Multifunctional correcting tool

A multi-functional, tooling technology, applied in the field of tooling, can solve the problems of low roundness qualification rate, out-of-tolerance roundness, and difficult processing of parts, so as to achieve the effect of guaranteed quality and production progress, low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

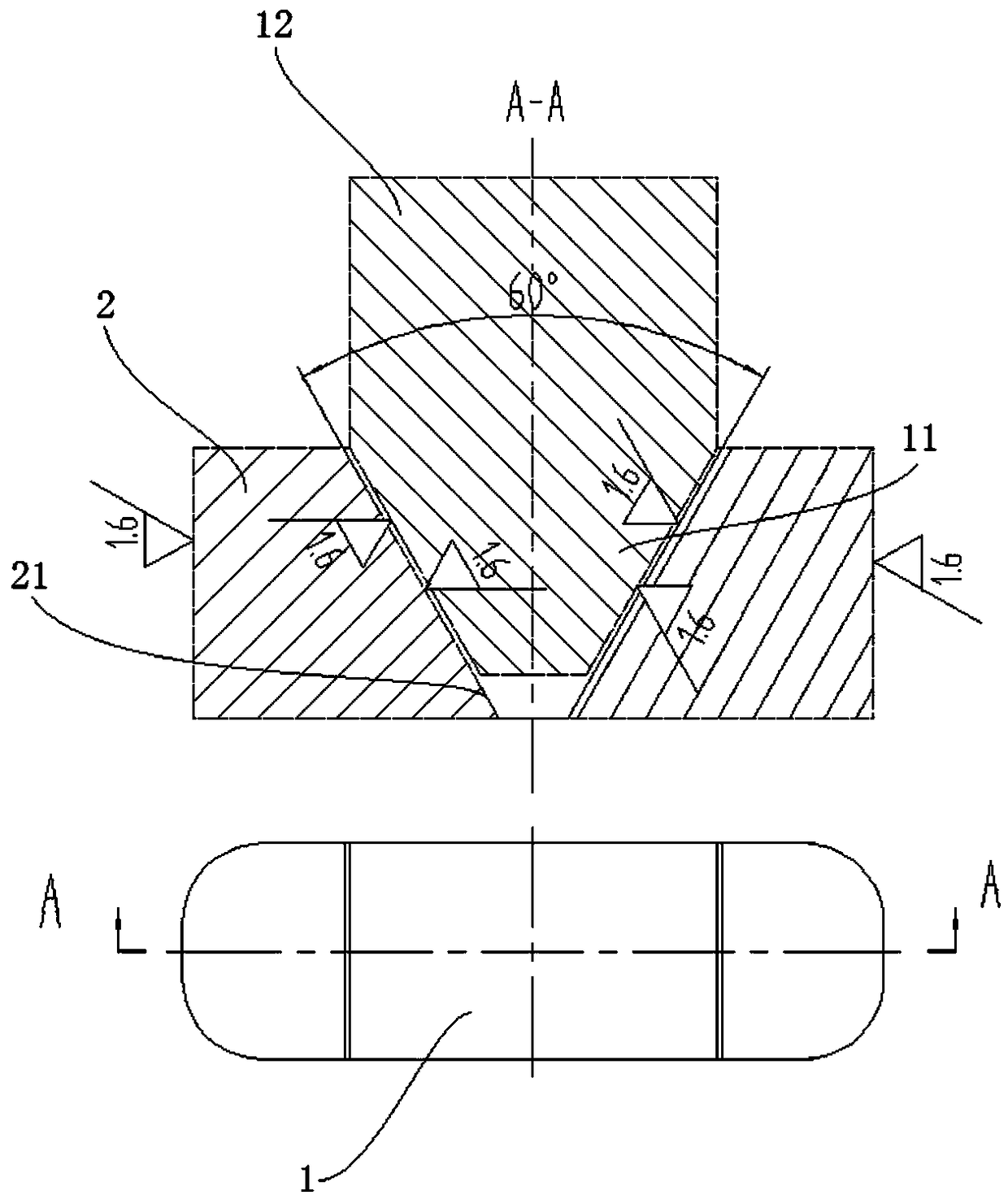

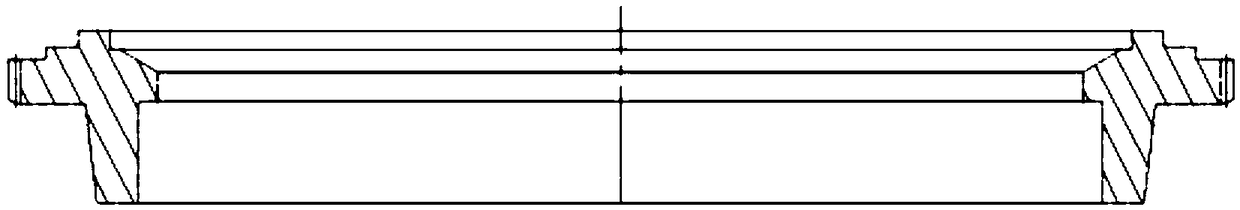

[0030] Such as Figures 1 to 4 As shown, a multifunctional calibration tool, the part to be calibrated is a thin-walled annular part, and the part to be calibrated is placed on a horizontal platform.

[0031] It is characterized in that it includes a pressing block 1, two expansion blocks 2 and a pressure unit.

