Portable screw extrusion juicer

A technology of screw extrusion and original juice machine, which is applied in the direction of household machinery for filtering food, household appliances, applications, etc., can solve the problems of limited actual capacity, irremediable juice overflow, and increased cost, and achieve a reasonable and compact internal space and a stable structure. Simple and user-friendly, the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

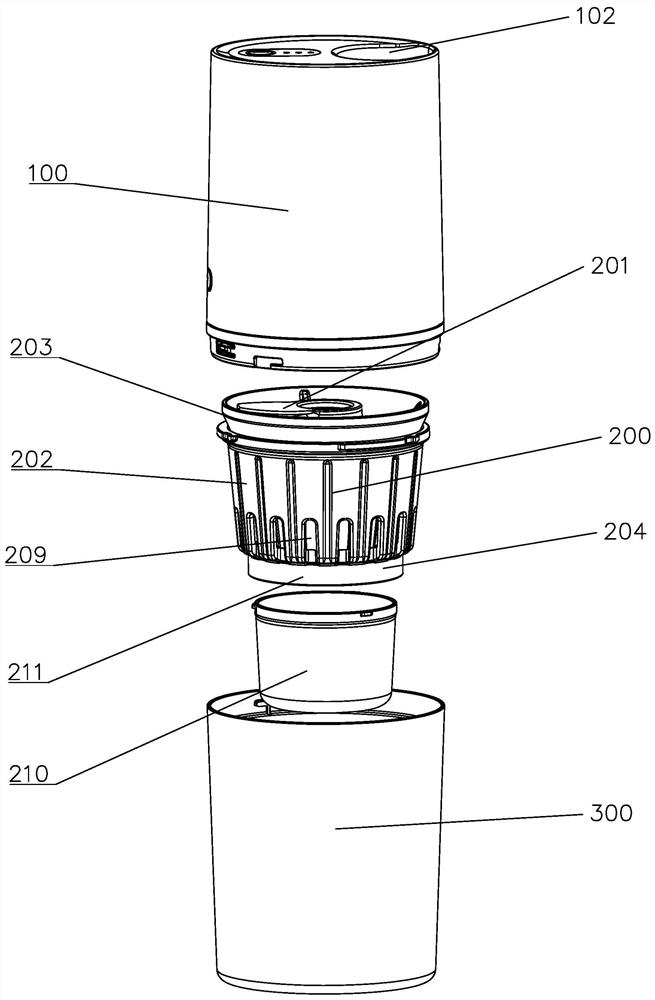

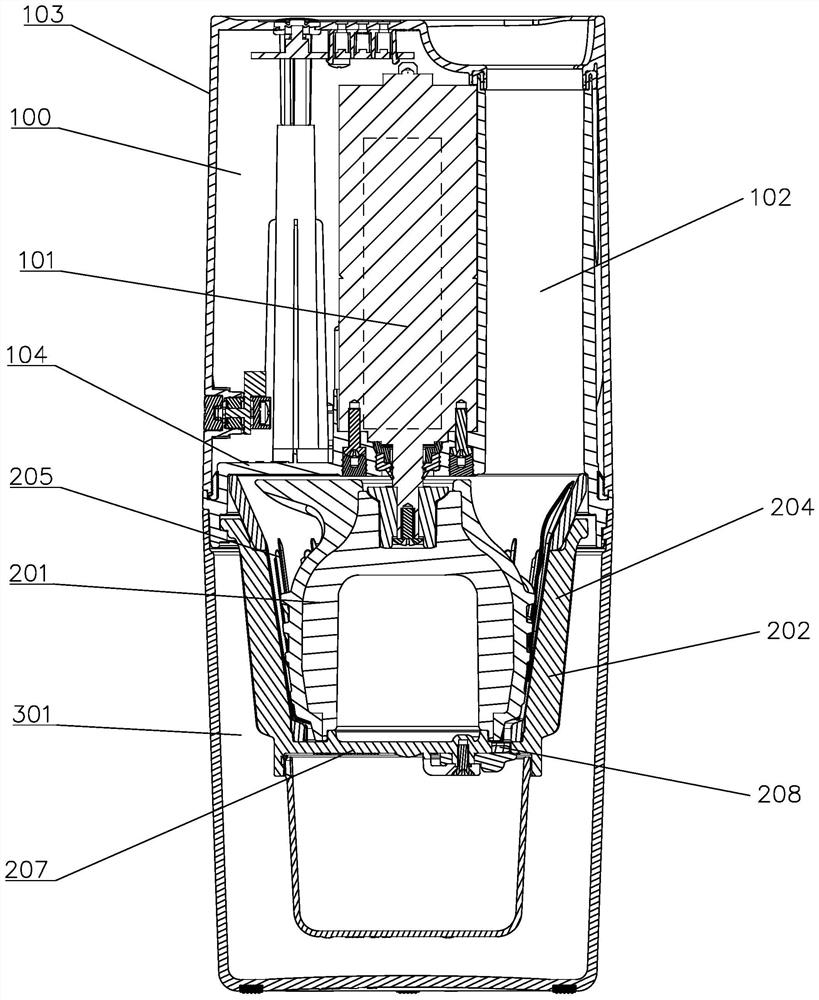

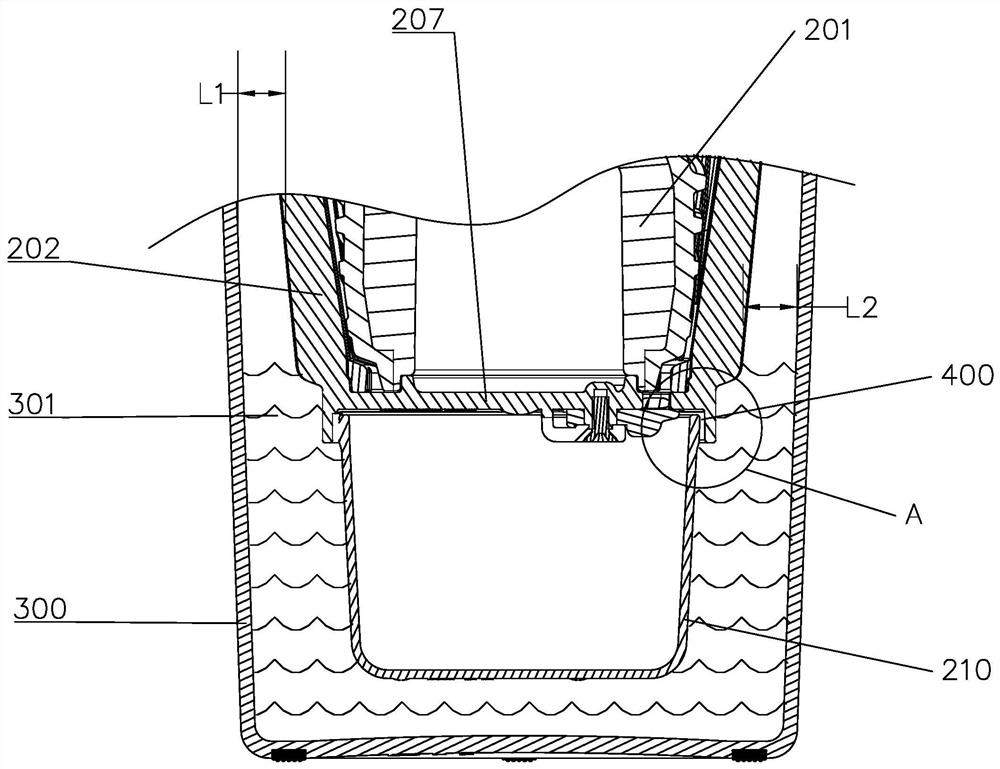

[0034] Such as Figure 1 to Figure 4 As shown, the present invention provides a portable screw extruder for raw juice, including a host 100, an extruding assembly 200 and a juice receiving container 300 arranged below the host, the extruding assembly includes a screw 201 and a screw sheathed outside the screw Squeeze cylinder 202, the host includes a housing 103 and a base 104, the extrusion assembly 200 is fixedly connected to the base 104, the upper port of the juice receiving container is connected with the extension of the base 104, and the bottom of the extrusion assembly is provided with a slag receiving container 210 , the host is provided with a motor 101, a circuit board and a battery, the host housing is provided with a USB charging interface for charging the battery, the circuit board is placed horizontally on the lower surface of the top wall of the host housing, and the top wall of the host housing There are buttons on the top, the output shaft of the motor is con...

Embodiment 2

