Patents

Literature

137results about How to "Increase foam resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

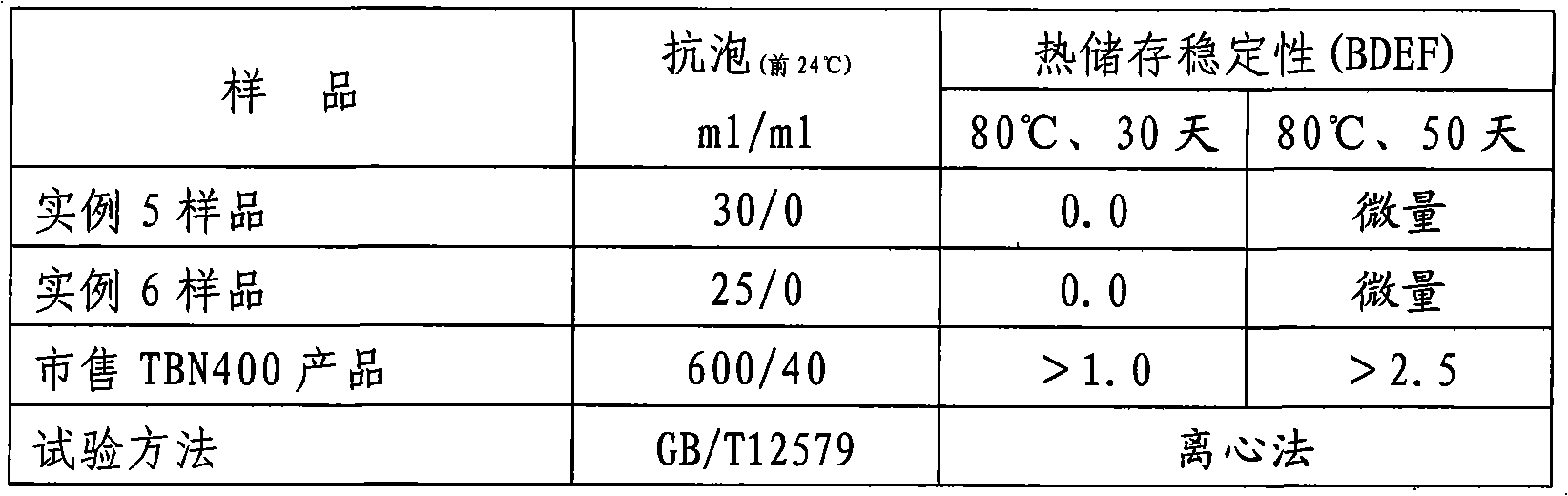

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

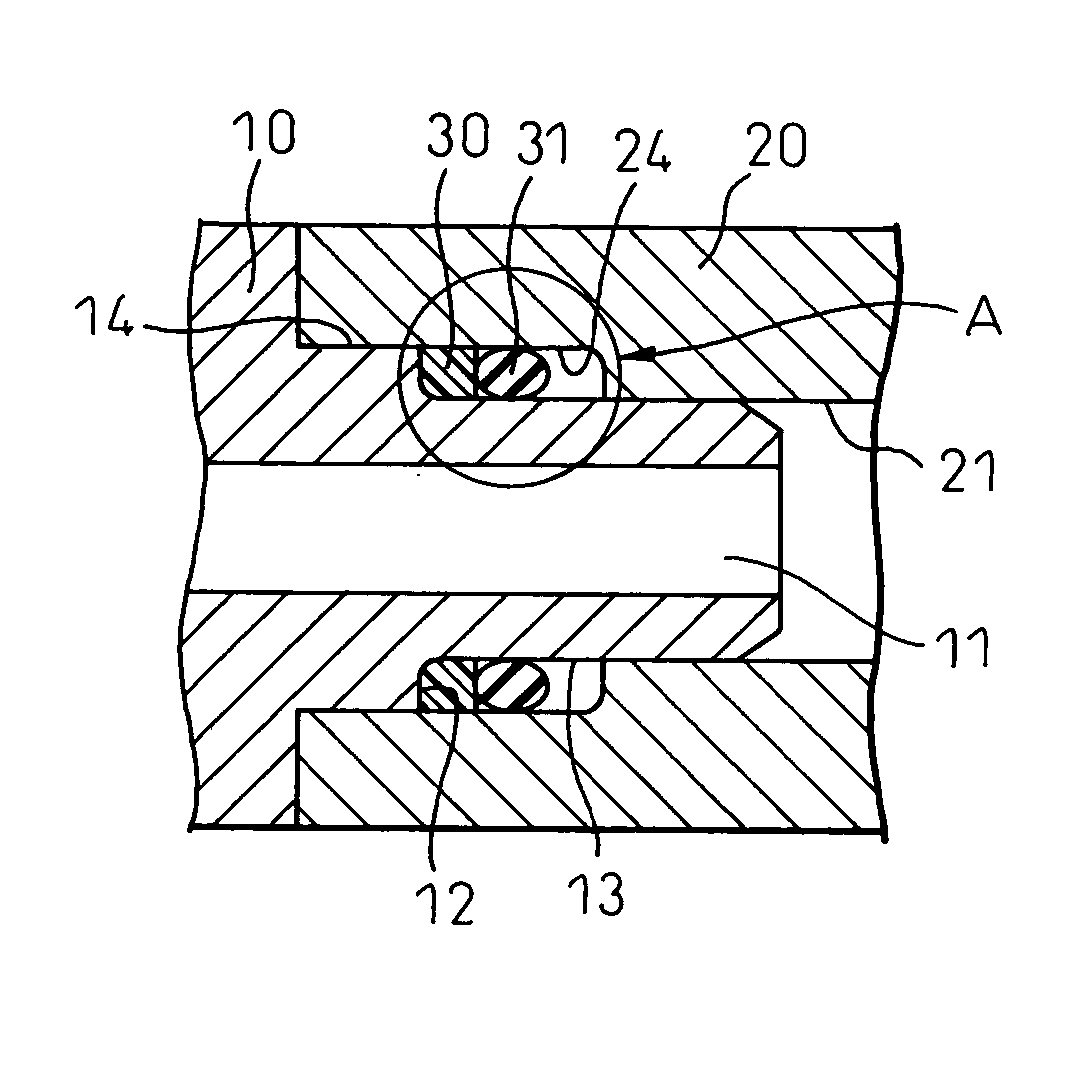

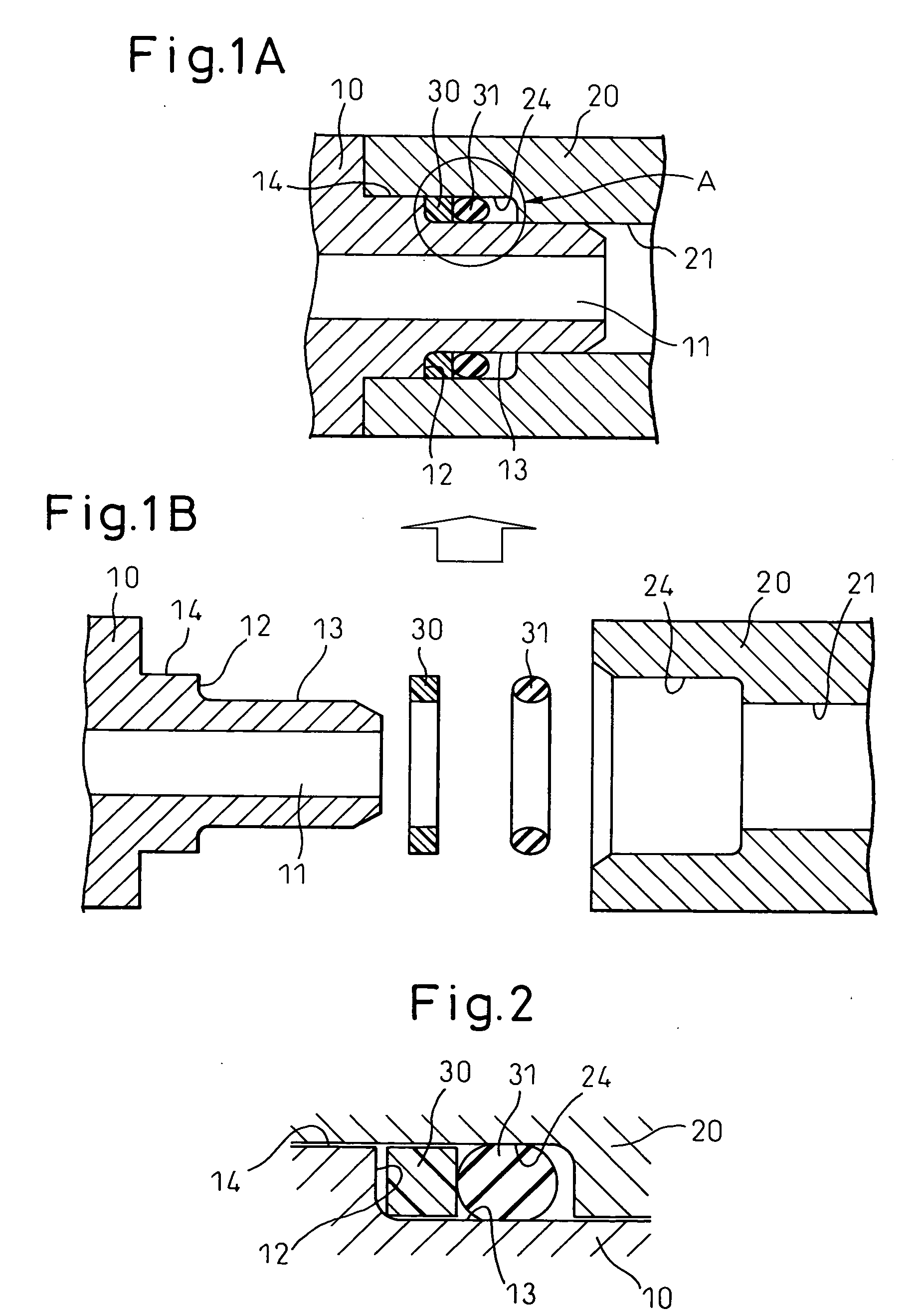

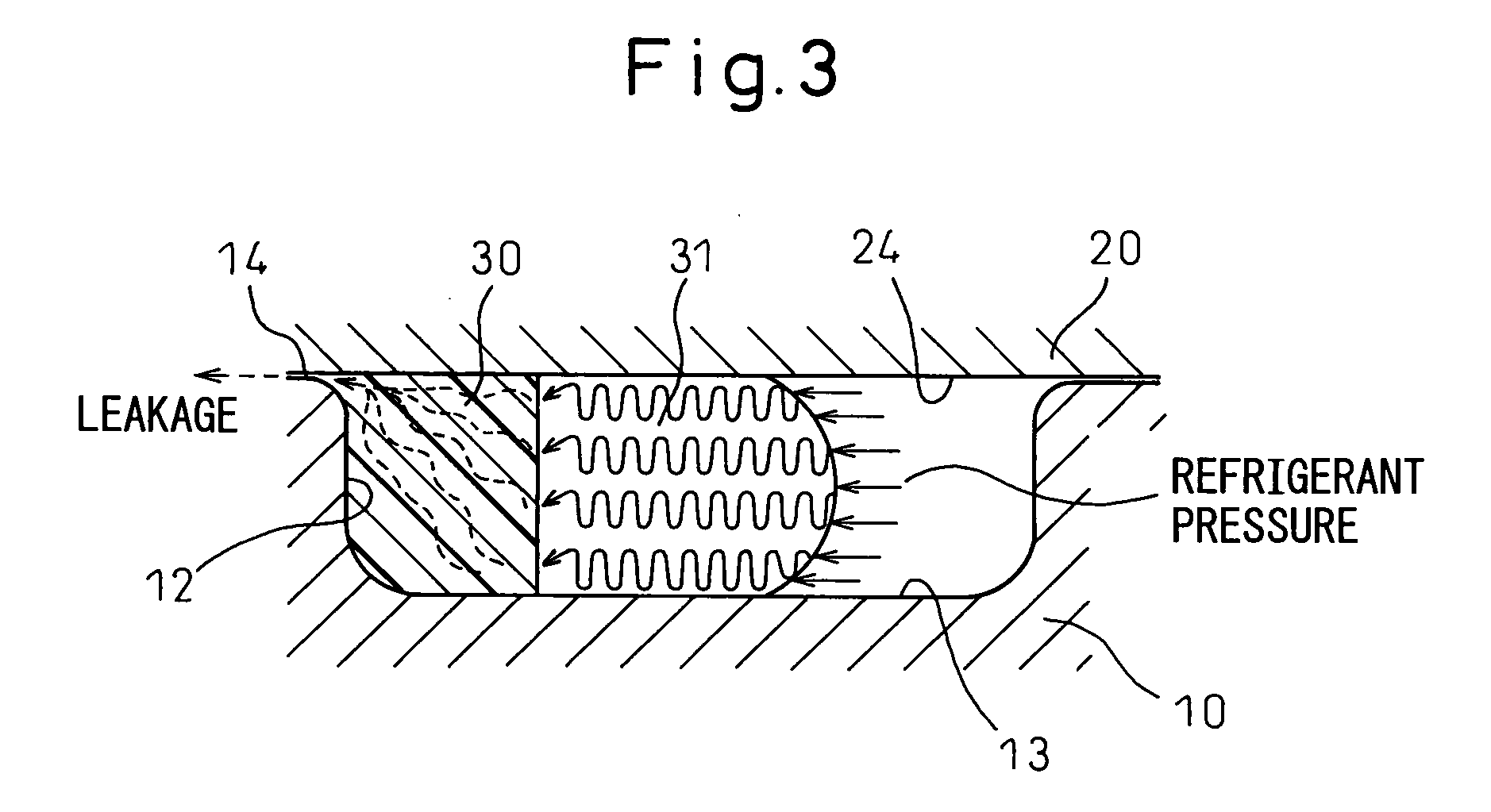

Pipe joint for refrigeration cycle having combination of O-ring and backup ring

InactiveUS20050046187A1Minimize refrigerant leakageMinimizing refrigerant leakageSleeve/socket jointsFluid pressure sealed jointsRefrigerantCarbon dioxide

A pipe joint for the refrigeration cycle is disclosed. A female joint (20) has a fitting recess (24), and a male join (10) has a fitting protrusion (14) and a stepped portion (13). In the male joint (10) and the female joint (20), a backup ring (30) and an O-ring (31) are fitted adjacently to each other in the stepped portion. The fitting protrusion (14), the backup ring (30) and the O-ring (31) are fitted in a fitting recess (24). The O-ring (31) is formed of an elastic material having a high blister resistance to carbon dioxide refrigerant. The backup ring (30) is formed of a resin material having a smaller permeability coefficient than the O-ring (31) against the carbon dioxide refrigerant and plastically deformable under the pressure of the refrigerant imposed on the O-ring (31). The refrigerant leakage amount can thus be minimized.

Owner:DENSO CORP

Gloss-coated paper with enhanced runnability and print quality

InactiveUS7018708B2Increase foam resistanceGuaranteed uptimeCoatings with pigmentsSynthetic resin layered productsMedicineOptical brightener

This invention provides a gloss-coated electrophotographic paper with superior runnability and print quality in colour and monochrome copiers and printers. The coated paper product comprises a paper substrate coated on at least one side with a pigmented coating. The pigment coating consists of a mixture of at least three different pigments and a binder. The coating may further include a lubricant. Optionally, the coating formulation may contain an optical brightening agent, a defoamer and a thickener. In addition, the gloss coated electrophotographic paper of this invention provides a superior toner adhesion in colour and monochrome electrophotographic imaging applications.