[0032] The expansion block 2 is a right-angled trapezoidal cylinder. One end of the expansion block 2 has an inclined surface, which is marked as an inclined surface 21 . The two corners at the other end of the expansion block 2 are rounded. When the multifunctional calibration tool corrects the parts, the lower bottom of the two expansion blocks 2 is placed inside the part as a mirror image, and the slopes 21 of the two expansion blocks 2 are opposite to form a trapezoidal groove.

[0033] The pressing block 1 consists of a tip 11 and a rectangular cylinder 12 . The tip 11 is an isosceles trapezoidal cylinder. In this embodiment, the angle between the two slopes ...

Embodiment 2

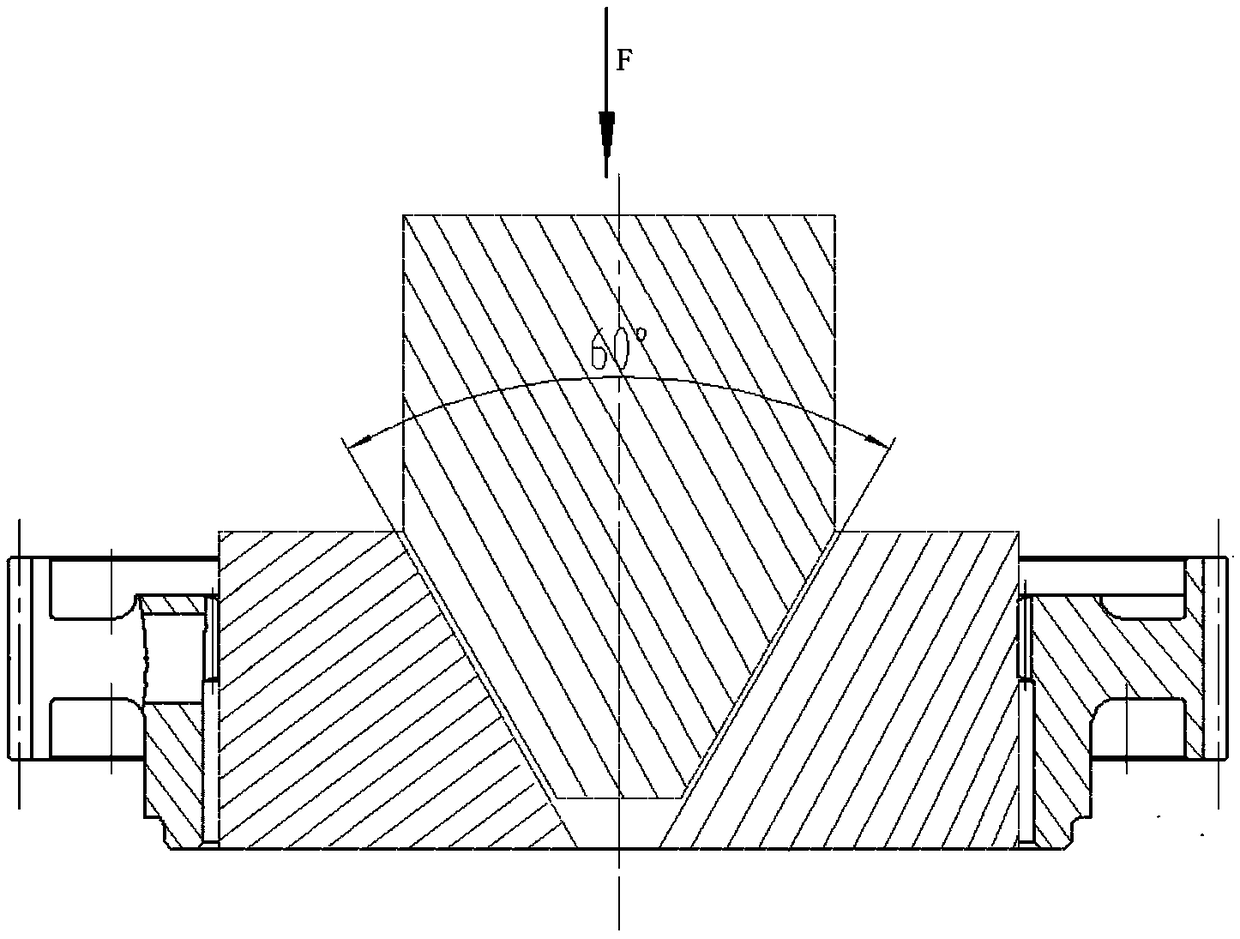

[0038] The structure of this embodiment is the same as that of Embodiment 1, and the operation process of the multifunctional calibration tool is further described. In this embodiment, the part to be corrected is the synchronizer cone. Refer to Figure 3 to Figure 4 ,Proceed as follows:

[0039] 1) Put the synchronizer cone on the horizontal platform, put the slopes 21 of the two expansion blocks 2 opposite, and put them into the synchronizer cone in a mirror image distribution.

[0040] 2) Insert the tip 11 of the pressing block 1 downward into the trapezoidal groove formed by the two expansion blocks 2 .

[0041] 3) Place the pressure unit on the top of the rectangular cylinder 12 of the briquetting block 1, and apply a force F perpendicular to the horizontal platform to the briquetting block 1.

[0042] 4) The pressing block 1 is forced and moves downward, and the tip 11 of the pressing block 1 applies force to the two expansion blocks 2, so that the two expansion blocks 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com