Connector box used for underground diaphragm wall steel-rubber connector and construction method

A technology for underground diaphragm walls and rubber joints, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of increased construction difficulty, digging dark areas, and adding wall brushing techniques, so as to solve the problem of water seepage and prolong The effect of seepage path and increasing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

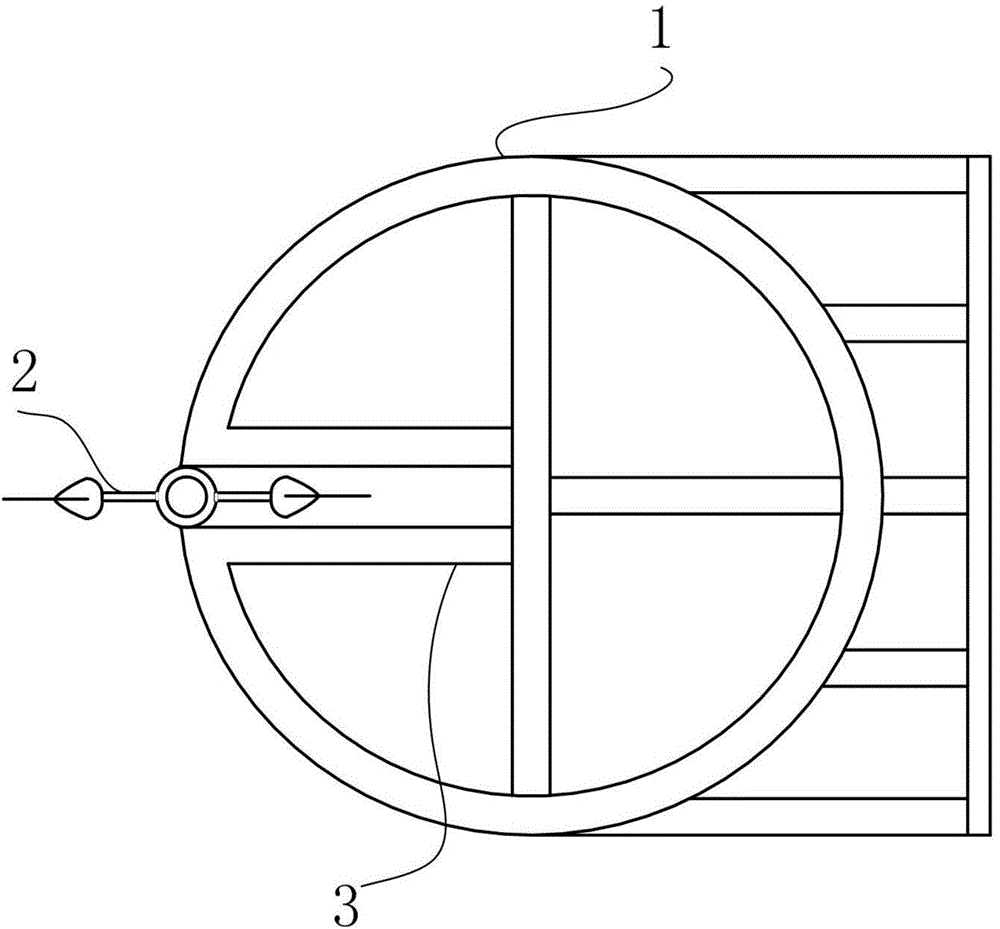

[0031] Combine below figure 1 The joint box and the construction method used for the steel-rubber joint of the underground diaphragm wall according to the present invention will be described in detail.

[0032] A joint box for steel-rubber joints of an underground diaphragm wall, used to connect the front construction groove section and the rear construction groove section of the underground diaphragm wall, including: a horseshoe-shaped locking pipe 1 that can be hung in the pit of the construction groove section , wherein, the end of the horseshoe-shaped lock pipe 1 close to the construction groove section of the front section forms an arc-shaped end face along the width direction of the construction groove section, and the end of the horseshoe-shaped lock pipe 1 close to the construction groove section of the rear section along the width direction of the construction groove section The direction forms a rectangular end face, and the end of the horseshoe-shaped lock pipe 1 cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com