A polymer plastic assembled pipe gallery and its construction method

A polymer, prefabricated technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as time-consuming and tedious processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

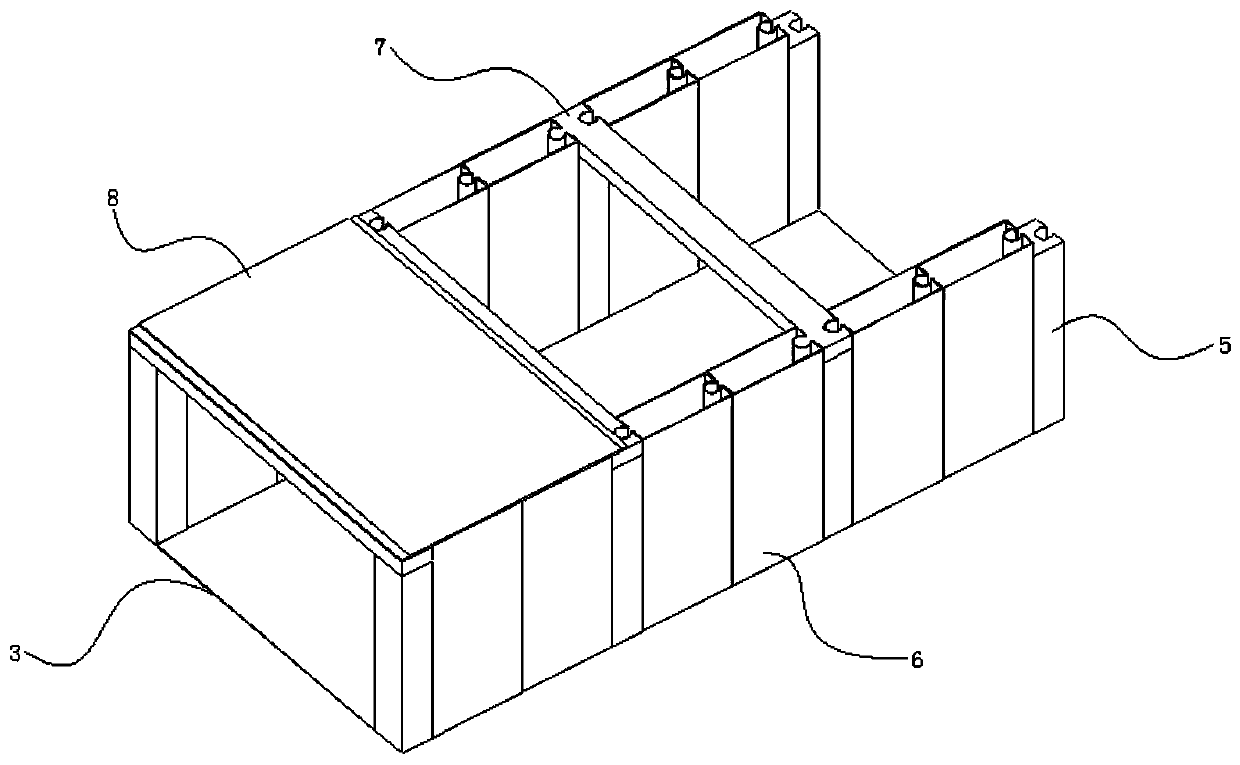

[0041] The direction of the corridor body is longitudinal, and the direction perpendicular to the direction of the corridor body is horizontal. see figure 1 , this embodiment discloses a polymer plastic fabricated pipe gallery: comprising a bottom plate 3 and a top plate 8 , and frame components arranged between the bottom plate 3 and the top plate 8 .

[0042] The bottom plate 3 is a polymer plastic plate. The lower surface of the bottom plate 3 is a rough surface. The bottom plate 3 is laid on the bottom cushion of the pipe gallery. The bottom cushion layer of the pipe gallery includes a clay layer, a crushed stone layer and a silt layer sequentially from top to bottom. The bottom plate 3 is laid on the clay layer and compacted.

