Acrylic adhesive composition, adhesive and adhesive sheet

An acrylic and acrylic resin technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as durability decline, and achieve excellent level followability , Low dielectric constant, improve the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0167] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited to the following examples unless the gist is exceeded. In addition, when there are "part" and "%" in an example, it is a basis of weight except haze value. In addition, about the measurement of the weight average molecular weight of an acrylic resin, it measured by the method mentioned above.

[0168] [Manufacturing example 1]

[0169] 100 parts of acetone (boiling point 56°C) as a polymerization solvent and 2,2'-azobis(2,4-dimethylvaleronitrile) (ADVN: 10 Hour half-life temperature 52°C) 0.6 parts, pre-mixed monomer solution (stearyl methacrylate (SMA: a2-1) 50 parts (15% relative to the entire copolymerization component), lauryl methacrylate and methyl A mixture of tridecyl acrylate (SLMA: a2-1) 192 parts (57.6% to the total copolymerization component), 2-ethylhexyl methacrylate (2EHMA: a2-2) 50 parts (to the copolymerization 15% of the w...

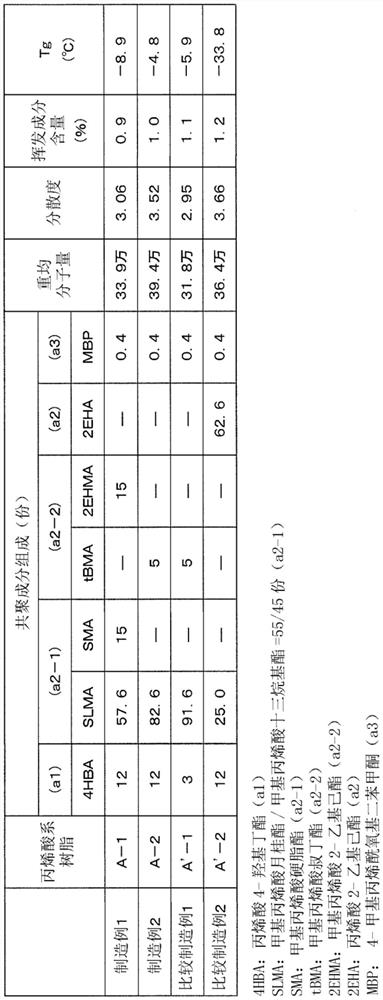

manufacture example 2、 comparative manufacture example 1~2

[0172] Acrylic resins [A-2], [A'-1], and [A'-2] were produced in the same manner as in Production Example 1 except that the copolymerization components of the acrylic resin were set in accordance with Table 1.

[0173] [Table 1]

[0174]

[0175]

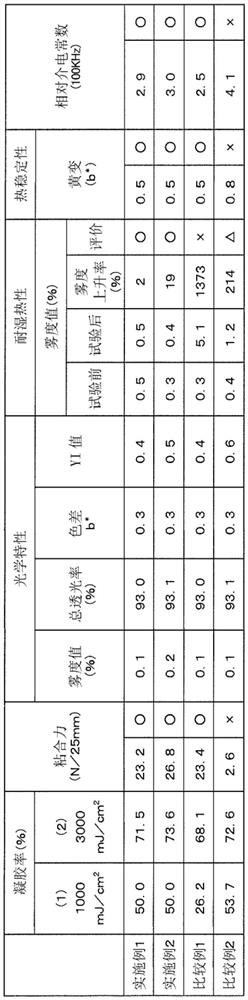

[0176] The acrylic resin [A-1] obtained above was sandwiched between two polyester release sheets (thickness 176 μm), and pressure was applied while heating at 100°C so that the thickness of the adhesive layer became 175 μm. , and then use high-pressure mercury UV irradiation device to peak illumination: 150mW / cm 2 , cumulative exposure: 1000mJ / cm 2 (500mJ / cm 2 ×2pass) was irradiated with ultraviolet rays to obtain a substrate-free double-sided adhesive sheet.

[0177] In addition, the release sheet on one side was peeled off from the adhesive layer of the double-sided adhesive sheet without the base material obtained above, and pressed onto an easy-adhesion-treated polyethylene terephthalate (PET) film (thickness 125 μm). ...

Embodiment 2

[0179] In the above-mentioned Example 1, except that the acrylic resin [A-1] was changed to the acrylic resin [A-2], the double-sided adhesive sheet without the base material of Example 2 was obtained in the same manner as in Example 1. and PET film with adhesive layer.

[0180]

[0181] In the above-mentioned Example 1, except that the acrylic resin [A-1] was changed to the acrylic resin [A'-1], the substrate-less double-sided adhesion of Comparative Example 1 was obtained in the same manner as in Example 1. Sheet and PET film with adhesive layer.

[0182]

[0183] In the above-mentioned Example 1, except that the acrylic resin [A-1] was changed to the acrylic resin [A'-2], the substrate-less double-sided adhesion of Comparative Example 2 was obtained in the same manner as in Example 1. Sheet and PET film with adhesive layer.

[0184] 〔Gel rate (1)〕

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com