Owner:INT PAPER CO

Gloss-coated paper with enhanced runnability and print quality

InactiveUS20060159910A1Guaranteed uptimeImprove image qualityCoatings with pigmentsDuplicating/marking methodsMedicineOptical brightener

This invention provides a gloss-coated electrophotographic paper with superior runnability and print quality in colour and monochrome copiers and printers. The coated paper product comprises a paper substrate coated on at least one side with a pigmented coating. The pigment coating consists of a mixture of at least three different pigments and a binder. The coating may further include a lubricant. Optionally, the coating formulation may contain an optical brightening agent, a defoamer and a thickener. In addition, the gloss coated electrophotographic paper of this invention provides a superior toner adhesion in colour and monochrome electrophotographic imaging applications.

Owner:INT PAPER CO

Method for producing instant vermicell made of potato and the like

The production method of sweet potato fast food vermicelli includes the following steps: mixing raw materials and making slurry, spraying, coating on the steaming cloth band, forming, steaming, cloth-removing, predrying, cooling, cutting, forming and drying. The prepared starch slurry can be uniformly coated on the steaming cloth band by spray-forming machine, and the coated thickness is 1.0-1.2 mm. Said method can implement industrial automatic production, can raise production efficiency, and can produce high-quality high-nutrient sweet potato fast food vermicelli.

Owner:GUOJI IND SICHUAN

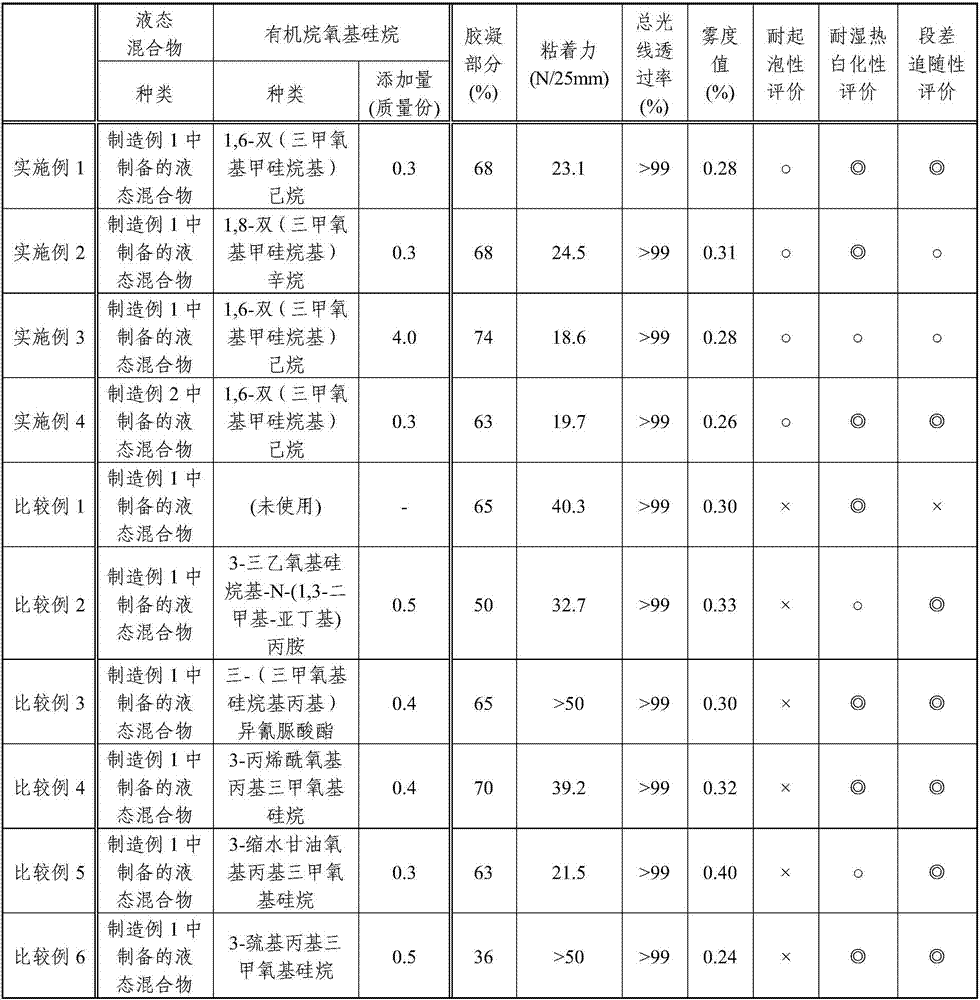

Adhesive, adhesive sheet and displayer

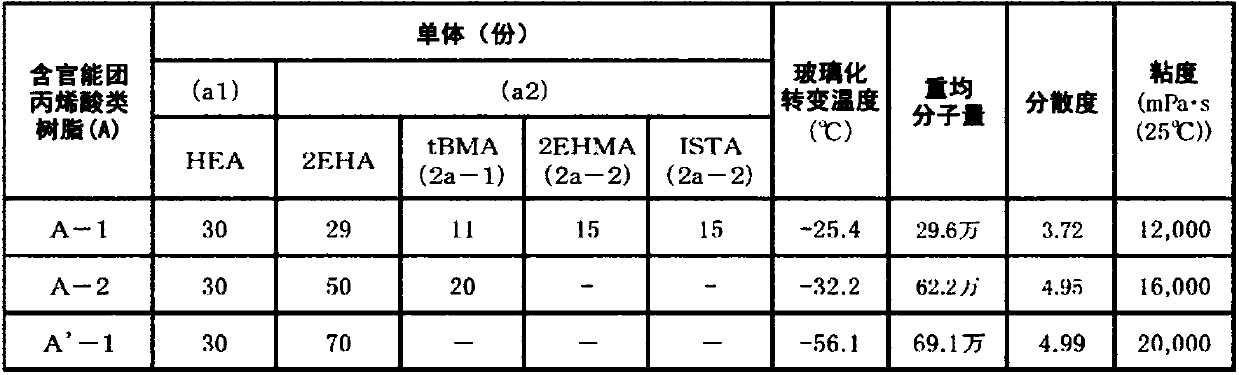

InactiveCN104231981AHigh affinityNot easy to turn whiteFilm/foil adhesivesEster polymer adhesivesPolymer scienceAdhesive