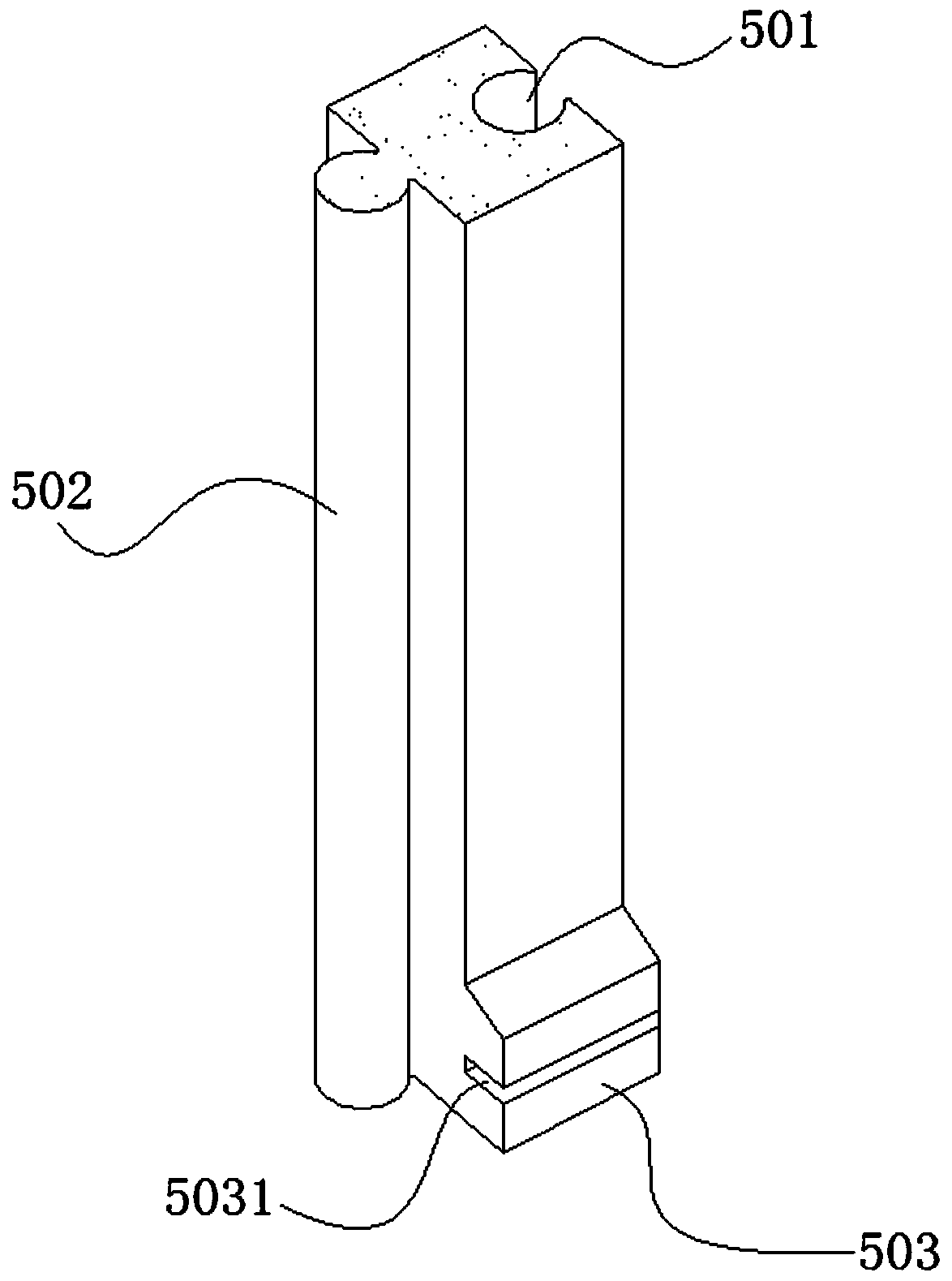

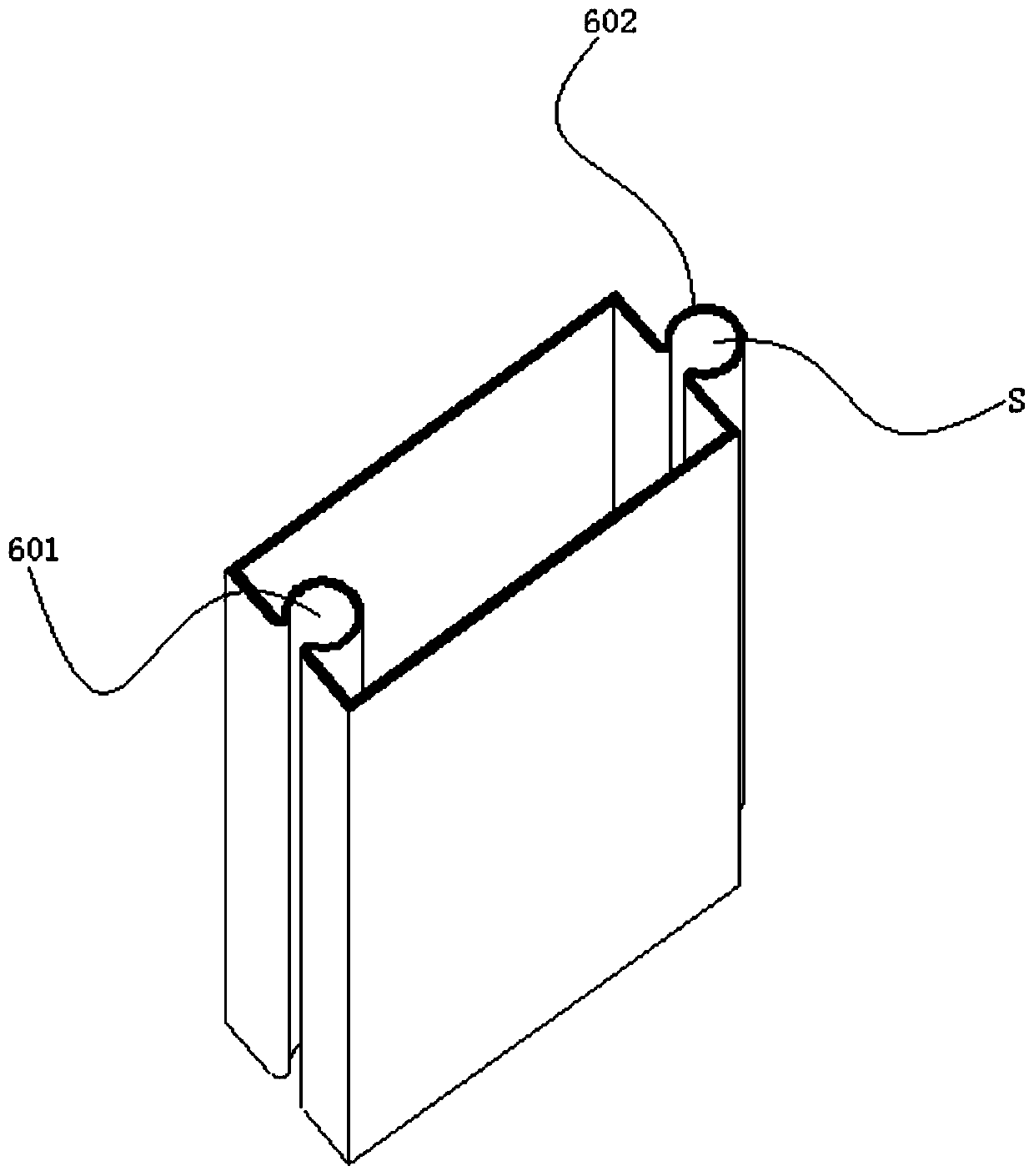

[0043] The frame members are arranged longitudinally at intervals. Each frame part includes two columns 5 and a beam 7 erected between the two columns 5 . Both the column 5 and the beam 7 are made of polymer plastics. see figure 2 , the co...

Embodiment 2

[0048] This embodiment discloses a construction method for the polymer plastic prefabricated pipe gallery described in Embodiment 1, which includes the following steps:

[0049] 1) Clean up and level the site according to the requirements of the construction site.

[0050] 2) Use excavating machinery to excavate the foundation pit, and carry out foundation pit support at the same time.

[0051] 3) Construction cushion: check the groove of the foundation pit, eliminate loose soil, weak soil layers and cavities, and perform bottom tamping twice to make the foundation pit smooth and clean. According to the design requirements, the location of the pipe gallery is determined by setting out the construction line, and the interior of the pipe gallery is filled with silt, gravel and clay in sequence, and compacted to form a cushion at the bottom of the pipe gallery.

[0052] 4) Lay the bottom plate 3 above the bottom cushion of the pipe gallery and compact it.

[0053] 5) Lift the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com