[0046] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the side wall of the extrusion cylinder is partially provided with a flared portion 206, specifically, the flared portion is protruding from the side wall of the extrusion cylinder locally. The flaring part 206 is arranged on the side close to the lower port of the feed channel. The extrusion cylinder 202 includes an inner tube 203 and an outer tube 204. The inner tube protrudes outward at the flared part and avoids the lower port of the feed channel. , and corresponding to the upper and lower ports of the lower port of the feed channel, the taper of the flared portion 206 is greater than the taper of the side wall of the extrusion barrel, and the taper of the flared portion gradually increases from bottom to top, and the flare The part 206 not only increases the extrusion juice and material storage space in the extrusion barrel, but also enables the material passin...

Embodiment 3

[0051] like Image 6 As shown, the difference between this embodiment and the second embodiment is that the upper end of the side wall of the extrusion cylinder is provided with a flared portion 206 in the circumferential direction. Specifically, the flared portion 206 is arranged on the outer cylinder 204 and the inner cylinder 203. The taper of the flaring part is larger than the taper of the outer wall of the extrusion barrel, and the projection of the flaring part in the horizontal plane covers the projection of the lower port of the feeding channel 102 in the horizontal plane, so as to ensure that the material can pass through the feeding channel. Quickly and accurately enter the extrusion crushing gap formed by the cooperation of the extrusion cylinder 202 and the screw 201, so as to prevent the material from being stuck between the extrusion cylinder and the juice receiving container, or between the lower surface of the main machine base and the screw.

[0052] It can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com