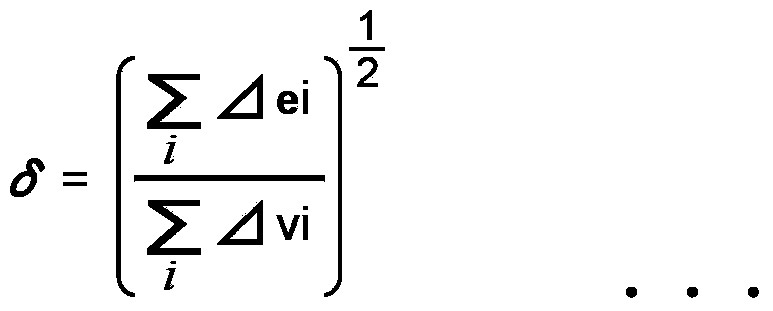

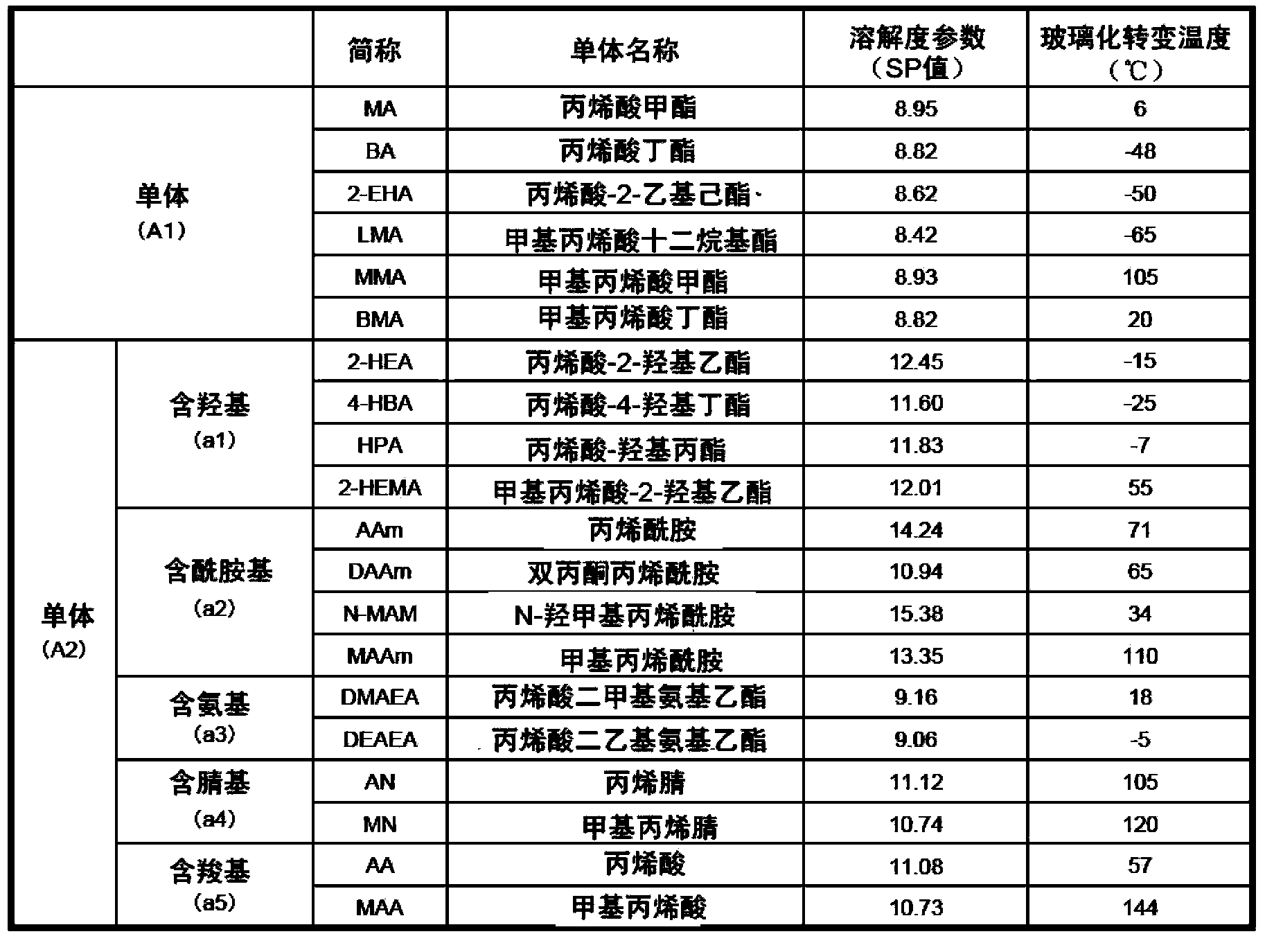

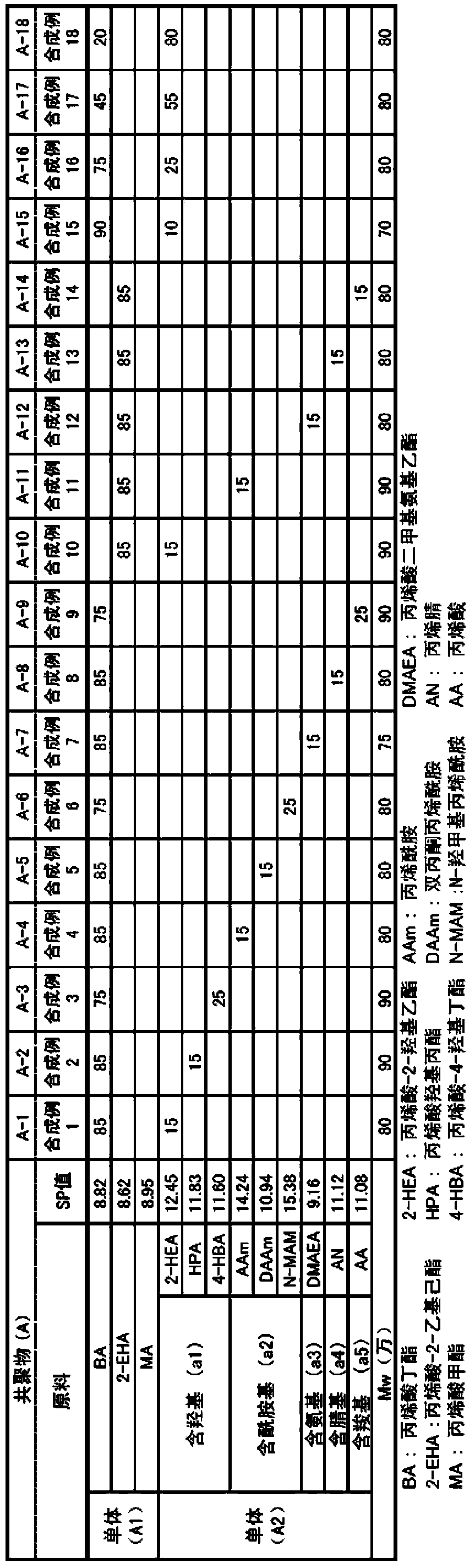

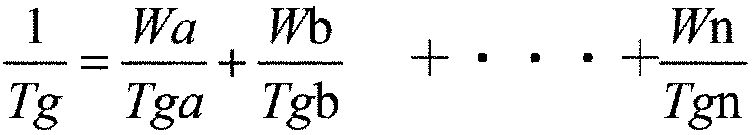

The invention aims to provide an adhesive having excellent adhesiveness, transparency, non whitening, foaming resistance and peeling resistance and also having a step difference tracing ability. The adhesive contains an acrylic copolymer (A), a polyisocyanate curing agent (B) and a silane coupling agent (C), wherein the acrylic copolymer (A) is formed through free radical polymerization of 20-90 wt% of an ethylenically unsaturated monomer (A1) having the SP value of 8 or more and less than 9.00 and having alkyl, and 10-80 wt% of an ethylenically unsaturated monomer (A2) having the SP value of 9.00 or more and 15 or less and having polar groups, and is a polymer with the weight average molecular weight of 200000-1000000; the ethylenically unsaturated monomer (A2) has more than one polar group selected from the group consisting of hydroxyl (a1), amide (a2), amino (a3) and nitrile (a4), and the glass transition temperature (Tg) of the homopolymer is -40 DEG C or more and 120 DEG C or less.

Owner:TOYO INK SC HOLD CO LTD +1

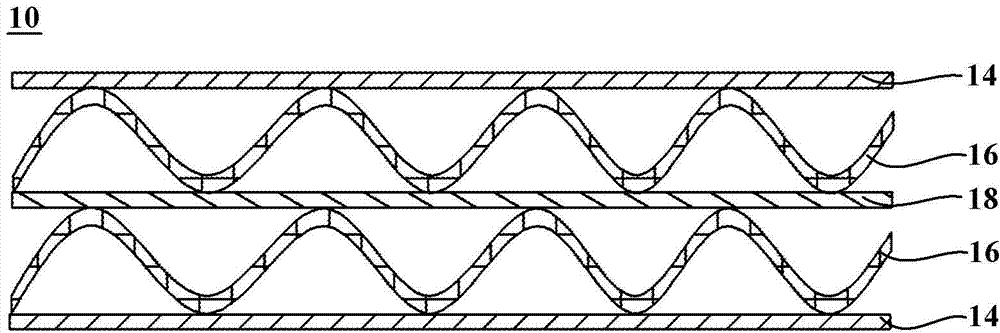

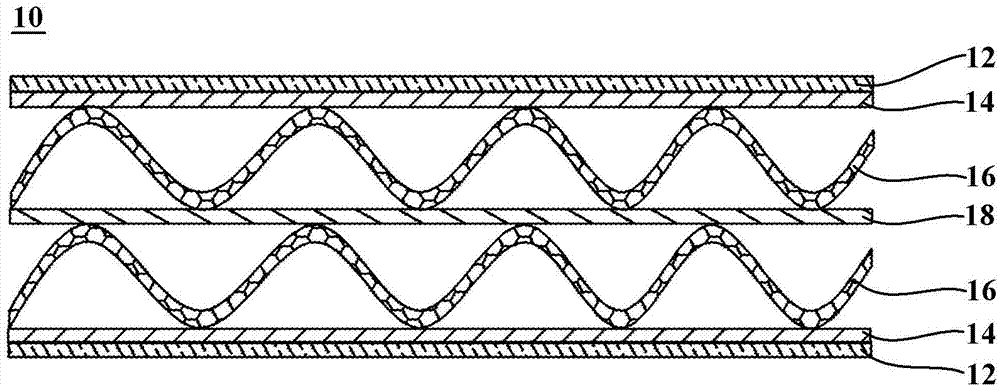

Adhesion agent, preparation method thereof and corrugated board

InactiveCN104845550AEasy to oxidizeHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesFiberPolymer science

The invention provides an adhesion agent, a preparation method thereof and a corrugated board. The adhesion agent is made of raw materials including, by weight, 1000 parts of water, 220-350 parts of starch, 6-12 parts of sodium hydroxide, 1-6 parts of moisture-resistant agent red glue, 1-4 parts of moisture-resistant agent white glue, 7-15 parts of bridging agents and 1-4 parts of sodium borate. The invention further provides a preparation method of the adhesion agent and a corrugated board prepared by the aid of the adhesion agent. The formula of the adhesion agent is improved, the moisture-resistant agent red glue and the moisture-resistant agent white glue are added into the starch, glue bodies of the moisture-resistant agent red glue and the moisture-resistant agent white glue has a lot of active groups, the active groups and starch hydroxide radical can three-dimensionally crosslink, so that a solidified glue layer is further hardened, and the performances such as hardness, bursting and edge pressing of the corrugated board are remarkably improved. In addition, the moisture-resistant agent red glue and the moisture-resistant agent white glue has high permeability, the active groups of the moisture-resistant agent red glue and the moisture-resistant agent white glue can instantaneously penetrates paper fiber gaps, contact angles among the adhesive layers and fibers are reduced, the permeability of glue is improved, and adhesive strength is improved.

