Well drilling device for generating hydraulic pulse

A pulse and drilling technology, which is applied in the direction of liquid/gas jet drilling, wellbore flushing, earthwork drilling and production, etc. It can solve the problems of energy loss and the effect of device speed increase, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

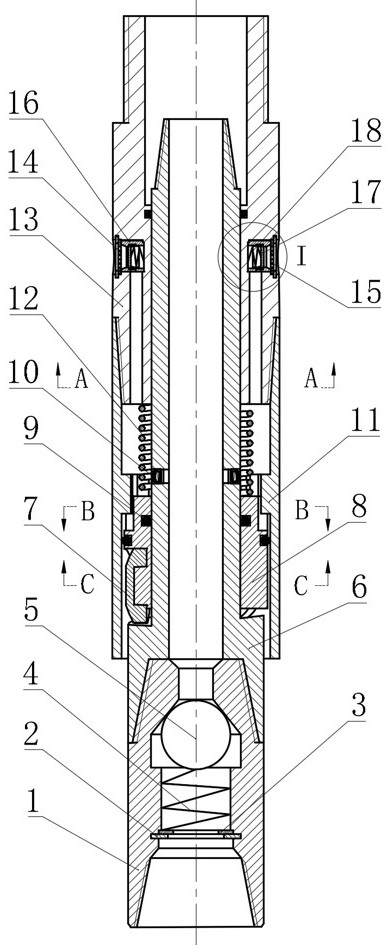

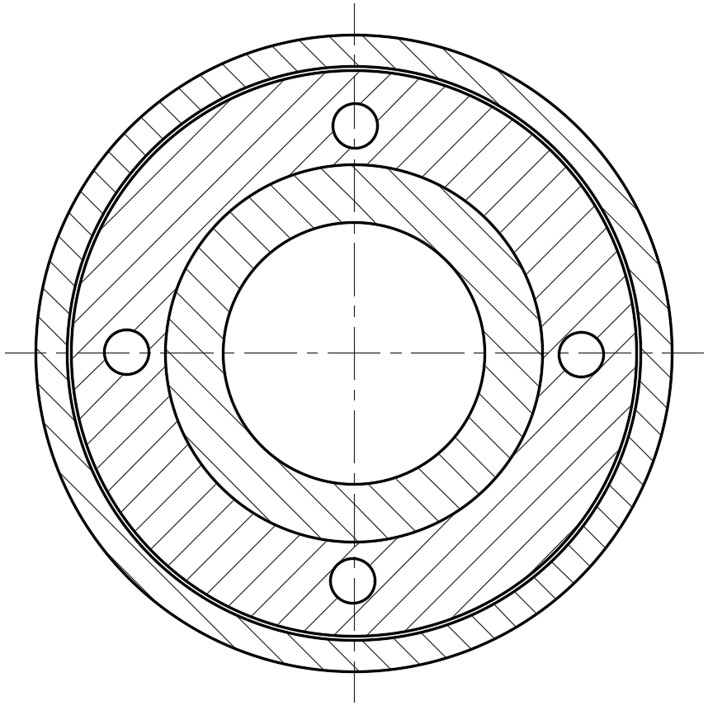

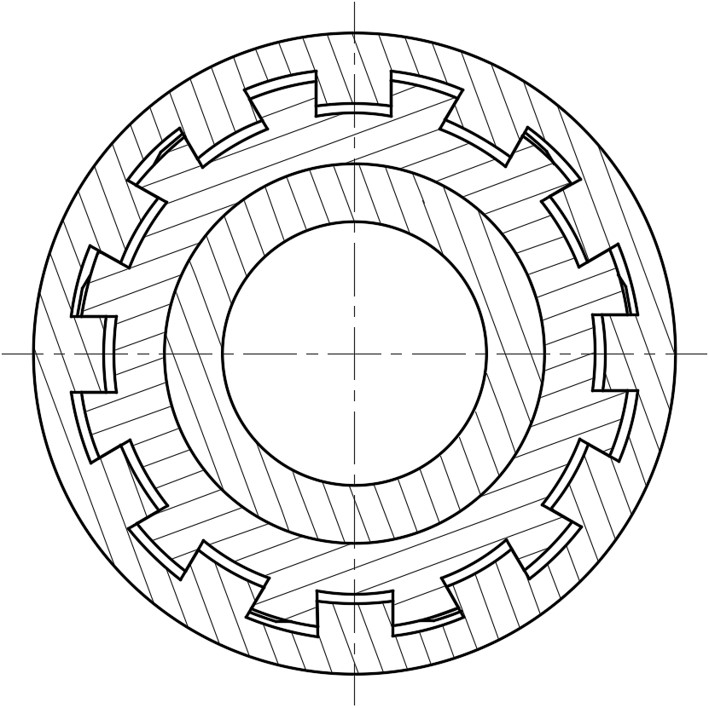

[0043] like Figure 1-18 As shown, a drilling device for generating hydraulic pulses includes a transmission sub 1, a mandrel 6, a hydraulic piston 8, a lower body 11 and an upper body 13. The upper end of the transmission sub 1 is connected to the mandrel 6 The lower end is connected by thread, the lower body 11 and the upper body 13 are connected by thread, the mandrel 6 passes through the lower body 11 and the upper body 13, the transmission short joint 1 is provided with a third retaining spring 2, a spring The support plate 3, the third spring 4 and the pressure-holding ball 5, the main spring 12 is arranged between the upper body 13 and the hydraulic piston 8, the mandrel 6 passes through the hydraulic piston 8 and the main spring 12, the hydraulic A roller 7 is installed on the lower end of the movable piston 8, a check valve hole 6d is provided on the small diameter section 6b of the spindle 6, and a check valve 10 is installed in the check valve hole 6d, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com