Method for treating depression watertight in hydraulic engineering by employing yellow mud grout

A technology for water conservancy engineering and yellow mud, which is applied in infrastructure engineering, soil protection, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

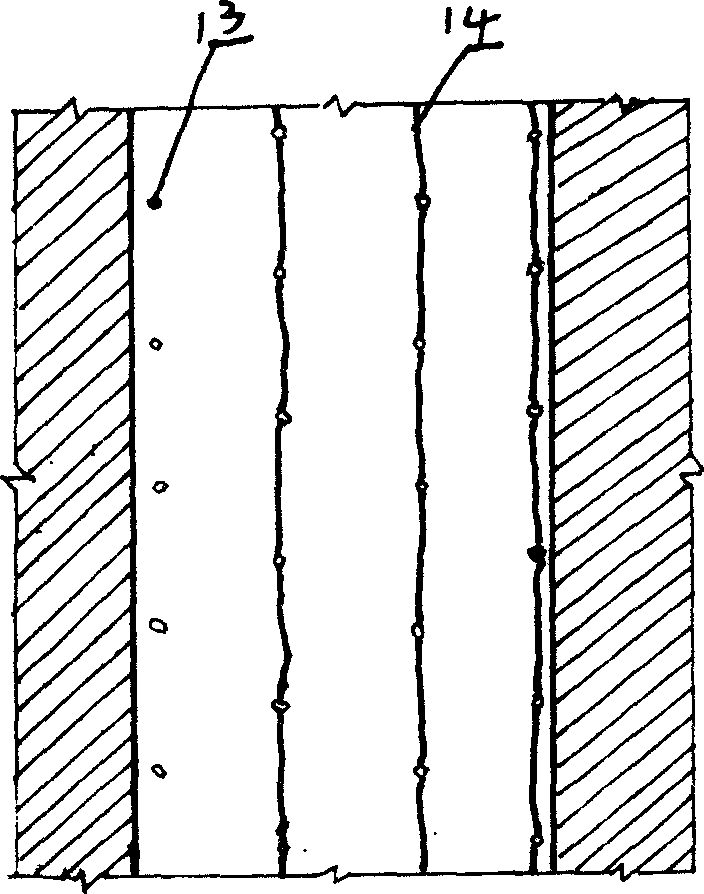

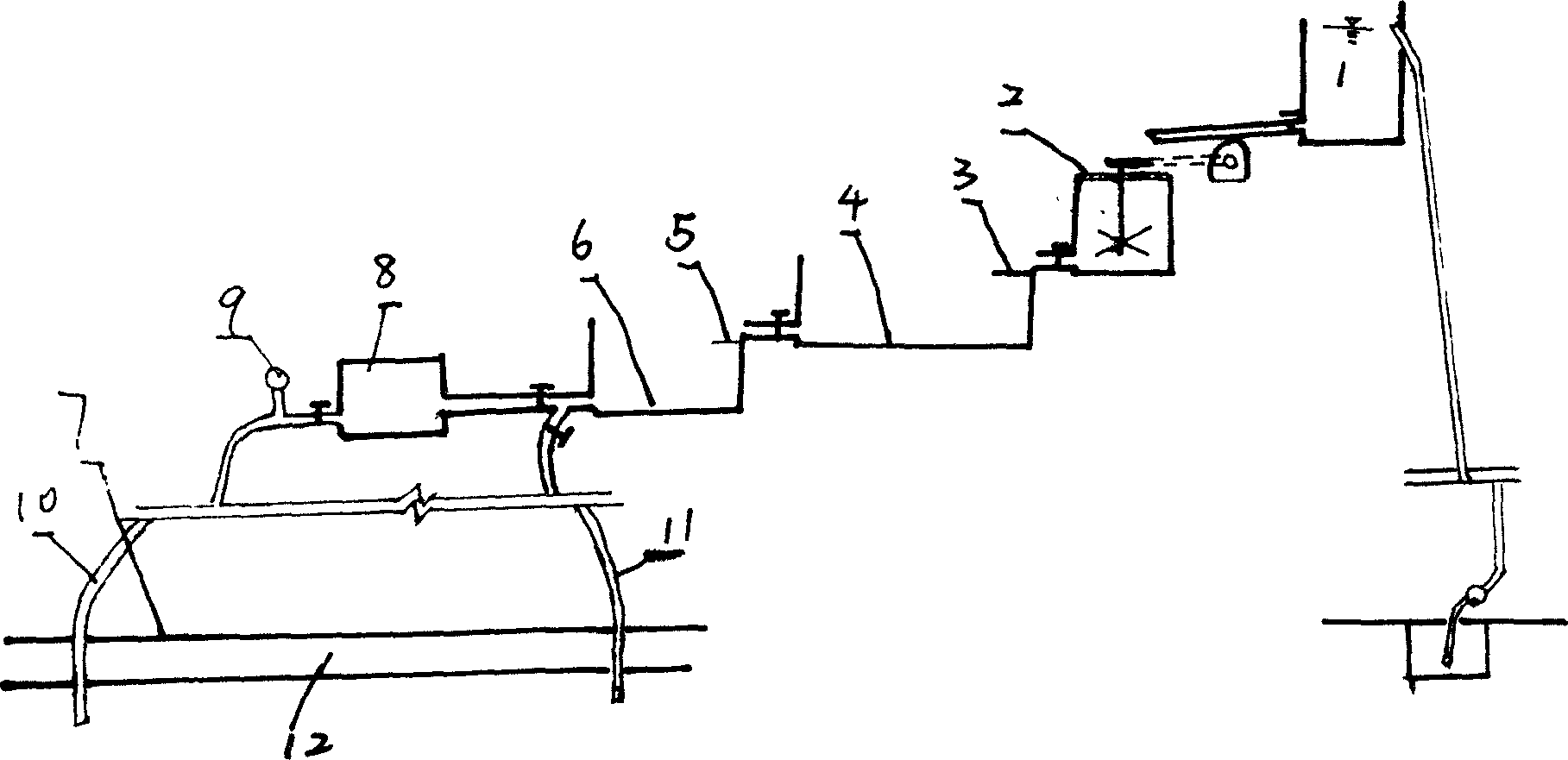

[0008] Such as figure 1 As shown, the arrangement and hole making of the first grouting holes: the grouting holes 13 are arranged in a quincunx shape, and the first, second, and third rows of holes are all located on the cracks 14, and the row spacing and hole spacing are both 4 to 5 meters. The grouting hole is to pass through the lining base plate with a 1-inch iron pipe, and then go deep into the foundation 20 cm, and expose 10 cm to connect with the grouting pipe. Before grouting, the cracks in the lining layer at the bottom of the canal should be chiseled and cleaned, and the small cracks should be repaired with No. 80 mortar and the large cracks should be repaired with No. 150 concrete.

[0009] The second step is the preparation of the yellow mud slurry: to prepare the slurry, yellow mud with many clay particles and small coarse grains should be selected. The gradation is: 42% of the particle size is less than 0.005 mm, 34% of the particle size is 0.005 ~ 0.05 mm, 0.05 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com