Owner:HAIER SMART HOME CO LTD

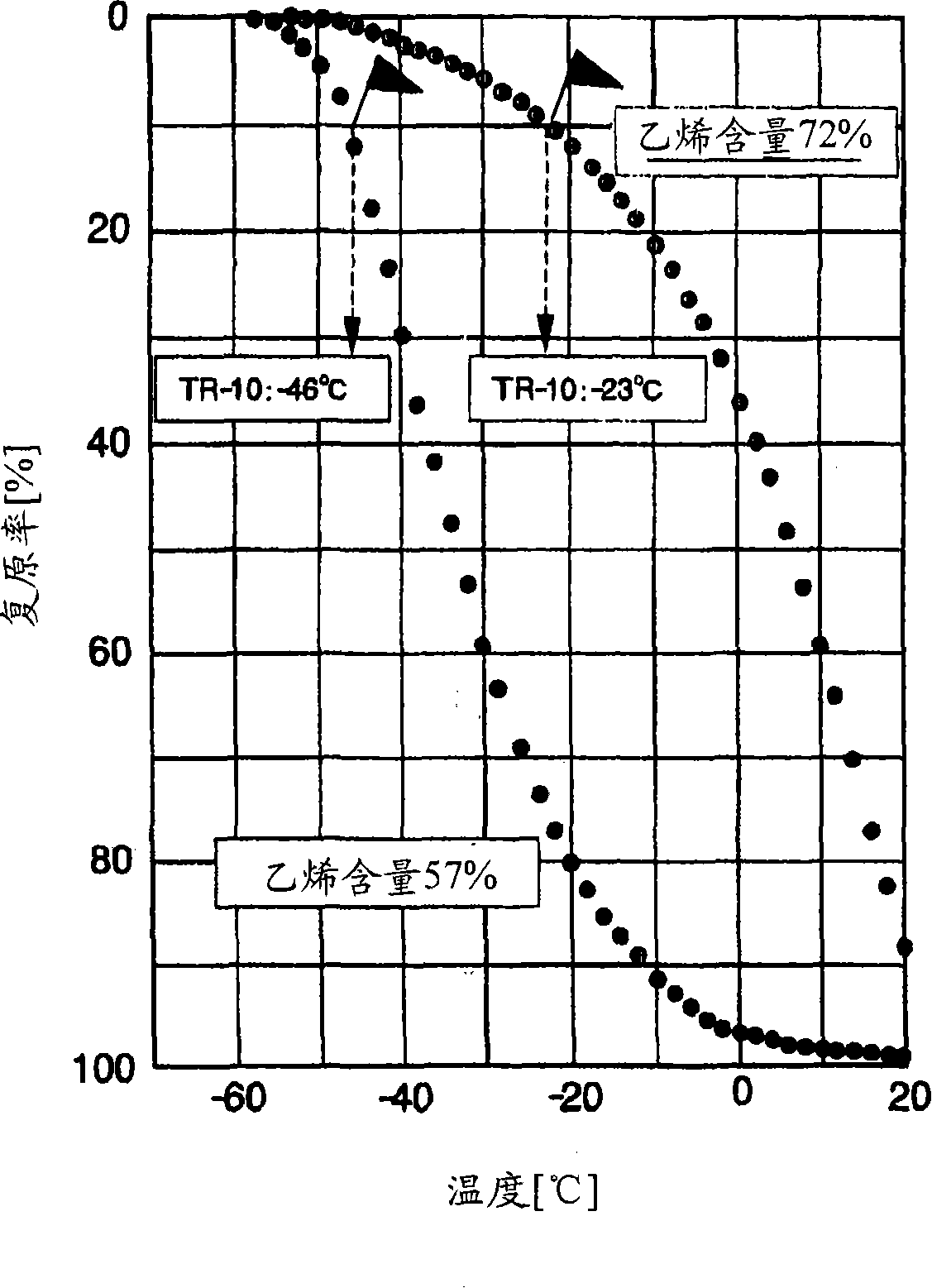

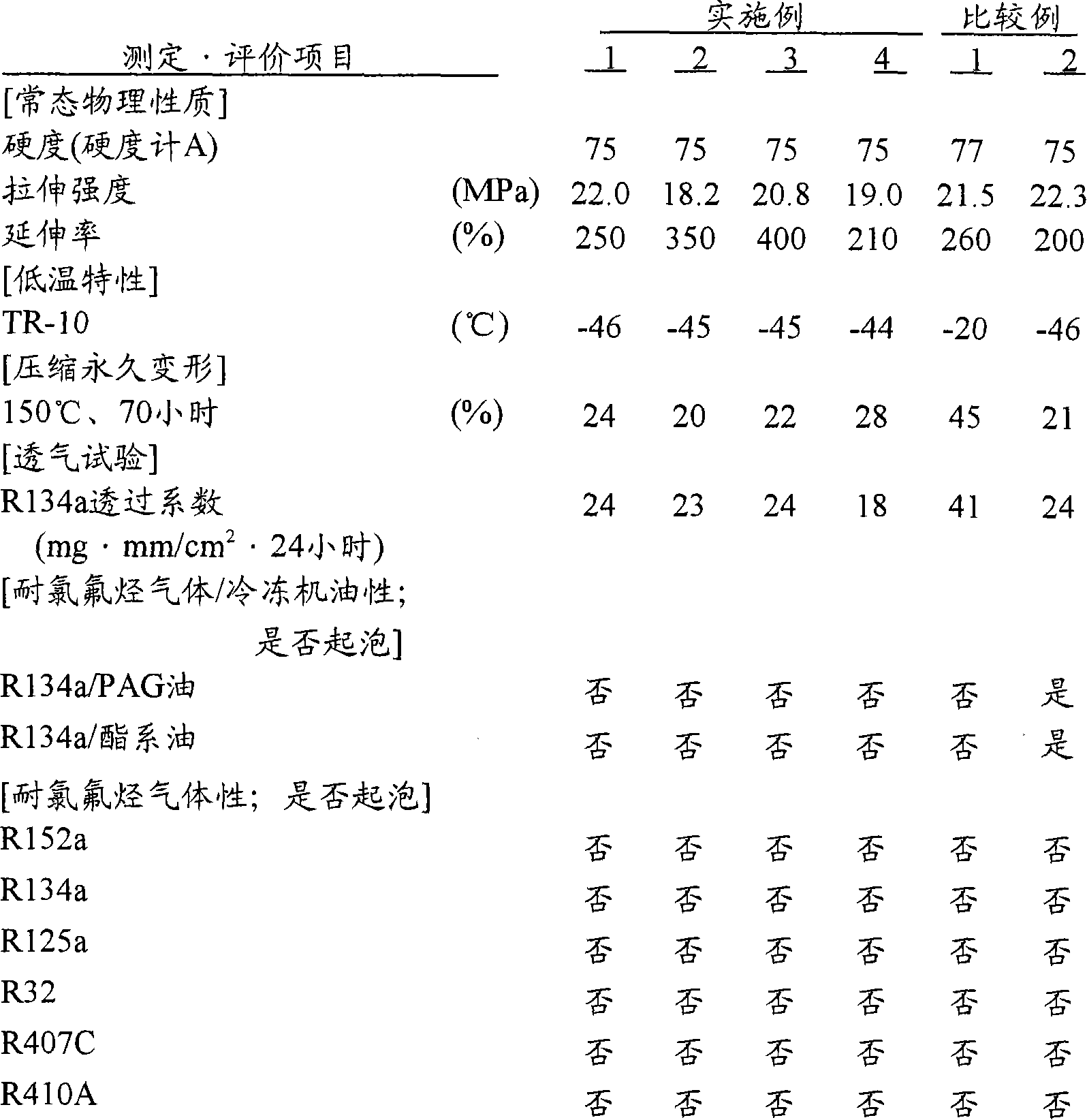

EPDM composition

InactiveCN101203565AGood molding performanceIncrease foam resistanceEngine sealsOther chemical processesVulcanizationChlorofluorocarbon

An EPDM composition which contains, as a crosslinking agent, an organic peroxide in an amount of 0.2 to 4.0 parts by weight relative to 100 parts by weight of EPDM having an ethylene content of 50 to 58% by weight and a Mooney viscosity (ML1+4) (at 100 DEG C) of 10 to 48. The EPDM composition shows an excellent blistering resistance under co-presence of flon gas / refrigerating machine oil which is a matter of concern in practical use as a rubbery material for molding a sealing material for a flon-type cooling medium (e.g., R134a), and also shows an excellent molding property. A sealing material produced by vulcanization-molding the EPDM composition, when used for sealing of a flon-type cooling medium, shows a smaller amount of permeation / leak of the cooling medium compared to that in a sealing material comprising hydrogenated NBR which has been used as a shaft seal for a compressor provided in an automotive air-conditioning system.

Owner:NOK CORP +1

Method for preparing compressed green tea and product thereof

InactiveCN103518874AImprove pressure resistanceIncrease profitPre-extraction tea treatmentGreen teaMoisture

The invention discloses a method for preparing compressed green tea. Finished loose green tea is used as raw material tea in the method, and the method specifically comprises the steps that 1) the raw material tea is humidified and softened, and mould pressing is carried out on the softened raw material tea to enable the softened raw material tea to be in a preset shape; 2) through vacuum dehumidifying, with the help of optical wave heating and / or microwave heating and cooling methods, the raw material tea in the preset shape through the mould pressing is dried to a preset moisture content, and the needed compressed green tea is obtained. The tradition that original finished green tea can only be loose tea is broken through by the compressed green tea, the resistance to pressure of the tea is improved, the tea is convenient to transport and carry, and the storage condition of the tea is lowered.

Owner:林志宾

Preparation method and product of tuan-shaped black tea (tuan is a Chinese character)

InactiveCN103493910AEasy to drinkImprove pressure resistancePre-extraction tea treatmentChinese charactersBlack tea

The invention discloses a preparation method of tuan-shaped black tea (tuan is a Chinese character). The method takes bulk tea of finished black tea as raw tea and comprises the following specific steps: (1) humidifying and softening the raw tea and carrying out mould pressing on the softened raw tea to form tuan-shaped raw tea; (2) drying the tuan-shaped raw tea into the tea with the predetermined water content through using vacuum dehumidification, optical wave heating and / or microwave heating and cooling means to obtain the required tuan-shaped black tea. The method provides a feasible technical way for preparing different types of the bulk tea of the black tea into the tuan-shaped black tea; the tuan-shaped black tea brings a brand-new black tea drinking way to people and can be conveniently drunk by the people.

Owner:林志宾

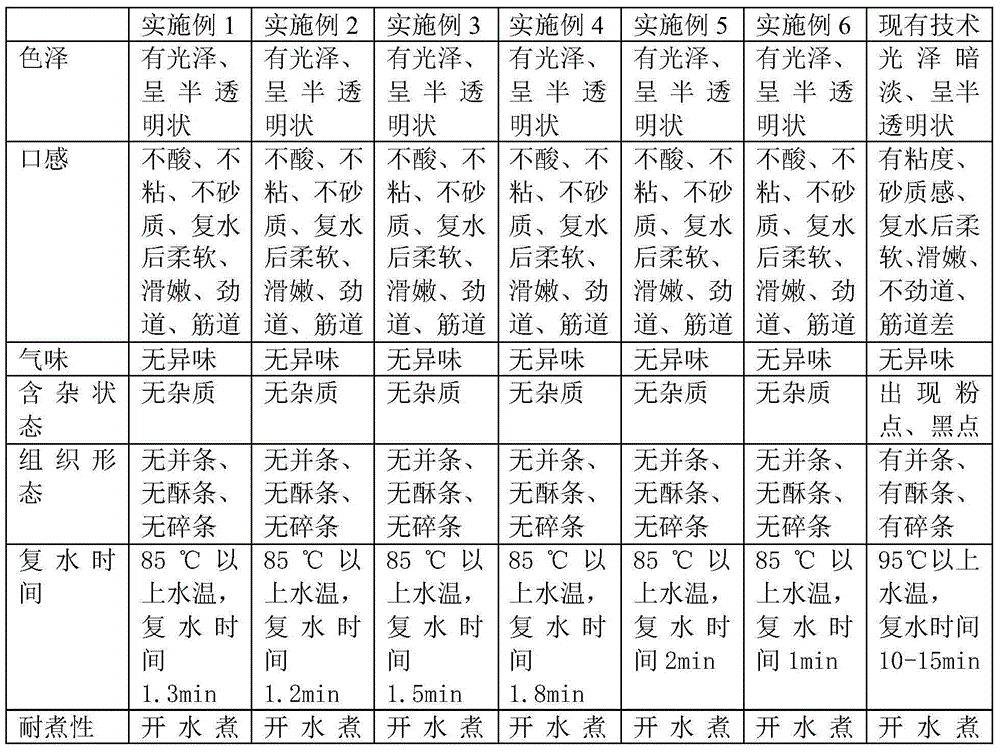

Manufacturing process of convenient vermicelli

InactiveCN105076946AExtended shelf lifeGood fresh-keeping effectFood preparationSlurryExpiration date

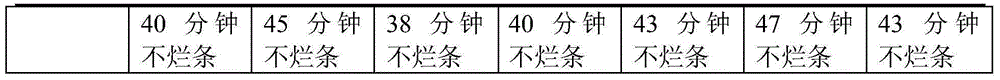

The invention provides a manufacturing process of convenient vermicelli and belongs to the technical field of vermicelli processing. The process includes the following operating steps of raw material preparation, thickening, pulp mixing and pulp preparing, coating, decoating, aging, slitting, bagging, vacuumizing, sterilization, and encasement and storage input. The finished convenient vermicelli is obtained. The pH value of pulp prepared in the pulp mixing and pulp preparing step is controlled to be 3.5-4.0 through acid, then coating and decoating operation is conducted, and then aging is conducted through a normal temperature aging process. In the pulp mixing process, the pulp is prepared into the acid pulp with the pH value of 3.5-4.0, the pulp is in an acid environment, the expiration date of the convenient vermicelli can be prolonged, and the shelf life of the convenient vermicelli is prolonged by 3-5 months. The prepared finished convenient vermicelli is good in freshness keeping effect, bright, quick in soaking rehydration, split but not mushy after 40 minutes, smooth and chewy in taste, good in boiling fastness and free of burnt soup.

