Ultraviolet ray-curable adhesive sheet, and adhesive sheet

An adhesive sheet, ultraviolet technology, applied in the direction of non-polymer organic compound adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of reducing resin crosslinking density and film thickness. Non-uniformity, overflow of adhesive, etc., to achieve the effect of excellent moisture and heat whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

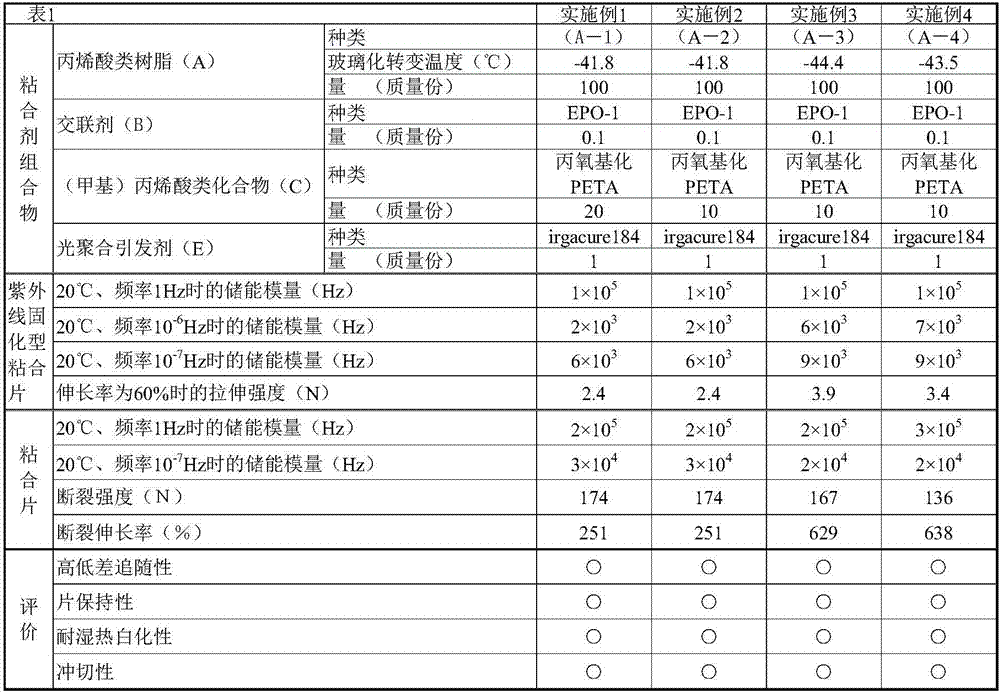

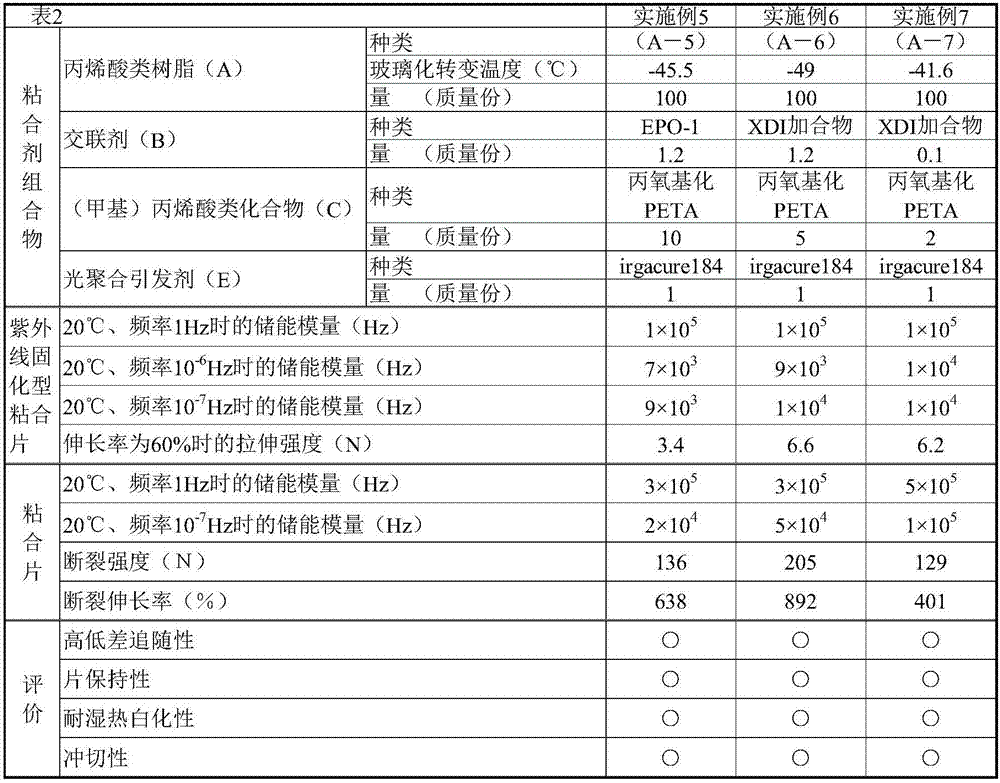

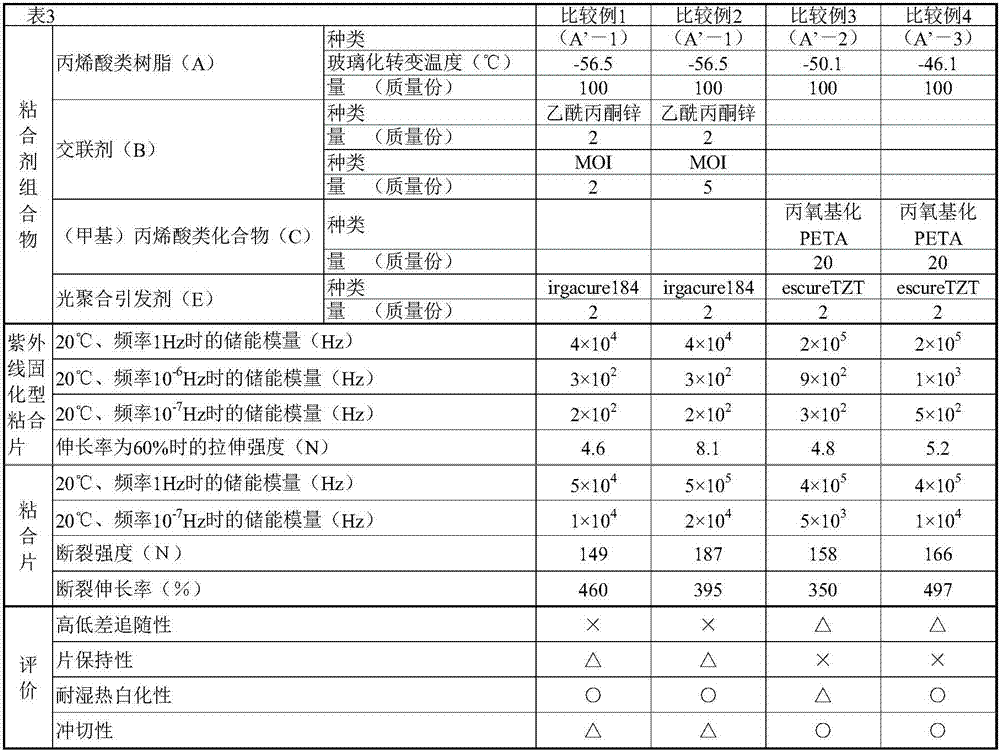

[0101] The present invention will be described in more detail below using examples.

Synthetic example 1

[0103]

[0104] 73 parts by mass of 2-ethylhexyl acrylate (hereinafter abbreviated as "2EHA"), dicyclopentanyl acrylate (manufactured by Hitachi Chemical Co., Ltd. " FA-513AS") 20 parts by mass, acrylic acid (hereinafter abbreviated as "AA") 5 parts by mass, 2-hydroxyethyl acrylate (hereinafter abbreviated as "HEA") 2 parts by mass, ethyl acetate 50 parts by mass, toluene 50 parts by mass portion, and the temperature was raised to 70° C. while blowing nitrogen gas under stirring. After 1 hour, 0.04 parts by mass of an azobisisobutyronitrile solution previously dissolved in ethyl acetate was added. Thereafter, after