Pressure-sensitive adhesive sheet, process for producing laminate including pressure-sensitive adhesive layer, laminate including pressure-sensitive adhesive layer, image display device, and touch panel

A technology of adhesive layer, manufacturing method, applied in the direction of film/sheet-shaped adhesive, non-polymer organic compound adhesive, adhesive type, etc., capable of solving problems such as deformation, distortion, and poor durability, Excellent foaming resistance, well-balanced moisture and heat resistance, and excellent reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

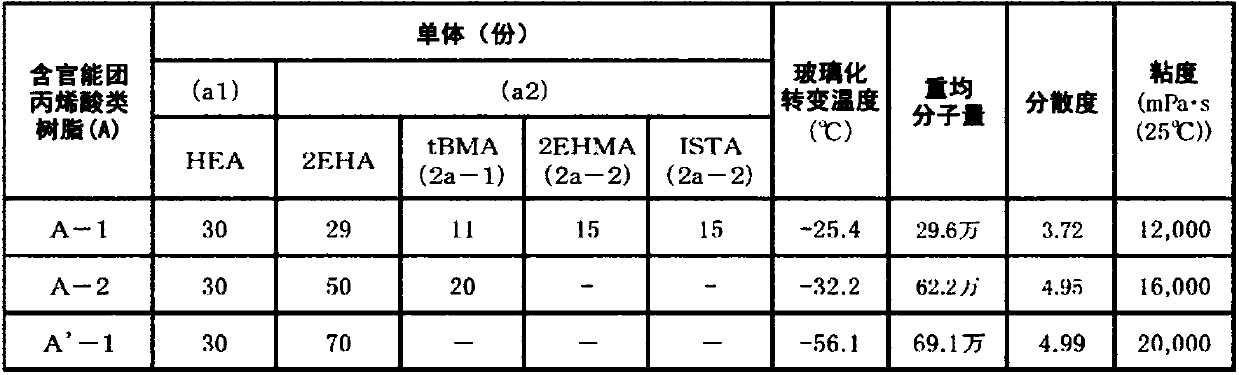

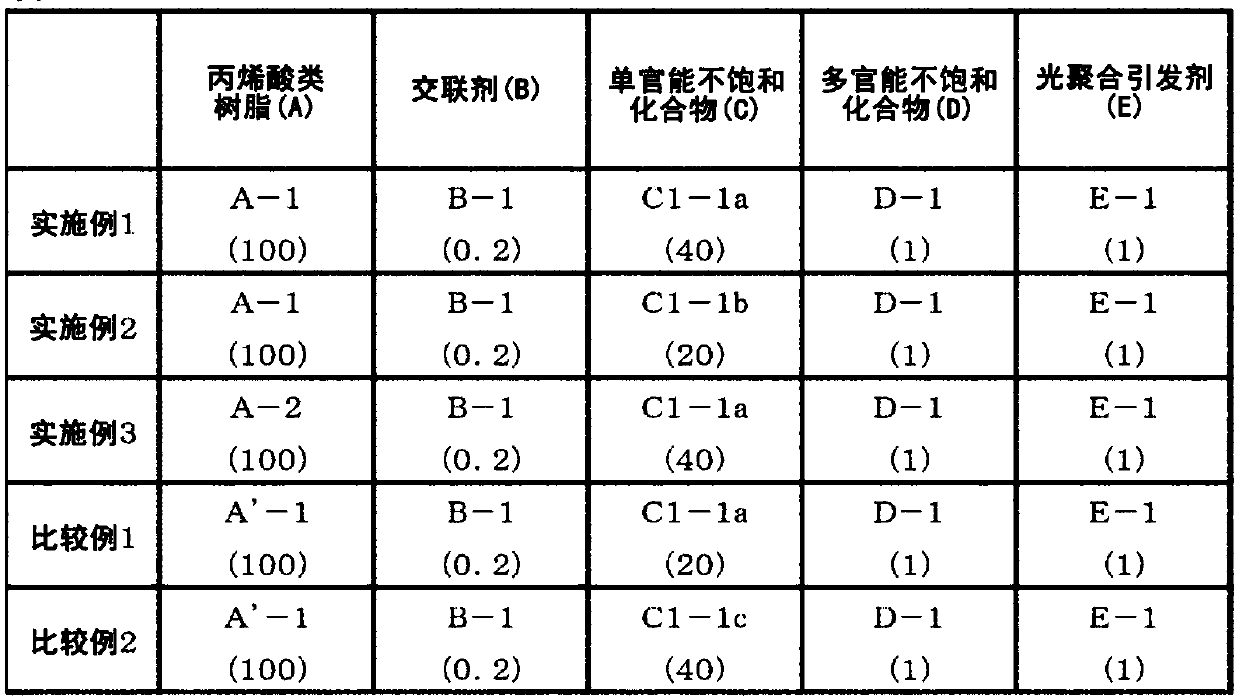

[0218] 0.2 parts of crosslinking agent (B-1), 40 parts of monofunctional unsaturated compound (C-1), 40 parts of polyfunctional unsaturated compound ( D-1) 1 part, photopolymerization initiator (E-1) 1 part, and the adhesive composition solution were prepared.

[0219] The pressure-sensitive adhesive composition solution was coated on a polyester release sheet so that the thickness after drying was 100 μm, and dried at 90° C. for 5 minutes to form a pressure-sensitive adhesive layer. The obtained pressure-sensitive adhesive layer was sandwiched between polyester-based release sheets, and aged at 40° C. for 3 days to obtain a substrate-free double-sided pressure-sensitive adhesive sheet [I-1].

[0220] In addition, the release sheet on one side was peeled off from the adhesive layer of the substrate-free double-sided adhesive sheet obtained above, and pressed against a 125 μm thick easily-adhesive treated polyethylene terephthalate (PET) sheet to obtain The adhesive layer-atta...

Embodiment 2

[0222]

[0223] Except that the compounding ratios of (A) to (E) components were changed to the compounding ratios described in Table 2, the substrate-less double-sided adhesive sheets [I-2] and [I' were obtained in the same manner as in Example 1. -1], [I'-2] and PET sheet with adhesive layer [II-2], [II'-1], [II'-2], [III-2], [III'-1 ], [III'-2].

Embodiment 3

[0225] An adhesive was obtained in the same manner as in Example 1, except that the compounding ratios of the components (A) to (E) were changed to the compounding ratios described in Table 2 and applied so that the thickness after drying was 160 μm. A substrate-less double-sided adhesive sheet [I-3] and a PET sheet with an adhesive layer [II-3], [III-3] with a layer thickness of 160 μm.

[0226] [Table 2]

[0227] Table 2

[0228]

[0229] The gel fraction of the adhesive layer, the Optical properties and resistance to blistering. In addition, the adhesive strength of the adhesive layer was measured using the above-mentioned PET sheets [II-1] to [II-3], [II'-1], [II'-2] with an adhesive layer, and the height difference was evaluated. followership. Furthermore, the heat-and-moisture resistance of the adhesive layer was evaluated using the PET sheets [III-1] to [III-3], [III'-1], and [III'-2] with an adhesive layer described above. The results are shown in Table 3 below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com