Owner:河北中祥农业发展有限公司

Preparation method of oolong compressed tea and product of preparation method

ActiveCN103535456AImprove pressure resistanceIncrease profitPre-extraction tea treatmentFermentationWater content

The invention discloses a preparation method of oolong compressed tea. The method takes finished-product oolong loose tea as raw tea and comprises the following specific steps: (1) wetting and softening the raw tea and carry out mould pressing on the softened raw tea to obtain a pre-set shape; (2) drying the raw tea which is in the pre-set shape formed by the mould pressing to pre-set water content through vacuum dehumidification by using an optical wave heating and / or microwave heating and cooling means, so as to obtain the needed oolong compressed tea. According to the oolong compressed tea, the technical limitations that traditional oolong can only be the loose tea and the fermentation degree of the prepared compressed tea cannot be controlled and the like are broken through, so that the pressure resistance of the tea is improved, the transportation and the carrying of the tea are convenient and the storage condition of the tea is reduced.

Owner:林志宾

Preparation method and product of tuan-shaped oolong tea (tuan is a Chinese character)

ActiveCN103461559AEasy to drinkImprove pressure resistancePre-extraction tea treatmentProcess engineeringFood science

The invention discloses a preparation method of tuan-shaped oolong tea (tuan is a Chinese character). The method takes bulk tea of finished oolong tea as raw tea and specifically comprises the following steps: (1) softening the raw tea by wetting and carrying out mould pressing on the softened raw tea to form tuan-shaped tea; and (2) drying the tuan-shaped tea to achieve the predetermined water content through vacuum dehumidifying, light wave heating and / or microwave heating and cooling means so as to obtain the required tuan-shaped oolong tea. According to the preparation method, a feasible technical way is provided for preparing the tuan-shaped oolong tea, and the tuan-shaped oolong tea brings a brand-new oolong tea drinking way to people and provides convenience for people to drink the oolong tea.

Owner:林志宾

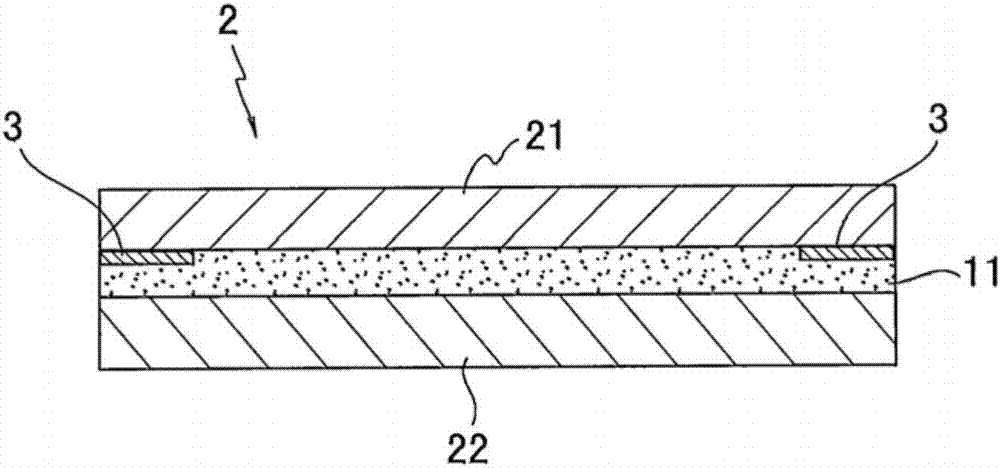

Pressure-sensitive adhesive sheet, process for producing laminate including pressure-sensitive adhesive layer, laminate including pressure-sensitive adhesive layer, image display device, and touch panel

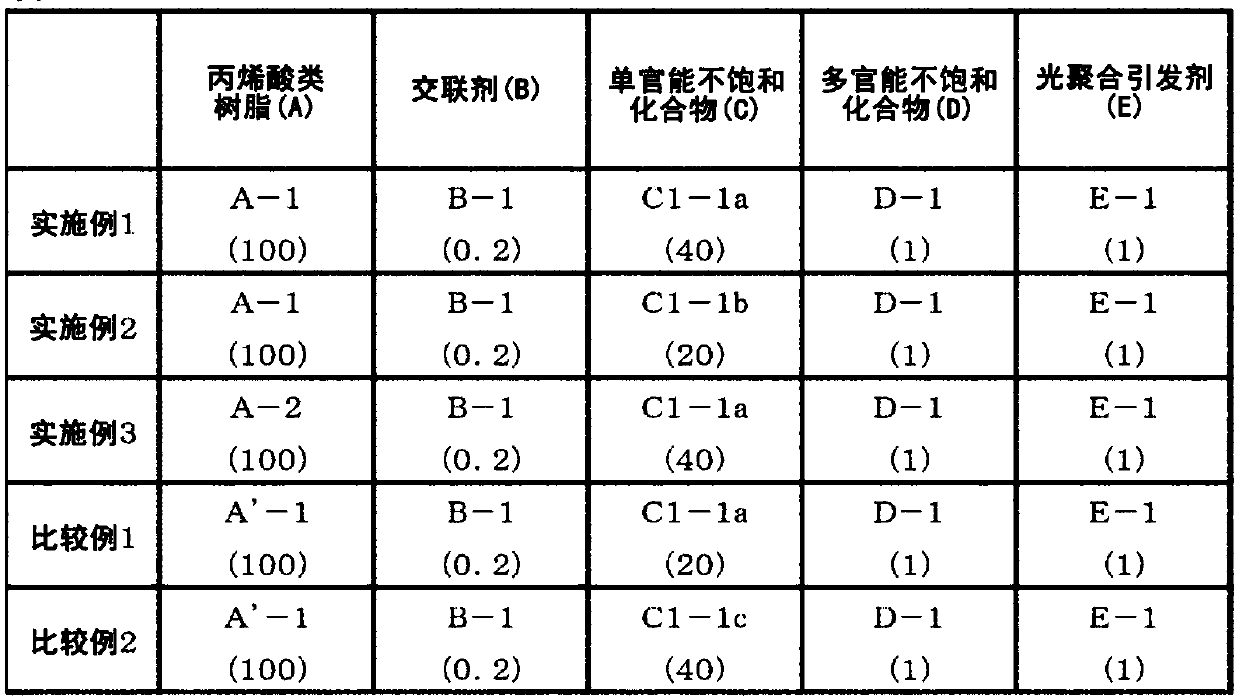

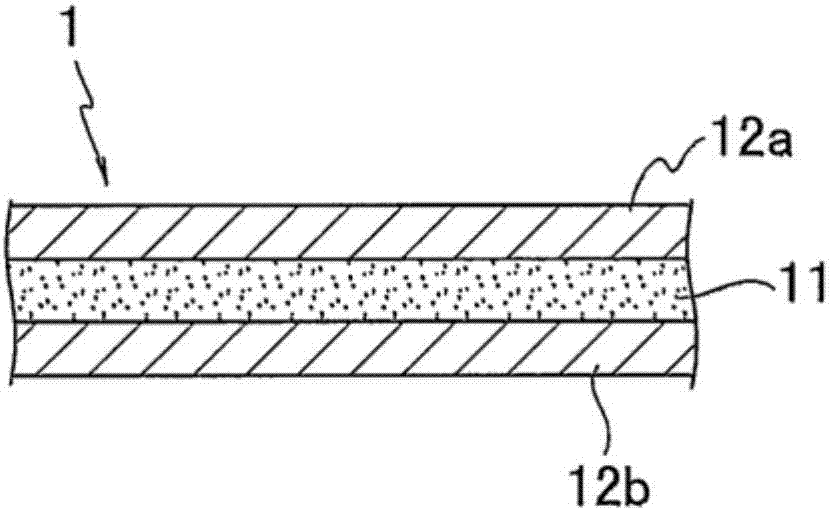

ActiveCN107849397AExcellent height difference followabilityIncrease foam resistanceSynthetic resin layered productsEster polymer adhesivesPolymer scienceAcrylic resin

The purpose of the present invention is to provide a pressure-sensitive adhesive sheet which is excellent in terms of level difference conformability and blistering resistance and which has an excellent balance among pressure-sensitive adhesive properties (adhesive force, holding power), moist-heat resistance, and blistering resistance and has a high level of reliability. The pressure-sensitive adhesive sheet according the present invention includes a pressure-sensitive adhesive layer which comprises a crosslinked resin obtained from a functional-group-containing acrylic resin (A) and a crosslinking agent (B) and which further includes an ethylenic compound (C) having one ethylenically unsaturated group, the functional-group-containing acrylic resin (A) having a glass transition temperature of -35 DEG C or higher.

Owner:MITSUBISHI CHEM CORP

Solventless type adhesive composition, adhesive, adhesive sheet and display body

ActiveCN106967380AIncrease foam resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHydrogenOligomer

The invention is to provide a solventless type adhesive composition, an adhesive, an adhesive sheet and a display body capable of exhibiting excellent blister resistance. There is provided a solventless type adhesive composition containing at least one kind of polymerization component selected from a polymerizable vinyl monomer, a polymerizable vinyl prepolymer, a polyfunctional (meth)acrylate monomer and a polyfunctional (meth)acrylate oligomer and organoalkoxysilane having a linear structure and alkoxysilyl groups at both terminals, wherein at least a part of the polymerization component contains an active hydrogen group.

