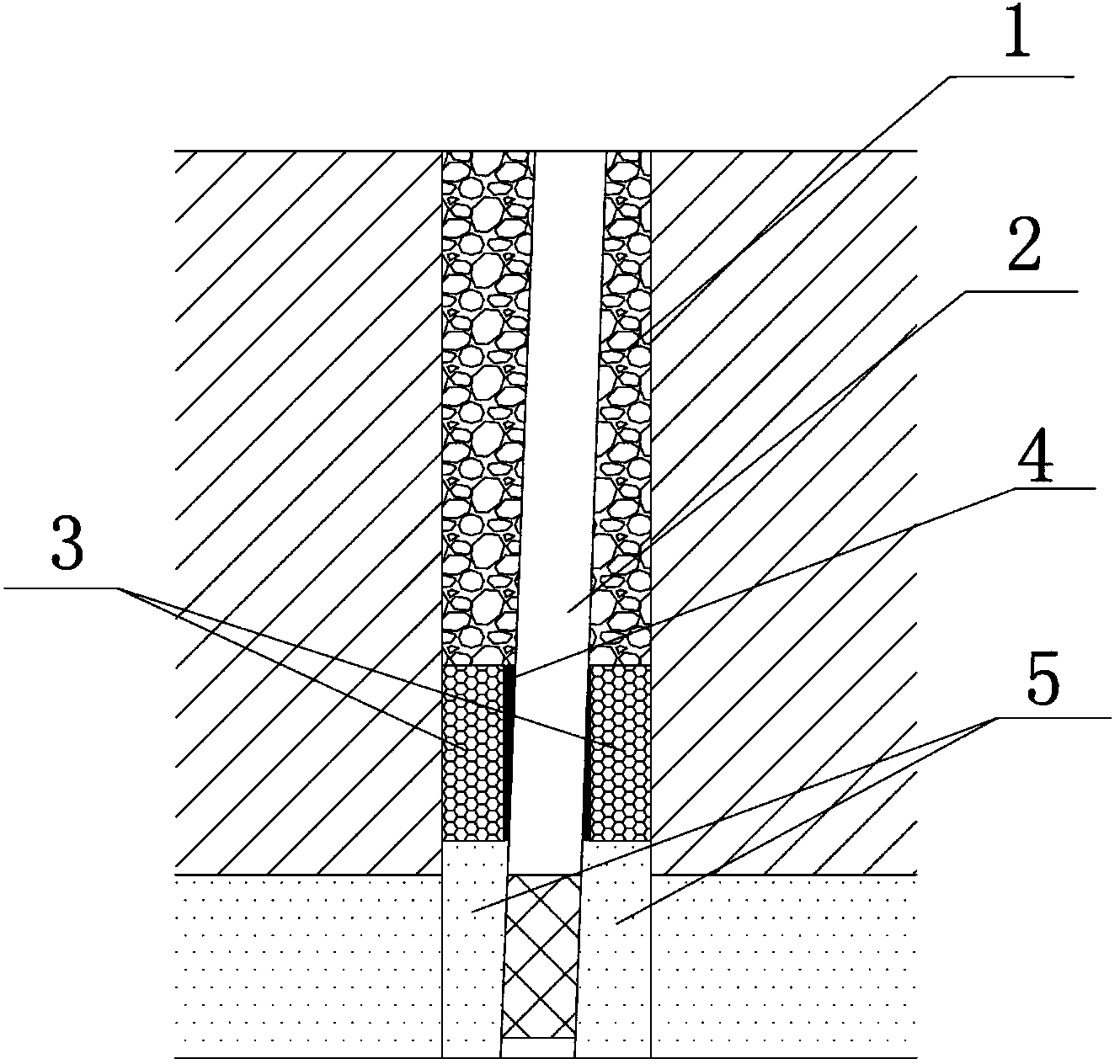

[0042] First, a brief introduction to the failure mode of water plugging and anti-seepage of conventional recharge wells. Such as figure 1As shown, during the well construction process, especially when the concrete water blocking layer 1 is applied, the concrete needs to be vibrated and compacted. Under the action of uneven or asymmetric vibration loads, the well pipe 2 is prone to sideways the tilt. On the one hand, since the clay ball water-resisting layer 3 is essentially a layer of cohesive soil with fine particles, its plasticity makes it have a certain shape before the well pipe 2 is not inclined, and after the well pipe 2 is inclined, when the water-resisting layer Before the medium clay balls have time to deform in the future, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com