Preparation method of composite fragrant cold-brewed tea and composite fragrant cold-brewed tea prepared by preparation method

A technology for compound aroma and cold-brewed tea, which is applied in the directions of tea, tea extraction, tea treatment before extraction, etc., can solve the problems of complex industrial production operation, single taste of cold-brewed tea leaves, and long brewing time of cold-brewed tea, etc. To achieve the effect of long leaching time, rich aroma and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

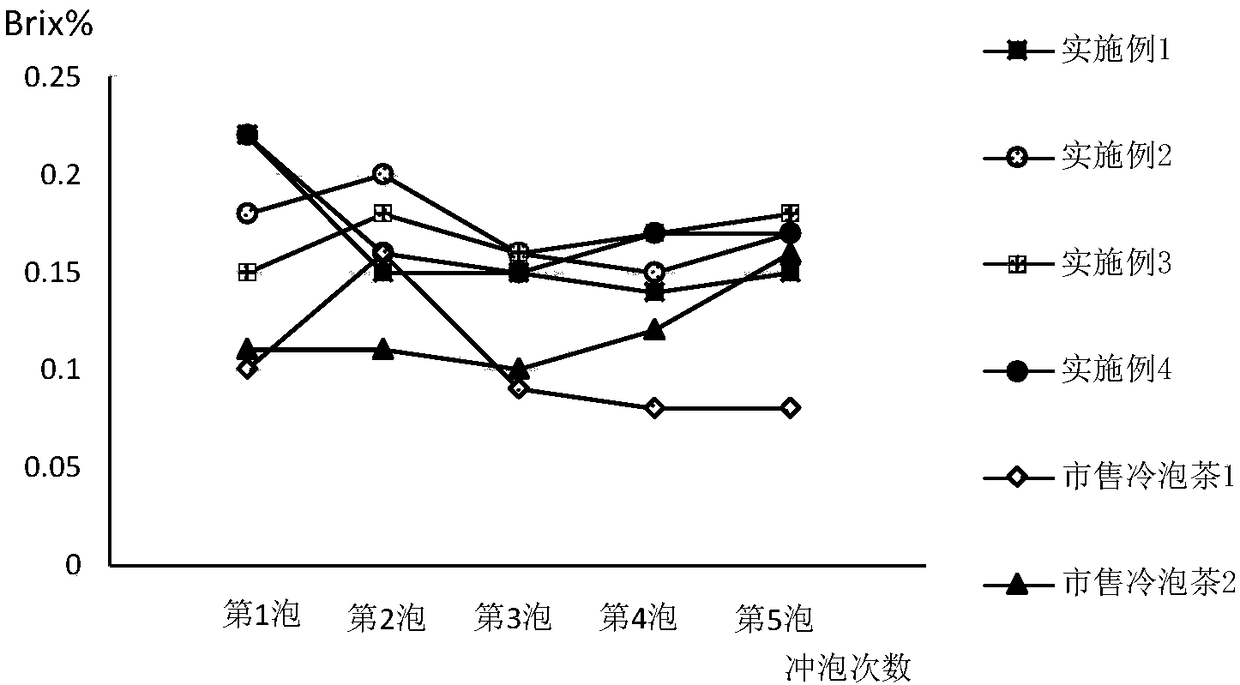

Examples

Embodiment 1

[0027] The tealeaves A of the present embodiment is jasmine tea; the tealeaves B is white peony, and the size of the tealeaves C is about 0.5cm;

[0028] The preparation process of the present embodiment is as follows:

[0029] Step 1: Weigh 250g of tea leaves A, add 80°C pure water at a ratio of 1:10, and extract at a constant temperature of 85°C for 60 minutes. After leaching, use a 500-mesh filter cloth to filter out the tea dregs, then cool the tea soup until the temperature of the tea soup is not higher than 40°C, and then transfer it to a ceramic membrane filtration equipment (Hangzhou Rena Membrane, model RNM-TCM50) for further filtration . The filtered tea soup was concentrated in a roll-type RO membrane concentration equipment (Hangzhou Rena Membrane, model RNM-18G) until the solid content of the tea soup was about 20 Brix°, and about 300 mL of tea A concentrated juice was obtained.

[0030]Step 2: According to the mass ratio of dry tea A and tea B as 1:1, take 120m...

Embodiment 2

[0034] Tea A in this embodiment is stir-fried green tea; tea B is Ceylon black tea CTC; tea C is charcoal roasted oolong tea, the size of which is about 2cm.

[0035] The preparation process of the present embodiment is as follows:

[0036] Step 1: Weigh 250g of tea leaf A, add 60°C pure water at a ratio of 1:15, and extract at a constant temperature of 65°C for 40 minutes. After leaching, filter out the tea dregs with a 500-mesh filter cloth, and when the temperature of the tea soup drops to 40-50°C, add galactosidase to the tea soup for enzymatic hydrolysis for 1 hour. After the enzyme treatment, filter the tea soup with a 500-mesh filter cloth and cool it until the temperature of the tea soup is not higher than 40°C, and then transfer it to a ceramic membrane filtration equipment (Hangzhou Rena Membrane Engineering Co., Ltd., model RNM-TCM50) for further filtration. The filtered tea soup was concentrated in a roll-type RO membrane (Hangzhou Rena Membrane Engineering Co., L...

Embodiment 3

[0041] Tea A in this embodiment is Tieguanyin tea with a light fragrance; tea B is fried green tea with a size of about 1 cm;

[0042] The preparation process of the present embodiment is as follows:

[0043] Step 1: Weigh 250g of tea A, add pure water at a ratio of 1:15, and extract at room temperature for 2 hours. After the leaching is finished, filter out the tea dregs with a 500-mesh filter cloth, then raise the temperature of the tea soup to 40-50°C, and add 1.25g of pectinase for enzymatic hydrolysis for 0.5h. After the enzyme treatment, filter the tea soup with a 500-mesh filter cloth and cool it until the temperature of the tea soup is not higher than 40°C, and then transfer it to a ceramic membrane filtration equipment (Hangzhou Rena Membrane, model RNM-TCM50) for further filtration. The filtered tea soup was concentrated in a roll-type RO membrane concentration equipment (Hangzhou Rena Membrane, model RNM-18G), until the solid content of the tea soup was about 30 Br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com