Owner:LINTEC CORP

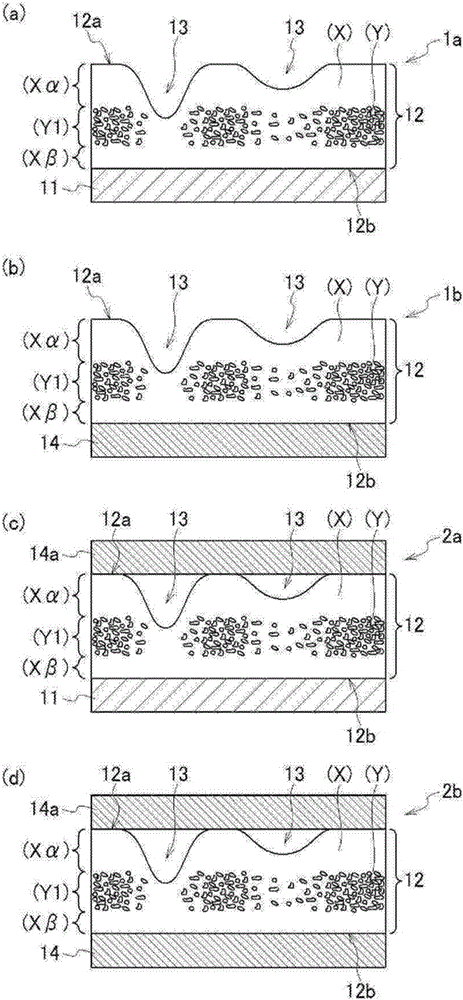

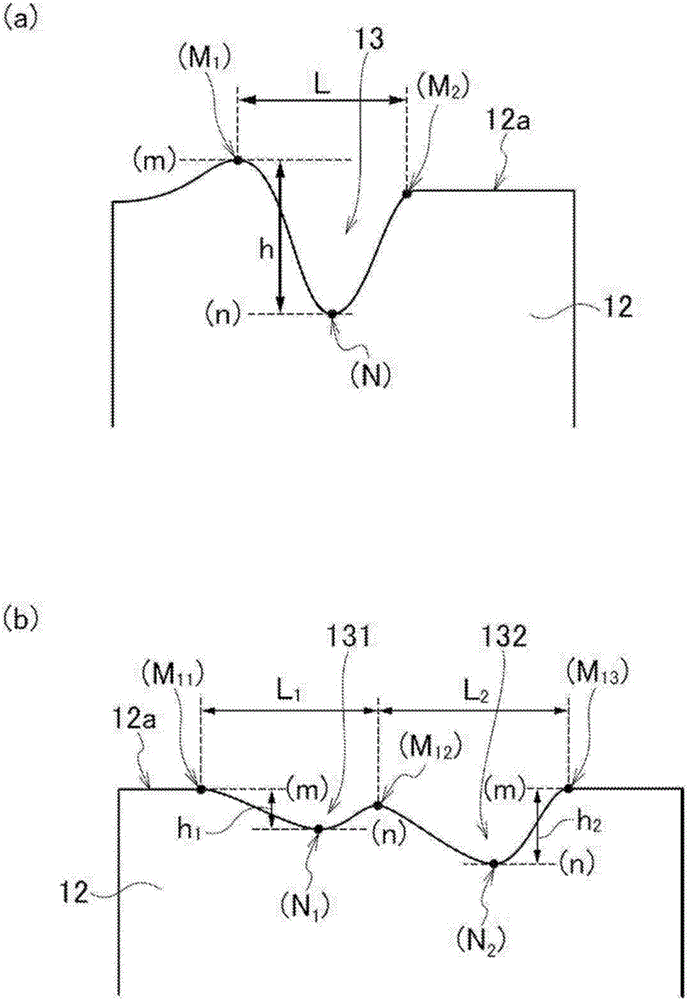

Adhesive sheet

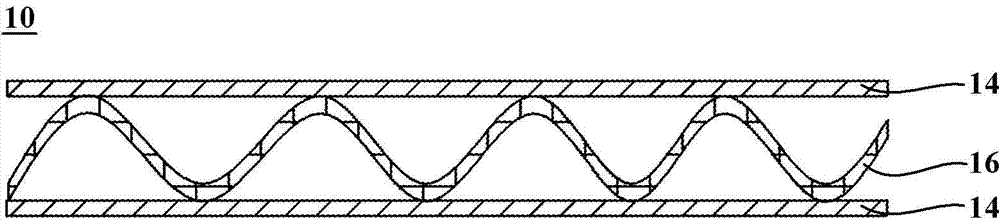

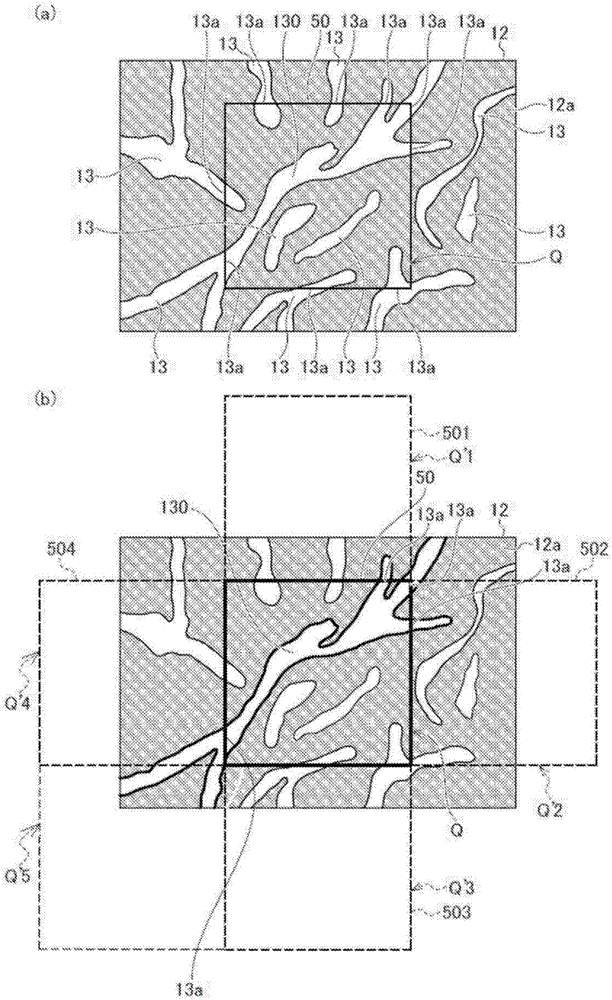

ActiveCN106164199AImprove degassing effectIncrease foam resistanceNon-macromolecular adhesive additivesEster polymer adhesivesHeight differencePrimary component

Provided is an adhesive sheet having, on a base member or release member, a resin layer containing a resin component (X), which contains resin as the primary component, and a particle component (Y), which comprises microparticles, at least the surface ([Alpha]) of the resin layer at the reverse side from the side to which the base member or release member is provided having adhesive properties, wherein a plurality of concavities having a maximum height difference of at least 0.5 [Mu]m are present within a predetermined region (P) on the surface ([Alpha]), at least 95% of the plurality of concavities present within the region (P) have shapes that differ from each other, and at least one concavity is present within a predetermined region (Q) on the surface ([Alpha]). The adhesive sheet has favorable blistering resistance and adhesive properties, and has superior air passage properties such that collections of air that can arise when the adhesive sheet is pasted to an adhesion subject can be easily eliminated.

Owner:LINTEC CORP

Preparation method and product of tuan-shaped yellow tea (tuan is a Chinese character)

InactiveCN103493911AImprove pressure resistanceIncrease profitPre-extraction tea treatmentChinese charactersWater content

The invention discloses a preparation method of tuan-shaped yellow tea (tuan is a Chinese character). The method takes bulk tea of finished yellow tea as raw tea and comprises the following specific steps: (1) humidifying and softening the raw tea and carrying out mould pressing on the softened raw tea to form tuan-shaped raw tea; (2) drying the tuan-shaped raw tea into tea with the predetermined water content through using vacuum dehumidification, optical wave heating and / or microwave heating and cooling means to obtain the required tuan-shaped yellow tea. The method provides a feasible technical way for preparing the bulk tea of the yellow tea into the tuan-shaped yellow tea; the tuan-shaped yellow tea brings a brand-new yellow tea drinking way to people and can be conveniently drunk by the people.

Owner:林志宾

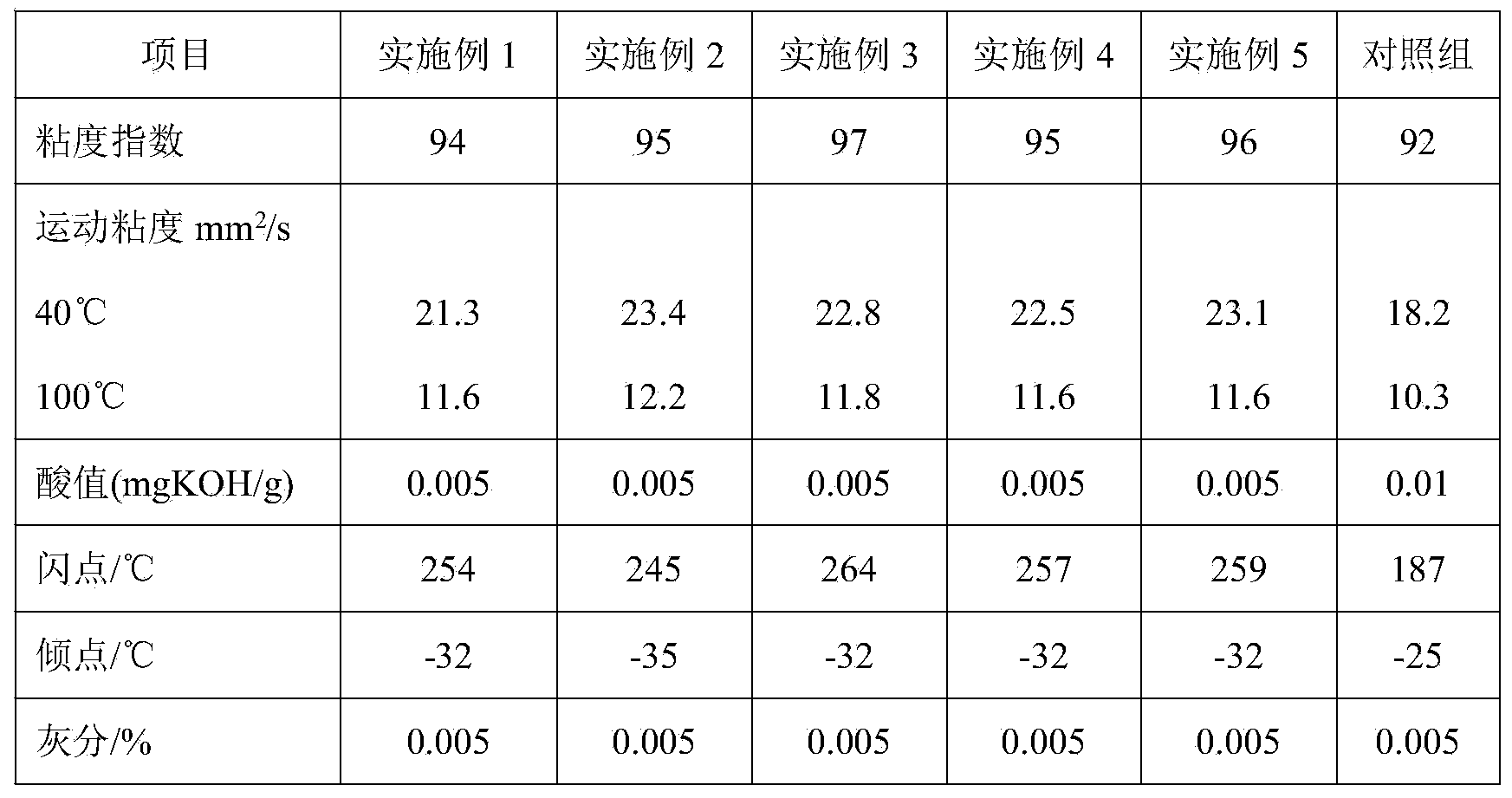

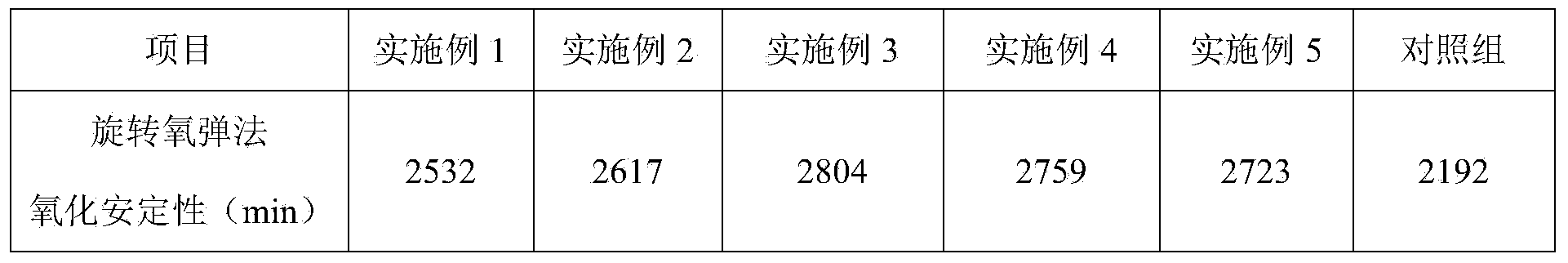

Steam turbine oil composition and preparation method thereof

InactiveCN104357183ALow viscosityHigh specific heatLubricant compositionAntioxidantSulfonated polymer