maintaining at 70° C. for 3 hours with stirring, the temperature was raised to 75° C., and 0.2 parts by mass of tetramethylbutylperoxyethylhexanoate and 1 part by mass of tert-hexyl peroxypivalate were added and kept for 5 hour, thereby obtaining the acrylic resin (A-1) with a non-volatile content of 50% by mass, a viscosity of 8,540 mPa·s, a weight-average molec...

Synthetic example 2

[0106]

[0107] Put 73 parts by mass of 2EHA, 20 parts by mass of FA-513AS, 5 parts by mass of AA, 2 parts by mass of HEA, and 100 parts by mass of ethyl acetate into a reaction vessel equipped with a stirrer, a reflux condenser, a nitrogen gas introduction tube, and a thermometer, and stir It heated up to 70 degreeC blowing nitrogen gas. After 1 hour, 0.04 parts by mass of an azobisisobutyronitrile solution previously dissolved in ethyl acetate was added. Thereafter, after holding at 70°C for 3 hours under stirring, the temperature was raised to 75°C and held for 5 hours to obtain a non-volatile content of 50% by mass, a viscosity of 49,900mPa·s, a weight average molecular weight of 740,000, and a number average molecular weight of Acrylic resin (A-2) with a temperature of 93,000 and a glass transition temperature of -41.8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com