Water retaining device for water turbine main shaft seal

A main shaft sealing and water blocking device technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of water and oil mixing, the influence of the operation of the hydraulic turbine unit, long construction period, etc., to achieve easy installation, time saving and The effect of low labor cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

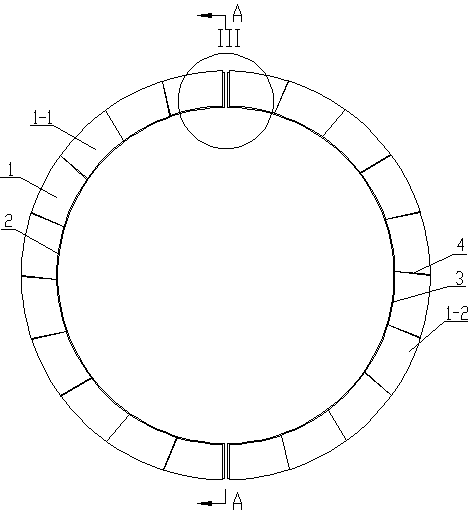

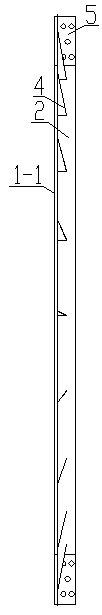

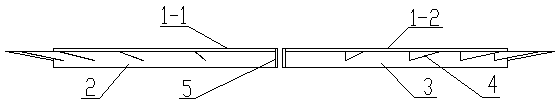

[0021] see figure 1 , figure 2 , image 3 , a hydraulic turbine main shaft seal water retaining device, by the water retaining plate coaming 1, the left water retaining plate gusset 2, the right water retaining plate gusset 3, rib plate 4 and flange 5 constitute. The fender enclosure 1 is a ring split structure, the fender enclosure 1 is composed of the left fender enclosure 1-1 and the right fender enclosure 1-2, the left fender enclosure 1-1 Respectively semi-circular structure with right water retaining plate coaming 1-2, the opening of left water retaining plate coaming 1-1 and right water retaining plate coaming 1-2 is arranged relatively. The edge of the inner circumference of the left fender 1-1 is welded with a semicircular left fender gusset 2, and the edge of the inner circumference of the right fender 1-2 is welded with a semicircular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com