The invention discloses a steam turbine oil composition and a preparation method thereof, and relates to the field of industrial lubricants. The steam turbine oil composition comprises the following components: (1) base oil; (2) an antioxidant; (3) an anticorrosive antioxidant; (4) an antirust agent; (5) an extreme pressure wear resisting composite agent; (6) an organic sulfonated substance or organic sulfonated polymer; (7) an anti-bubbling agent; (8) a demulsifying agent; (9) a dispersing agent. The preparation method of the steam turbine oil composition comprises the following steps: (1) weighing; (2) mixing compressed air; (3) mixing by using a mixing pump; (4) performing standing. The steam turbine oil composition provided by the invention is stable in quality, moderate in viscosity and good in liquidity, has excellent lubricating performance, extreme pressure wear resistance, cooling performance, high temperature stability and oxidation stability and relatively good bubbling resistance and demulsibility, and is very ideal steam turbine oil.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

Pumpkin cornflake and preparation method thereof

InactiveCN102919716AIncrease foam resistancePrevent moisture absorptionFood preparationChemistryLiquid food

The invention provides a pumpkin cornflake. The pumpkin cornflake is prepared by the following preparation method: uniformly mixing 55-65 weight parts of waxy corn powder, 15-25 weight parts of sweet corn powder, 8-10 weight parts of pumpkin powder and 15-25 weight parts of water; feeding the mixture to a twin-screw extruder for extruding and forming; pelleting and tabletting the extruded and formed mixture to prepare a cornflake which is 0.2-0.4 millimeter thick; roasting the cornflake at 150 DEG C plus (minus) 5 DEG C for 8-10 minutes; uniformly spraying 5-8 weight parts of molten bee wax to the surface of the cornflake when the roasted cornflake is cooled to 55 DEG C plus (minus) 2 DEG C, quickly cooling the roasted cornflake to the room temperature to acquire the pumpkin cornflake. The bee wax is added in the preparation process, and so soaking resistance of the pumpkin cornflake in liquid food is better than that of the traditional cornflake; simultaneously, the pumpkin cornflake can be prevented from absorbing moisture in a storage process. The pumpkin powder and the sprayed bee wax are added to the ingredients, so that the nutrition of the cornflake is increased, and the variety of the cornflakes is enriched.

Owner:HARBIN PATERNA BIOTECH DEV

Production process and storage process of Rizhuhong black tea

PendingCN105394207ASimple production processThe taste is fresh and moistPre-extraction tea treatmentCooking & bakingBlack tea

The present invention discloses a production process and a storage process of a Rizhuhong black tea. The production process comprises fresh leaf spreading, withering, rolling, fermenting, primary drying, shaping with a frying pot, primary baking, and secondary baking. The storage process comprises: equally dividing black tea; wrapping a layer of a film outside the packaged tea leaf; coating a layer of a quicklime glue outside the film; wrapping a layer of a film after drying the quicklime glue; and storing the obtained tea bag in a cooling cabinet with a temperature of 0-5 DEG C. According to the present invention, the improvement is performed on the basis of the traditional black tea production process, the shaping with the frying pot is added, and other traditional processes are improved, such that the produced black tea has characteristics of coiling, black and moistening shape, fresh and moistening taste, sweet and lasting aroma, good infusion resistance, red color, and sweet and mellow taste; and the two technologies such as cold preservation and storage with lime are combined, such that the black tea can be stored for a long time while no deterioration is generated, the aroma of the black tea can be stored for a long time, and the possibility of gas leakage is extremely low.

Owner:SHAOXING DONGFANG TEA IND CO LTD

Winter fermented tea preparation method

InactiveCN106993666AReduce pesticide residuesNatural raw materialsPre-extraction tea treatmentTheaflavinAdditive ingredient

The invention relates to winter fermented tea and a preparation method. The preparation method comprises the following preparation operation steps: (1) picking and pretreating fresh leaves; (2) steaming tea at high temperature; (3) flushing with cold water; (4) secondarily steaming; (5) rolling; (6) performing pile fermentation; (7) secondarily rolling; (8) parching; (9) improving fragrance; (10) breaking to obtain finished-product tea. The preparation method disclosed by the invention is adopted to improve tea biological activity, increases ingredients of theaflavin, theanine and the like, eliminate bitter and astringent of the tea and enables tea fragrance to be mellower. According to the preparation method, old leaves are utilized, and tea stems are remained; thus, not only is the utilization rate of tea resources improved and tea yield improved, but also the prepared tea has rich nutrition, pure liquid color and good brewing resistance and still has bright color and luster and mellow smell after being brewed for many times; furthermore, the tea has the characteristics of tonifying spleen and warming stomach and has a good health-maintenance effect.

Owner:合肥福润茶业技术有限公司

Preparation method for green tea

InactiveCN103976054AStrong overall senseThe rope is tightly knotted and evenPre-extraction tea treatmentThirstDigestion

The invention especially discloses a preparation method for green tea. The preparation method comprises the following steps: (1) blending of attached liquids; (2) spraying; (3) drying; and (4) shaping and fragrance promotion. The invention has the following beneficial effects: the preparation method is simple, raw materials can be fully and uniformly mixed, so the prepared green tea presents a strong sense of wholeness and has compact and uniform cords and an oily color; malt extract, peach seed extract, lophatherum gracile extract, geranium wilfordii tea and green tea are fully and effectively mixed, raw materials are scientifically proportioned, so the prepared green tea has good quality, presents pure, fresh and agreeable taste and rich delicate fragrance when drunk, is convenient to drink, endures brewing, exerts a good health care effect on a human body, promotes the production of body fluid to quench thirst, has after-taste sweetness after drinking of the green tea, can raise spirit, clear away the heart-fire, clear heat and relieve summer heat and is capable of helping digestion, reducing phlegm, removing greasiness, losing weight, reliving internal heat, improving eyesight, moisturizing dryness, lubricating intestines, removing inflammation, promoting diuresis, dispelling wind, invigorating blood circulation and the like after long-term drinking.

Owner:山东华夏茶联信息科技有限公司

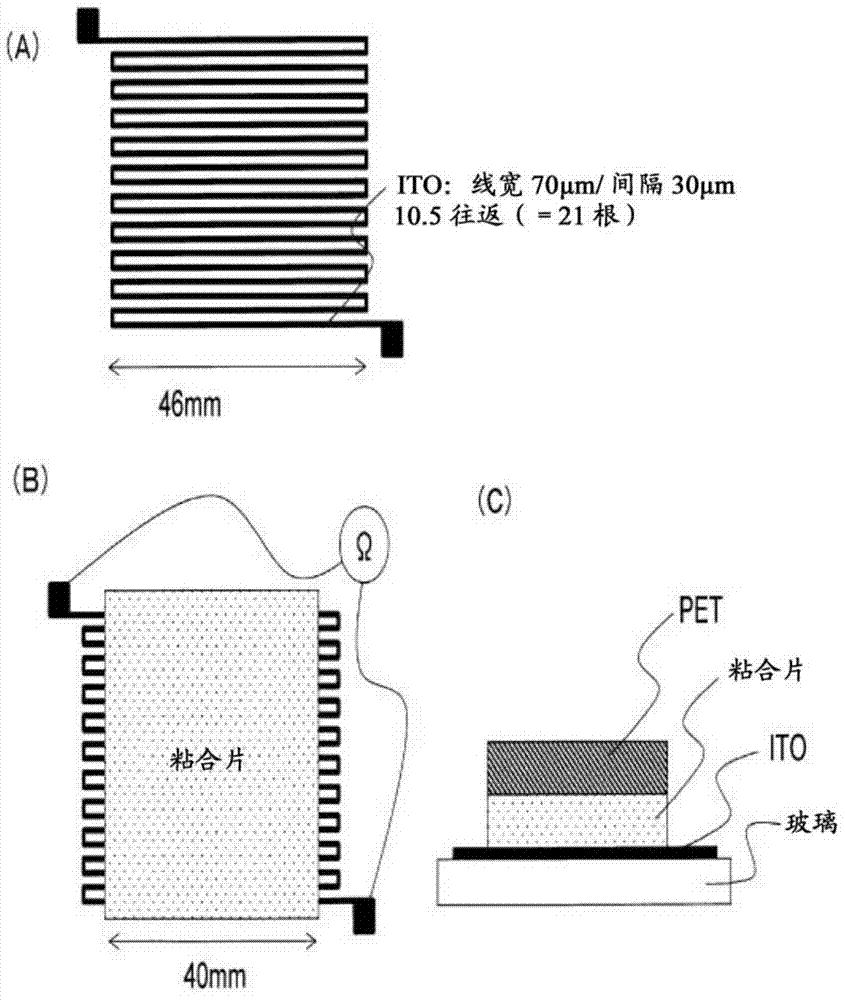

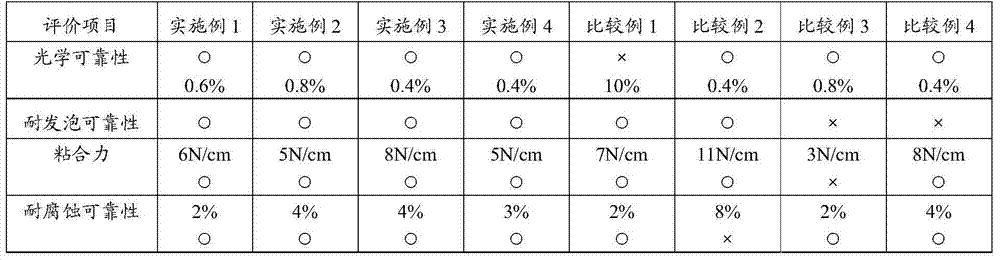

Transparent double-sided adhesive sheet and image display device using same

ActiveCN104769063ASufficient corrosion resistance reliabilityOptical reliability does not occurNon-macromolecular adhesive additivesAdhesive articlesBond interfaceUltraviolet lights

Provided is a novel transparent double-sided adhesive sheet which has corrosion resistance reliability that enables an object to be bonded to be prevented from deterioration due to corrosion, while having foaming resistance reliability that enables prevention of foaming at a bonding interface and optical reliability that enables suppression of haze increase even in a wet heat environment. Proposed is a transparent double-sided adhesive sheet which is first characterized by having an adhesive layer that contains a (meth)acrylic acid ester copolymer containing less than 2% by mass of a carboxyl group-containing monomer as a copolymerization component and fine silica particles having an average particle diameter of 4-500 nm. This transparent double-sided adhesive sheet is secondly characterized in that the adhesive layer can be cured by heat or ultraviolet light.

