Tunnel lining waterproof joint

A technology for waterproof joints and tunnels, used in tunnel linings, tunnels, wellbore linings, etc., can solve the problems of decreased anti-seepage performance, poor anti-seepage effect, poor waterproof performance, etc. The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

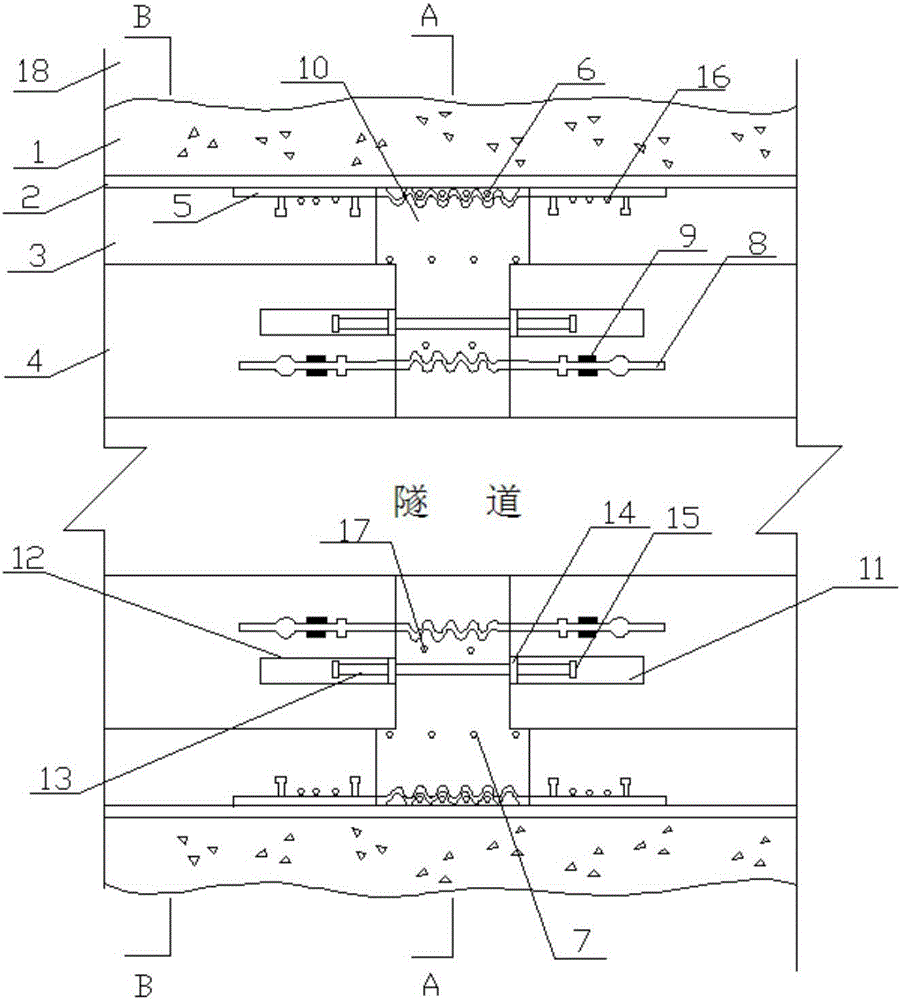

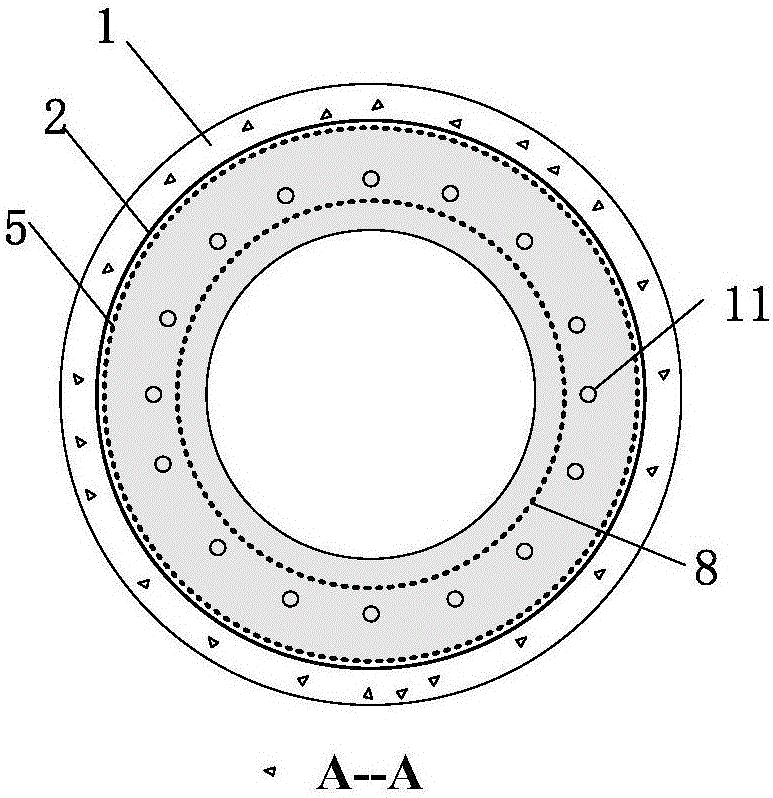

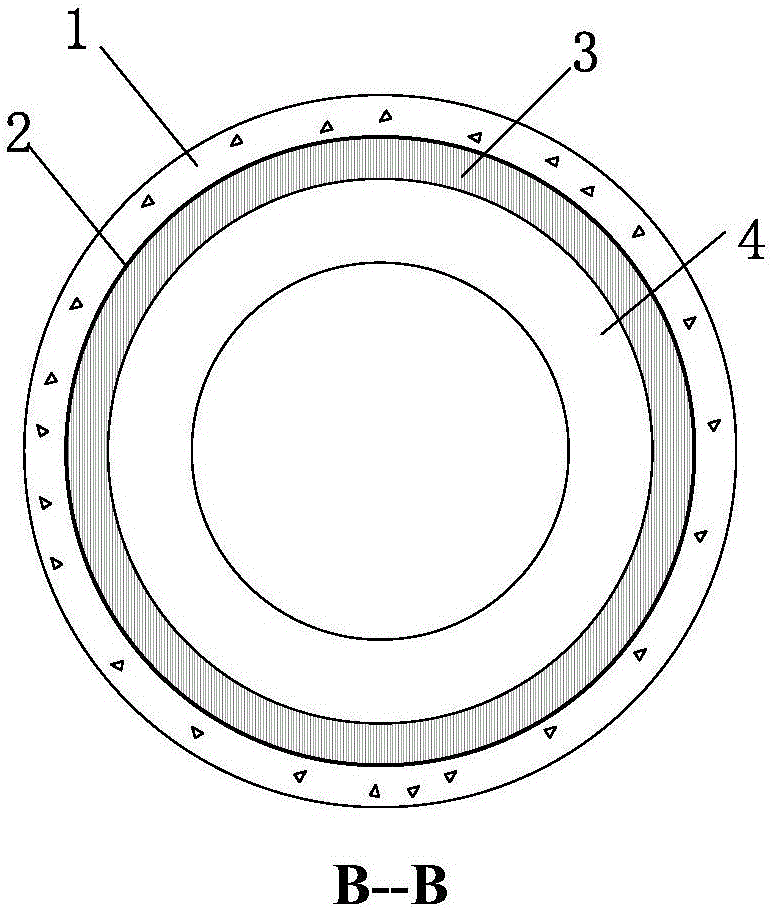

[0064] A tunnel lining waterproof joint, which mainly includes an initial lining layer composed of a sprayed concrete layer 1 close to the surrounding rock 18, a waterproof layer composed of a PVC waterproof board 2, a deformation layer composed of a foam concrete deformation layer 3, and a second lining reinforced concrete layer 4, in which a flexible joint, that is, a "T"-shaped deformation joint 10, is provided along the ring direction of the tunnel at the cross-section of the fault.

[0065] The "T"-shaped deformation joint 10 separates the foam concrete deformation layer 3 and the second lining reinforced concrete layer 4, and is the main deformation part of the flexible joint. In addition to the deformation performance requirements, since the deformation joint is the weak link in the waterproofing of the entire joint, the permeability coefficient of the deformation joint filling material should not be too large, so plastic concrete is selected. According to the mechanica...

Embodiment 2

[0092] The difference from the above example is: the formula of the plastic concrete material is: cement: 10 parts; sand: 80 parts; water: 20 parts; stone: 90 parts; admixture: 4 parts; bentonite: 2 parts; clay: 9 parts ; 0.8% polyvinyl alcohol fibers.

Embodiment 3

[0094] The difference from the above examples is: the formula of the plastic concrete material is: cement: 20 parts; sand: 70 parts; water: 30 parts; stone: 70 parts; admixture: 2 parts; bentonite: 4 parts; clay: 6 parts ; 1.2% polyvinyl alcohol fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com