Owner:MITSUBISHI CHEM CORP

Preparation method of composite fragrant cold-brewed tea and composite fragrant cold-brewed tea prepared by preparation method

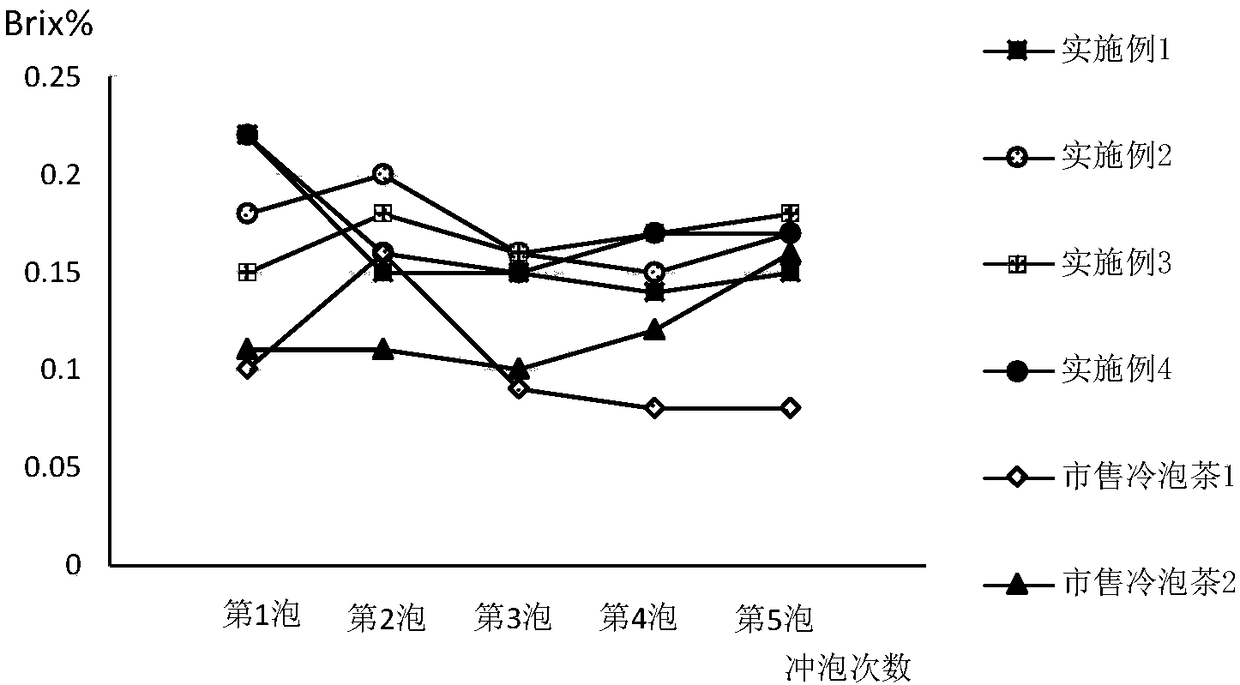

ActiveCN109329485AReduce lossRelieve pressurePre-extraction tea treatmentTea extractionFlavorBlack tea

The application provides a preparation method of composite fragrant cold-brewed tea. The preparation method comprises the following steps of step 1, preparing tea leaf A condensed juice; step 2, applying the tea leaf A condensed juice to the surface of tea leaves B, and performing drying until the tea leaves are sufficiently dried, so as to obtain tea leaf B products; and step 3, adding tea leavesC to the tea leaf B products prepared in the step 2, and performing uniform mixing so as to obtain the composite fragrant cold-brewed tea. The tea leaves A, the tea leaves B and the tea leaves are one or a combination of several kinds of green tea, black tea, scented tea, white tea, dark tea, oolong tea and yellow tea, and the tea leaves A, the tea leaves B and the tea leaves B are different. Thepreparation of the tea leaf A condensed juice can also comprises enzyme treatment. The application further provides the composite fragrant cold-brewed tea prepared by the preparation method. Under the condition of cold brewing, taste and fragrance of three or more kinds of tea leaf products are merged, and fragrant and taste substances of the three kinds of the tea are released in a staged manner. The composite fragrant cold-brewed tea is sweet and mellow in mouth feel, rich in fragrance, and natural in flavor, and is progressive layer by layer,, and the brewing resistance and the leaching speed are notably increased.

Owner:SHENZHEN SHENBAO HUACHENG TECH

Processing method of fresh-and-mellow type and sweet-and-mellow type summer-autumn green tea in tea area north of Yangtze River

ActiveCN108552326ASolve the problem of poor shape uniformityReduce deliveryPre-extraction tea treatmentCataphyllBreakage rate

The present invention relates to a processing method of fresh-and-mellow type and sweet-and-mellow type summer-autumn green tea in tea area north of Yangtze River. A current raw material of "one bud and two leaves" is replaced by two raw materials of "one bud and one leaf" and "single leaf"; a cycle alternation of "long-time spreading for 3-4 h + short-time vibrating for 1-3 min is conducted for 2-3 times; finally, after the vibrating, then the spreading is conducted for 4-6 h; fresh leaves are spread for a total time reaching 10-16 hours to prepare the green tea. The method can realize the processing of the two raw materials to respectively obtain the fresh-and-mellow type green tea and sweet-and-mellow type green tea. A multifunctional strip-tidying machine combines processes of enzyme-deactivating and primary shaping processes; traditional methods of past roller enzyme deactivating and rolling and shaping by a rolling machine are changed; a problem that the color and luster of the summer-autumn green tea are deep and dark is avoided; and the processing method also reduces a breakage rate of tea leaf cells and can effectively solve problems that summer fresh leaves are long in internodes and adjacent blade shapes are large in differences, leading to poor shape uniformity of the product.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Coffee cornflake and preparation method thereof

InactiveCN102919722AIncrease foam resistancePrevent moisture absorptionFood preparationWaxy cornAdditive ingredient

The invention provides a coffee cornflake. The coffee cornflake is prepared by the following preparation method: uniformly mixing 55-65 weight parts of waxy corn powder, 20-30 weight parts of sweet corn powder, 2-4 weight parts of coffee powder and 15-25 weight parts of water; feeding the mixture to a twin-screw extruder for extruding and forming; pelleting and tabletting the extruded and formed mixture to prepare a cornflake which is 0.2-0.4 millimeter thick; roasting the cornflake at 150 DEG C plus (minus) 5 DEG C for 8-10 minutes; uniformly spraying 5-8 weight parts of molten bee wax to the surface of the cornflake when the roasted cornflake is cooled to 55 DEG C plus (minus) 2 DEG C, quickly cooling the roasted cornflake to the room temperature to acquire the coffee cornflake. The bee wax is added in the preparation process, and so soaking resistance of the coffee cornflake in liquid food is better than that of the traditional cornflake; simultaneously, the coffee cornflake can be prevented from absorbing moisture in a storage process. The coffee powder and the sprayed bee wax are added to the ingredients, so that the nutrition of the cornflake is increased, and the variety of the cornflakes is enriched.

Owner:HARBIN PATERNA BIOTECH DEV

Black tea cornflake and production method of same

InactiveCN102919708AIncrease foam resistancePrevent moisture absorptionFood preparationWaxy cornAdditive ingredient

The invention provides a black tea cornflake and a production method of the same. The black tea cornflake can be produced via the following production method which comprises the following steps: uniformly mixing 55-65 parts by weight of waxy corn flour, 20-30 parts by weight of sweet corn flour, 2-4 parts by weight of black tea flour, and 15-25 parts by weight of water; conveying the ingredients into a double-screw extruder to perform extrusion moulding; preparing cornflake with a thickness of 0.2-0.4 mm via granulating and flake-pressing; roasting the cornflake for 8-10 minutes at a temperature of 150+ / -5 DEG C; cooling to 55+ / -2 DEG C; uniformly spraying 5-8 parts by weight of melted beewax on the surface of the cornflake; and rapidly cooling to a room temperature, and then obtaining the black tea cornflake. As the beewax is sprayed during the production process, the soaking resistance of the black tea cornflake provided by the invention in a liquid food is better than the soaking resistance of the traditional cornflake, and the black tea cornflake can also be prevented from absorbing moisture during a storage process simultaneously. Via the added black tea flour and the sprayed beewax in the ingredients, the nutrition of the cornflake is enhanced, and the varieties of the cornflake are enriched.

Owner:HARBIN PATERNA BIOTECH DEV

Blueberry cornflake and production method of same

InactiveCN102919702AIncrease foam resistancePrevent moisture absorptionFood preparationAdditive ingredientRoom temperature

The invention provides a blueberry cornflake and a production method of the same. The blueberry cornflake can be produced via the following production method which comprises the following steps: uniformly mixing 55-65 parts by weight of waxy corn flour, 20-30 parts by weight of sweet corn flour, and 10-20 parts by weight of blueberry juice; conveying the ingredients into a double-screw extruder to perform extrusion moulding; preparing cornflake with a thickness of 0.2-0.4 mm via granulating and flake-pressing; roasting the cornflake for 8-10 minutes at a temperature of 150+ / -5 DEG C; cooling to 55+ / -2 DEG C; uniformly spraying 5-8 parts by weight of melted beewax on the surface of the cornflake; and rapidly cooling to a room temperature. As the beewax is sprayed during the production process, the soaking resistance of the blueberry cornflake provided by the invention in a liquid food is better than the soaking resistance of the traditional cornflake, and the blueberry cornflake can also be prevented from absorbing moisture during a storage process simultaneously. Via the added natural blueberry juice and the sprayed beewax in the ingredients, the nutrition of the cornflake is enhanced, and the varieties of the cornflake are enriched.

Owner:HARBIN PATERNA BIOTECH DEV

Preparation method and product of tuan-shaped green tea (tuan is a Chinese character)

InactiveCN103493915AEasy to drinkImprove pressure resistancePre-extraction tea treatmentChinese charactersGreen tea

The invention discloses a preparation method of tuan-shaped green tea (tuan is a Chinese character). The method takes bulk tea of finished green tea as raw tea and comprises the following specific steps: (1) humidifying and softening the raw tea and carrying out mould pressing on the softened raw tea to form tuan-shaped raw tea; (2) drying the tuan-shaped raw tea into tea with the predetermined water content through using vacuum dehumidification, optical wave heating and / or microwave heating and cooling means to obtain the required tuan-shaped green tea. The method provides a feasible technical way for preparing the bulk tea of the green tea into the tuan-shaped green tea; the tuan-shaped green tea brings a brand-new green tea drinking way to people and can be conveniently drunk by the people.

Owner:林志宾

Banana cornflake and preparation method thereof

InactiveCN102919717AIncrease foam resistancePrevent moisture absorptionFood preparationCornflakesChemistry

The invention provides a banana cornflake. The banana cornflake is prepared by the following preparation method: uniformly mixing 55-65 weight parts of waxy corn powder, 20-30 weight parts of sweet corn powder, 2-4 weight parts of banana powder and 15-25 weight parts of water; feeding the mixture to a twin-screw extruder for extruding and forming; pelleting and tabletting the extruded and formed mixture to prepare a cornflake which is 0.2-0.4 millimeter thick; roasting the cornflake at 150 DEG C plus (minus) 5 DEG C for 8-10 minutes; uniformly spraying 5-8 weight parts of molten bee wax to the surface of the cornflake when the roasted cornflake is cooled to 55 DEG C plus (minus) 2 DEG C, quickly cooling the roasted cornflake to the room temperature to acquire the banana cornflake. The bee wax is added in the preparation process, and so soaking resistance of the banana cornflake in liquid food is better than that of the traditional cornflake; simultaneously, the banana cornflake can be prevented from absorbing moisture in a storage process. The banana powder and the sprayed bee wax are added to the ingredients, so that the nutrition of the cornflake is increased, and the variety of the cornflakes is enriched.

Owner:HARBIN PATERNA BIOTECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com